Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214results about How to "Does not affect purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for extracting and separating rare-earth elements

ActiveCN101994004AEliminate pollutionReduce manufacturing costProcess efficiency improvementRare-earth elementOrganic acid

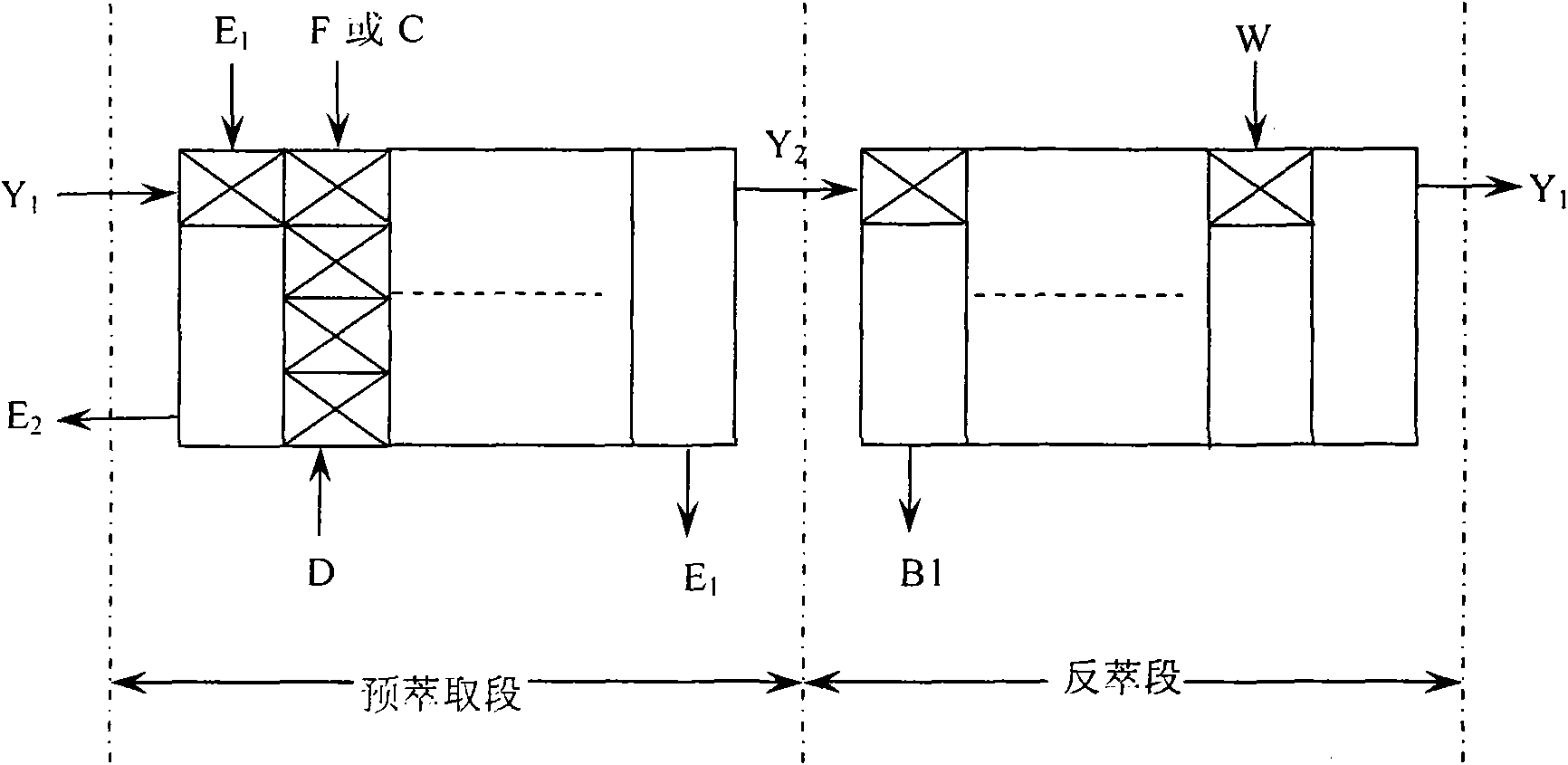

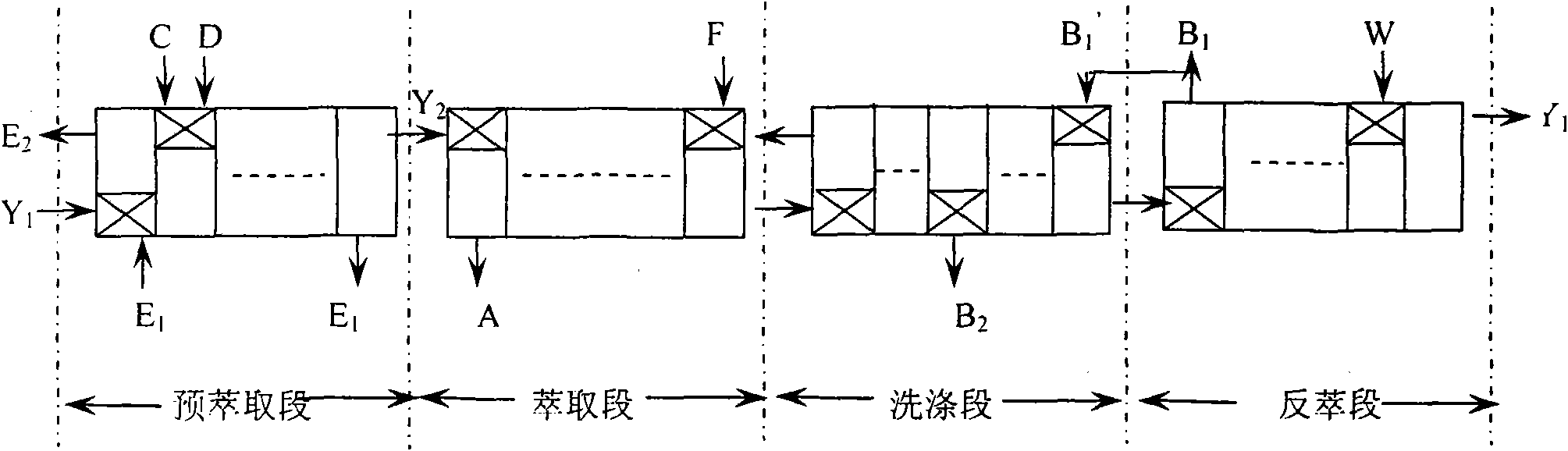

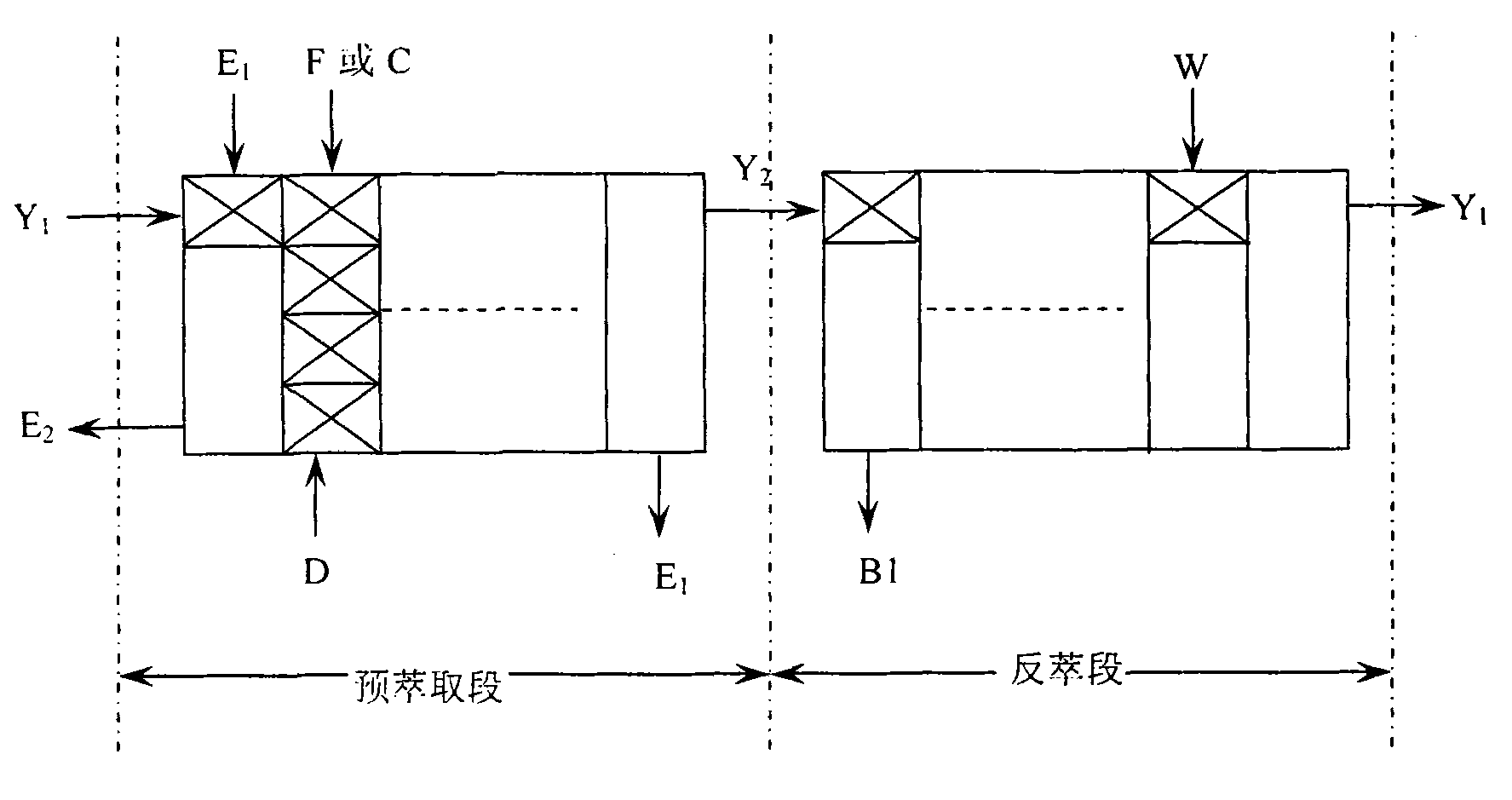

The invention provides a process for extracting and separating rare-earth elements. In the process, acid organic extracting agents such as P507, P204, C272 and naphthenic acid, aqueous solution of organic acid salt of magnesium and / or calcium, and rare-earth solution are mixed for pre-extraction; rare earth ions are extracted into an organic phase; and the organic phase is clarified to form a rare earth ion loaded organic phase used for extracting and separating mixed rare earth feed liquor. A single rare-earth compound or a concentrate of several rare-earth elements is obtained through multi-stage extraction-washing-back extraction. The aqueous solution of organic acid salt of magnesium and / or calcium is prepared by roasting minerals such as magnesite, limestone, calcite and dolomite and dissolving with organic acid; the contents of impurities such as silicon, iron and aluminium are low; three-phase substances are not generated in the pre-extraction and extraction and separation processes; the purity of rare earth products is not influenced; the organic phase is not subjected to ammonia saponification, and ammonia nitrogen wastewater is not generated; the production cost of the rare earth products is greatly reduced; and a great amount of three-waste treatment cost is saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Catalyst for synthesizing benzaldehyde and benzyl alcohol from toluol, the preparation process and application thereof

InactiveCN1485131AEasy to separateEase of usePreparation by oxidation reactionsCarbonyl compound preparation by oxidationAlkaline earth metalBenzaldehyde

A catalyst of synthesizing benzaldehyde and benzyl alcohol by methylbenzene, its manufacturing method and application. The active component is zirconium, or transit metals, alkaline metal, alkaline-earth metals, metals of IIIAíóIVA and VA Group in the Periodic Table. The method comprises solving a zirconium compound or a zirconium compound and a compound of an element as the active component, adding a precipitator; drying, burning, pulverizing to particles. In reactions, a gas containing oxygen is the oxygen source, such as oxygen and air, an organic solution wouldn't be used. The catalyzing reaction is 180-195 degree C, the pressure is 0.8-1.2Mpa. when the conversion rate of methylbenzene is 13.0úÑ, the total selectivity of benzaldehyde and benzyl alcohol is 86.6úÑ. In the method, the catalyst is easy to be separated and could be recyclable, the reaction condition is mild.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

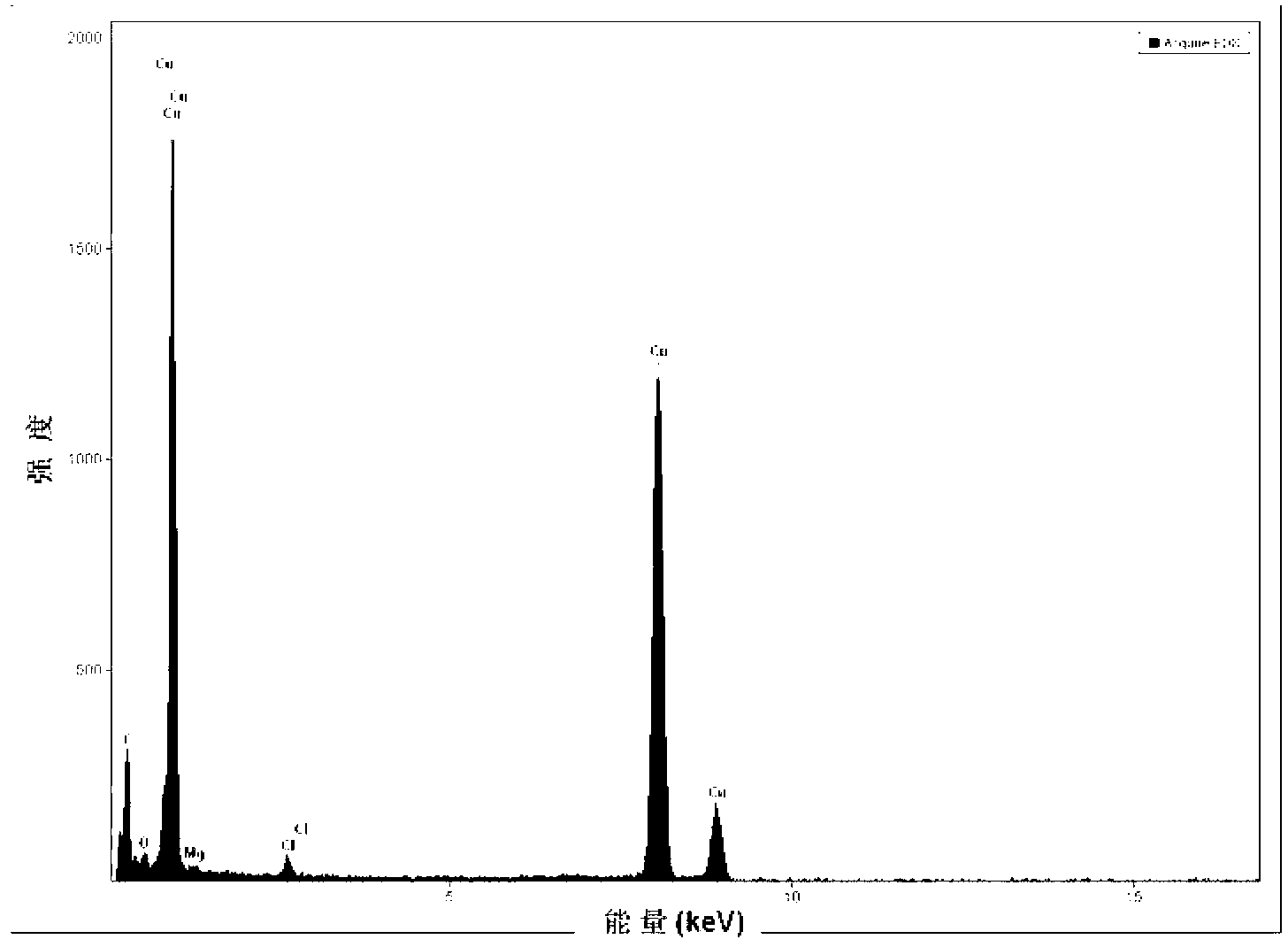

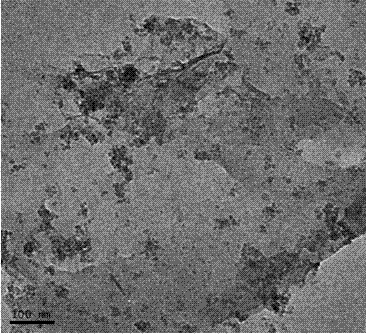

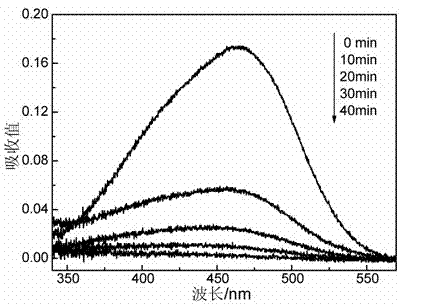

Method for preparing metal nanoparticles

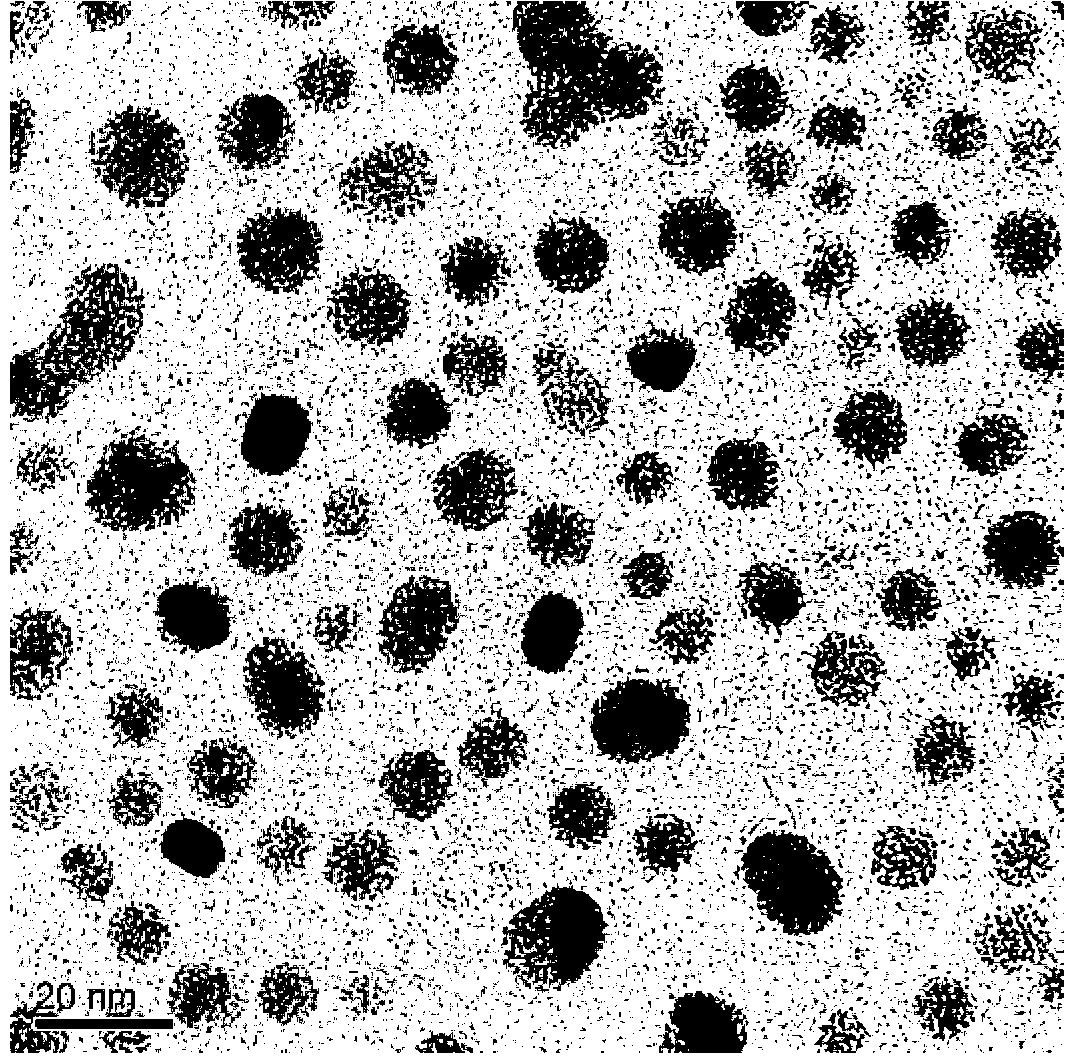

The invention provides a method for preparing metal nanoparticles. By a dealloying method, firstly, precursor alloy solid fine materials containing target metal elements are prepared, secondly, the precursor alloy solid fine materials and acid solution containing hydrogen ions are in dealloying reaction under the condition of violent oscillation, the concentration of the hydrogen ions in the acid solution is controlled in the reaction process, magnesium, rare earth and other relatively active atoms preferentially react with the hydrogen ions and change into ions entering the solution, target metal atoms are freed out, and porous self-assembly and conglobation trend of the target metal atoms is effectively restrained under the condition of violent oscillation, so that uniformly scattered target metal nanoparticles are obtained. Compared with an existing method, the method is low in cost, simple in operation, green, environmentally friendly, high in preparation efficiency, high in by-product value and suitable for large-scale production, and accordingly has a fine application prospect.

Owner:赵远云

Ladle furnace use nitrogen gas nitrogen alloying process

The invention relates to a ladle furnace use nitrogen gas nitrogen alloying process. The process comprises the following steps: a) smelting nitrogen-contained stainless steel, controlling the components of the molten steel except the nitrogen to the targeted components, and controlling a nitrogen flush initial temperature at 30 to 50 DEG C above a refining treatment out-station temperature; b) during the nitrogen bottom blowing for the smelting of the nitrogen-contained stainless steel in the LF furnace, adding 1 to 20 ppm of nitrogen to each standard cube of nitrogen; c) during the nitrogen bottom blowing for the micro-alloying treatment, controlling the nitrogen flow at 6 to 120m<3> / h and the nitrogen flush pressure at 0.60 to 0.80 MPa; and d) when the nitrogen bottom blowing is finished, carrying out the argon bottom blowing for 4 to 6 minutes with the argon flow of 2 to 20 m<3> / h so as to average the stainless steel components and temperature. The process adds the nitrogen alloying function through the nitrogen bottom flowing to the ladle furnace (LF) in the prior stainless steel production process so as to replace a nitro alloy, make the nitrogen-contained stainless steel carry out continuous and stable nitrogen alloying in the ladle furnace, improve the purity of the molten steel, and consequently improve the molten steel quality and reduce the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD +1

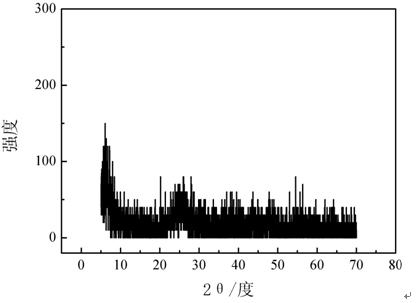

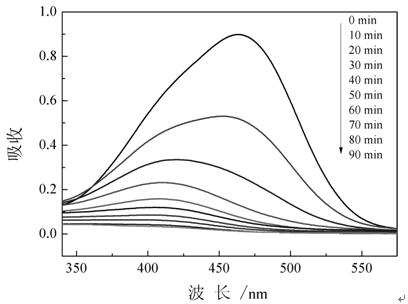

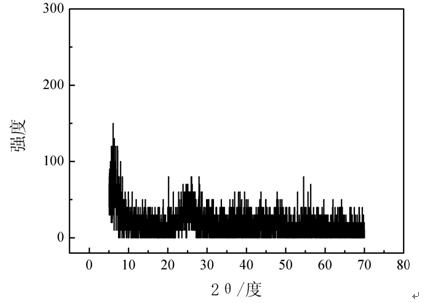

Preparation method of graphene/titanium dioxide photocatalyst

InactiveCN103028387ASimple processEasy to implementPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyePhysical chemistry

The invention discloses a preparation method of a graphene / titanium dioxide photocatalyst, which comprises the following steps of (1) preparing a solution A, slowly adding tetrabutyl titanate into chloroform, and obtaining the solution A, (2) preparing a mixed solution B, adding oxidized graphene into a mixed solution of deionized water and ethanol, and obtaining the mixed solution B, (3) stirring the mixed solution B, adding the mixed solution B into the solution A simultaneously, stirring uniformly, and obtaining a mixed solution, and (4) placing the mixed solution into a hydrothermal kettle, conducting the hydrothermal treatment, naturally cooling to a room temperature, separating and washing, and obtaining the graphene / titanium dioxide photocatalyst. The graphene / titanium dioxide photocatalyst prepared by the method has an excellent photocatalytic degradation property for organic dye.

Owner:LIAOCHENG UNIV

Preparation method of graphene/titania composite material

InactiveCN102600823ASimple processEasy to implementPhysical/chemical process catalystsWater/sewage treatment by irradiationReaction speedMaterials science

The invention discloses a preparation method of a graphene / titania composite material, which comprises the steps of preparing a precursor solution, and heating and stirring the precursor solution and the like. The preparation method of the graphene / titania composite material has the beneficial effects: the process is simple, the implementation is easy, and the opportunity of introducing impurities is reduced, so that the purity of a product can not be affected. The preparation process is mild without protection of a special atmosphere, the required equipment is simple, the reaction speed is quick, and the preparation method is suitable for mass production. Graphene oxide can be reduced by microwave heating, and a toxic reductant is not used.

Owner:LIAOCHENG UNIV

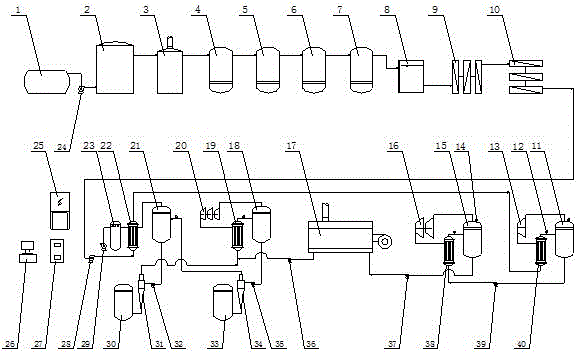

Industrial wastewater resource zero-discharge system

ActiveCN105776711ALong resolution processEasy to handleFatty/oily/floating substances removal devicesWater contaminantsChemical oxygen demandEvaporation

The invention relates to an industrial wastewater resource zero-discharge system. The industrial wastewater resource zero-discharge system comprises a pretreatment unit, a resource treatment unit, a membrane concentration unit, a MVR (melt volume flow rate) evaporation and concentration unit, an incineration and purification unit, an MVR quality crystallizing unit, and a self control and Internet of Things remote monitoring diagnosis management unit, wherein the pretreatment unit comprises an oil removal device, a filtering device, a blowoff device and an extraction device; the resource treatment unit comprises an acid adsorbing device, an organic matter adsorbing device and an ion adsorbing device; the membrane concentration unit comprises a high-grade oxidizing device, an ultrafiltering device and a reverse osmosis device; the MVR evaporation and concentration unit comprises a low-salinity wastewater MVR evaporation device and a high-salinity wastewater MVR evaporation device. The industrial wastewater resource zero-discharge system has the advantages that the defect of difficult biochemical treatment of industrial wastewater which has high slat content and high COD (chemical oxygen demand) content and contains oil, acid and heavy metals is overcome; the valent components are recycled according to quality, the resources are utilized, and the zero discharge is reliably realized; by adopting the Internet of Things remote monitoring diagnosis, the operation, management and maintenance of a project are favorably realized.

Owner:李明

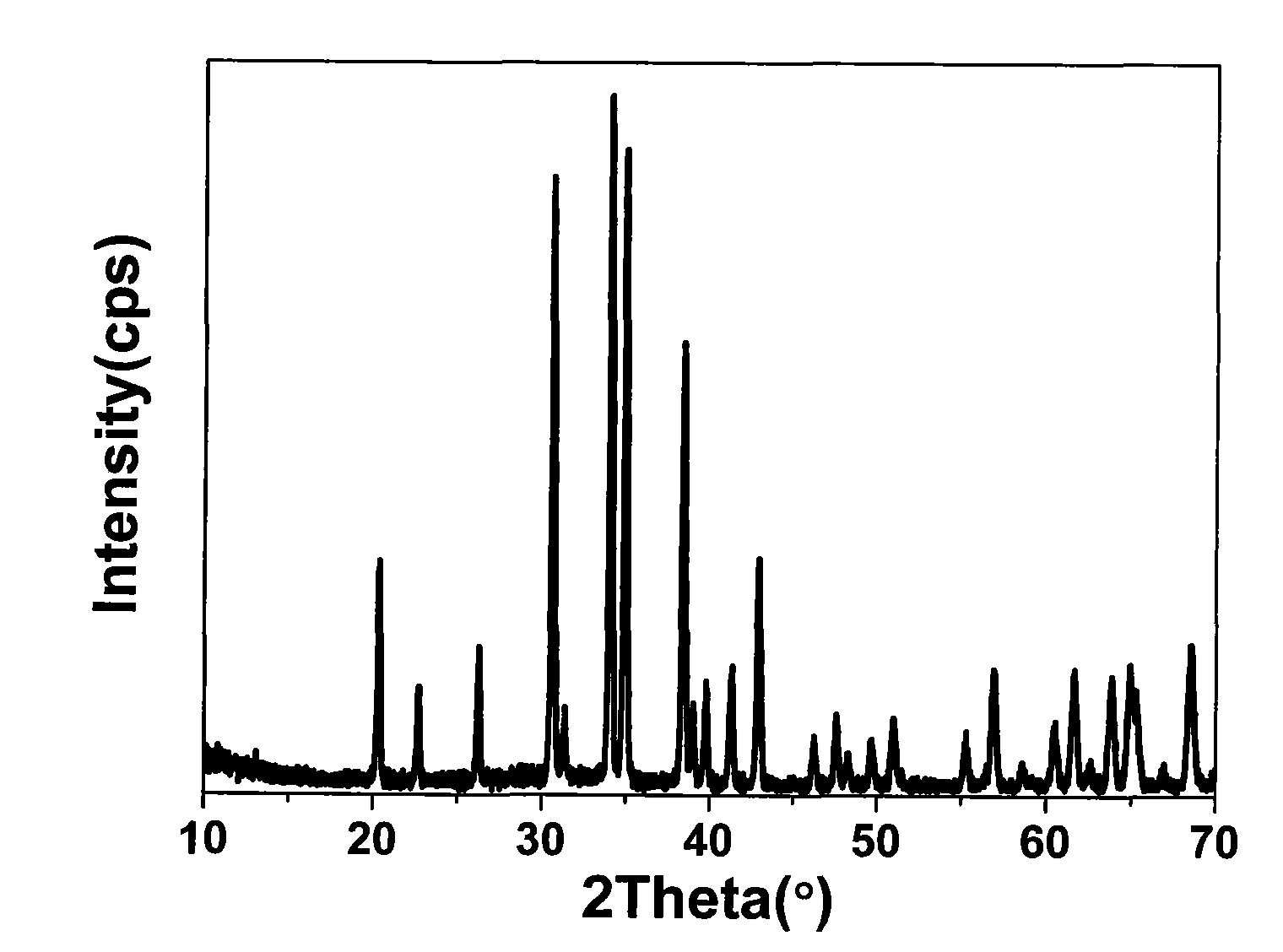

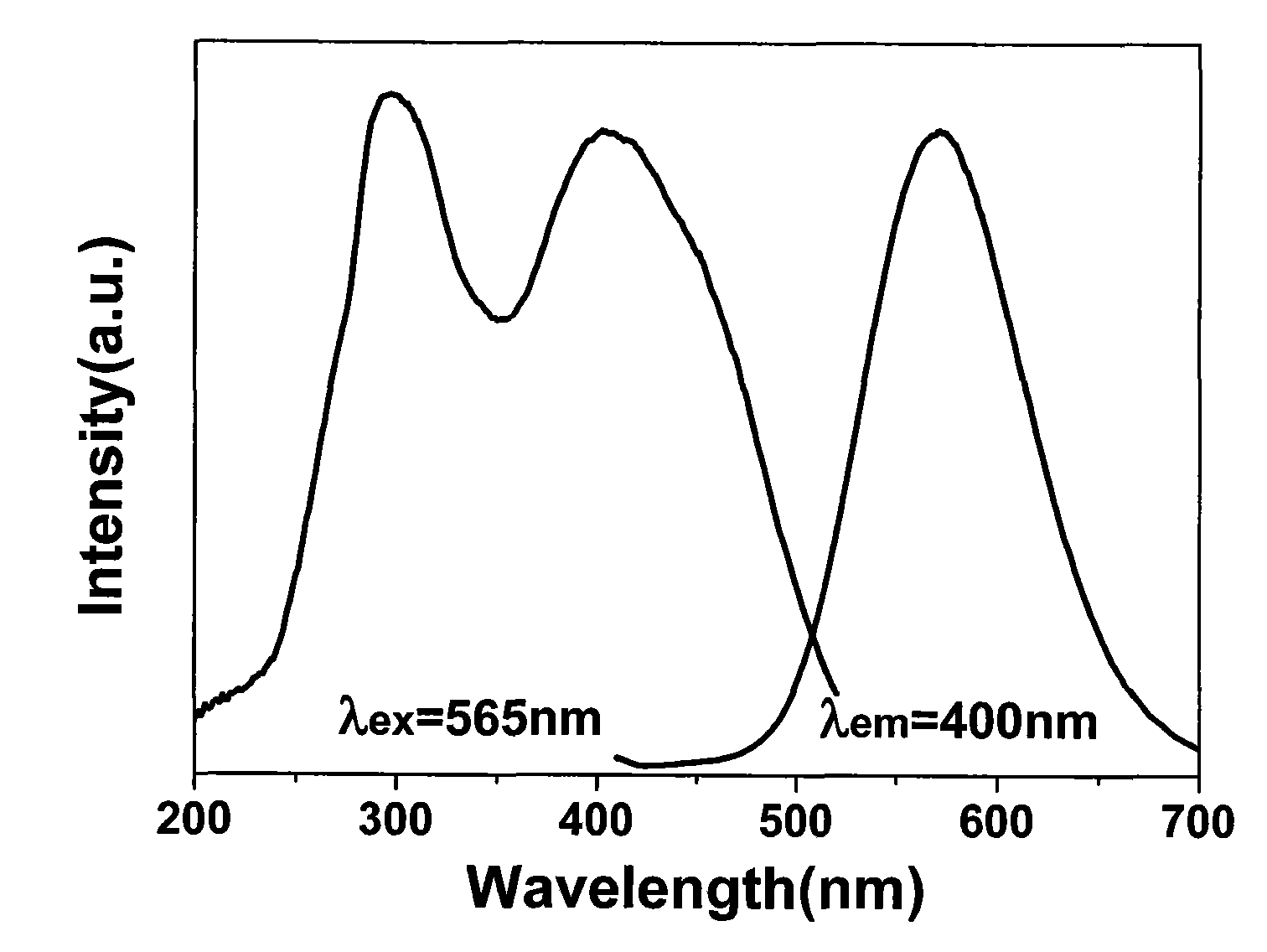

Method for preparing silicon-based oxynitride fluorescent powder

InactiveCN101818063ALow costSynthesis temperature is lowLuminescent compositionsLuminous intensityFluorescence

The invention discloses a method for preparing silicon-based oxynitride fluorescent powder, which comprises the following steps of: weighing corresponding raw materials and silica powder based on stoichiometric proportion of each element in the chemical formula of the silicon-based oxynitride fluorescent powder, after uniformly mixing the raw materials and the silica powder, raising the temperature to 800 to 1,000 DEG C under any one of the conditions of condition a to condition c, performing reduction reaction under the condition c or the condition d, and cooling the reaction product to roomtemperature to obtain the silicon-based oxynitride fluorescent powder, wherein the condition a is vacuum; the condition b is the atmosphere of inert gases; the condition c is the atmosphere of nitrogen-containing gases; and the condition d is the atmosphere of reductive gas. The silicon-based oxynitride fluorescent powder doped with various luminescent ions and prepared by the method has bright fluorescence under the excitation of ultraviolet ray, near ultraviolet or visible light. The method has the advantages of low preparation temperature of the product, high phase purity of the product, controllable particle size of the product, good luminous intensity of the product, low cost, simple process and the like, and is easy to enlarge industrialization.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing zirconium oxide powder from zircon

ActiveCN101100312AExcellent microscopic appearancePrevent reunionZirconium oxidesSodium carbonateSilicon oxide

This invention relates to a method for preparing zirconium oxide. The preparation method is: mixing zircon and soda, reaction under high temperature, cooling the product, adding water and acid; regulation its pH value, filtering, washing and drying the obtained product; the above mentioned product is then added with sodium pyrosulfate, reaction under temperature of 700-800deg.C, cooling, adding water, filtering, washing and drying, obtaining product of powder of mixture of zirconium oxide and silicon oxide; above mentioned mixture is added with solution of sodium hydroxide, reacting under proper pressure and temperature for 2-3hrs, then cooling, separation, washing, drying to obtain the inventive product. This invention has advantages of: low cost, short process, simple operation. And the product is of high pureness, with regular octahedron particles, its size is 1-3um. The power of the inventive product has well dispersiveness, no blocking problem.

Owner:PUYANG REFRACTORIES GRP CO LTD

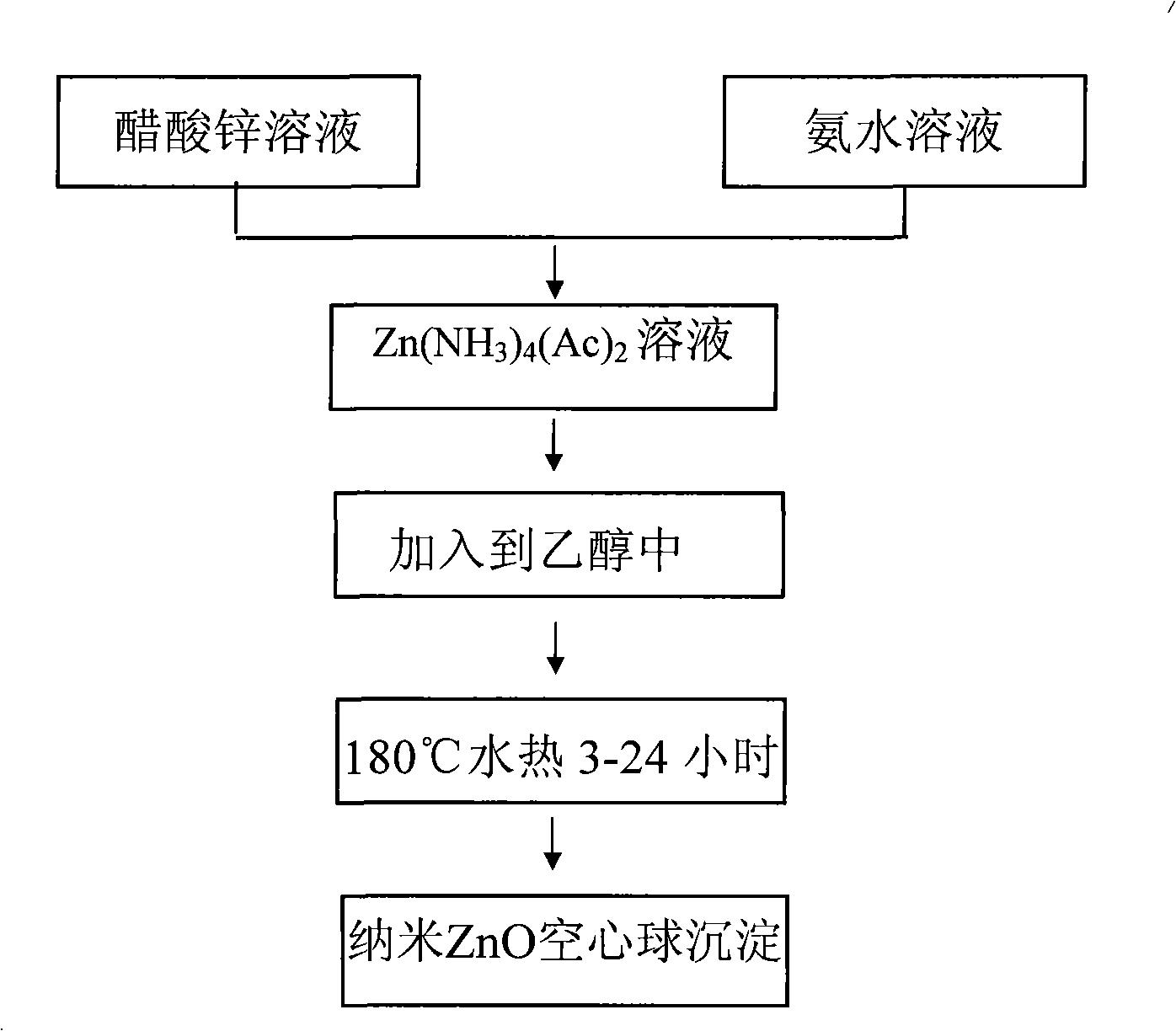

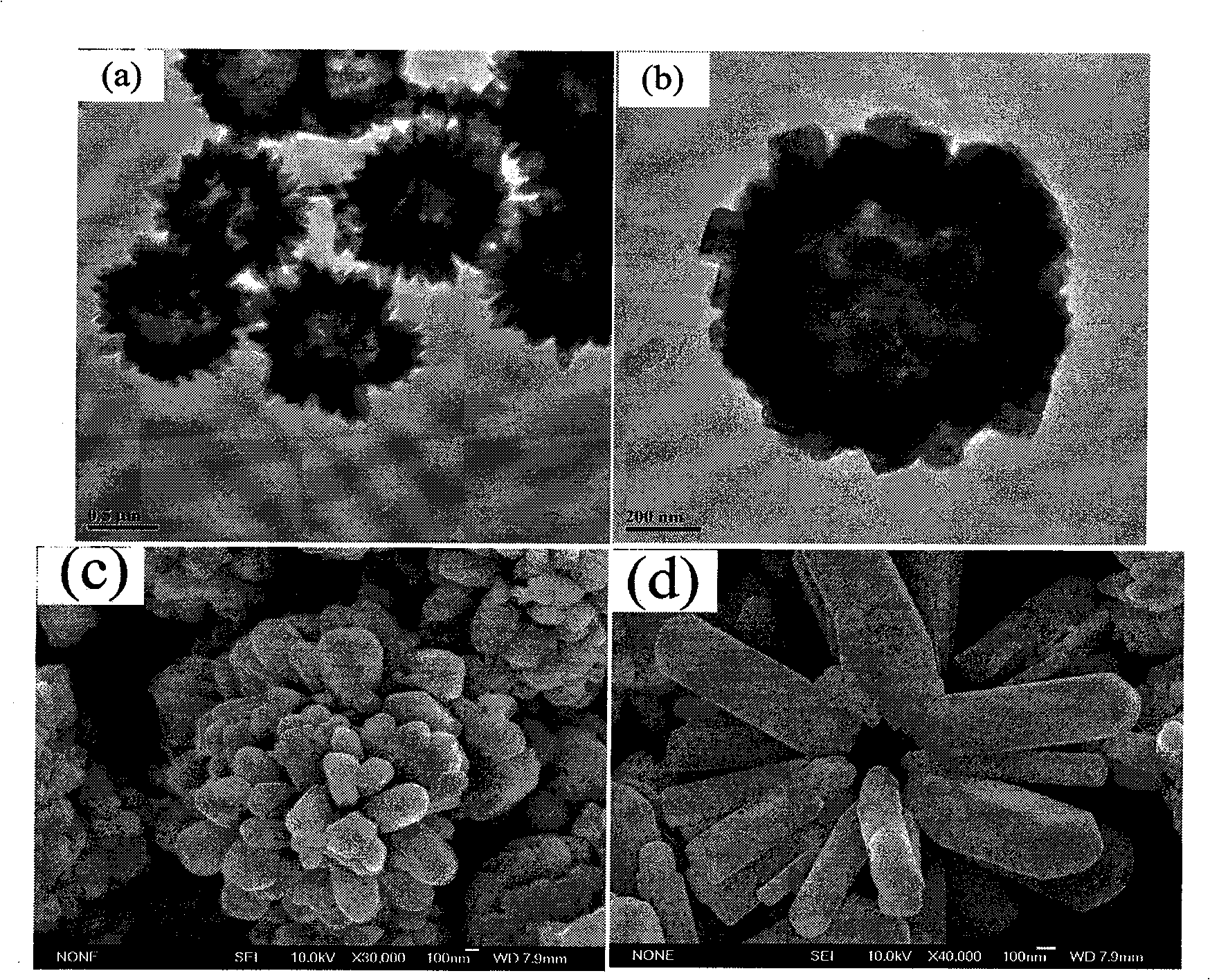

Method for preparing zinc oxide nano hollow spheres by caustic corrosion reaction

InactiveCN101254939AAdd less typesAvoid introducingNanostructure manufactureZinc oxides/hydroxidesCorrosion reactionProduction rate

The invention provides a method for preparing zinc oxide nanometer hollow spheres in caustic corrosion reaction. The method is mainly characterized in including using the solution of Zn(Ac)2 as the initial reactant first, adjusting the pH value to 11.5-14 by adding ammonia, using ethanol as the solvent, finally forming the nanometer hollow spheres in the hydrothermal reaction between Zn(NH3)4<2+> and excessive ammonia at a high temperature. The entire reaction has simple material, easy operation, no need for any complex instrument processing, convenience and rapidness, which is a method of rapidly preparing the zinc oxide nanometer hollow spheres. The obtained hollow spheres have narrow size distribution and good dispersibility with an external diameter of 600 nm and an internal diameter of 200-300 nm. The caustic corrosion reaction is adopted to synthesize zinc oxide nanometer hollow spheres in the method, thus agglomeration phenomenon caused by an aging machine is obviated, complex operation steps of organic reaction synthesis, contamination and disturbance to objective material zinc oxide caused by the complex operation steps are obviated. The method is obviously characterized in high production rate, rapidness, easiness, convenient operation, low cost and environment friendliness.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

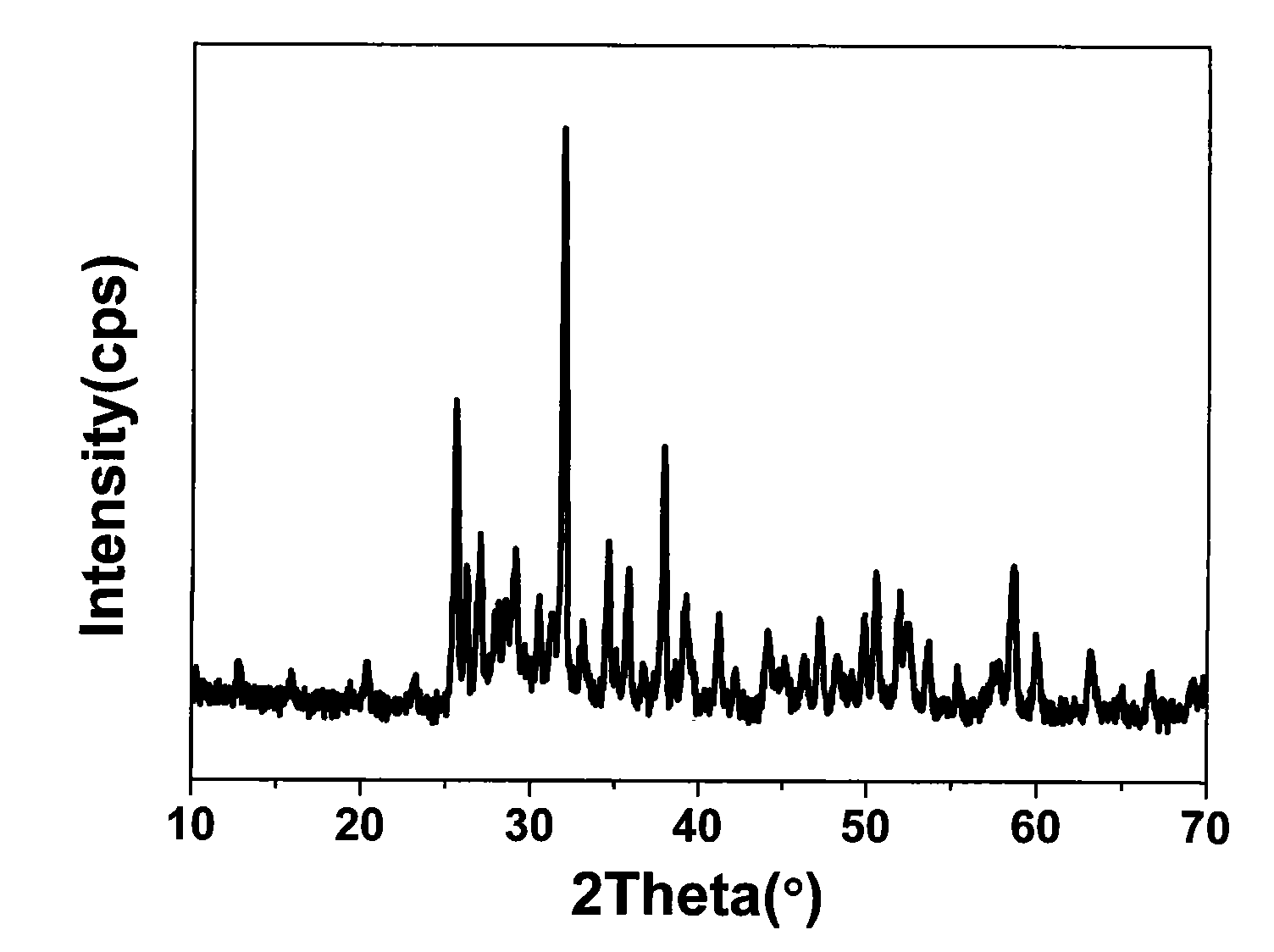

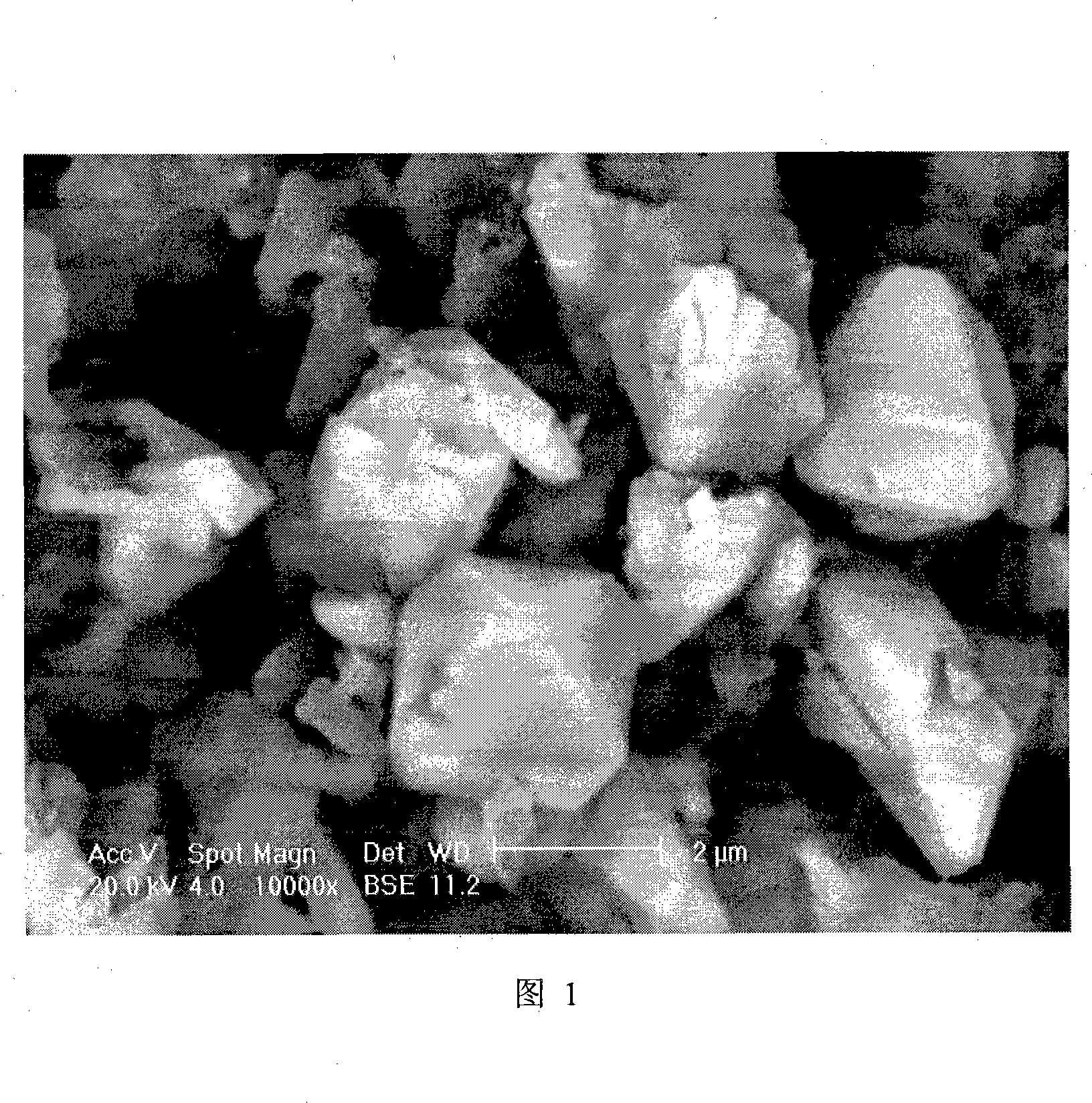

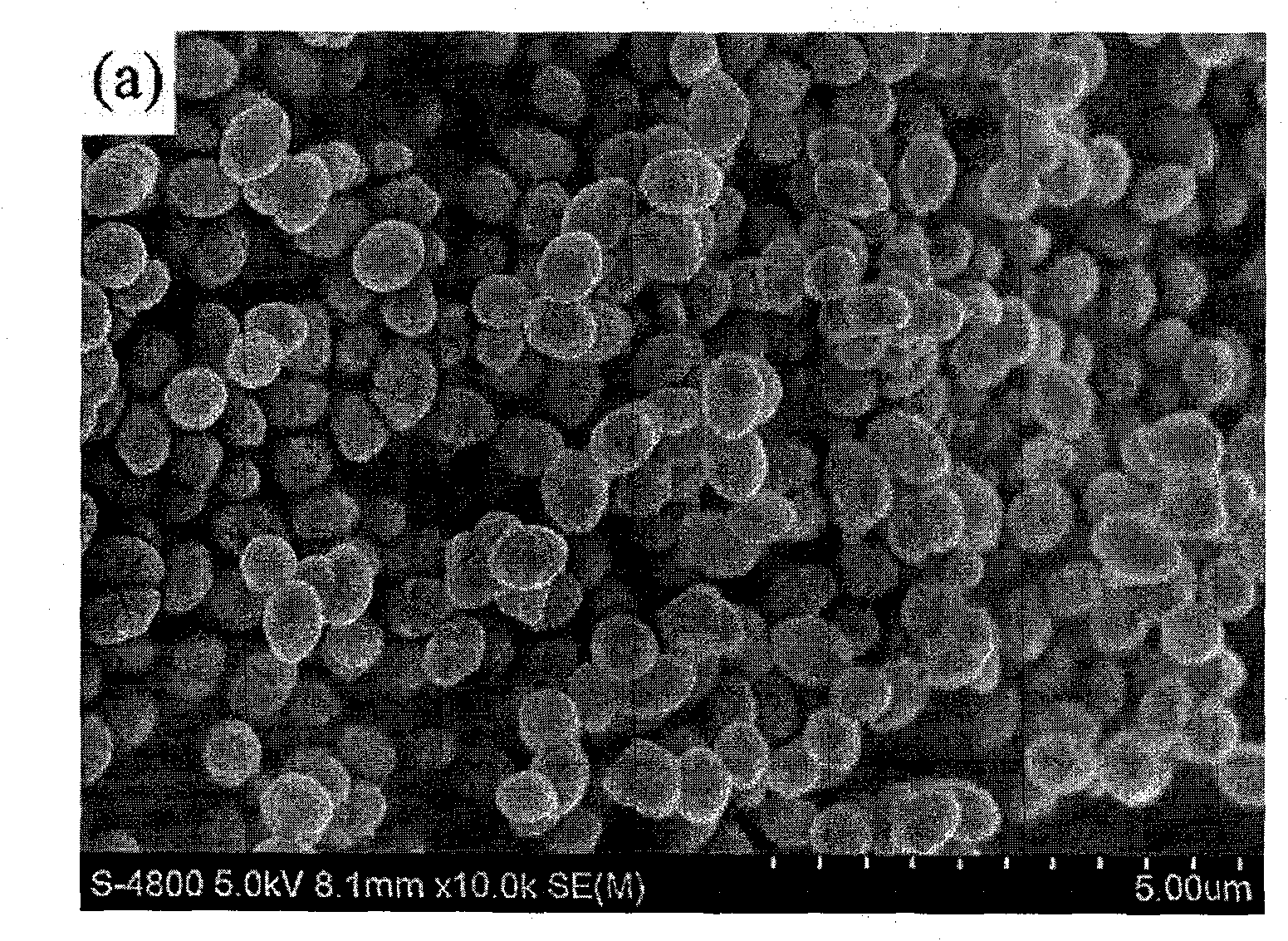

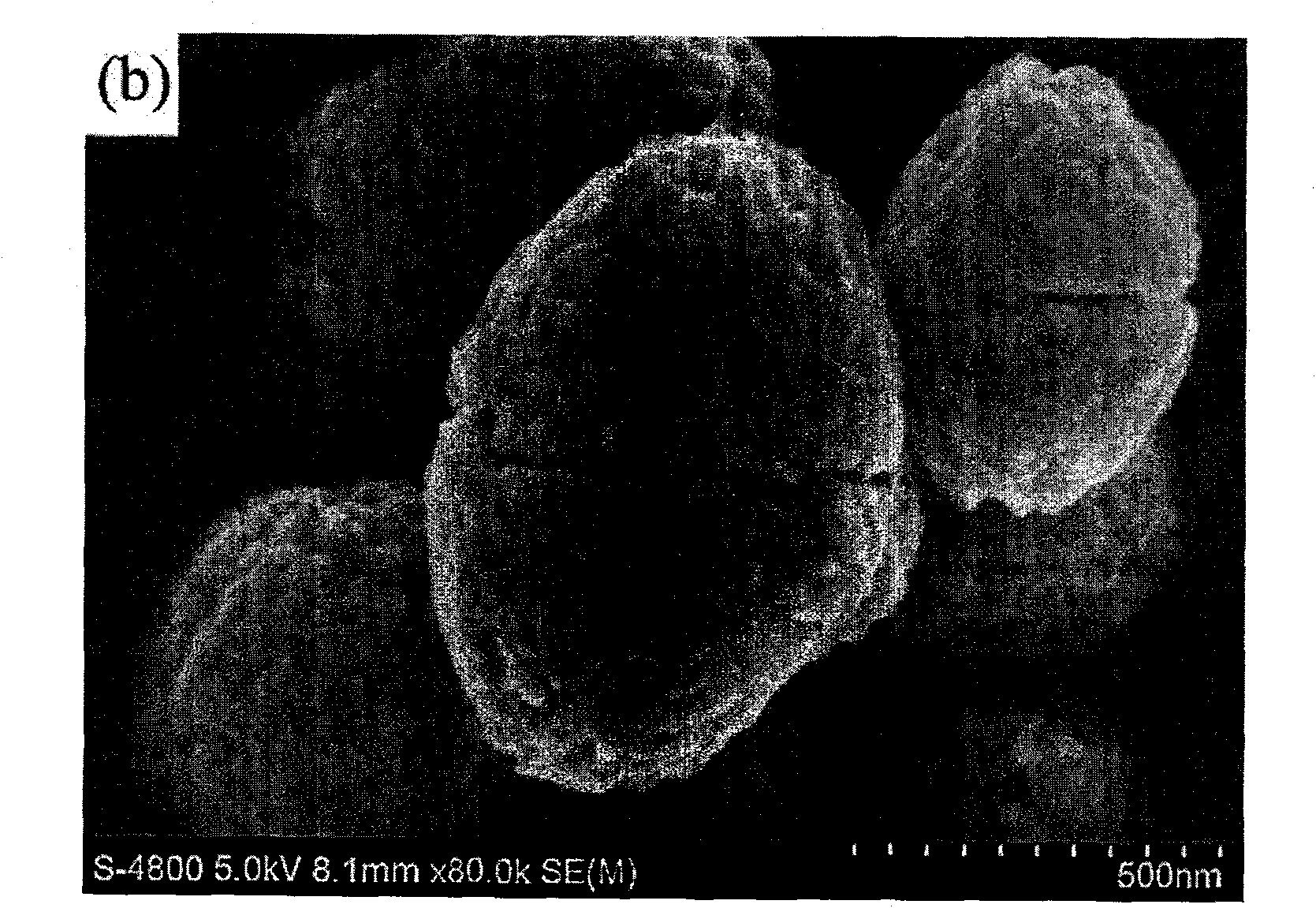

Method for preparing ellipsoid-shaped zinc oxide

InactiveCN101613121AReduce the chance of introducing impuritiesDoes not affect purityZinc oxides/hydroxidesDispersityMicrowave

The invention provides a method for preparing ellipsoid-shaped zinc oxide. The method comprises the following steps of: dissolving a certain amount of zinc slat in water, and stirring the mixed solution until the mixed solution is clear; heating the mixed solution up to between 50 and 100 DEG C, dripping an alkali solution into the mixed solution when the mixed solution is stirred until the pH value of the mixing solution is between 6 and 14, and obtaining a white precipitate; filtering, washing and drying the white precipitate to obtain the finished product. The method has the advantages that: (1) only two raw materials are needed in the whole preparation process, other reaction raw materials are unnecessarily added, and the chance of introducing impurities is lowered, so that the purity of products is not affected; (2) the whole preparation process is mild, the conditions of high temperature, special atmosphere protection and ultrasonic and microwave assistance are not needed, so that the needed equipment is simple, the reaction speed is fast, and the method is more suitable for mass production; and (3) the prepared ellipsoid-shaped zinc oxide has uniform size and good dispersity. By adjusting concentrations of the raw materials, the ellipsoid-shaped zinc oxide of which the sizes of the long shaft and the short shaft are between 50 and 1,000nm can be obtained.

Owner:LIAOCHENG UNIV

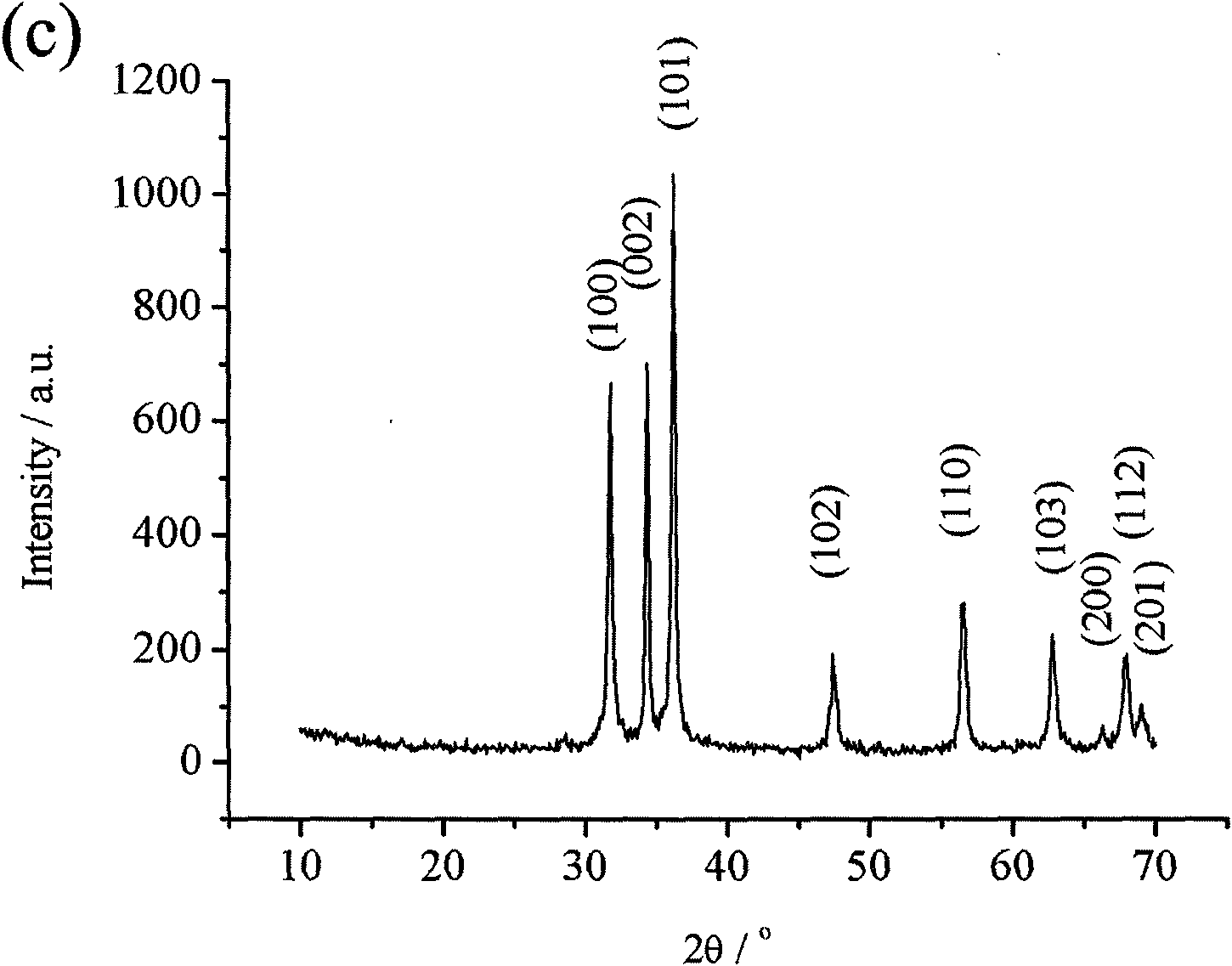

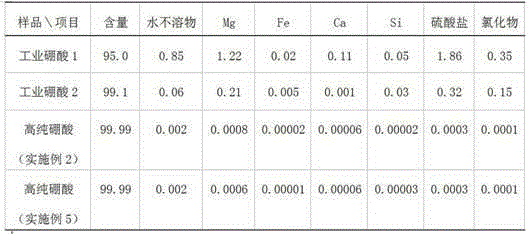

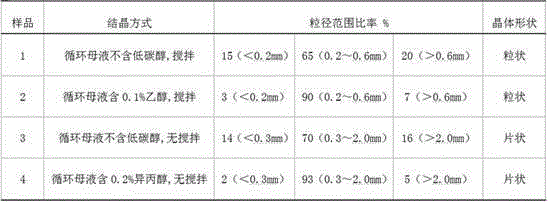

Preparation method of high-purity boric acid

ActiveCN105347353ANo pollution in the processSimple processBoron oxyacidsLamellar crystalsPhysical chemistry

The invention provides a preparation method of high-purity boric acid. The preparation method comprises the following steps: putting industrial boric acid into a mixed solution of circulating mother liquor and trace inorganic acid, stirring, and heating for dissolution; performing thermal reaction for 1-2 hours in a temperature range of 80-95 DEG C; cooling to obtain wet boric acid crystals; respectively washing the crystals by virtue of mother liquor alternately purified by a cation exchange resin column and an anion exchange resin column; and drying to prepare high-purity boric acid. Compared with the prior art, the technical scheme provided by the invention has the technical advantages of being simple in process flow, having no environmental pollution, being high in crystal purity and low in manufacturing cost, selecting between granular or lamellar crystals, and the like; moreover, the crystal particle size distribution can be greatly improved.

Owner:DANDONG CHEM REAGENT FACTORY

Preparation method of m-phenylenediamine

InactiveCN108164425AReduce lossReduce pollutionAmino compound purification/separationOrganic compound preparationFiltrationNitrobenzene

The invention discloses a preparation method of m-phenylenediamine. M-dinitrobenzene is subjected to continuous catalytic hydrogenation, settlement and membrane filtration, and m-phenylenediamine is obtained. The method is simple to operate and high in safety, can be used for continuous production, can achieve the effects of high production efficiency, high product quality, low labor intensity, environmental friendliness and high utilization rate of a catalyst, and is beneficial to the effect of industrialization.

Owner:YANTAI ANOKY FINE CHEM CO LTD +4

Ultrasonic treating process of preparing spherical nanometer silica particle

The present invention belongs to the field of chemical technology, and is especially one sol-gel process of preparing spherical solid nanometer silica powder. The preparation process includes the following steps: dissolving ammonia in certain amount in organic solvent, dissolving non-ionic high molecular dispersant and polyelectrolyte type dispersant in certain amount in deionized water, mixing the organic solution and the water solution via high speed stirring to maintain the homogeneity of the solution, adding Si(OC2H5)4 slowly to react while ultrasonic treatment and maintaining at 25 deg.c for 5-60 min until finishing the reaction to obtain homogeneous sol, and final vacuum freeze drying to obtain the spherical solid nanometer silica powder with high dispersivity and high chemical stability.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Collosol gel production method of nano NiO material

InactiveCN1493526AControl the rate of hydrolysisSmall particle sizeNickel oxides/hydroxidesColloidal chemistry detailsPolyethylene glycolEthanol

A process for preparing NiO nanoparticles in the form of tetragonal crystal by sol-gel method includes dissolving polyethanediol in deionized water, adding less ammonia water to regulate pH=7.5-8, dissolving nickel acetate in absolute alcohol, slowly adding the solution to said aqueous solution of polyethanediol, high-speed stirring, holding temp at 70 deg.c for 4 hr while stirring to obtain sol, filtering, drying and calcining at 500 deg.C for 2 hr.

Owner:SHANGHAI UNIV

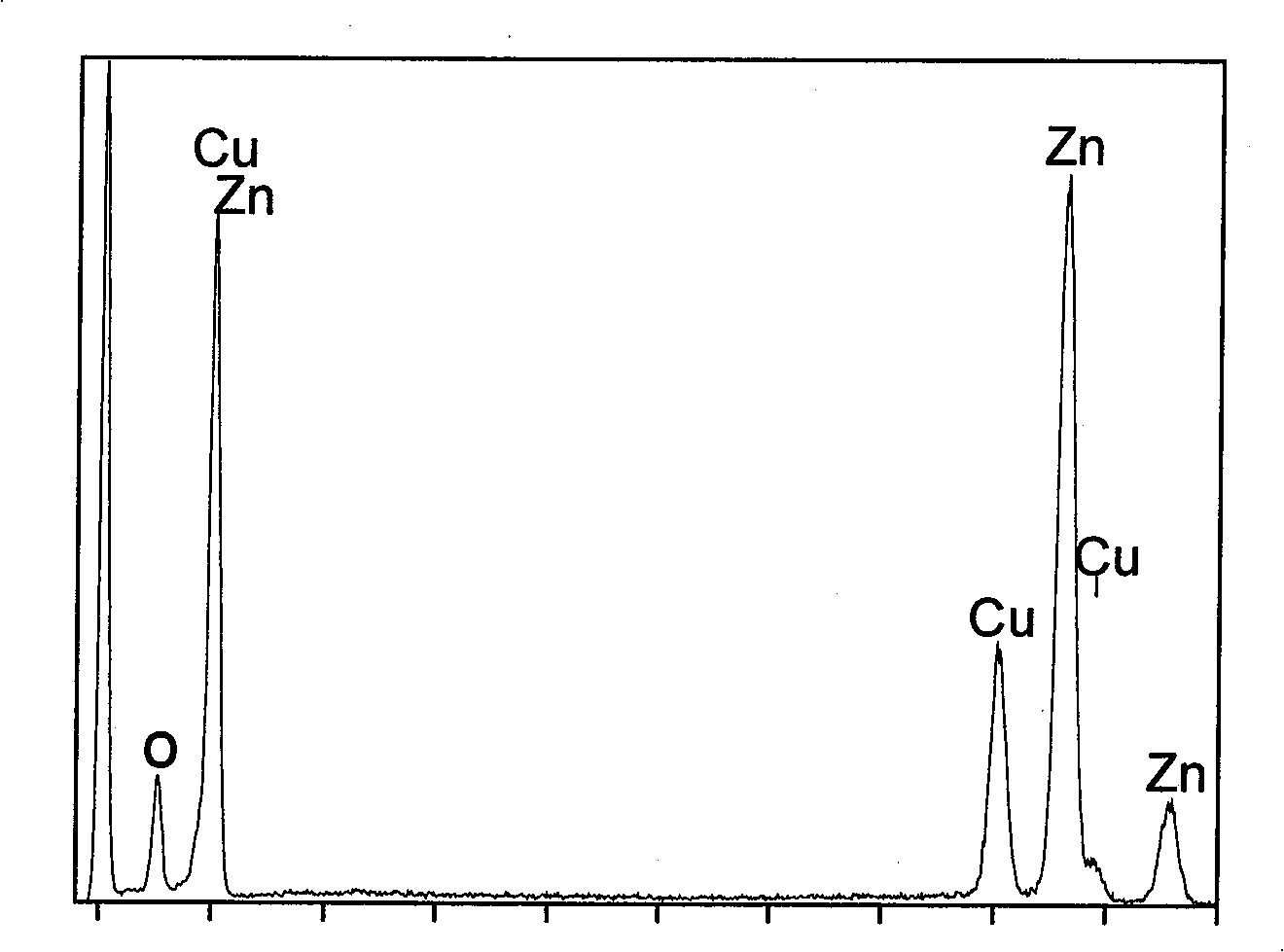

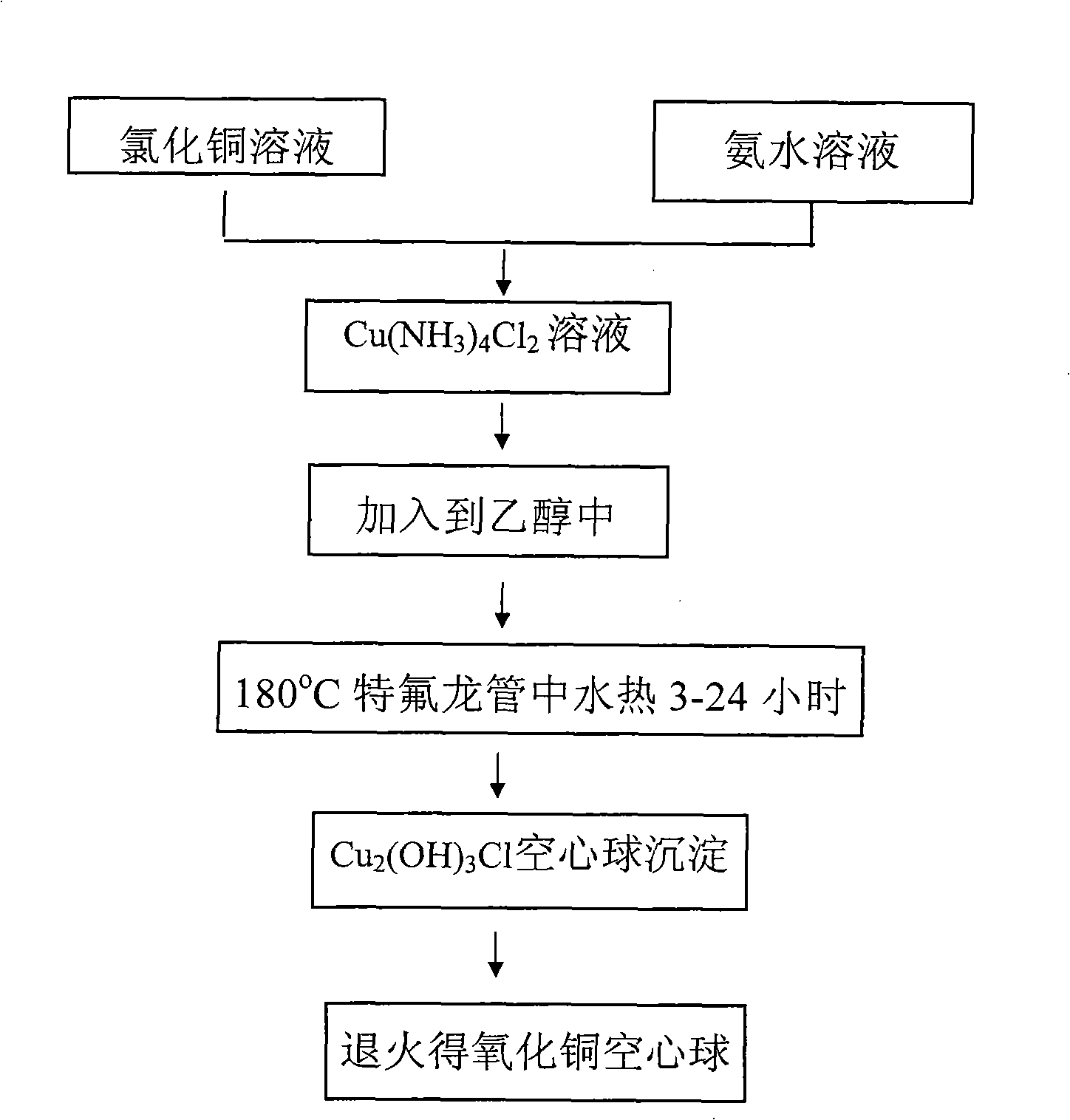

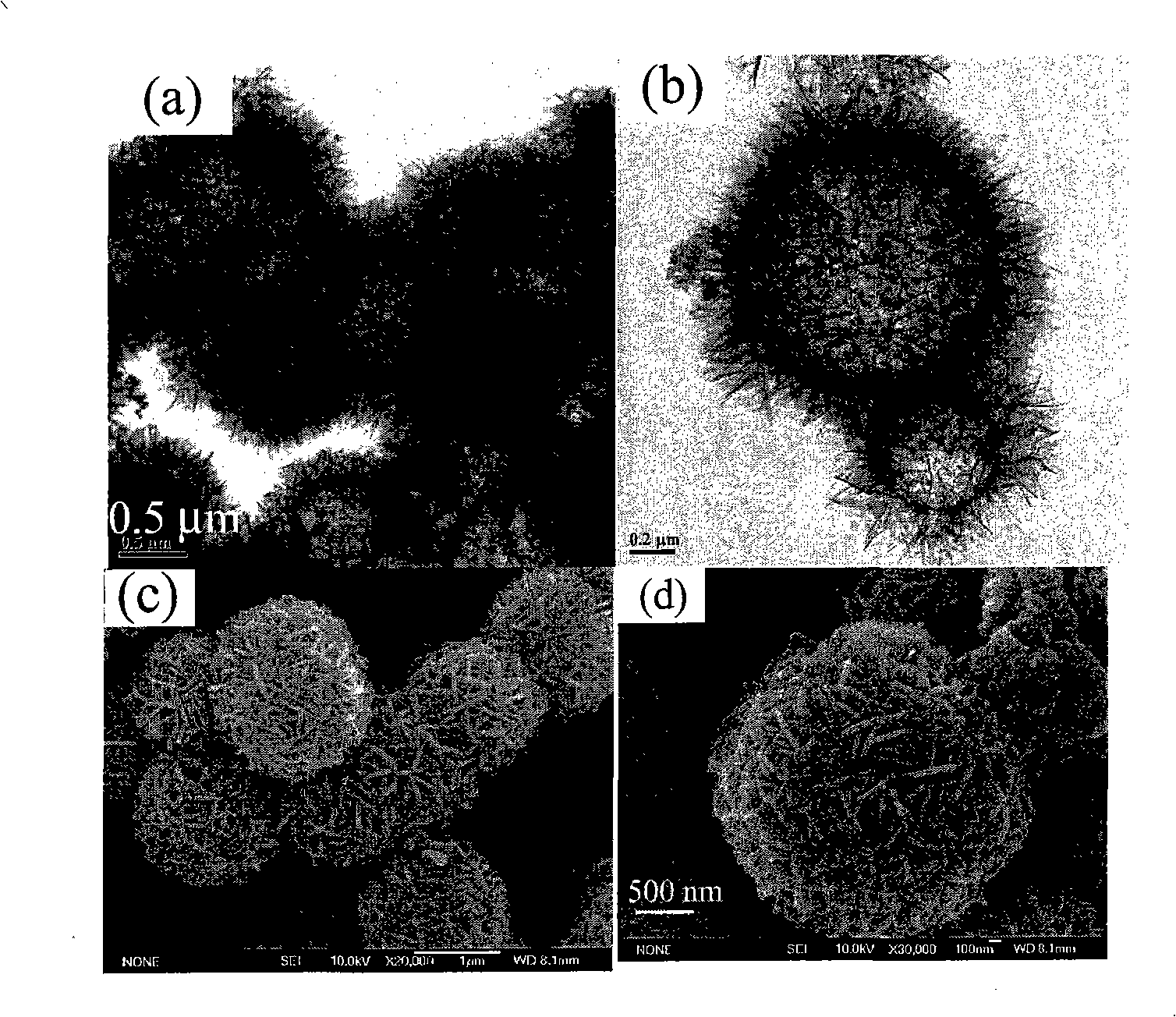

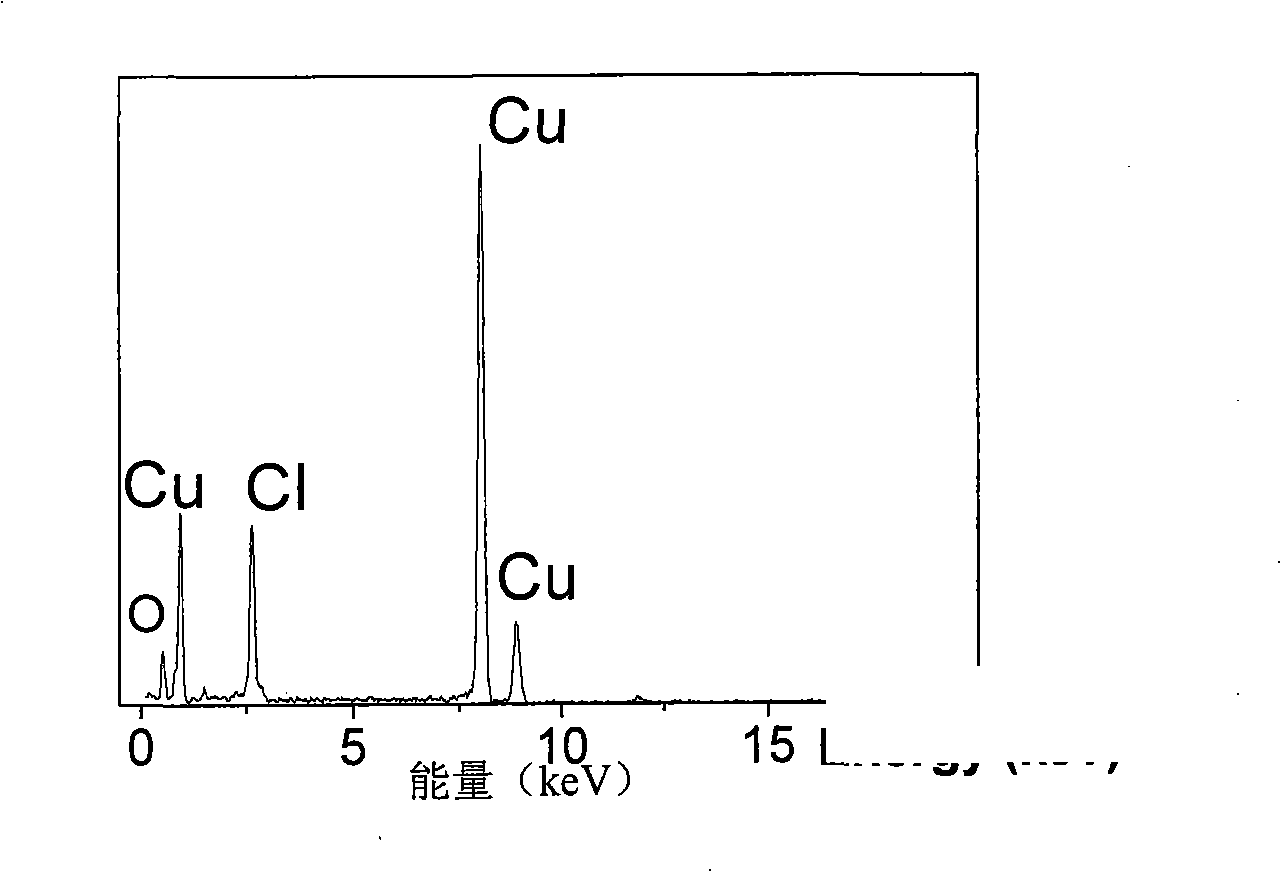

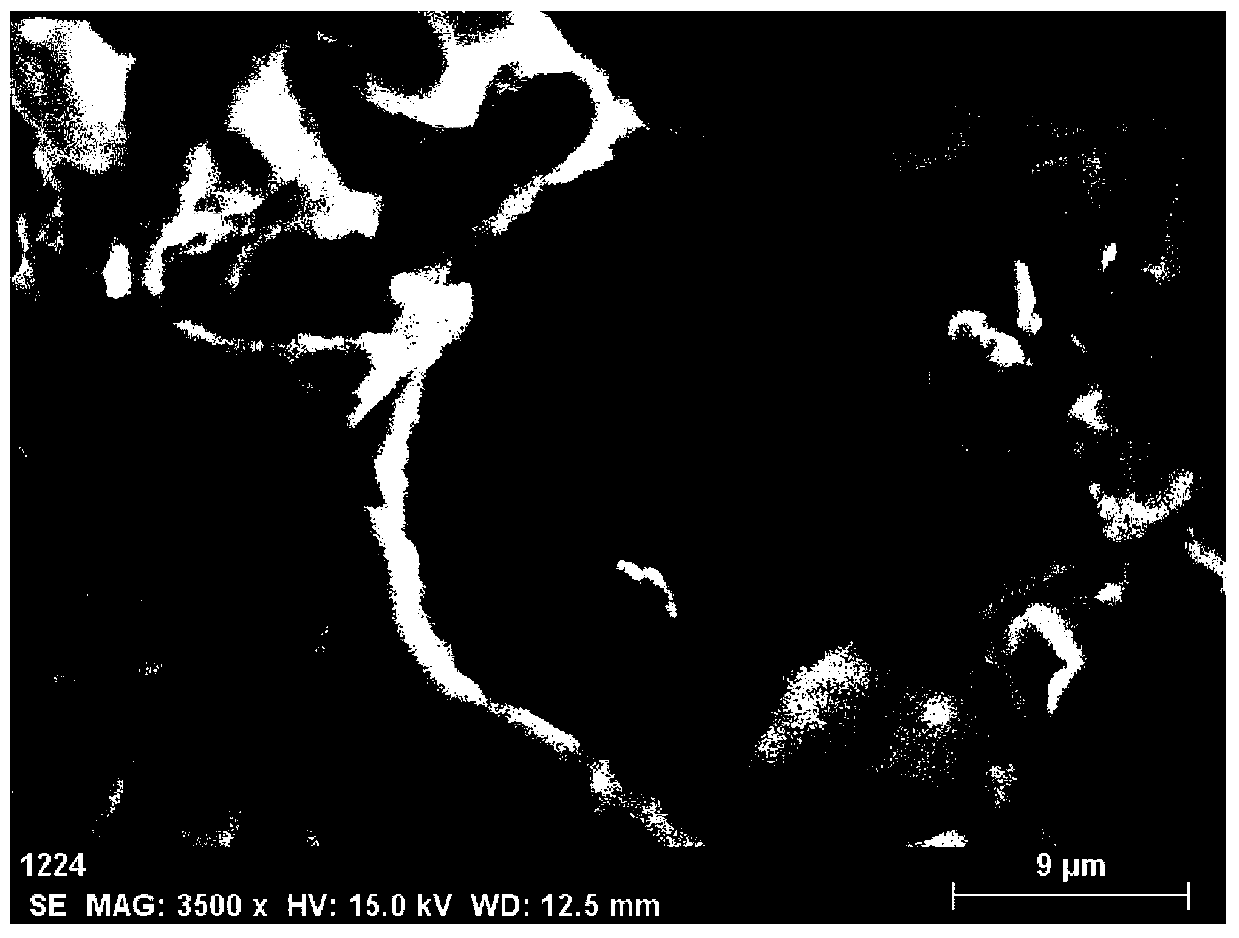

Method for preparing cupric oxide nano-hollow ball with forerunner reaction

The invention provides a method for preparing a copper oxide nano hollow ball through precursor reaction, which is characterized in that: firstly, a CuCl2 solution is taken as an initial reactant and added with ammonia to be adjusted until the pH is equal to between 10 and 14; secondly, ethanol is taken as a solvent, and Cu(NH3)4<2+> and excessive ammonia generate hydrothermal reaction at a high temperature, and then alkali Cu2(OH)3Cl precursor is obtained; and thirdly, after annealing for 2 hours at a temperature of between 300 and 500 DEG C, the copper oxide nano hollow ball is formed. The copper oxide nano hollow ball prepared has an outside diameter between 400 and 600 nanometers and a thickness between 100 and 300 nanometers, and has narrow size distribution and good dispersity. The method removes the agglomeration phenomenon brought by a curing mechanism, complex operational steps of synthesis through a template method, and pollution and interference on target materials - copper oxide. Moreover, the method has the obvious characteristics of high yield, quickness and simpleness, convenient operation, low cost, friendly environment and so on.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

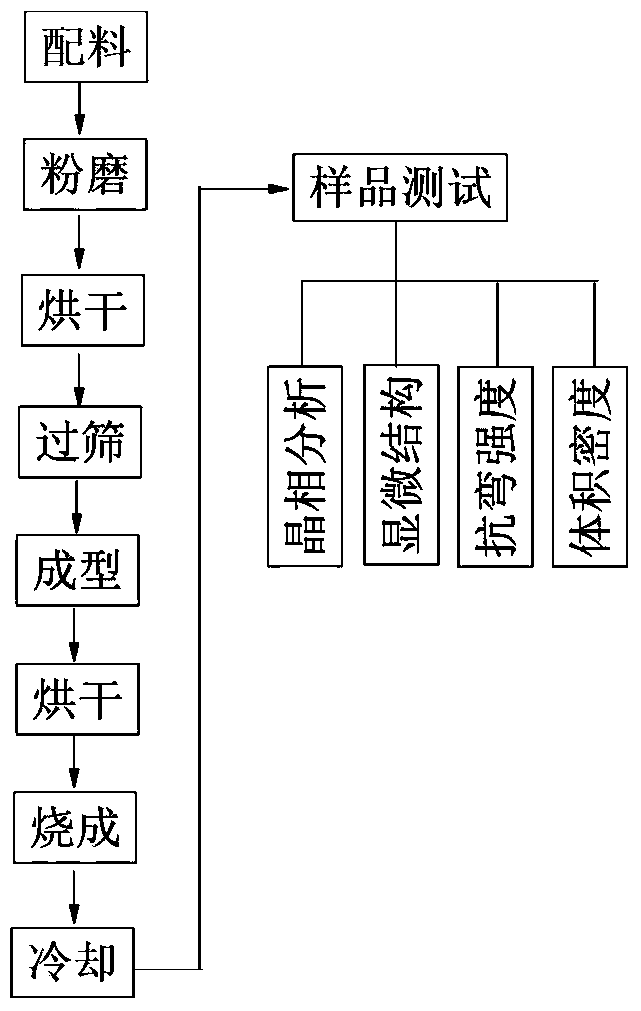

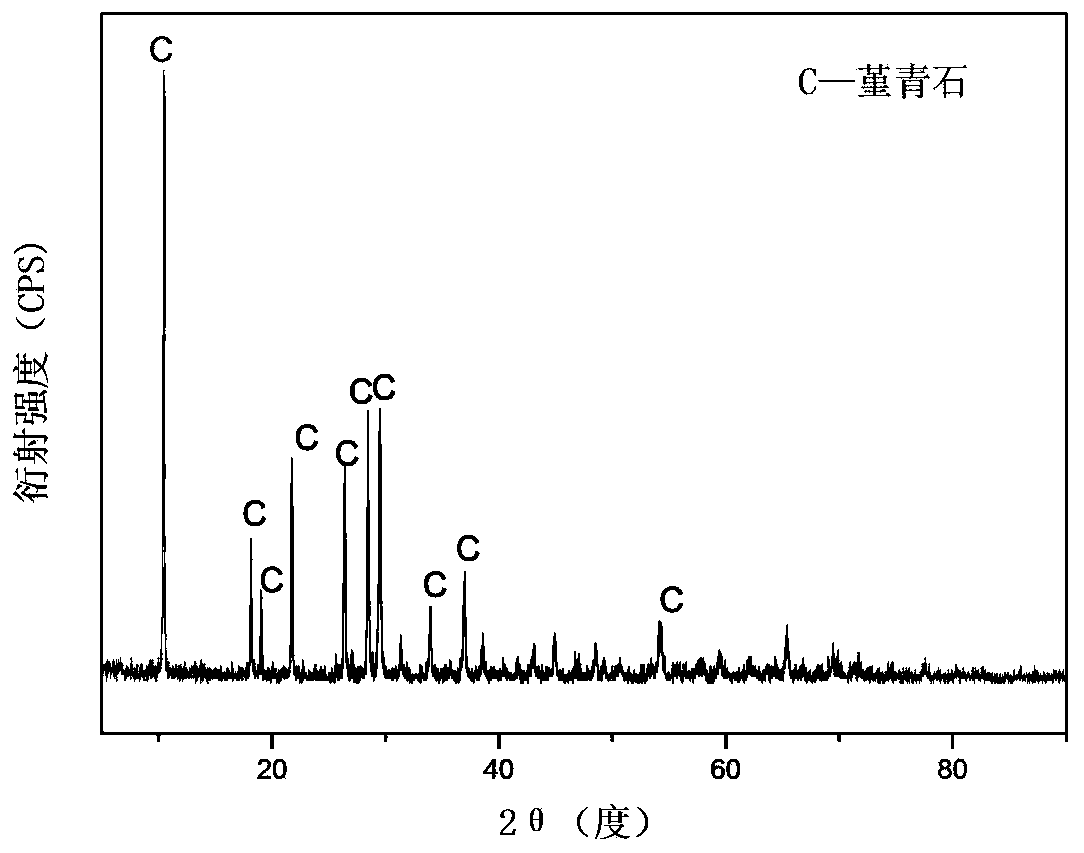

Preparation method for synthesizing cordierite material by use of waste ceramic rollers

InactiveCN103626481AReduce manufacturing costSolve the problem that poor forming performance is not conducive to processing and formingAir atmospherePolyvinyl alcohol

The invention discloses a preparation method for synthesizing a cordierite material by use of waste ceramic rollers, which comprises the following steps: A) mixing the following raw materials in parts by weight: 40-50 parts of waste ceramic rollers, 20-30 parts of kaolin, 21-26 parts of talc, 4-6 parts of quartz and 0-3 parts of titanium dioxide; B) grinding the raw materials, spheres and water at a ratio of 1:1.5:0.8 in a grinder for 4-6 hours; C) filtering and dehydrating the slurry after grinding, drying in a drying oven at 100 DEG C for 12 hours, breaking and sieving with a 100-mesh sieve; D) mixing the powder with a polyvinyl alcohol adhesive, forming under a pressure of 20MPa, and drying the formed blank in the drying oven at 100 DEG C for 12 hours; E) calcining the dry blank in a kiln in the air atmosphere, and preserving heat, wherein the calcining temperature is 1,320-1,380 DEG C, and the heat preserving time is 1-4 hours; naturally cooling to room temperature to obtain the cordierite material. The method disclosed by the invention is used for preparing the cordierite material by use of waste rollers; with ecological environmental protection technology and raw material innovation, the method is of great significance to environmental protection.

Owner:FUJIAN UNIV OF TECH

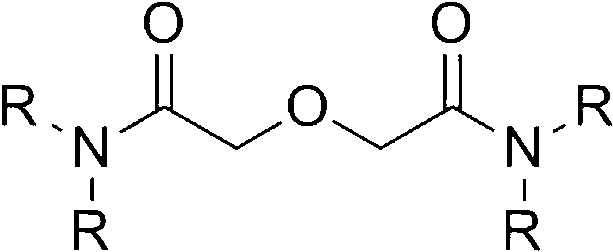

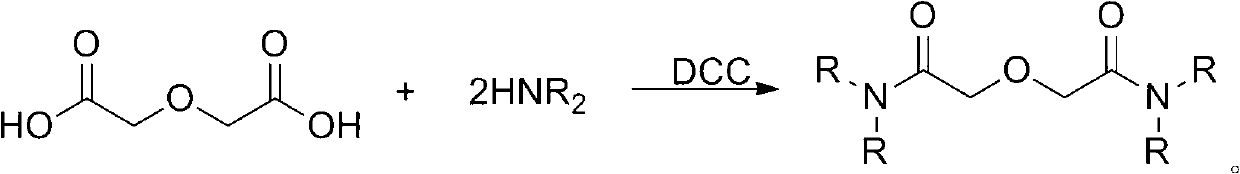

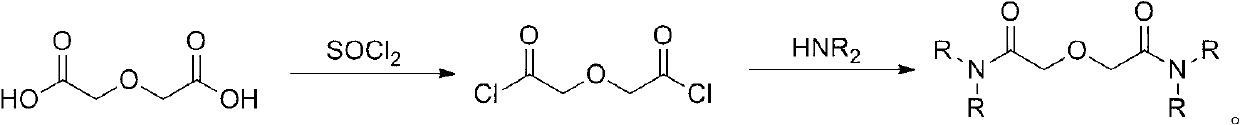

Method for synthesizing diamide podand extraction agent

ActiveCN102993042AEasy to purifyMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationLiquid wasteFuel reprocessing

The invention discloses a method for synthesizing diamide podand extraction agent, wherein chloro-carbonic ester and diglycolic anhydride react to generate mixed anhydride under the action of tertiary amine, and then the reaction is performed with amine to generate the diamide podand extraction agent. The method has mild reaction condition, can be performed at a low temperature, and has high reaction speed and short consumed time; the product purification operation is simple and easy; the obtained diamide podand extraction agent can meet the extraction purity requirement, and is beneficial to establishing flow that the diamide podand is used for treating high-level liquid waste in spent fuel reprocessing plant; the used chloro-carbonic ester is easy to prepare and has a low price, therefore, the cost for preparation of a great amount of extraction agent is greatly reduced; and besides, the yield of the extraction agent is high, so that the method is very suitable for industrial production and application.

Owner:SICHUAN UNIV

Method for preparing low-sulfur rare earth oxide through hydroxide precipitation

ActiveCN105803199ADoes not affect purityPrevent chemical adsorptionProcess efficiency improvementSulfate radicalsChemical adsorption

The invention discloses a method for preparing a low-sulfur rare earth oxide through hydroxide precipitation. The method mainly comprises the following steps: 1, adding a soluble organic matter containing malic acid, acetylacetone and the like into a rare earth sulfate solution for mixing, so as to prepare a primary precipitation solution; 2, adding one or more alkaline precipitants into the primary precipitation solution for a precipitation reaction, wherein the consumption of the alkaline precipitants is 105-120% of the theoretical consumption of rare earth precipitating in the rare earth sulfate solution; and 3, carrying out solid-liquid separation to obtain a rare earth hydrate precipitate and a precipitation mother liquor, and subjecting the rare earth hydrate precipitate to calcination at 600-900 DEG C to obtain the low-sulfur rare earth oxide. The method provided by the invention has the advantages that through competitive coordination with sulfate, chemical adsorption of sulfate ions is avoided; meanwhile, a homogeneous-phase-like precipitation system can be formed, the forming of a crystalline precipitation is facilitated, and the precipitation process is simple and easy to control; the organic matter entering rare earth hydrate can be removed through roasting; and finally, the low-sulfur rare earth oxide can be obtained

Owner:JIANGXI UNIV OF SCI & TECH

Preparation and purification methods of silicon tetrafluoride

InactiveCN105502410AAvoid introducingReduce contentHalogenated silanesPurification methodsSilicon tetrafluoride

The invention relates to preparation and purification methods of silicon tetrafluoride and belongs to the field of fluorine chemical engineering and electronic industry gas. The preparation method comprises the step as follows: a silicon-containing substance and a fluorine-containing substance are mixed to react to produce silicon tetrafluoride. The purification method comprises steps as follows: the to-be-purified coarse product, namely, silicon tetrafluoride, and a reactive material for purification react to produce coarse product Mm(SiF6)p or Mn(HSiF6)q, then thermal decomposition is performed, and purified silicon tetrafluoride is obtained. With the adoption of the preparation method, no acid or corrosive liquid substances are used, the silicon-containing substance and the fluorine-containing substance, particularly a gaseous fluorine-containing substance, react to produce silicon tetrafluoride, fewer impurities are introduced, the purity of the product silicon tetrafluoride is higher, the preparation method has the advantages of high safety, simplicity in operation, high yield, economy and the like, fewer waste acid and residues can be produced, and environmental pollution is lower; with the adoption of the purification method, high-purity silicon tetrafluoride gas can be obtained, and the content of impurity (SiF3)2O and HF is extremely low.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

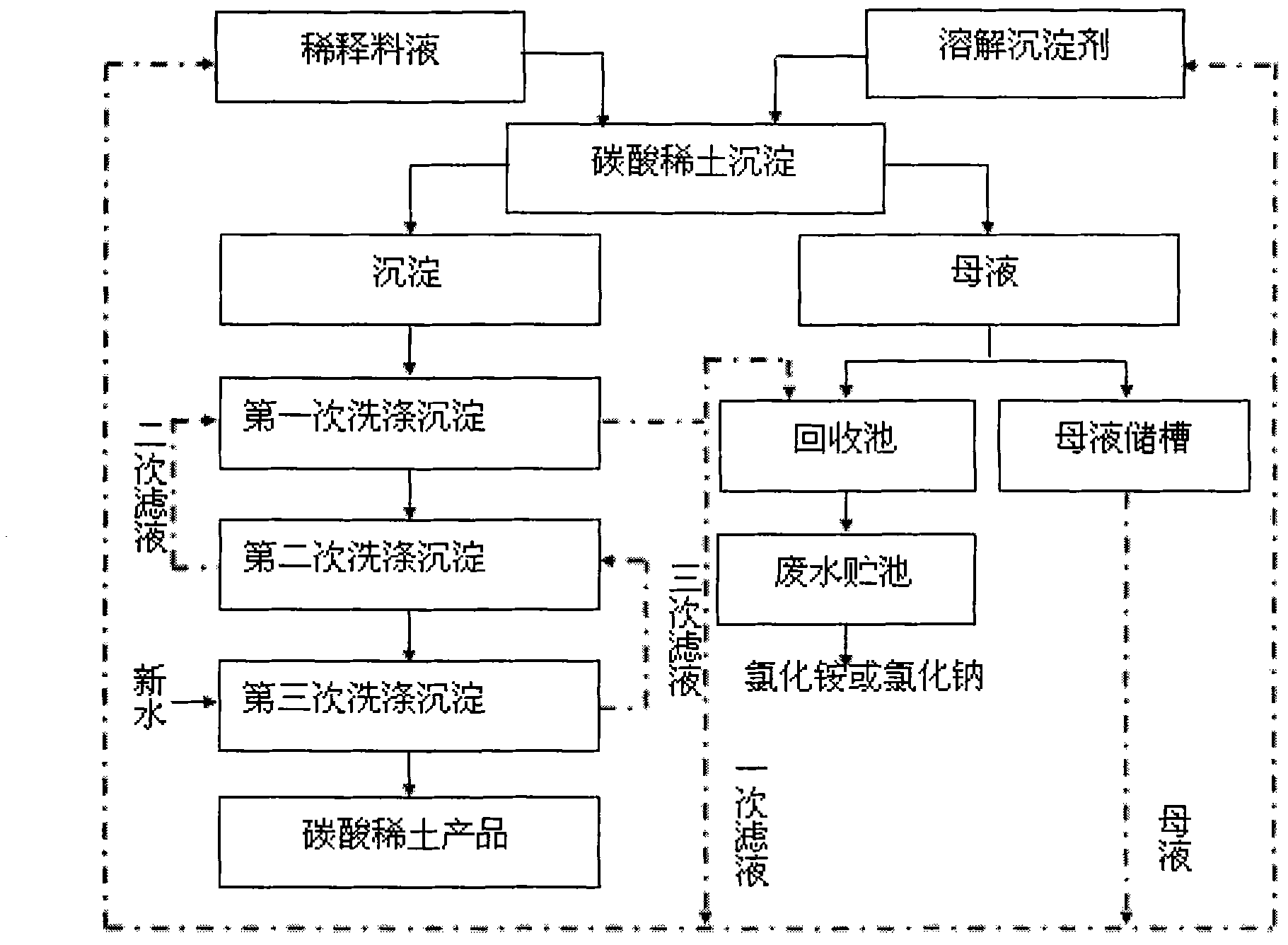

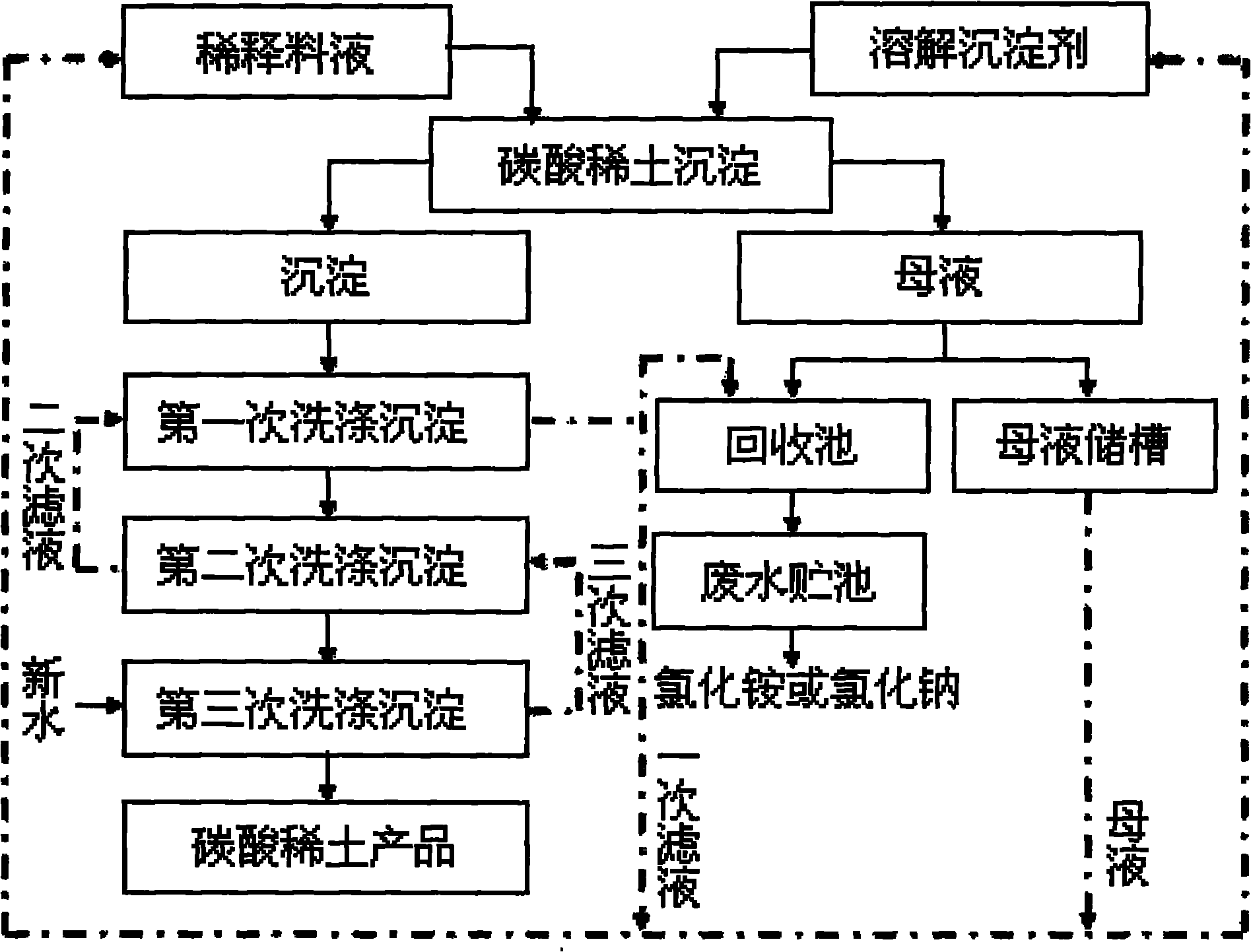

Self recycling method of waste water in rare earth carbonate precipitation

InactiveCN101967559AReduce wasteDoes not affect purityRare earth metal compoundsProcess efficiency improvementWater dischargeRare earth

The invention relates to a self recycling method of waste water in rare earth carbonate precipitation, which belongs to the field of rare earth hydrometallurgy. The method comprises the following steps: part of mother liquor, which is generated in the rare earth carbonate precipitation production process, is directly transmitted into a rare earth carbonate recycling pool to be clarified, and concentrating and crystallization equipment is used for recyling ammonium chloride or sodium chloride; the rest of the mother liquor is transmitted into a mother liquor storage tank, and is used for adjusting the concentration of carbonate precipitation liquor and dissolving the precipitant; the rare earth carbonate precipitate is washed in a reverse flow mode to obtain a first filtrate; the first filtrate and the mother liquor are recycled to the rare earth carbonate precipitation technique to dissolve the precipitant and dilute the liquor; and the residual waste water after recycling is concentrated and crystallized to recycle ammonium chloride or sodium chloride. The precipitation waste water is recycled, thereby reducing waste water discharge amount and the consumption of new water, increasing the concentration of ammonium chloride or sodium chloride in waste water and lowering the energy consumption for concentration and crystallization.

Owner:BAOTOU JINGRUI NEW MATERIAL

Crucible and preparation method thereof

InactiveCN103359918APrevent precipitationDoes not affect purityGlass shaping apparatusGlass productionCrucibleSilicon oxide

The invention provides a preparation method of a crucible and the crucible prepared by the method. The method comprises the steps of: mixing raw material compositions to obtain slurry; then, homogenizing, mixing and molding the slurry to obtain a green body; and drying and sintering the green body to obtain the crucible, wherein the raw material compositions comprise first fused quartz sand and deionized water; and before the slurry is molded, silicon monoxide is added into the slurry. The crucible prepared by the method is high in strength.

Owner:BYD CO LTD

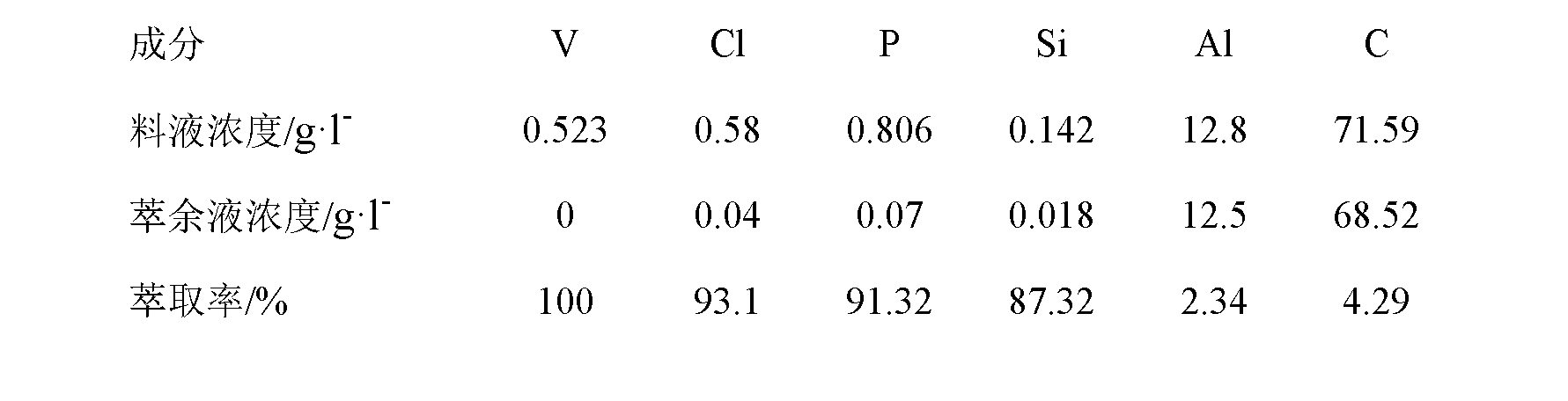

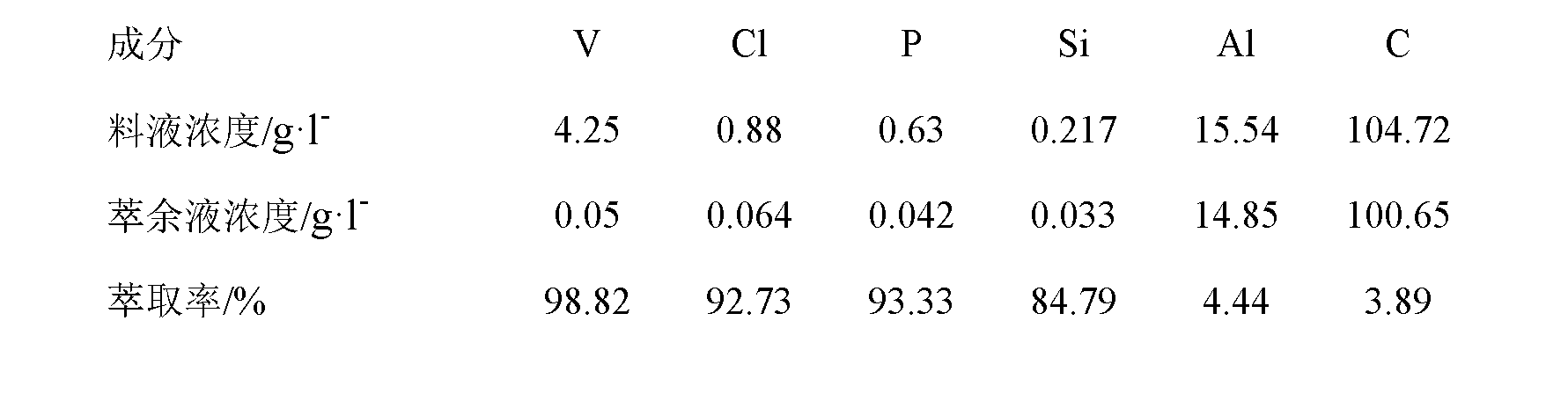

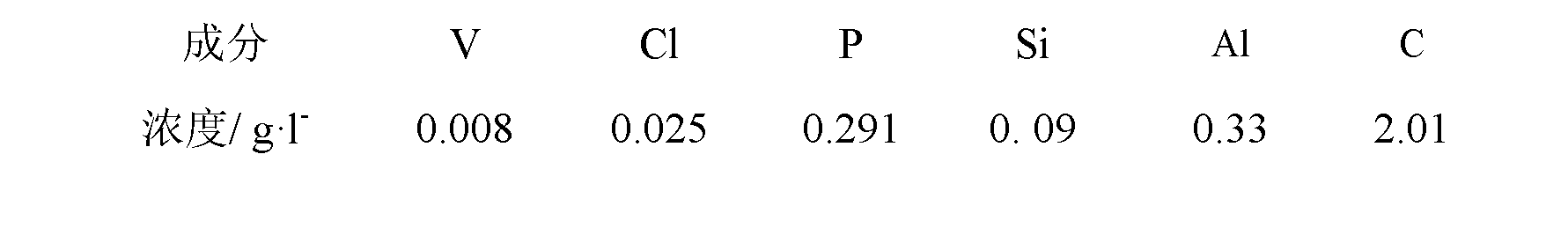

Method for extracting vanadium from production flow of aluminum oxide

InactiveCN103290239ANo lossImprove extraction efficiencyProcess efficiency improvementPhysical chemistryReaction speed

The invention discloses a new method for extracting vanadium from a production flow of aluminum oxide. The method comprises the following steps of: firstly, complexing vanadium in a carbon mother solution by using a complexing agent; then, extracting the vanadium-containing complex by using a modified amine extractant, wherein a sodium vanadate solution can be obtained by performing reverse extraction on a loaded organic phase by using a Na2CO2+NaOH solution, and the sodium vanadate solution is crystallized and then calcined to obtain the vanadium pentoxide of which the purity is more than 99%; depositing vanadium by directly using a reverse extraction solution without purification; and returning extraction raffinate to the production flow directly. By adopting the method, a process of crystallizing first and then extracting vanadium in the conventional process is improved, the extraction reaction speed is high, the time is short, and the efficiency is improved; and vanadium is separated from impurities such as Si and P in the process of extraction and washing, and the recovery rate of vanadium is more than 99%.

Owner:JIANGXI UNIV OF SCI & TECH

Preparation method of nano activated calcium carbonate

InactiveCN107010650AIncreased adsorption load capacityIncreased local calcium carbonate ion concentrationCalcium/strontium/barium carbonatesCalcareous fertilisersSlurryOxygen

The invention relates to a preparation method of calcium carbonate and particularly relates to a preparation method of nano activated calcium carbonate. The method comprises the steps of firstly preparing slurry from activated carbon, adsorbing dopamine into an activated carbon pore structure in a weak alkaline environment, carrying out oxidative autopolymerization under the action of dissolved oxygen in water to form a three-dimensional network structure in the pore structure, loading a microorganism obtained through fruticose lichen culture by using pretreated activated carbon, adding the microorganism-loaded activated carbon into a calcium chloride solution, chelating an organic matter with negative charges on the cell surface of the microorganism and calcium ions in the solution, and continuously generating carbon dioxide through the respiratory action of the microorganism, so that the concentration of carbonate ions in a surrounding solution of the microorganism is continuously increased, the concentration of the carbonate ions and calcium ions in activated carbon pores is increased, calcium carbonate crystal precipitate formed by combination of the carbonate ions and the calcium ions is separated out and adsorbed by the activated carbon and is burnt to remove the activated carbon, and the nano activated calcium carbonate is prepared through activating treatment of a silane coupling agent.

Owner:FOSHAN SUXING MASTERBATCH

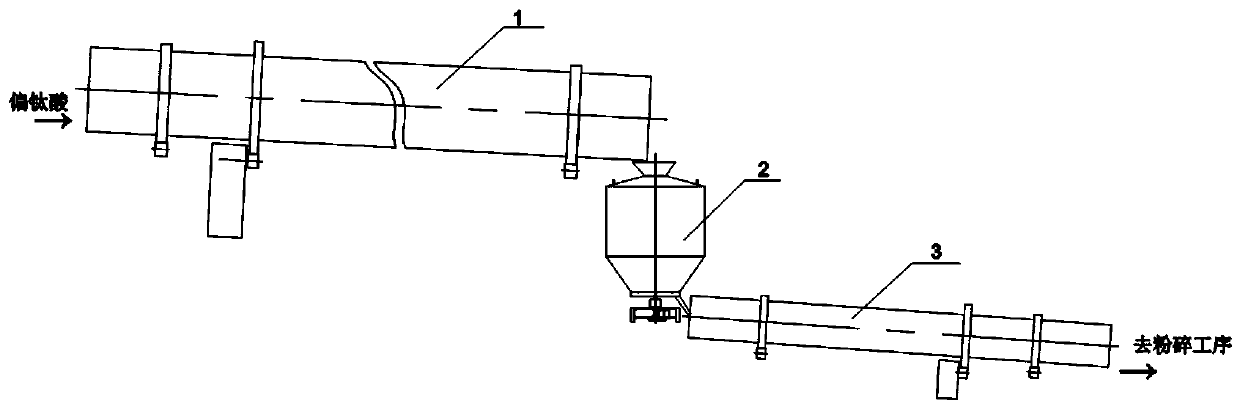

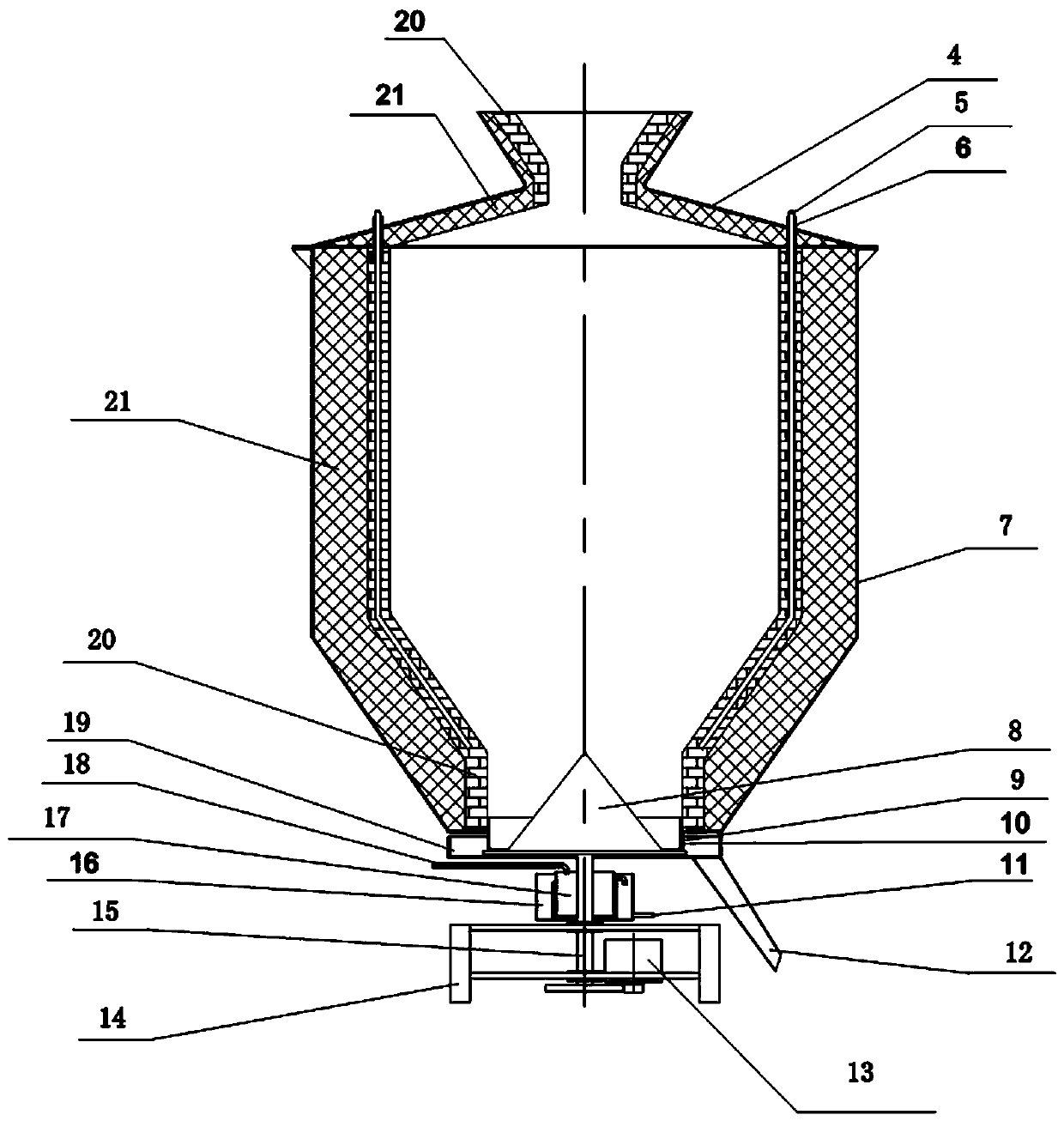

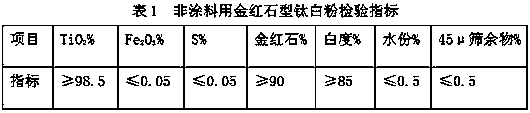

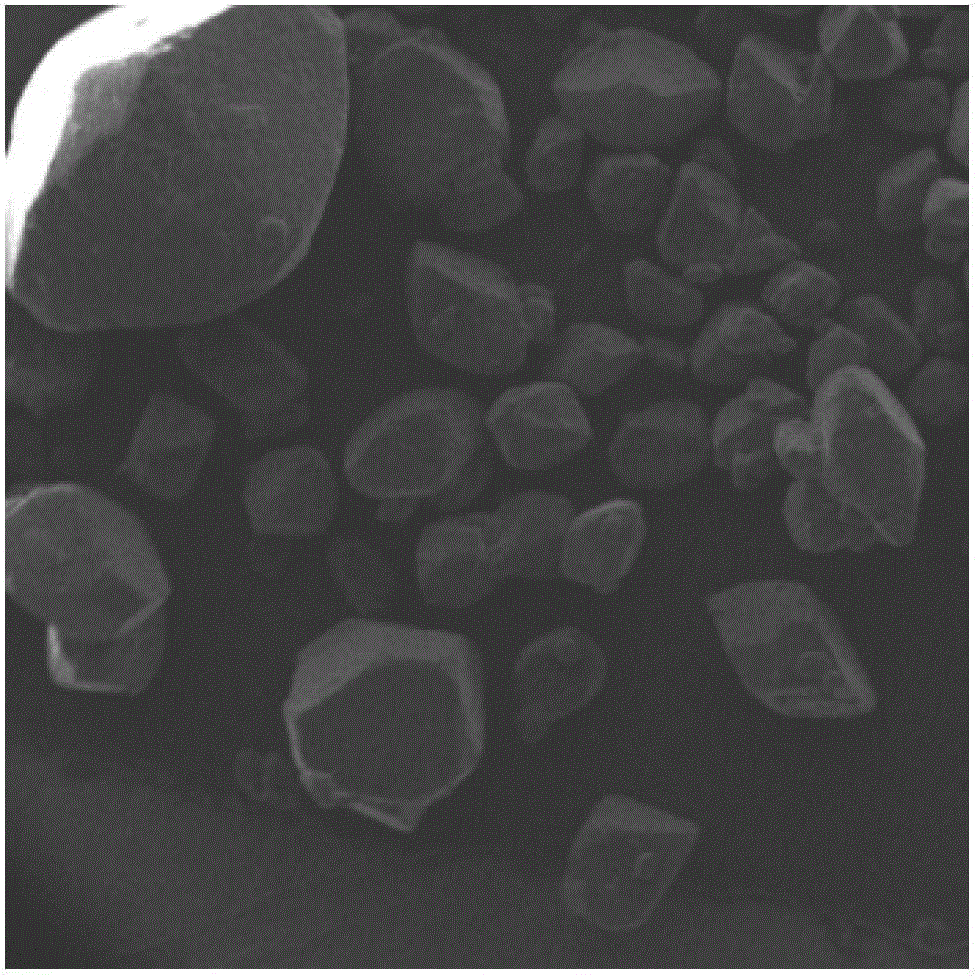

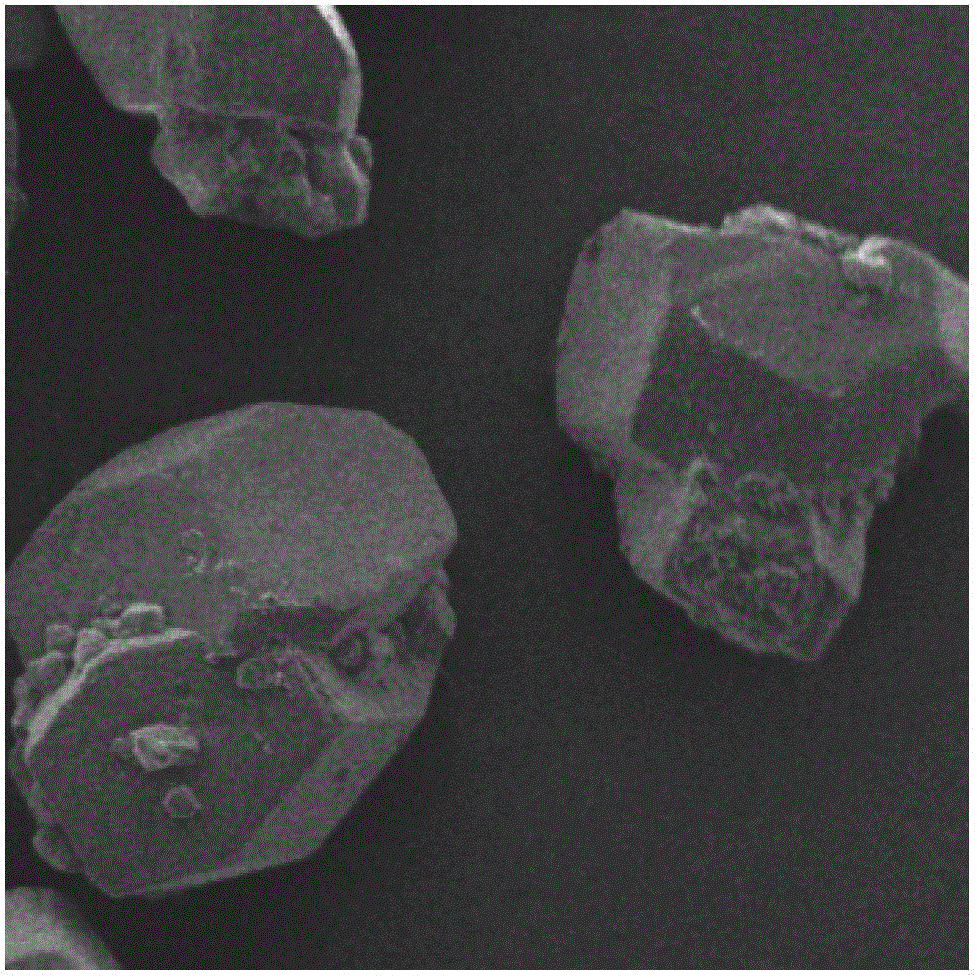

Production method of non-coating rutile type titanium dioxide

The invention relates to the field of titanium dioxide preparation, in particular to a production method of non-coating rutile type titanium dioxide. The method includes the steps of (1), selecting ofraw materials; (2), preparation of a titanium solution; (3), preheating of the titanium solution; (4), manufacturing of seed crystals; (5), adding of the seed crystals; (6), hydrolyzing; (7), flushing; (8), washing; (9), calcining. The acid-split titanium solution can be hydrolyzed without being concentrated, the energy consumption is low, a crystal form accelerant is added when the seed crystalsare prepared, the titanium dioxide can be converted into rutile in the production process, a high crystal form conversion accelerating effect is achieved, the calcining temperature is low, and damageto equipment is greatly relieved; by means of the two links that the crystal form accelerant is added when the seed crystals are prepared, and heat preservation is carried out for 3 hours after calcining is completed, it can be promoted that the produced titanium dioxide is converted into the rutile, the conversion rate of the rutile is high, and therefore the non-coating rutile type titanium dioxide with high rutile content is obtained.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

Anhydrous citric acid crystal and production method thereof

InactiveCN102976925AReduce adhesionDoes not affect purityCarboxylic compound separation/purificationSlurryAnhydrous

The invention provides a production method of anhydrous citric acid crystal. The production method comprises the following steps in sequence: evaporating and crystallizing citric acid solution; and carrying out solid-liquid separation on the crystal size containing an anhydrous citric acid crystal, so as to obtain a wet anhydrous citric acid crystal, wherein the temperature of the wet anhydrous citric acid crystal which is obtained by separating under the solid-liquid separation condition is not less than X to 5 DEG C and higher than 36.6 DEG C, and X DEG C is the temperature of the crystal size to be treated by solid-liquid separation. The invention also provides the anhydrous citric acid crystal prepared by the production method provided by the invention. According to the production method provided by the invention, the adhesion of the anhydrous citric acid crystal can be obviously reduced while the purity of the anhydrous citric acid crystal is not influenced and the process is not increased.

Owner:COFCO BIOTECHNOLOGY CO LTD

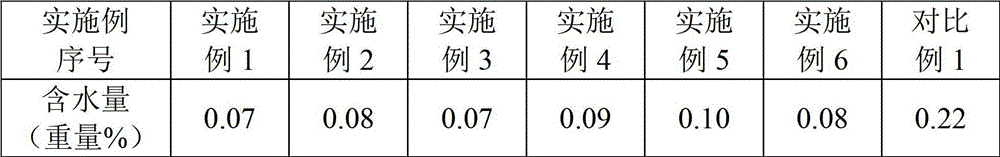

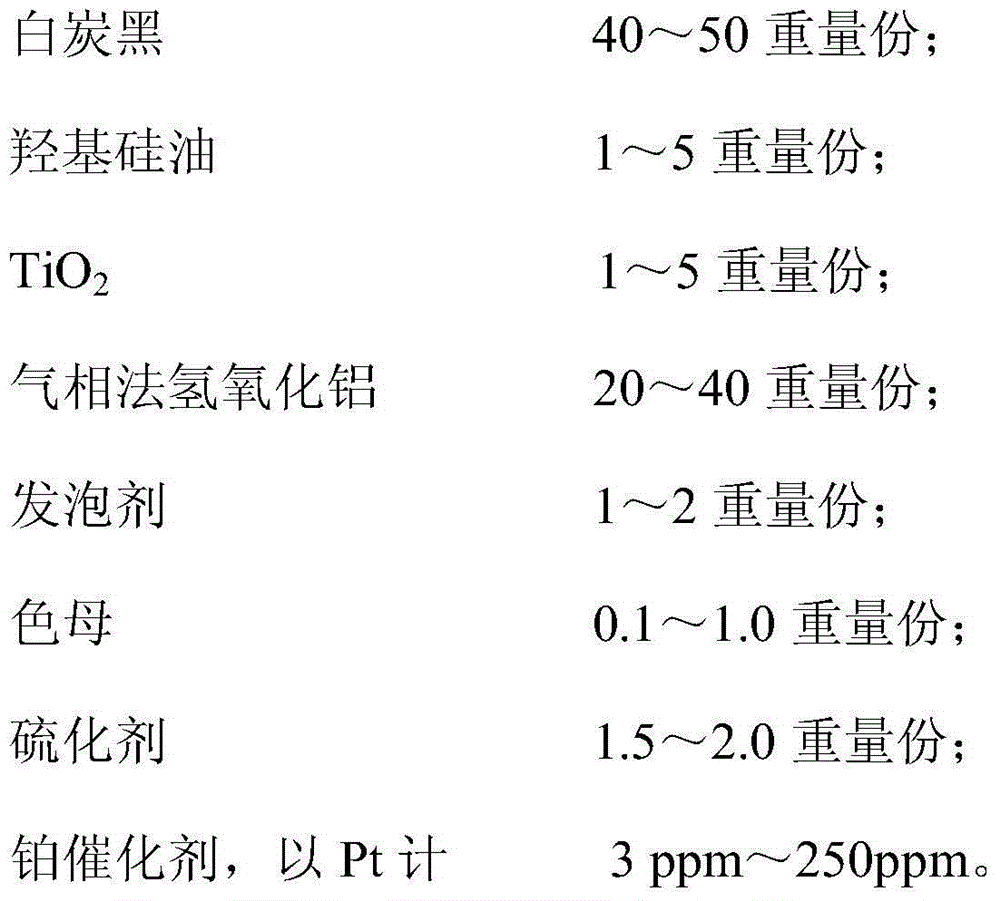

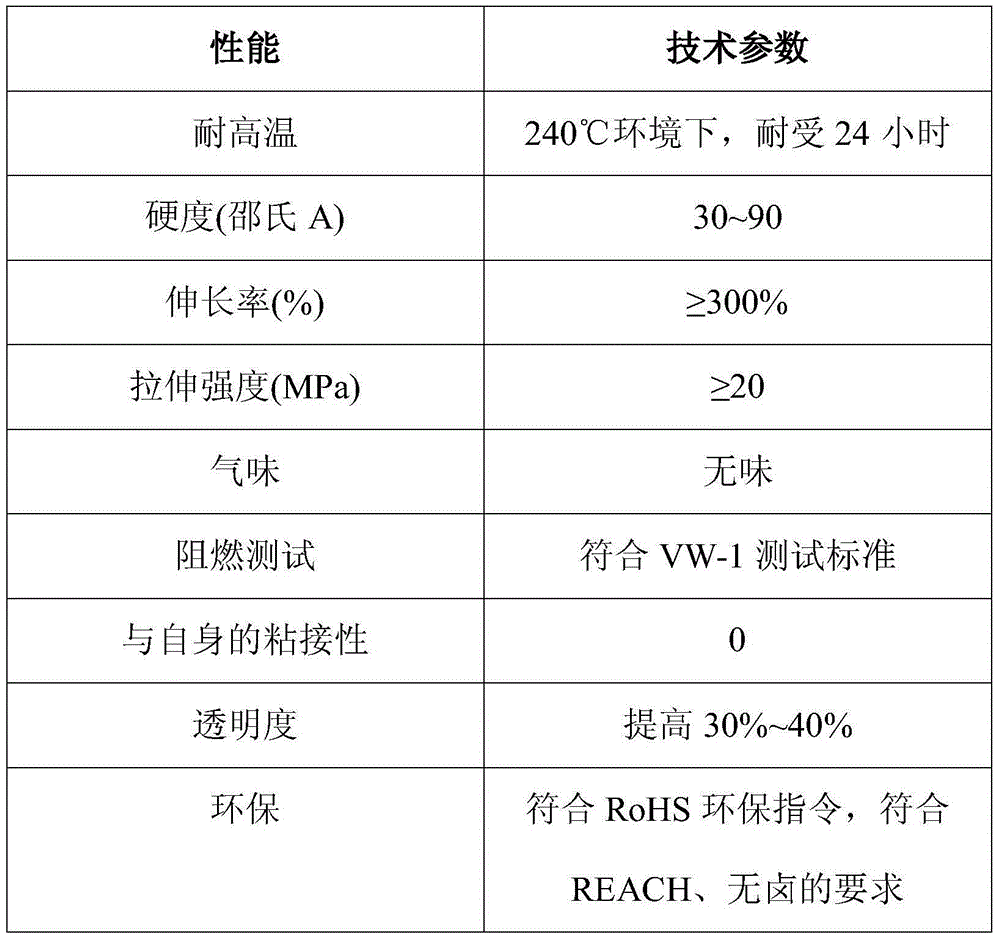

Silicone rubber insulating sizing material, high-temperature and high-pressure resistant silicone rubber wire and preparation process

InactiveCN104479358AMeet environmental protection requirementsImprove high temperature resistanceRubber insulatorsPolymer scienceHigh pressure

The invention discloses a silicone rubber insulating sizing material, a high-temperature and high-pressure resistant silicone rubber wire and a preparation process of the wire; the high-temperature and high-pressure resistant silicone rubber wire is made of the silicone rubber insulating sizing material; the silicone rubber insulating sizing material comprises raw silicone rubber, white carbon black, hydroxyl silicone oil, TiO2, aluminum hydroxide prepared through a vapour phase method, a foaming agent, a platinum catalyst, colour master, a vulcanizing agent and the like; and an antistatic agent can also be added properly. The silicone rubber insulating sizing material disclosed by the invention can satisfy the environment-friendly requirements and has excellent high-temperature and high-pressure resistant performances; the addition proportion of TiO2 is proper; the heat-resistant effect is increased while the purity and the ageing resistance of rubber cannot be influenced; the cost is relatively lower; the aluminum hydroxide prepared through the vapour phase method is small in grain size and few in impurity; the flame retardant efficiency is increased while withstand voltage influence of aluminum hydroxide prepared through a precipitation method is little; the platinum catalyst is capable of isolating air under the catalytic action of platinum, so that flame is extinguished; the foaming agent has the effect of isolating air; and thus, the flame retardant property is increased.

Owner:DONGGUAN SUNTRACK WIRE

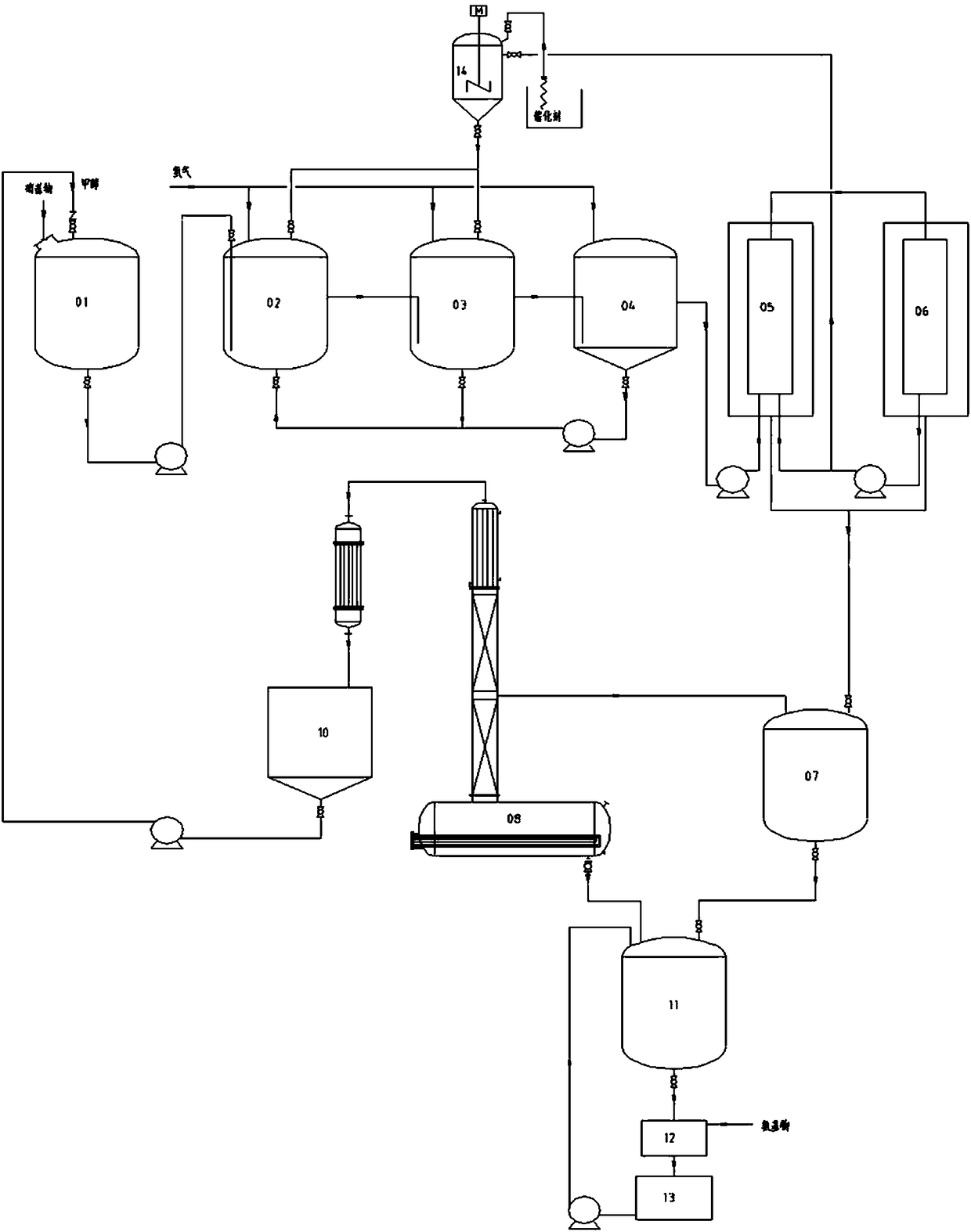

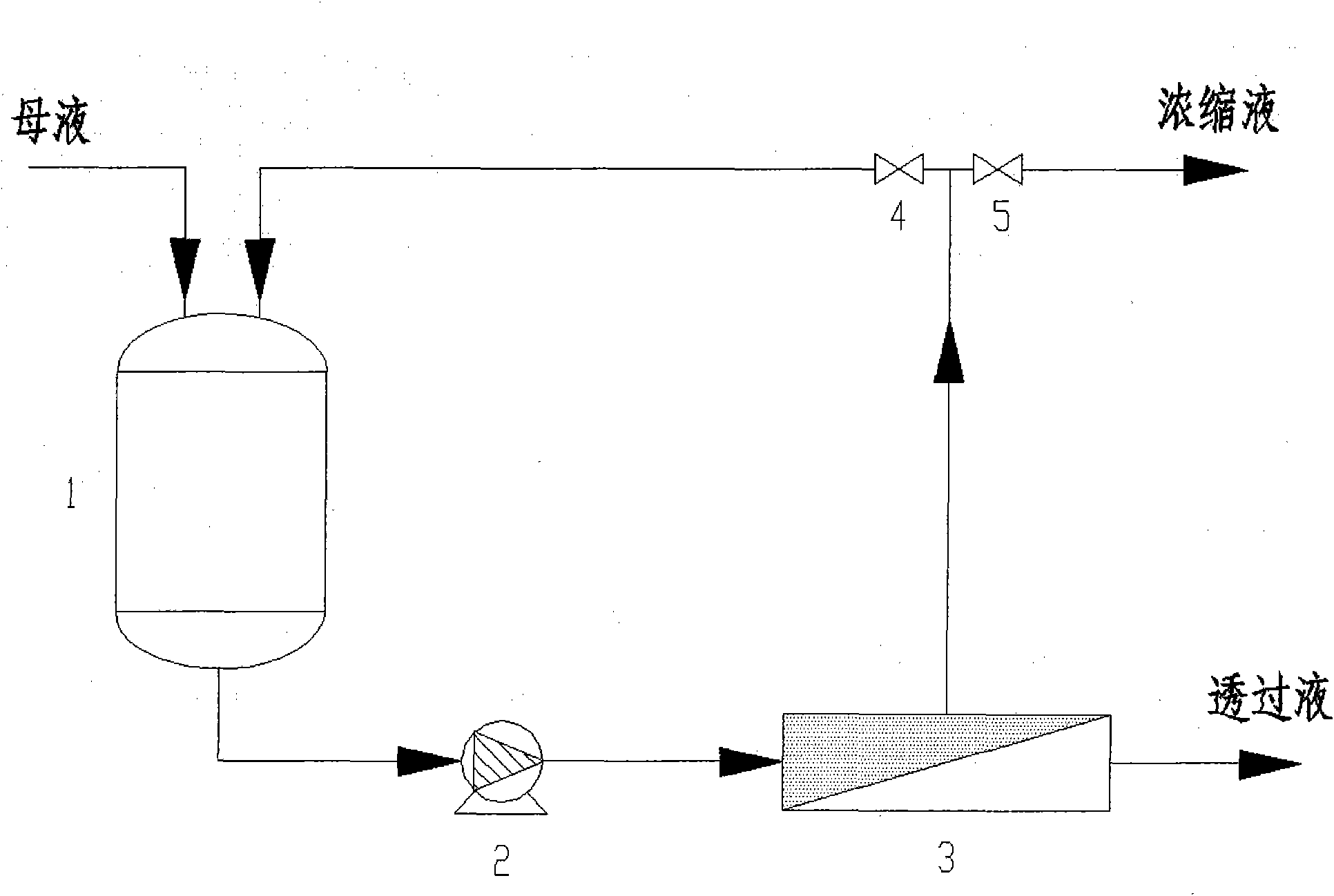

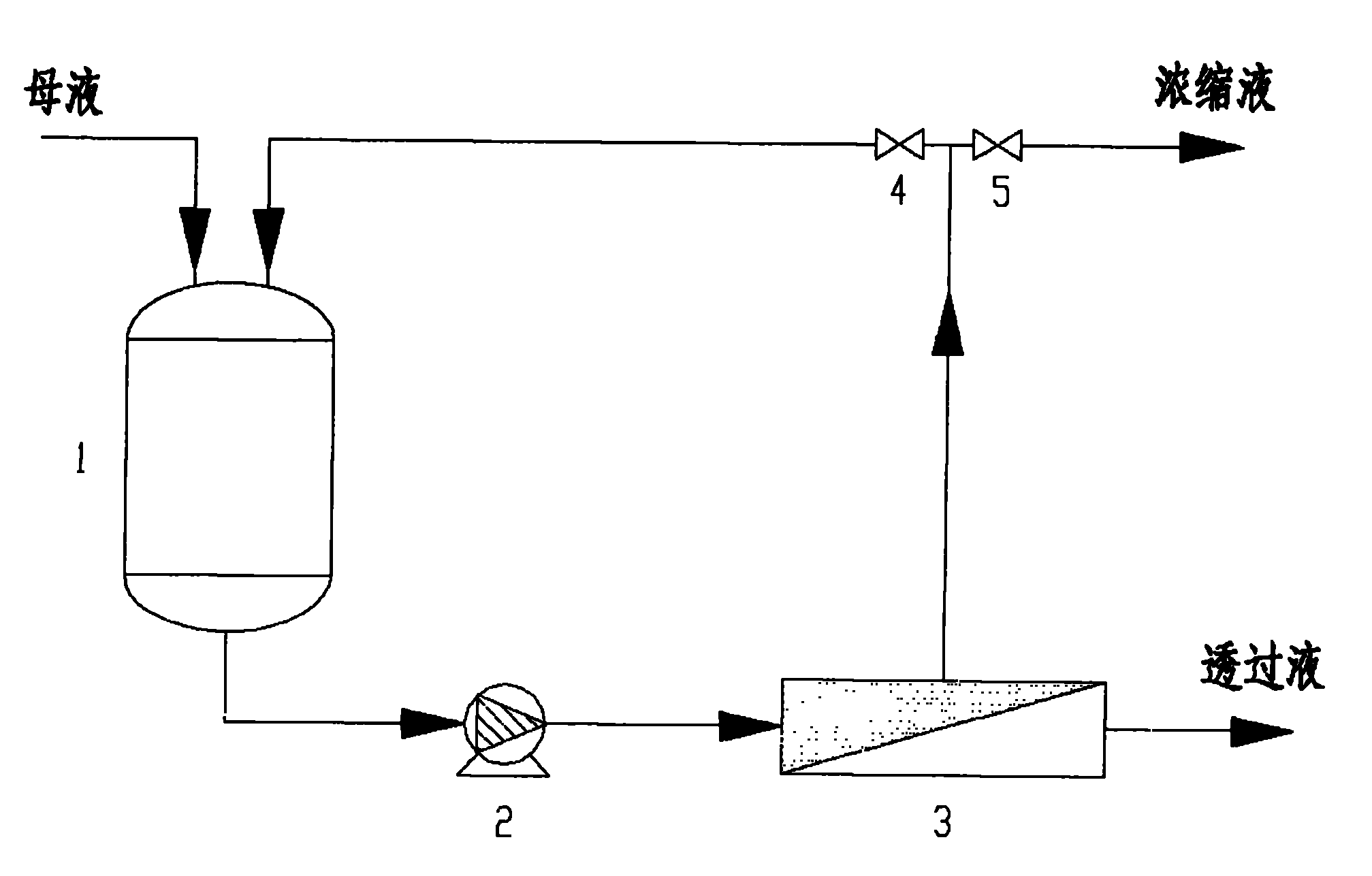

Technology for concentrating and crystallizing IDA method-produced glyphosate mother liquor by membrane method

InactiveCN101792464ADoes not affect purityShort processGroup 5/15 element organic compoundsMembrane methodFiltration

The invention relates to a technology for concentrating and crystallizing IDA method-produced glyphosate mother liquor by a method, in particular to a technology for concentrating and crystallizing IDA method-produced glyphosate mother liquor by a membrane filtration and separation method, with the advantages of no influence on powder purity, short process flow and low production cost. The IDA method-produced glyphosate mother liquor is processed by a membrane filtration and separation system for concentration to obtain crystallized powder; and the separated concentrated solution containing glyphosate crystallized powder (concentrated solution for short) is to further crystallize in the next procedure to obtain powder, and the separated penetrative solution is discharged or collected for utilization.

Owner:大连屹东膜工程设备有限公司

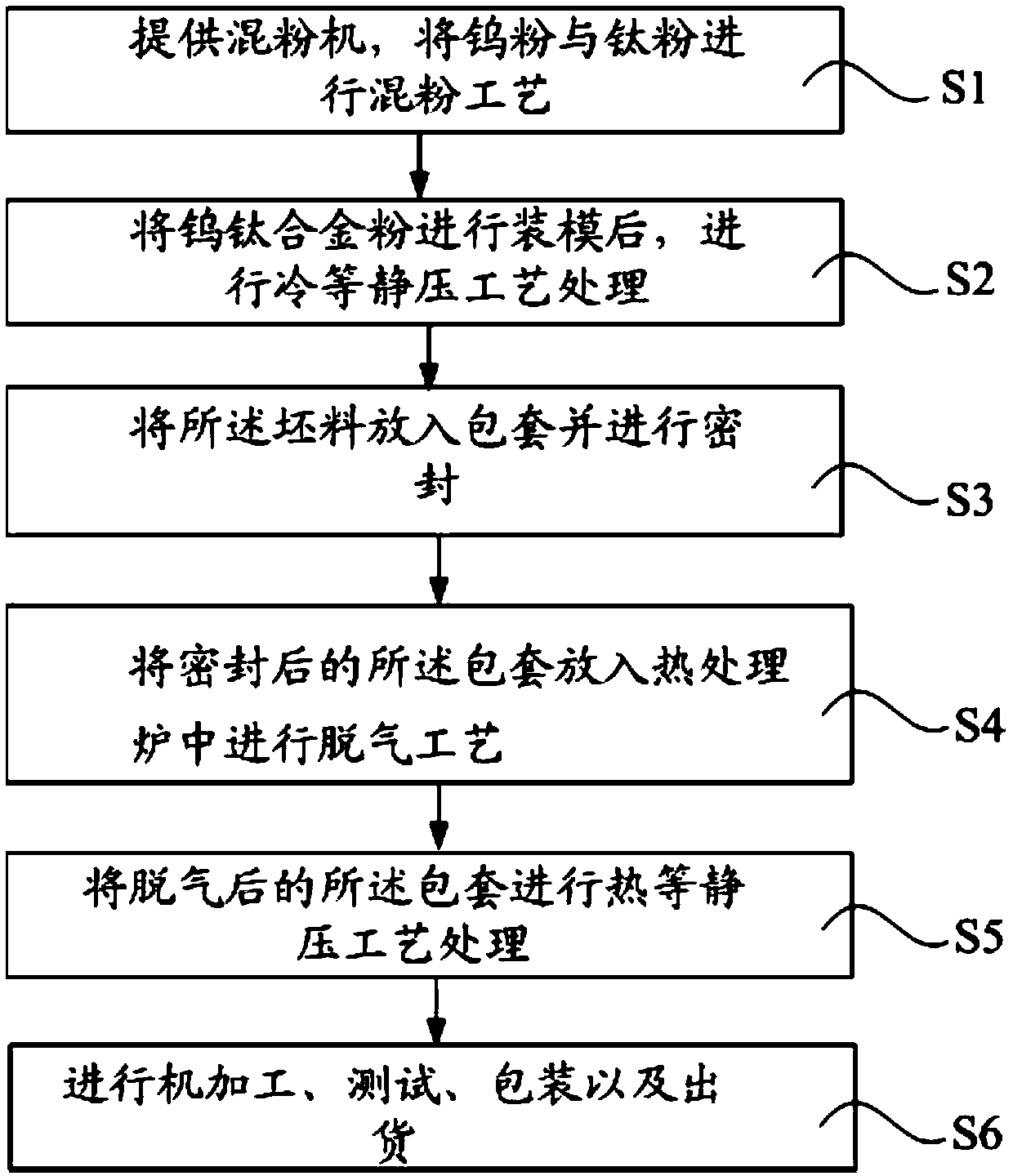

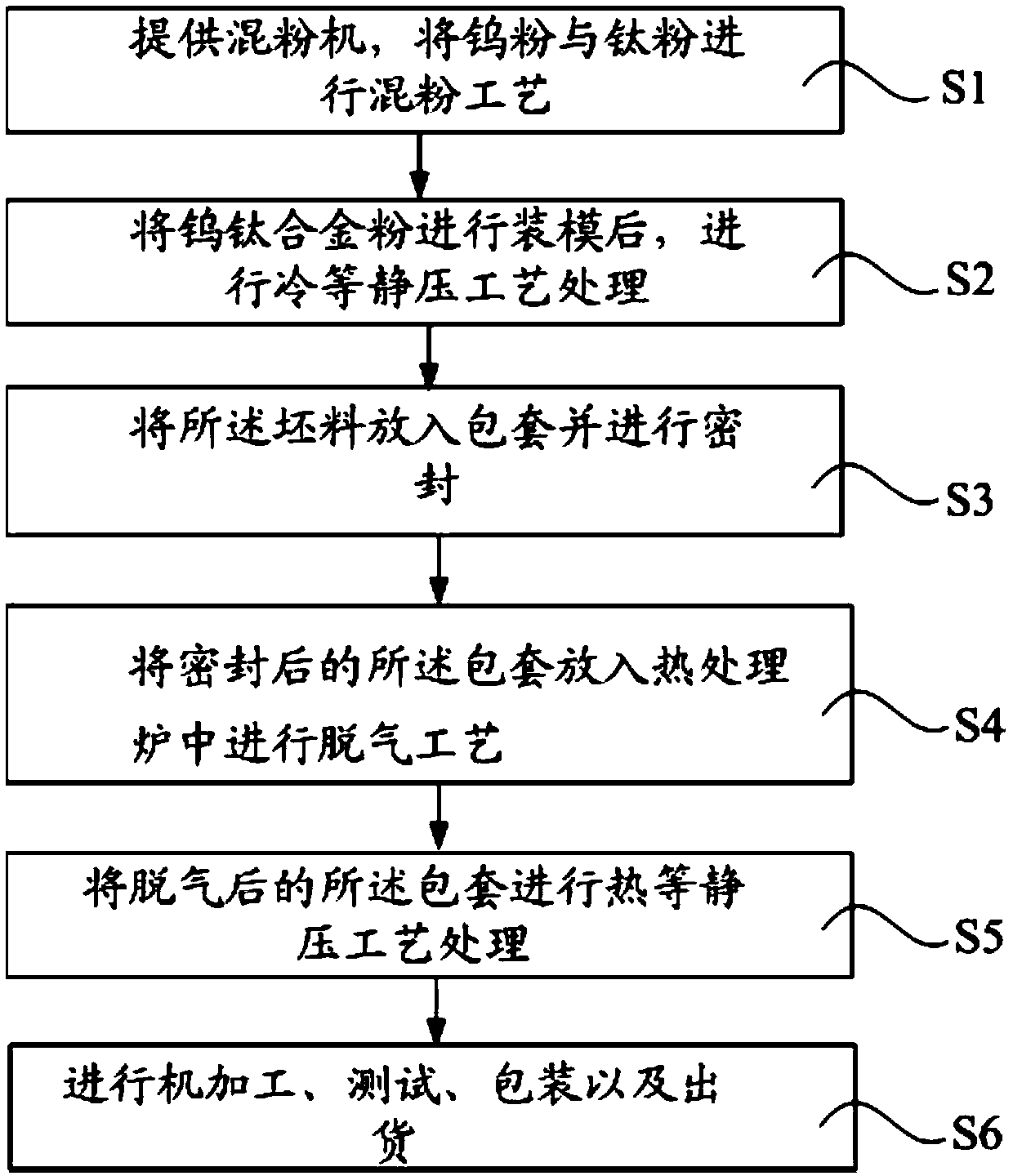

Preparation method of tungsten-titanium alloy target material

PendingCN111151763AGuaranteed DensityUniform microstructureVacuum evaporation coatingSputtering coatingTitanium alloyMaterials science

The invention provides a preparation method of a tungsten-titanium alloy target material. The preparation method comprises the steps of carrying out cold isostatic pressing technological treatment ontungsten-titanium alloy powder; charging a blank into a sheath and carrying out sealing, wherein the sheath and the blank are isolated through refractory wool so that the blank cannot have a reactionwith the sheath during the follow-up process, a finished tungsten-titanium alloy target material can be taken out from the sheath conveniently after later tapping, and meanwhile, after sealing, it isensured that no impurities can go into the sheath; charging the sealed sheath into a heat treatment furnace for degassing to completely extract the air in the blank, and the gaps between molecules ofthe blank are uniform; and finally, carrying out hot isostatic pressing technological treatment on the degassed sheath to machine the blank into a mature target material. The microstructure of the formed tungsten-titanium alloy target material can be uniform, has toughness and is free of cracks, and the compactness can reach up to 100%.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

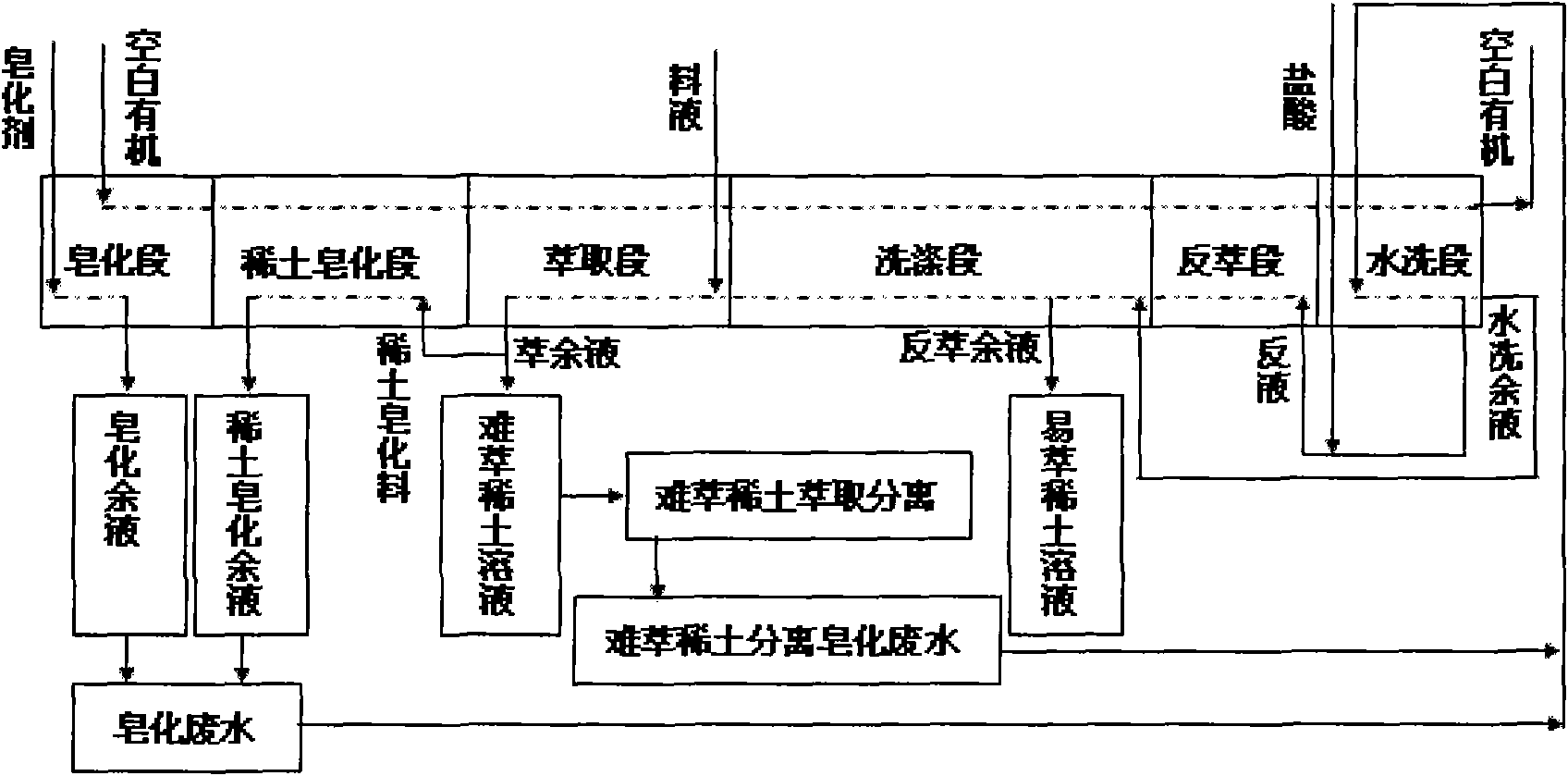

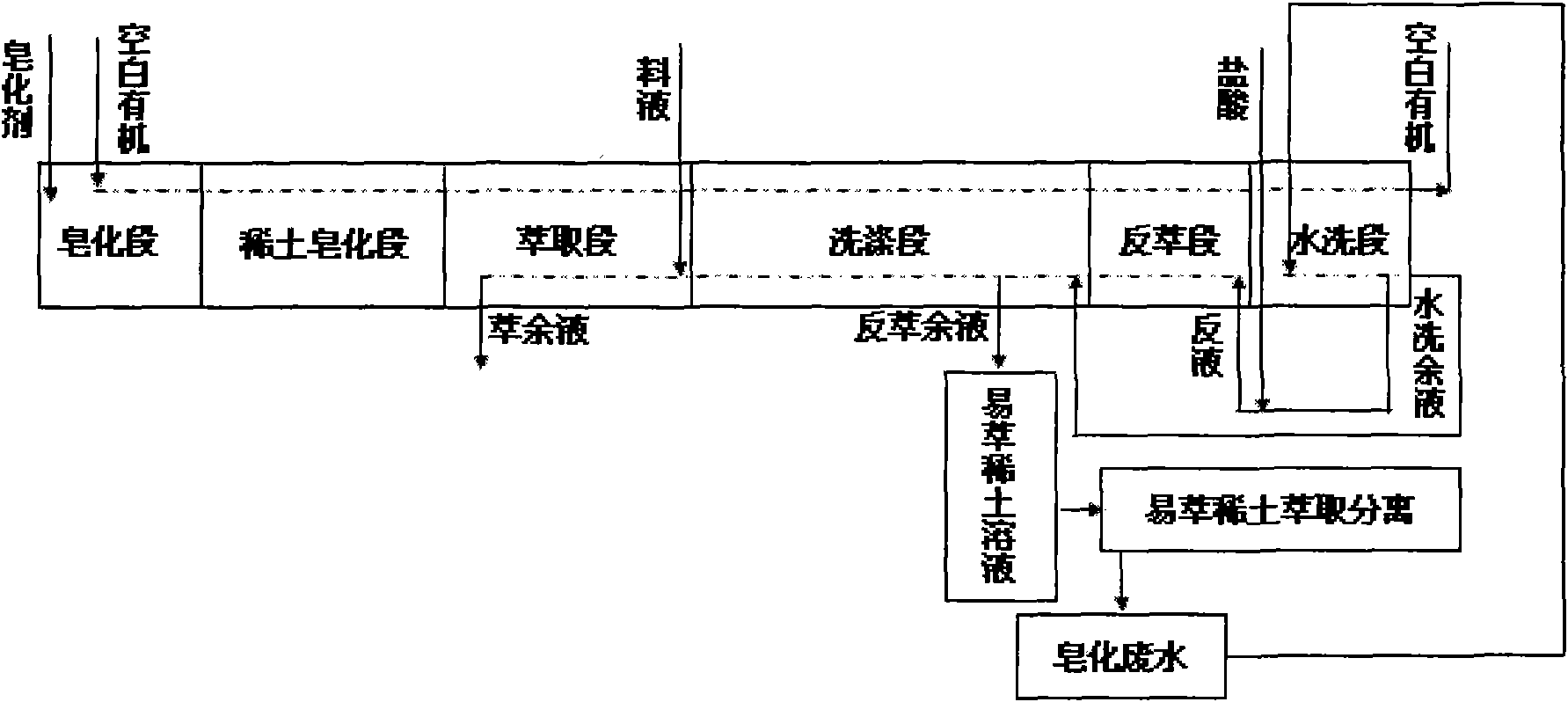

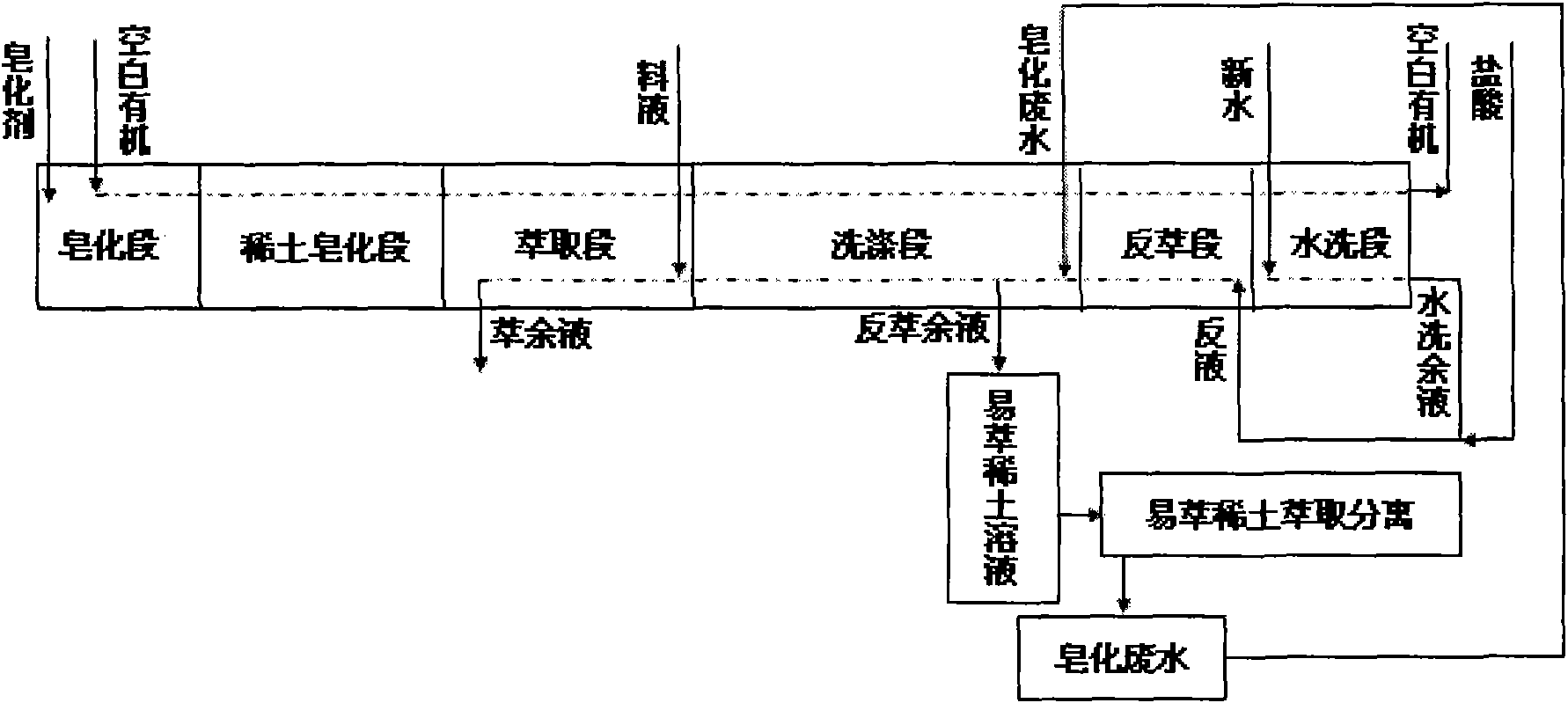

Back extraction solution prepared by extraction separation of washing organic matter of saponification wastewater by recycling rare earth and solution washing method

InactiveCN101974686ADoes not affect purityReduce wasteProcess efficiency improvementRare earthWastewater

The invention relates to a back extraction solution prepared by extraction separation of a washing organic matter of saponification wastewater by recycling rare earth and a solution washing method, belonging to the field of rare earth wet method hydrometallurgy. According to the requirement on purity of difficultly-extracted and easily-extracted elements by a rare earth extraction separation process and different ammonium chloride or sodium chloride media in a water phase in the process, the saponification wastewater is recycled and used as a washing organic matter water solution for preparing a back extraction solution and a washing solution, thus the wastewater discharge is lowered, the consumption of fresh water is reduced, the concentration of ammonium chloride or sodium chloride in the wastewater is improved, the energy consumption of concentrating and crystallizing as well as recycling the ammonium chloride or sodium chloride is decreased, the rare earth yield is improved and the organic matter loss is lowered.

Owner:BAOTOU JINGRUI NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com