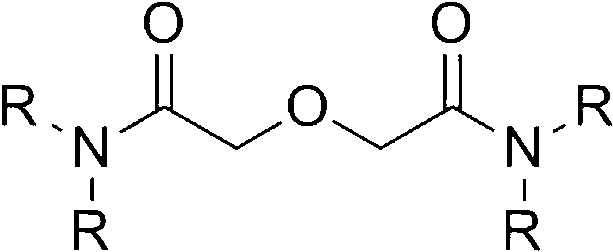

Method for synthesizing diamide podand extraction agent

A technology of diamide pod ether and synthesis method is applied in the field of synthesis of diamide pod ether extractant, and achieves the effects of short time consumption, simple and mature method, and fast reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

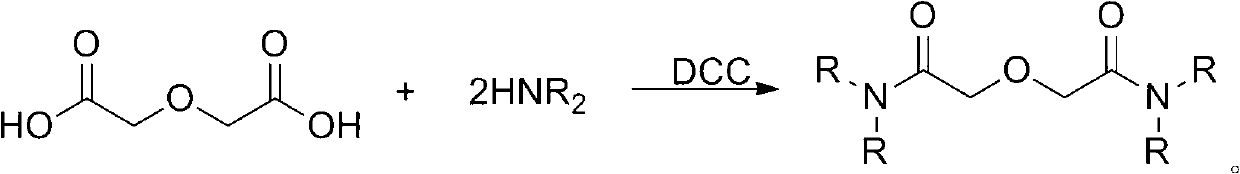

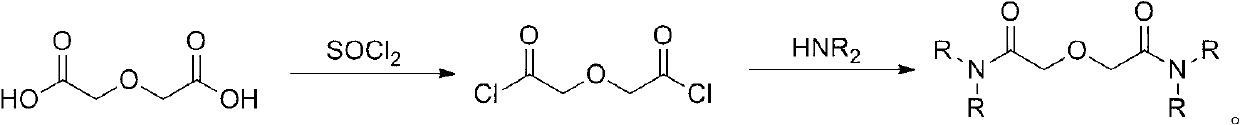

Method used

Image

Examples

Embodiment 1

[0034] 1) Add 11.6g (0.1mol) of diglucoside anhydride to 77mL (0.9mol) of 1,4-dioxane, and place it in an ice-water bath at 7°C, while stirring, add 10.2mL (0.1mol) of diethyl The mixture of amine and 8.2mL (0.102mol) of pyridine was reacted for 0.5h after the dropwise addition, the ice-water bath was removed, and then reacted at room temperature for 3h, and then the 1,4-dioxane solvent was removed by rotary evaporation, and the volume ratio It is a 1:1 mixed solution of hydrochloric acid and water, that is, a large number of white crystals are precipitated, then filtered by suction, recrystallized with ether, and dried in vacuum to obtain white flaky crystals of N,N-diethyl-3-oxopentaramic acid 16.9 g, yield 71%.

[0035] 2) Stir and mix 5.67g (0.03mol) N, N-diethyl-3-oxopentaramic acid, 3.3mL (0.03mol) N-methylmorpholine and 280mL tetrahydrofuran and cool to -10°C, drop Add a mixture of 3.9mL (0.03mol) of isobutyl chloroformate and 5mL of tetrahydrofuran, stir for 2 minutes...

Embodiment 2

[0037] 1) Add 11.6g (0.1mol) of diglucoside anhydride to 96mL (15mol) of dichloromethane, and place in an ice-water bath at 3°C, while stirring, add 10.7mL (0.105mol) of diethylamine and 10.4mL (0.13 mol) the mixed solution of pyridine, react 1h after dropwise addition, remove the ice-water bath, react at room temperature for 5h, and then rotary evaporation removes the methylene chloride solvent and then dropwise add the mixed solution of hydrochloric acid and water with a volume ratio of 1:1, That is, a large amount of white crystals were precipitated, which were then suction filtered, recrystallized with ether, and dried in vacuo to obtain 12.8 g of white flaky crystals of N,N-diethyl-3-oxopentaramic acid, with a yield of 54%.

[0038] 2) Stir and mix 1.89g (0.01mol) N, N-diethyl-3-oxopentaramic acid, 2.8mL (0.02mol) triethylamine and 60mL dichloromethane and cool to -15°C, then drop Add 1mL (0.0103mol) of a mixture of ethyl chloroformate and 1mL of dichloromethane, stir the...

Embodiment 3

[0040] 1) Add 11.6g (0.1mol) of diglycolic anhydride to 105mL (13mol) of tetrahydrofuran, and place it in an ice-water bath at 4°C, while stirring, add 10.5mL (0.103mol) of diethylamine and 9.3mL (0.115mol) of diethylamine dropwise. The mixed solution of pyridine was reacted for 0.5h after the dropwise addition, the ice-water bath was removed, and then reacted at room temperature for 3.5h, and then the tetrahydrofuran solvent was removed by rotary evaporation, and the mixed solution of hydrochloric acid and water with a volume ratio of 1:1 was added dropwise thereto, that is, A large number of white crystals were precipitated, and then filtered by suction, recrystallized with ether, and dried in vacuum to obtain 16.2 g of white flaky crystals of N,N-diethyl-3-oxopentaramic acid, with a yield of 68%.

[0041] 2) Stir and mix 2.835g (0.015mol) N,N-diethyl-3-oxopentaramic acid, 2.3mL (0.0165mol) N,N-dimethylethylamine and 70mL dimethylformamide and Cool to -11°C, then add dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com