Method for preparing metal nanoparticles

A metal nanoparticle and metal technology, which is applied in the field of metal nanomaterials, can solve the problems that it is difficult to prepare metal nanoparticles with uniform dispersion characteristics, and achieves the effects of low cost of raw materials, low purity of raw materials and fast preparation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

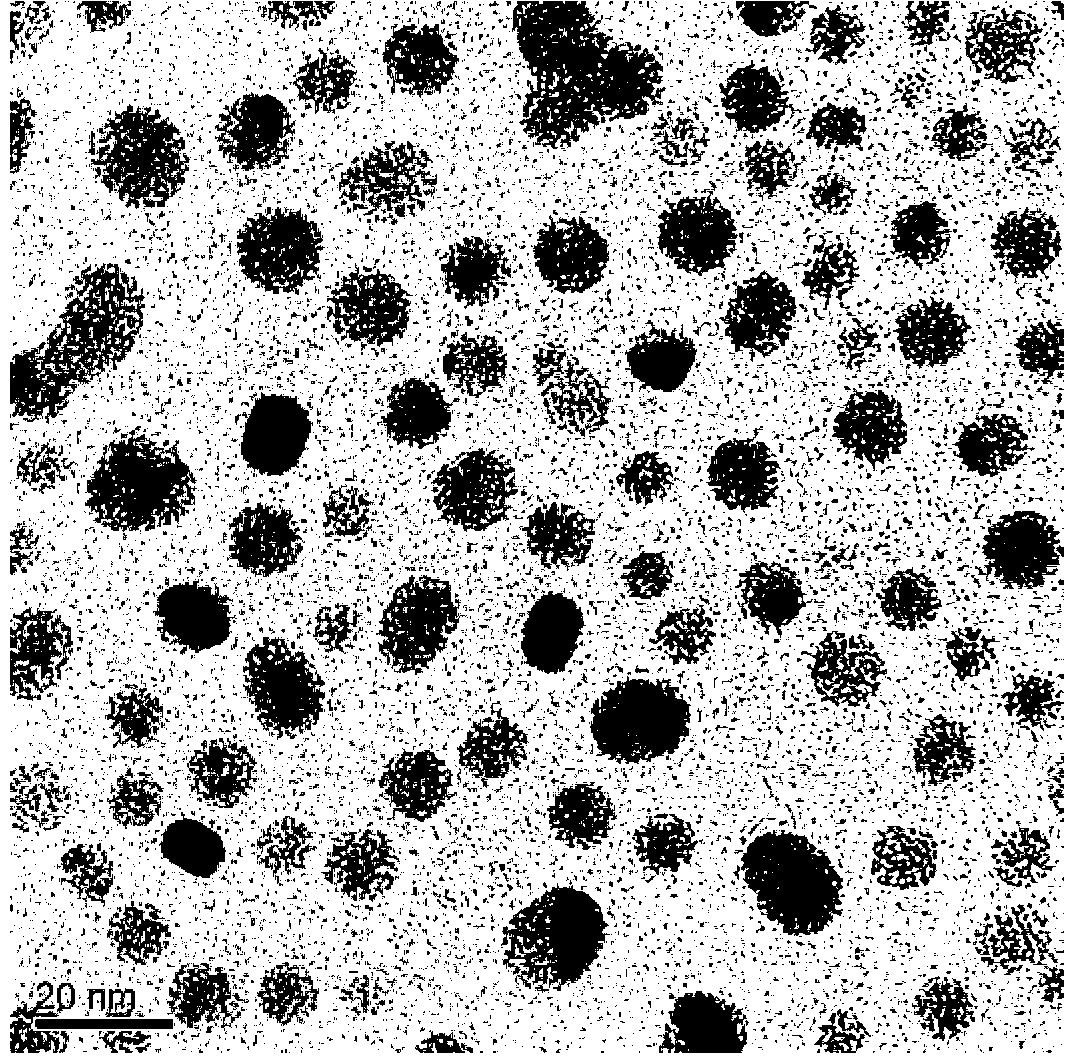

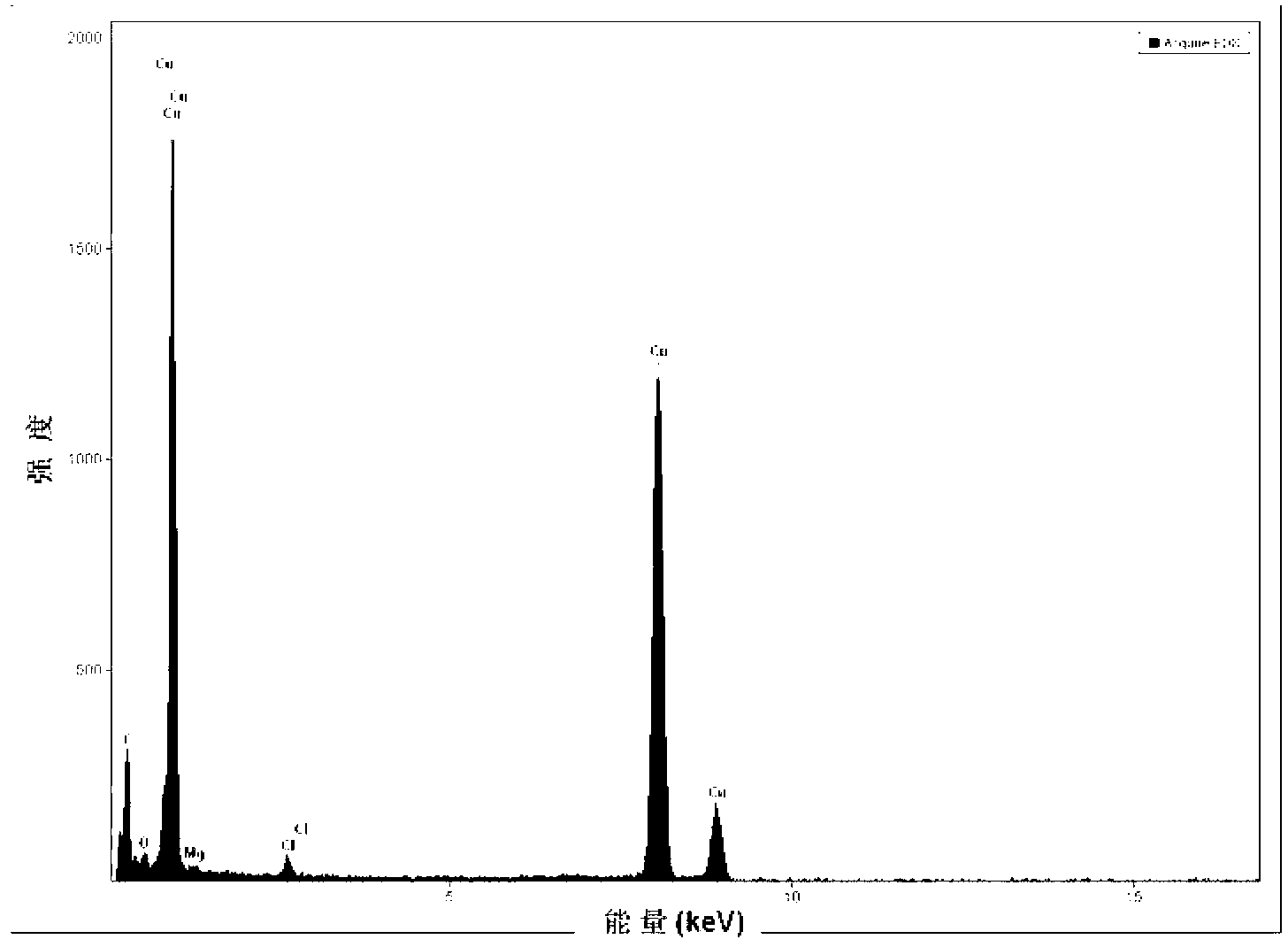

[0042] This embodiment provides an example of preparing nano-copper particles, and the preparation method includes the following steps:

[0043] (1) The molecular formula of the selected formula is Mg 45 Zn 3 Cu 35 Gd 15 Ca 2 According to the formula, the raw materials are weighed, and after smelting, a solid granular precursor alloy is prepared, and the particle size of the particles is less than 0.25mm. .

[0044] (2) At room temperature, submerge 0.5 g of the precursor alloy fine material prepared in step (1) into 35 mL of aqueous hydrochloric acid solution with a concentration of 0.5 mol / L for dealloying reaction. The frequency is 40KHz. During the reaction process, magnesium, rare earth, calcium, and zinc atoms preferentially react with hydrogen ions to become ions and enter the solution, while copper atoms are dissociated, and the porous self-assembly tendency of the dissociated copper atoms is effectively suppressed under shaking conditions, about 45 Minutes, the...

Embodiment 2

[0051] This embodiment provides an example of preparing nano-nickel particles, and the preparation method includes the following steps:

[0052] (1) The molecular formula of the selected formula is Mg 44 Al 5 Ni 33 Nd 16 Ca 2 According to the formula, the raw material is weighed, and after melting, it is prepared into a solid fine chip precursor alloy, and the thickness of the fine chip is not more than 0.3mm.

[0053] (2) At room temperature, submerge 0.5 g of the precursor alloy fines prepared in step (1) into 90 mL of aqueous hydrochloric acid solution with a concentration of 0.2 mol / L for dealloying reaction. The frequency is 40KHz. During the reaction process, magnesium, aluminum, rare earth, and calcium atoms preferentially react with hydrogen ions to become ions and enter the solution, while nickel atoms are released, and the porous self-assembly tendency of the free nickel atoms is effectively suppressed under shaking conditions, about 60 Minutes, the reaction is...

Embodiment 3

[0057] This embodiment provides an example of preparing mixed nanoparticles of copper and silver, and the preparation method includes the following steps:

[0058] (1) The molecular formula of the selected formula is Mg 47 Cu 18 Ag 18 Gd 15 Ca 2 According to the formula, the raw materials are weighed, and after smelting, a solid granular precursor alloy is prepared, and the particle size of the particles is less than 0.25 mm.

[0059] (2) At room temperature, submerge 0.5 g of the precursor alloy fine material prepared in step (1) into 30 mL of ethanol hydrochloric acid solution with a concentration of 0.5 mol / L for dealloying reaction. The oscillation frequency is 40KHz. During the reaction process, magnesium, rare earth, and calcium atoms preferentially react with hydrogen ions to become ions and enter the solution, while copper atoms and silver atoms are freed. After 45 minutes, the reaction was completed, and uniformly dispersed nano-copper particles and silver parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com