Preparation method of graphene/titania composite material

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of long synthesis time, toxic reducing agents, and many preparation steps, and achieve easy implementation and equipment. Simple, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A graphene / TiO 2 A method for preparing a composite material, comprising the steps of:

[0032] (1) Preparation of graphene / TiO 2 Composite material precursor solution: prepare solution A, slowly add 1 g of tetrabutyl titanate into 10 mL of isopropanol in an ice-water bath, with a concentration of 0.1 g / mL. To prepare solution B, add 0.2 g of graphene oxide prepared by the Hummers method to a mixture of 1.3 mL of deionized water and 10.4 mL of isopropanol. After the obtained solution B was added dropwise to solution A while stirring, 0.4 mL of dilute nitric acid (37%) and 0.29 g of urea were added to the above mixed solution to obtain the precursor solution.

[0033] (2) Heating and stirring the expelling solution, steaming the solution until gelatinous, and then treating it in a microwave oven with a power of 0.7 kW for 32 minutes to obtain a graphene / titanium dioxide composite material with excellent photocatalytic properties.

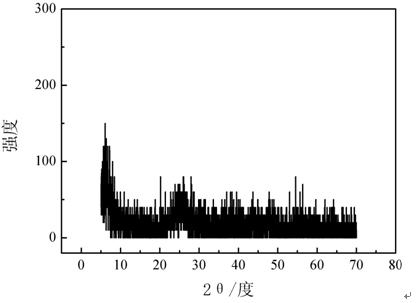

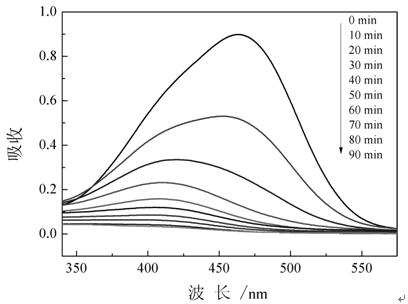

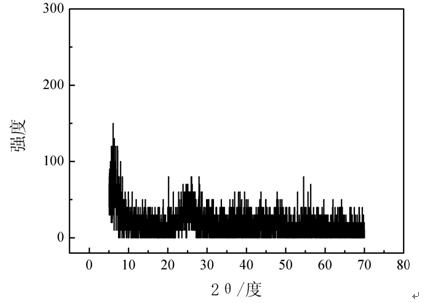

[0034] The TiO in the composite was ...

Embodiment 2

[0036] A graphene / TiO 2 A method for preparing a composite material, comprising the steps of:

[0037] (1) Preparation of graphene / TiO 2 Composite material precursor solution: prepare solution A, slowly add 2 g of tetrabutyl titanate into 5 mL of isopropanol in an ice-water bath, with a concentration of 0.4 g / mL. To prepare solution B, add 0.7 g of graphene oxide prepared by the Hummers method to a mixture of 2.0 mL of deionized water and 15.6 mL of isopropanol. After the obtained solution B was added dropwise to solution A while stirring, 0.8 mL of dilute nitric acid (37%) and 0.58 g of urea were added to the above mixed solution to obtain the precursor solution.

[0038] (2) Heat and stir the expelling solution, steam the solution until it becomes gelatinous, and then treat it in a microwave oven with a power of 1.2 kW for 20 minutes to obtain a graphene / titanium dioxide composite material with excellent photocatalytic properties.

Embodiment 3

[0040] A graphene / TiO 2 A method for preparing a composite material, comprising the steps of:

[0041] (1) Preparation of graphene / TiO 2 Composite material precursor solution: prepare solution A, slowly add 2 g of tetrabutyl titanate into 5 mL of isopropanol in an ice-water bath, with a concentration of 0.4 g / mL. To prepare solution B, add 0.82 g graphene oxide (prepared by Hummers method) to a mixture of 0.3 mL deionized water and 4.4 mL isopropanol. After the obtained solution B was added dropwise to solution A while stirring, 0.8 mL of dilute nitric acid (37%) and 0.58 g of urea were added to the above mixed solution to obtain the precursor solution.

[0042] (2) Heat and stir the expelling solution, steam the solution until it becomes gelatinous, and then treat it in a microwave oven with a power of 0.9 kW for 25 minutes to obtain a graphene / titanium dioxide composite material with excellent photocatalytic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com