Anhydrous citric acid crystal and production method thereof

A technology of anhydrous citric acid and its production method, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., and can solve the problems of reduced adhesion of anhydrous citric acid crystals and easy adhesion of anhydrous citric acid crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

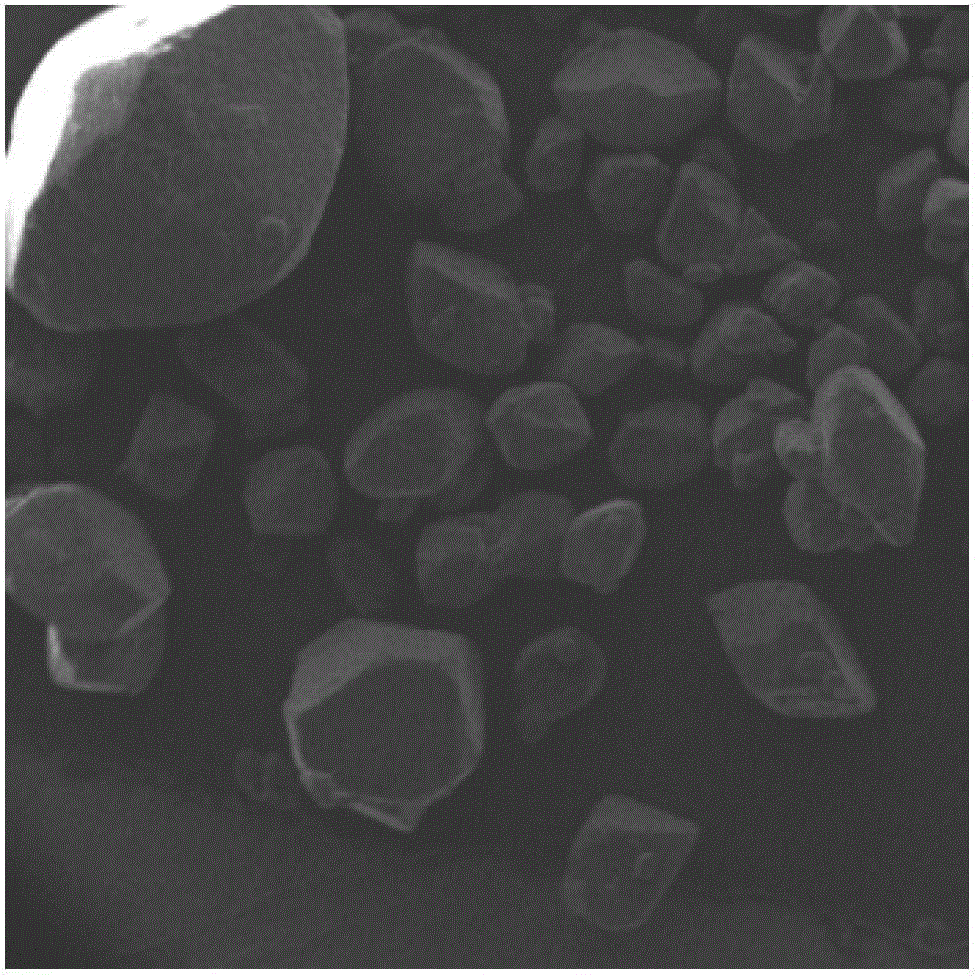

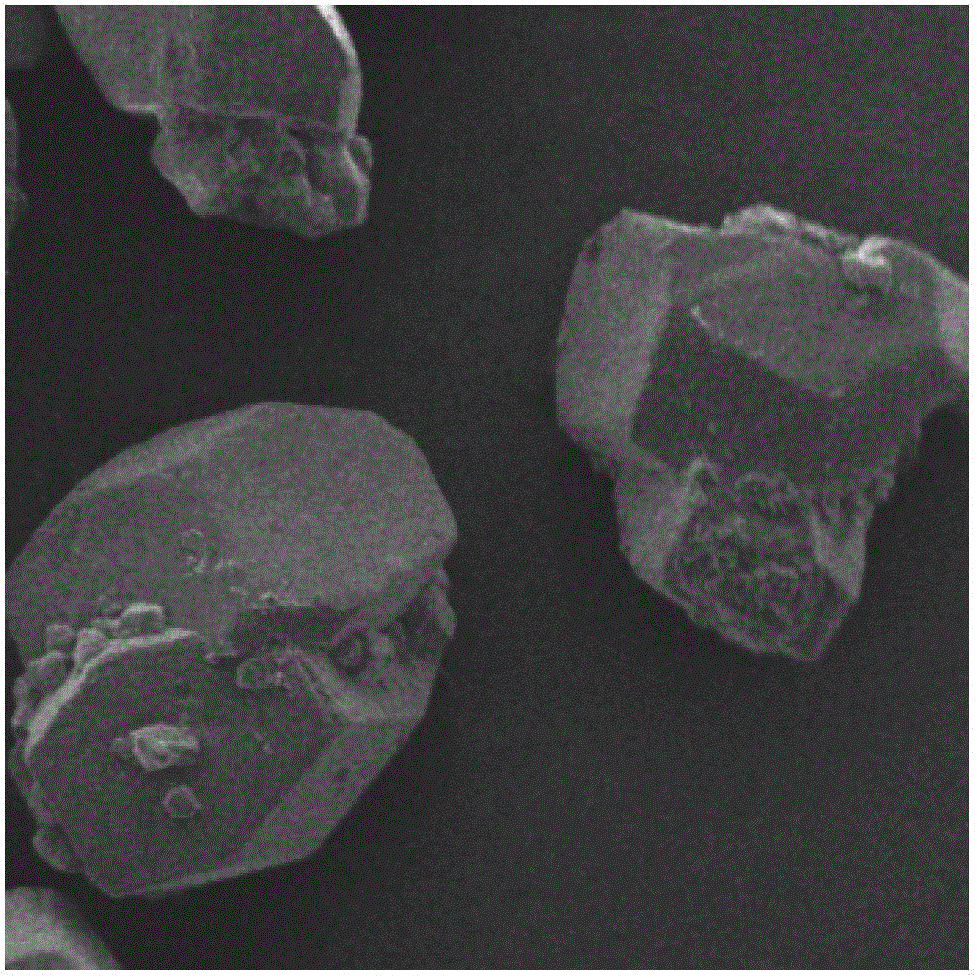

Image

Examples

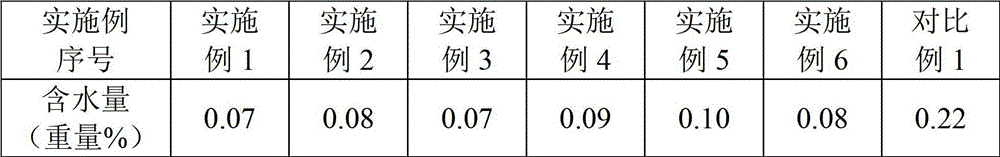

Embodiment 1

[0038] will be 5m 3 A citric acid solution with a citric acid concentration of 45% by weight and a citric acid purity of 99% by weight is obtained by concentrating a three-effect evaporation (the first-effect evaporation temperature is 93°C, the second-effect evaporation temperature is 74°C, and the third-effect evaporation temperature is 55°C). Anhydrous citric acid crystal content is 30% by weight crystal slurry liquid, then placed in the crystallization tank, in the crystallization tank jacket, feed cooling water to cool down, the cooling rate is 3 ° C / h, when the temperature of the crystal slurry liquid is 37 ° C When solid-liquid separation is carried out, the ambient temperature during solid-liquid separation is controlled so that the temperature of the wet crystal obtained after separation is 38°C, and the wet crystal is dried at 40°C for 27 minutes to obtain a crystal product. The content of anhydrous citric acid crystals in the obtained crystal product was 99.8% by ...

Embodiment 2

[0040] will be 5m 3 A citric acid solution with a citric acid concentration of 30% by weight and a citric acid purity of 99% by weight is obtained by concentrating a three-effect evaporation (the first-effect evaporation temperature is 100°C, the second-effect evaporation temperature is 79°C, and the third-effect evaporation temperature is 65°C). Anhydrous citric acid crystal content is the crystal slurry liquid of 5% by weight, then placed in the crystallization tank, in the crystallization tank jacket, feed cooling water to cool down, the cooling rate is 4 ° C / h, when the temperature of the crystal slurry liquid is 40 ° C When solid-liquid separation is carried out, the ambient temperature during solid-liquid separation is controlled so that the temperature of the wet crystal obtained after separation is 38°C, and the wet crystal is dried at 60°C for 9 minutes to obtain a crystal product. The content of anhydrous citric acid crystals in the obtained crystal product was 99....

Embodiment 3

[0042] will be 5m 3 A citric acid solution with a citric acid concentration of 60% by weight and a citric acid purity of 99% by weight is obtained by concentrating through three-effect evaporation (the first-effect evaporation temperature is 90°C, the second-effect evaporation temperature is 71°C, and the third-effect evaporation temperature is 50°C). Anhydrous citric acid crystal content is 60% by weight crystal slurry liquid, then placed in the crystallization tank, cooling water is passed into the crystallization tank jacket to cool down, the cooling rate is 4 ° C / h, when the crystal slurry liquid is cooled to 37 ° C , when the solid-liquid separation is controlled, the ambient temperature is consistent with the crystal slurry temperature to carry out constant-temperature solid-liquid separation, and the wet crystal is dried at 50° C. for 15 minutes to obtain a crystal product. The content of anhydrous citric acid crystals in the obtained crystal product was 99.8% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com