Silicone rubber insulating sizing material, high-temperature and high-pressure resistant silicone rubber wire and preparation process

A technology of silicone rubber insulation and preparation process, which is applied in rubber insulators, organic insulators, etc., can solve the problems of unattainable characteristics of silicone rubber, and achieve the effect of increasing heat resistance, good antistatic performance, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

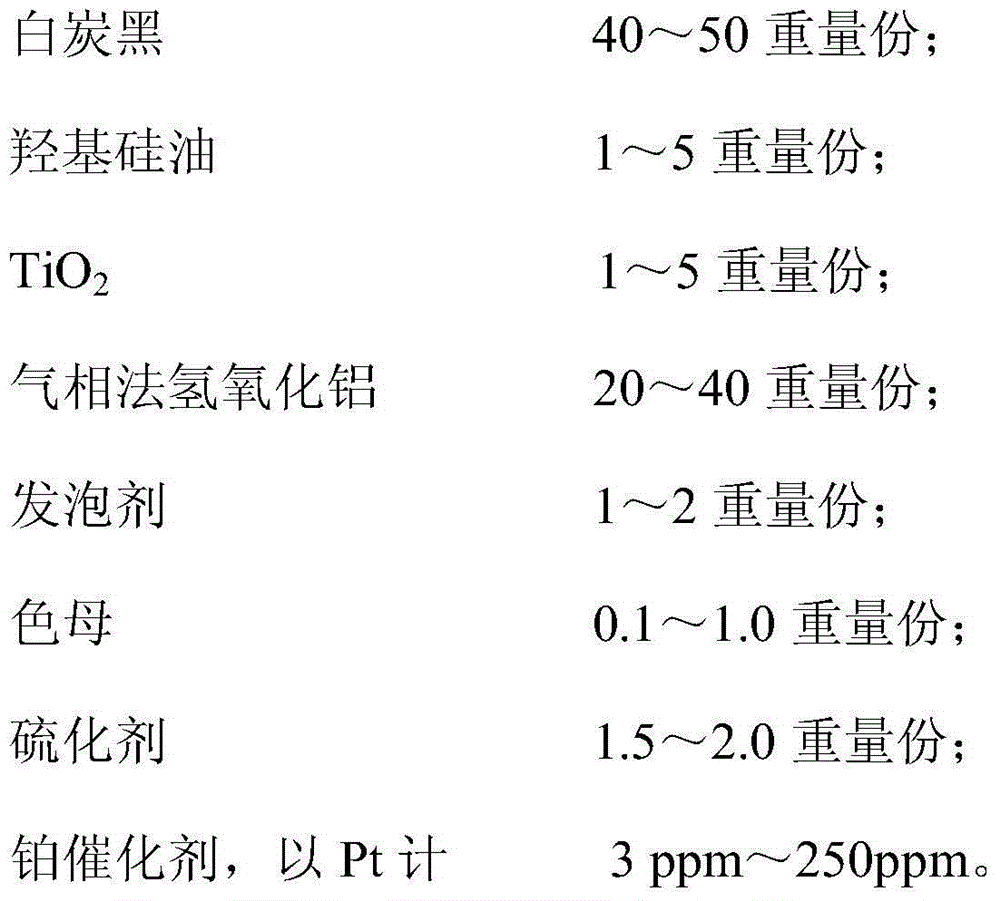

[0027] A kind of high temperature and high pressure silicone rubber wire, which is made of silicone rubber insulating rubber material, and the silicone rubber insulating rubber material includes the following raw materials:

[0028] 100 parts by weight of raw silicone rubber; 40 parts by weight of white carbon black; 1 part by weight of hydroxyl silicone oil; TiO 2 1 part by weight; 2 parts by weight of gas phase aluminum hydroxide; 1 part by weight of blowing agent; 0.1 part by weight of masterbatch; 1.5 parts by weight of vulcanizing agent; 3 ppm of platinum catalyst (calculated as Pt). Wherein, ppm is parts per million of the total composition.

[0029] A preparation process for high-temperature and high-pressure silicone rubber electric wires, comprising the following preparation steps:

[0030] (1) 100 parts by weight of raw silicone rubber, 40 parts by weight of white carbon black, 1 part by weight of hydroxyl silicone oil, TiO 2 1 part by weight, 2 parts by weight of ...

Embodiment 2

[0037] A kind of high temperature and high pressure silicone rubber wire, which is made of silicone rubber insulating rubber material, and the silicone rubber insulating rubber material includes the following raw materials:

[0038] 100 parts by weight of raw silicone rubber; 40 parts by weight of white carbon black; 2 parts by weight of hydroxyl silicone oil; TiO 2 5 parts by weight; 20 parts by weight of gas phase aluminum hydroxide; 1 part by weight of foaming agent; 0.3 parts by weight of masterbatch; 1.5 parts by weight of vulcanizing agent; platinum catalyst (calculated as Pt) 50ppm.

[0039] A preparation process for high-temperature and high-pressure silicone rubber electric wires, comprising the following preparation steps:

[0040] (1) 100 parts by weight of raw silicone rubber, 40 parts by weight of white carbon black, 2 parts by weight of hydroxyl silicone oil, TiO 2 5 parts by weight, 20 parts by weight of gas-phase method aluminum hydroxide are put into a kneade...

Embodiment 3

[0047] A kind of high temperature and high pressure silicone rubber wire, which is made of silicone rubber insulating rubber material, and the silicone rubber insulating rubber material includes the following raw materials:

[0048] 100 parts by weight of raw silicone rubber; 40 parts by weight of white carbon black; 2 parts by weight of hydroxyl silicone oil; TiO 2 2 parts by weight; 30 parts by weight of gas phase aluminum hydroxide; 1 part by weight of foaming agent; 0.3 parts by weight of masterbatch; 1.6 parts by weight of vulcanizing agent; platinum catalyst (calculated as Pt) 80ppm.

[0049] A preparation process for high temperature and high pressure resistant silicone rubber electric wires, comprising the following preparation steps:

[0050] (1) 100 parts by weight of raw silicone rubber, 40 parts by weight of white carbon black, 2 parts by weight of hydroxyl silicone oil, TiO 2 2 parts by weight, 30 parts by weight of gas-phase method aluminum hydroxide are put int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com