Method for preparing zirconium oxide powder from zircon

A zirconia powder, zirconia technology, applied in zirconia and other directions, can solve the problems of not properly controlling the amount of sodium carbonate, affecting the stability of the product, affecting the recovery rate, etc., to achieve excellent microscopic morphology, saving reaction costs, and improving The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

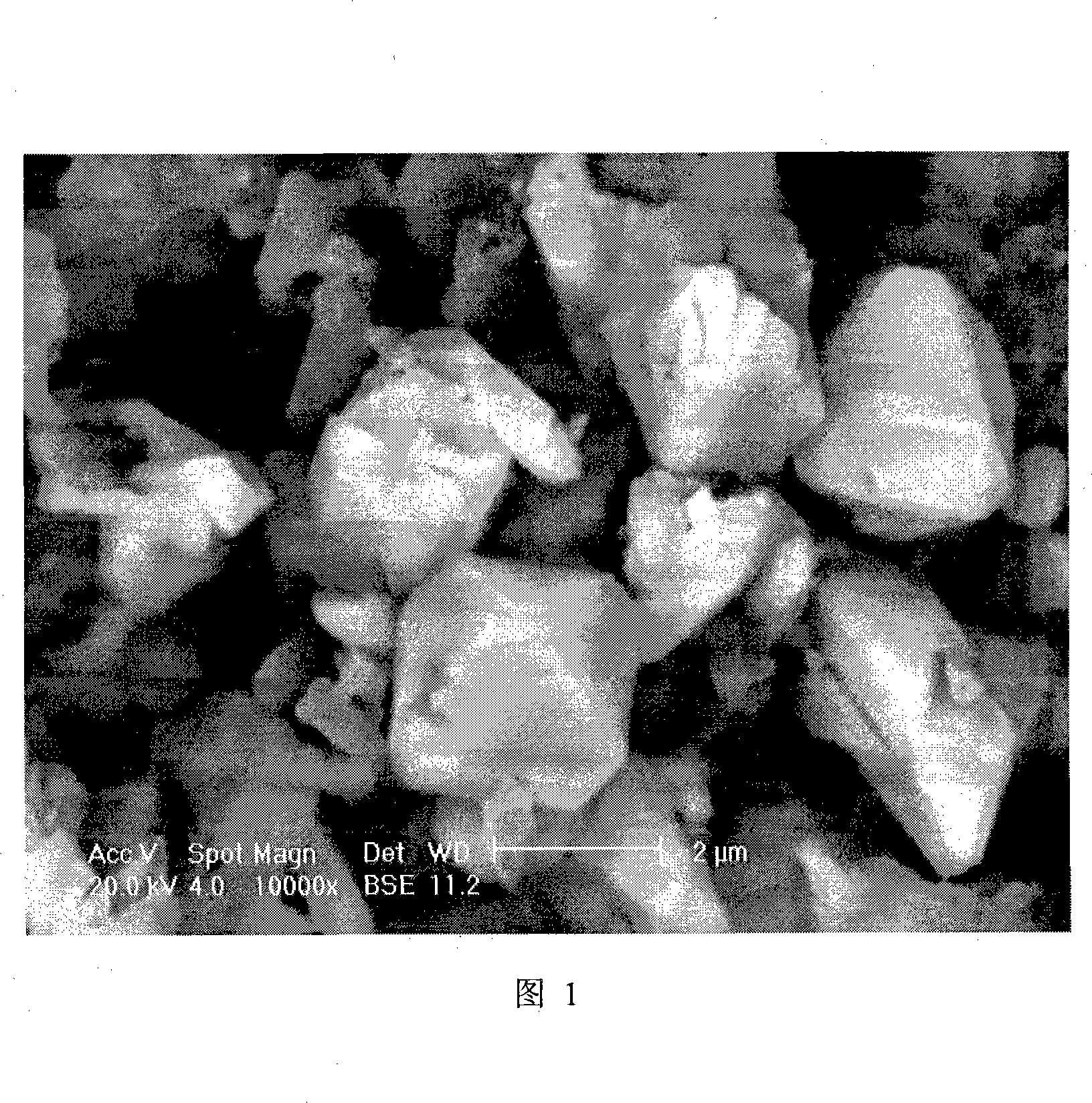

Image

Examples

Embodiment 1

[0021] Zircon with a zirconia content of 63% and a particle size of 43 μm and an analytically pure chemical reagent sodium carbonate were selected as the reaction raw materials in this embodiment.

[0022] Set the oven temperature to 100°C, and dry the above-mentioned zircon and sodium carbonate respectively; take 100g of the dried zircon and 58g of sodium carbonate and mix them uniformly in a ball mill, place them in a corundum crucible, and place them in a high-temperature furnace Incubate at 900°C for 2 hours; take out the above sample after cooling, add water at 90°C to it and stir thoroughly; add hydrochloric acid solution with a concentration of 5mol / L, and adjust the pH value of the above solution to 5; Filter the solution after adjusting the pH value above, wash the obtained solid product with water at the same temperature of 70°C, and then dry the washed product at a temperature of 100°C to obtain 125g of zirconium silicate sodium product.

[0023]Mix the above-menti...

Embodiment 2

[0027] Zircon with a zirconia content of 65% and a particle size of 35 μm and an analytically pure chemical reagent sodium carbonate were selected as the reaction raw materials in this embodiment.

[0028] Set the oven temperature to 100°C, and dry the above-mentioned zircon and sodium carbonate respectively; take 130g of dried zircon and 70g of sodium carbonate and mix them uniformly in a ball mill, and place them in a corundum crucible; The final zircon and sodium carbonate were mixed and placed in a corundum crucible, and kept in a high-temperature furnace at 960°C for 1.5 hours; after the above sample was cooled, it was taken out, and water at a temperature of 80°C was added to it and fully stirred; Concentration is the sulfuric acid solution of 0.8mol / L, adjusts the pH value of above-mentioned solution to be 6; The solution after above-mentioned adjusted pH value is filtered, and the solid product that obtains is washed with the water of 80 ℃ with the same temperature, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com