Preparation method of polymethyl methacrylate macromolecule extended chain

A polymethyl methacrylate and polymer technology, which is applied in the field of preparation of polymethyl methacrylate polymer extension chains, can solve the problems of complicated preparation process and poor repeatability of PMMA extension chains, and achieves preventing agglomeration and stretching. High degree and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

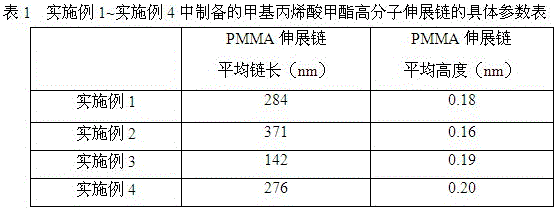

Embodiment 1

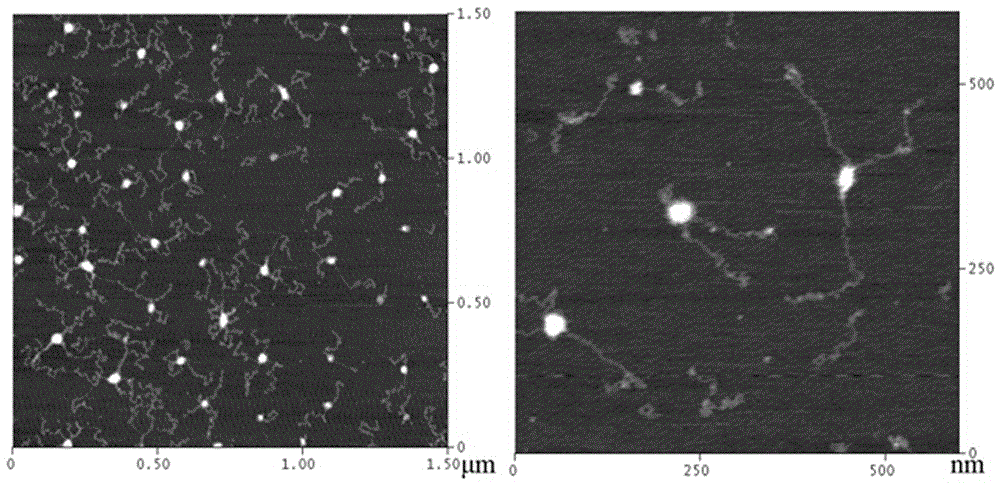

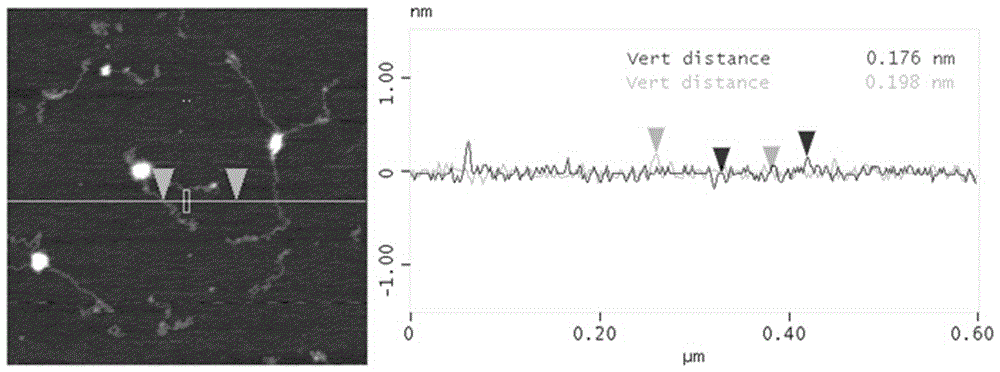

[0019] The preparation method of the polymethyl methacrylate polymer extended chain of the present embodiment is carried out according to the following steps:

[0020] (1) Preparation of PS-b-PMMA dilute solution: first dissolve a certain mass of PS-b-PMMA powder in toluene, and the molecular weight of the PS-b-PMMA block copolymer selected is 130,000-133,000, Mw / Mn= 1.10, it was prepared into a toluene solution with a weight concentration of 0.1wt%, added toluene for multiple dilutions, and finally prepared into a very dilute solution of PS-b-PMMA with a weight concentration of 0.0001wt% for subsequent use;

[0021] (2) Preparation of polymer extended chains by spin coating method: put the newly split mica sheet as the base on the spin coater, set the speed and time of the spin coater in advance, and the speed of the spin coater is 3000rpm , the spin coating time is 30s, drop the very dilute solution of PS-b-PMMA in step (1) onto the surface of mica, cover the lid, start the ...

Embodiment 2

[0023] The preparation method of the polymethyl methacrylate polymer extended chain of the present embodiment is carried out according to the following steps:

[0024] (1) Preparation of PS-b-PMMA dilute solution: first dissolve a certain amount of PS-b-PMMA powder in toluene, wherein the selected PS-b-PMMA block copolymer has a molecular weight of 130,000-360,000, Mw / Mn= 1.09, be prepared into a toluene solution with a weight concentration of 0.3wt%, add toluene to carry out multiple dilutions, and finally prepare a very dilute solution of PS-b-PMMA with a weight concentration of 0.0003wt% for subsequent use;

[0025] (2) Preparation of polymer extended chains by spin coating method: put the newly split mica sheet as the base on the spin coater, set the speed and time of the spin coater in advance, and the speed of the spin coater is 4000rpm , the spin coating time is 20s, drop the very dilute PS-b-PMMA solution in step (1) onto the mica surface, cover the lid, start the spin...

Embodiment 3

[0027] The preparation method of the polymethyl methacrylate polymer extended chain of the present embodiment is carried out according to the following steps:

[0028] (1) Preparation of PS-b-PMMA dilute solution: first dissolve a certain amount of PS-b-PMMA powder in toluene, wherein the selected PS-b-PMMA block copolymer has a molecular weight of 140,000-65,000, Mw / Mn= 1.09, be prepared into a toluene solution with a weight concentration of 0.2wt%, add toluene to carry out multiple dilutions, and finally prepare a very dilute solution of PS-b-PMMA with a weight concentration of 0.0002wt% for subsequent use;

[0029] (2) Preparation of polymer extended chains by spin coating method: put the newly split mica sheet as the base on the spin coater, set the speed and time of the spin coater in advance, and the speed of the spin coater is 2500rpm , the spin coating time is 40s, drop the very dilute PS-b-PMMA solution in step (1) onto the mica surface, cover the lid, start the spin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com