Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Sodium zirconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ca[4(1+x)/5]Mg[(1+x)/5]Zr4Si2xP(6-2x)O24 phosphate negative-expansion ceramic material and preparation method thereof

The invention relates to a Ca[4(1+x) / 5]Mg[(1+x) / 5]Zr4Si2xP(6-2x)O24 (CMZP for short) phosphate negative-expansion ceramic material and a preparation method thereof, belonging to the technical field of low-heat-expansion ceramic material. The preparation method comprises the following steps: using sodium zirconate-phsophate MIMIIZr4(PO4)6(NZP) ceramic system as a base body; doping a certain amount of alkaline earth metal elements Ca and Mg at MI position and MII position; replacing P with less Si; and sintering the mixed material at the temperature of 1200-1500 DEG C for 0.1-10h to obtain the CMZP ceramic material with the composition Ca[4(1+x) / 5]Mg[(1+x) / 5]Zr4Si2xP(6-2x)O24 (X is neither smaller than 0 nor greater than 1). The obtained material has high dense degree and low porosity, the average heat expansion coefficient is negative, and the material belongs to negative-expansion ceramic material. The material can be used for adjusting the expansion coefficient of the composite materials and producing zero-expansion or negative-expansion material, and also can be applied to the fields such as heat isolation, low-temperature sealing, gradient material, nuclear waste curing and corrosion inhibitors.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

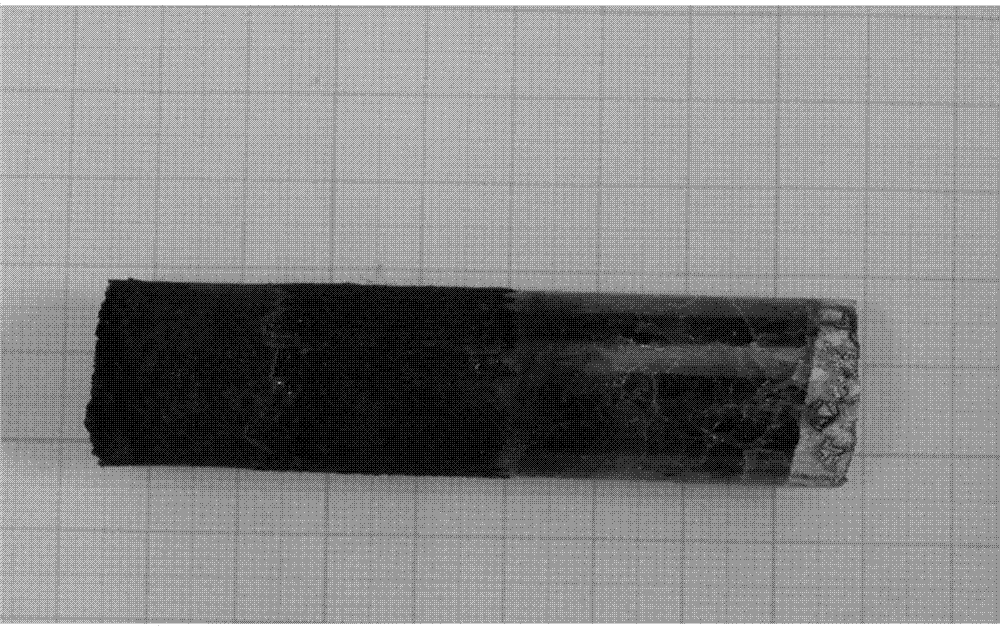

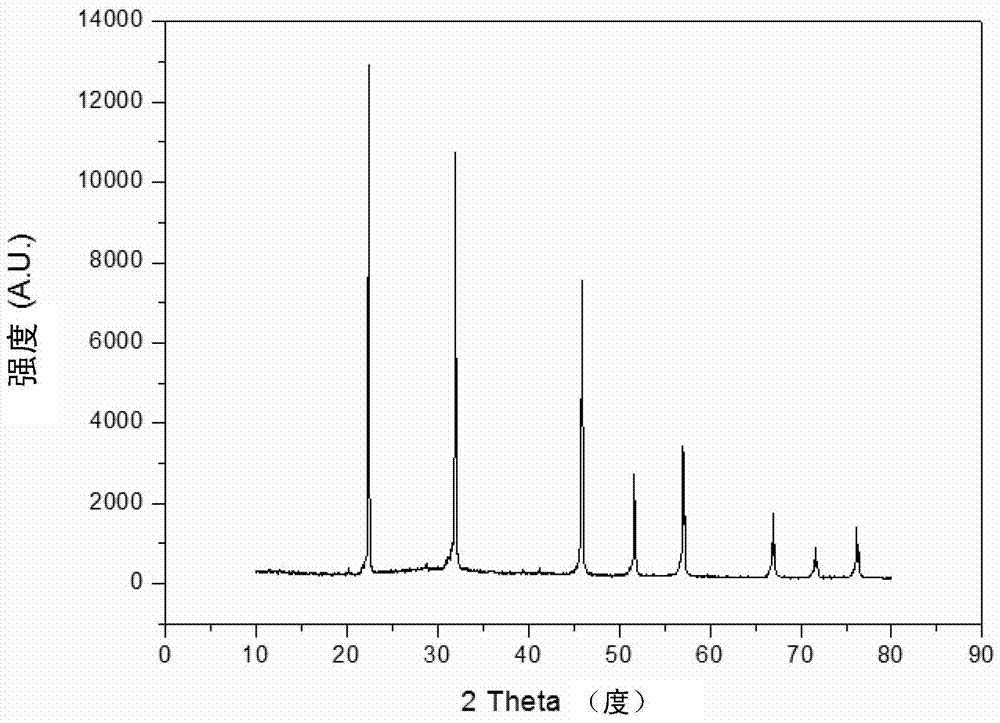

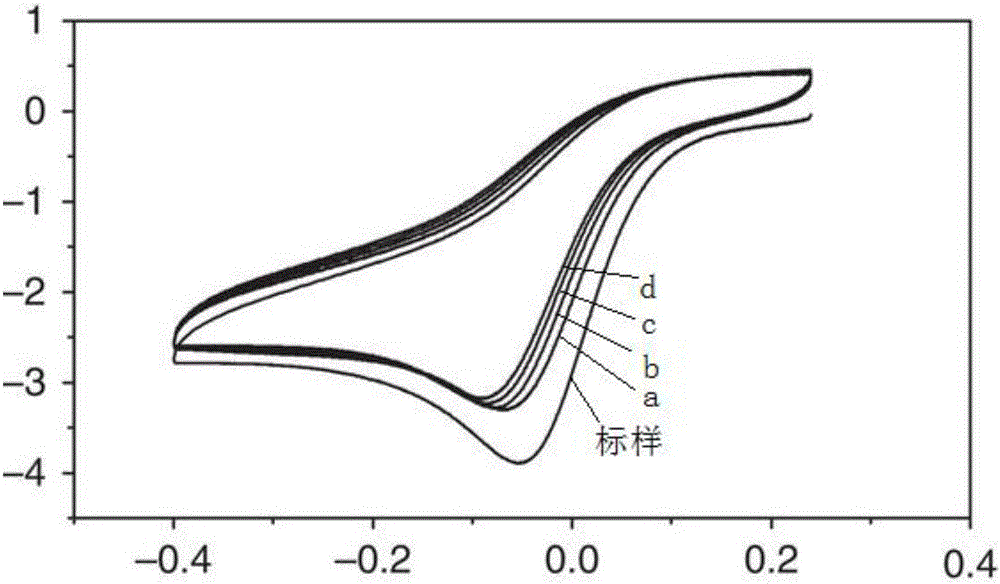

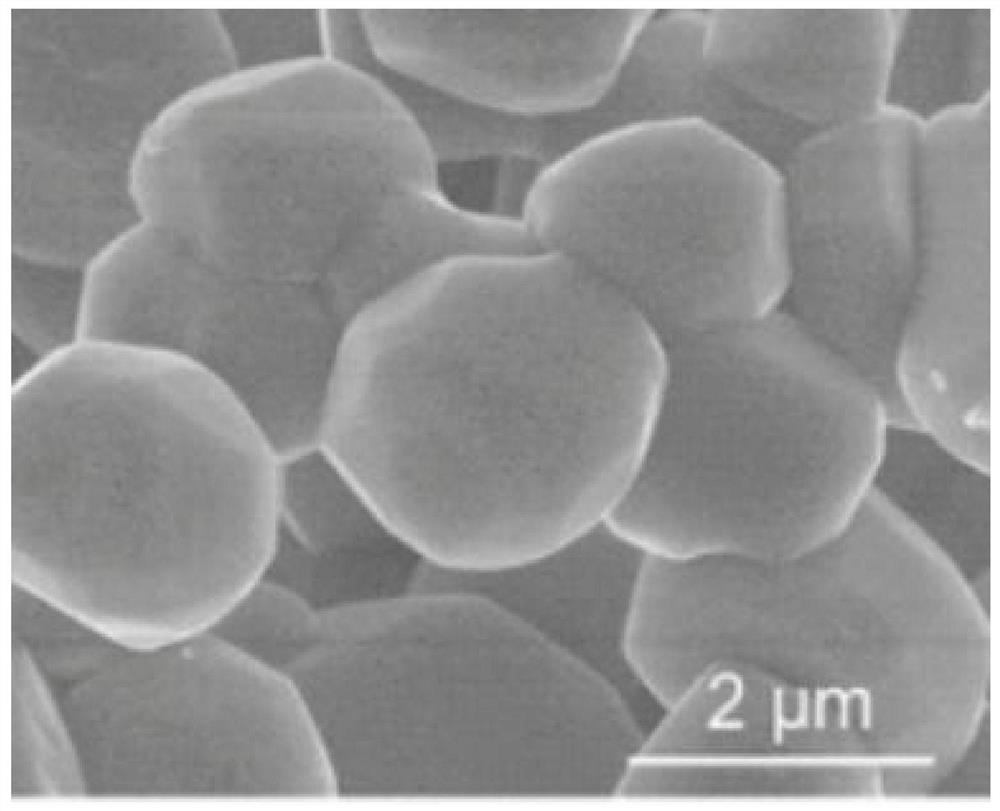

Potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and growing method thereof

ActiveCN107268084ASolve sizeSolve the problem of many cracksPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention relates to a potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and a growing method thereof. The chemical formula of the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is (1-y)(KxNa(1-x))NbO(3-y)(Bi0.5Na0.5)ZrO3, wherein x is larger than or equal to 0.4 and smaller than or equal to 0.6, and y is larger than or equal to 0 and smaller than or equal to 0.1. According to the method, raw materials and a growth auxiliary are mixed and presintered, and the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is obtained by growing with a Bridgman-Stockbarger method; the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal growing with the Bridgman-Stockbarger method after addition of the growth auxiliary has the advantages that a nucleus is formed easily, the crystal size is larger (2-20 mm), fewer cracks are formed and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

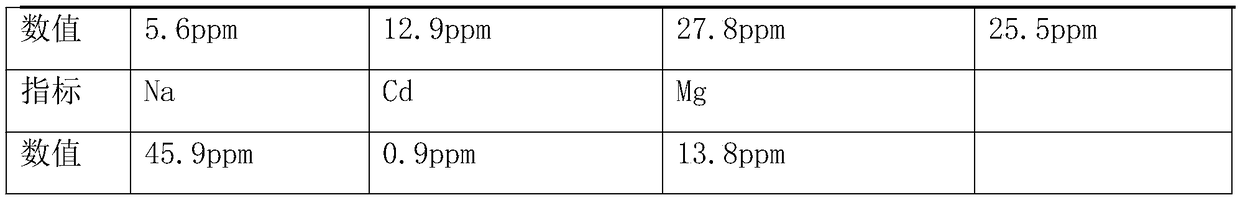

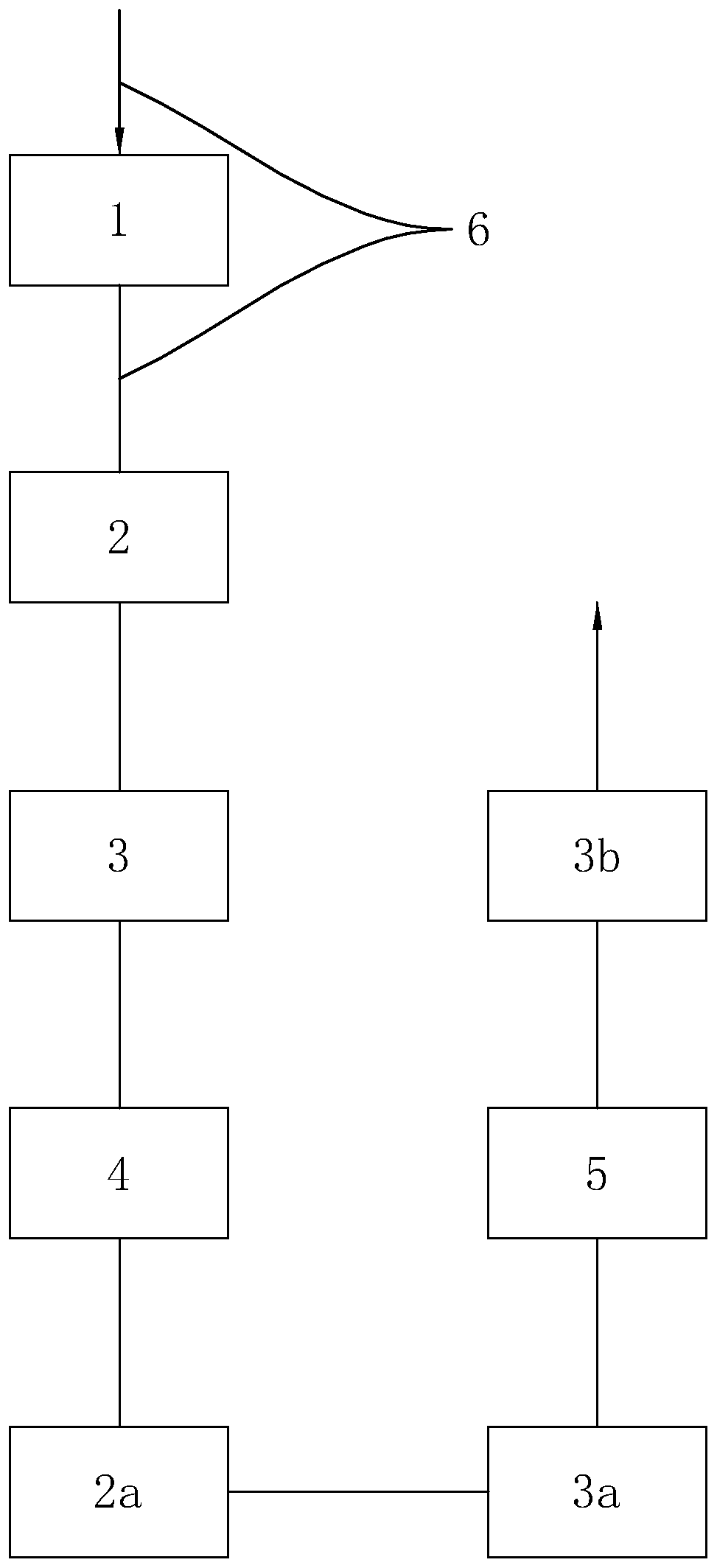

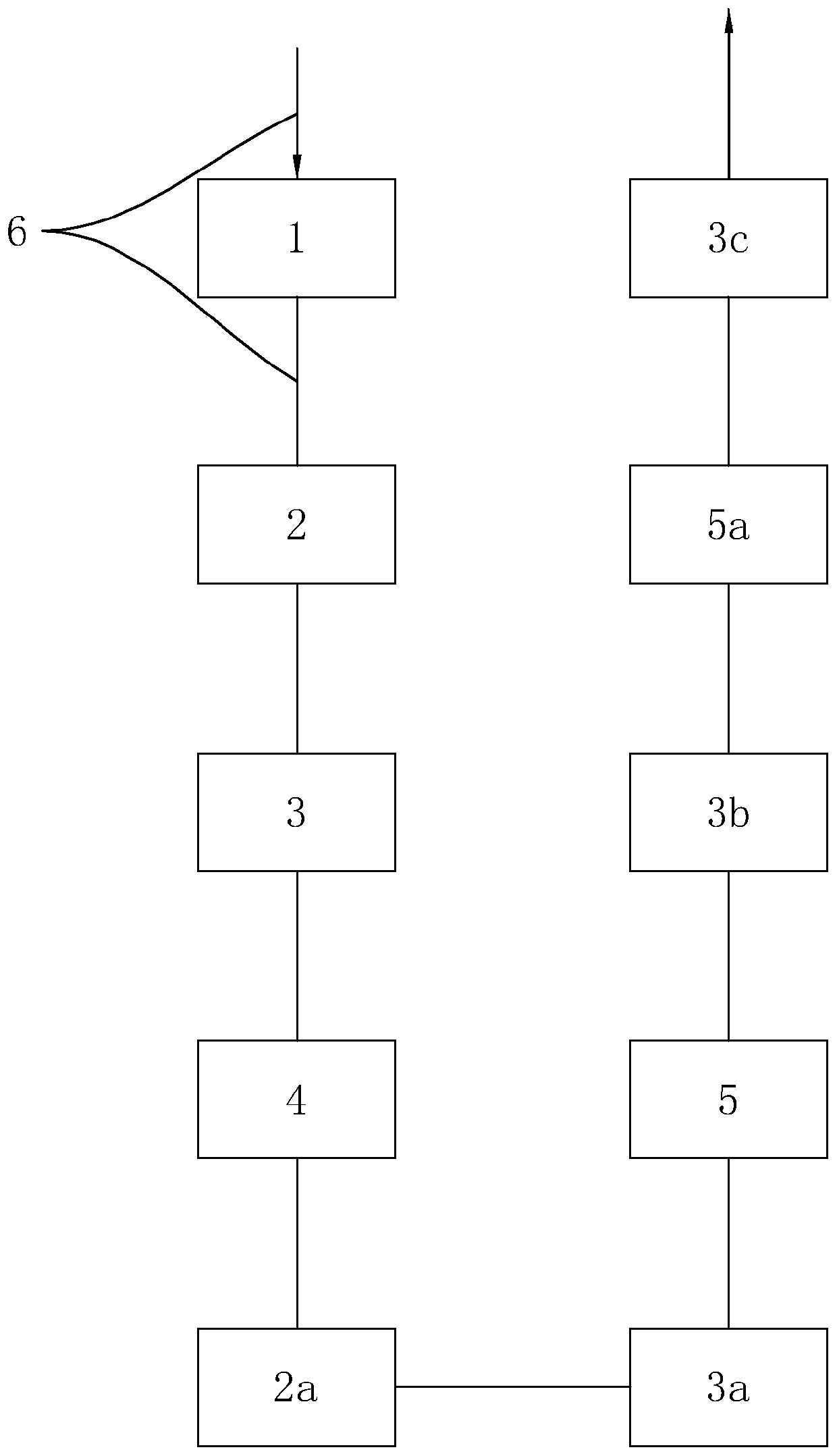

Method for extracting zirconium oxide from zirconium-containing solid solution substance

ActiveCN103950977ALarge heat lossDecrease stockZirconium oxidesNatural resourceZirconium oxychloride

The invention relates to a method for extracting zirconium oxide from a zirconium-containing solid solution substance. The method for extracting the zirconium oxide from the zirconium-containing solid solution substance comprises the following steps: mixing zirconium-containing solid solution substance powder with sodium hydroxide and then heating and sintering, so that an acid-soluble sintered material is obtained, carrying out immersion cleaning on the acid-soluble sintered material with a diluted hydrochloric acid aqueous solution, enriching for obtained mixture of sodium zirconate and zirconium hydroxide and a salt solution, carrying out hot dipping on the mixture for obtaining a zirconium oxychloride solution with a hydrochloric acid solution, evaporating, concentrating and cooling the zirconium oxychloride solution for separating out zirconium oxychloride crystals, and purifying the obtained zirconium oxychloride crystals; carrying out neutralizing treatment on the salt solution, extracting useful components, and then concentrating the salt solution for obtaining industrial salt. The method for extracting the zirconium oxide from the zirconium-containing solid solution substance has the advantages of simple technological process, energy conservation, low consumption, high metal recovery rate, less environmental pollution, benefit to harmonious development of natural resources and the ecological environment and obvious resource recycling effect.

Owner:山东鸿远新材料科技股份有限公司

High-stability coating material for hot-blast stove and preparation method thereof

InactiveCN106189409AImprove high temperature resistanceAccelerated corrosionFireproof paintsAnti-corrosive paintsFiberCarbon fibers

The invention discloses a high-stability coating material for a hot-blast stove and a preparation method thereof. The preparation method comprises the steps: (1) soaking river mud in acid liquor, then, carrying out filtering, and taking a filter cake, so as to prepare modified river mud; (2) dispersing silica gel, sodium zirconate, rare-earth oxide and the modified river mud into an organic solvent under ultrasonic conditions, then, carrying out filtering, and taking a filter cake, so as to obtain an activated substance; (3) subjecting organosilicone, an acrylonitrile-butadiene-styrene copolymer, maleic anhydride, an organic solvent, carbon fibers, attapulgite, cyclodextrin and the activated substance to a contact reaction under high-pressure and closed conditions, thereby preparing the high-stability coating material for the hot-blast stove. The coating material prepared by the method has excellent high-temperature resistance and corrosion resistance, and then, the service life of the hot-blast stove can be prolonged.

Owner:WUHU CHANGQI FURNACE

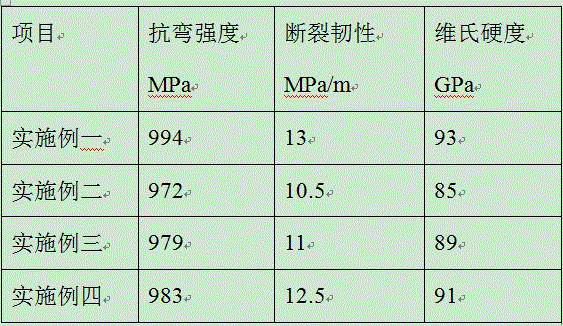

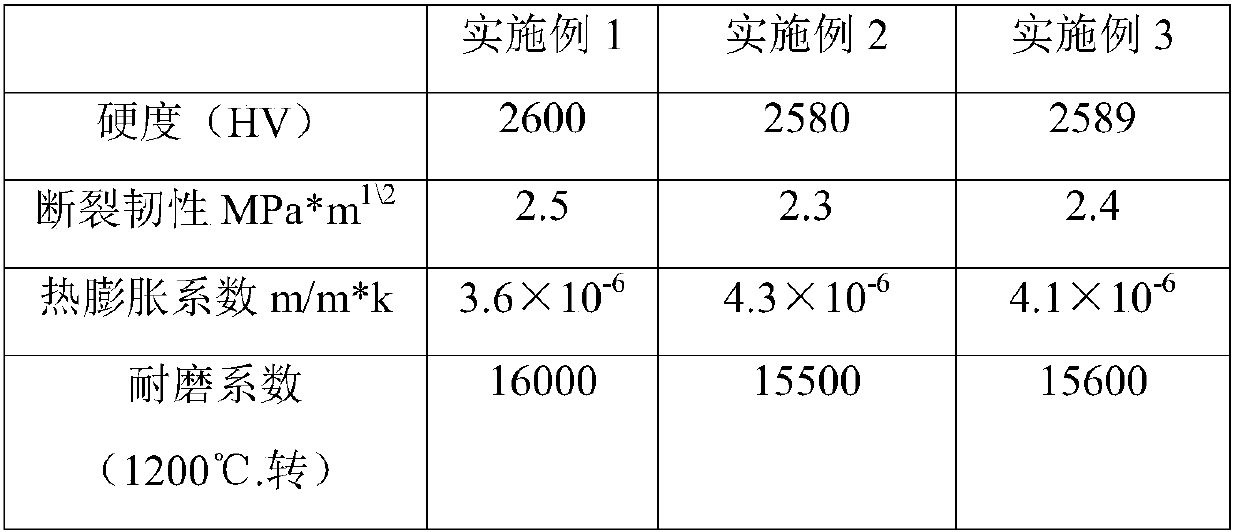

Novel special ceramic material and preparation method thereof

ActiveCN105481347AImprove corrosion resistanceImprove antioxidant capacityClaywaresBoron nitrideOxidation resistant

The invention discloses a novel special ceramic material. The material is prepared by the following raw materials in parts by weight: 40-50 parts of red clay, 1-3 parts of albite, 5-7 parts of nanometer aluminium oxide, 1-3 parts of nickel oxide, 1-3 parts of zinc oxide, 5-7 parts of niobium pentoxide, 5-7 parts of boron nitride, 5-7 parts of wollastonite, 3-4 parts of sodium zirconate, and 5-7 parts of an auxiliary agent. The novel special ceramic material has the advantages of high strength, good resistance to corrosion and oxidation resistance, good toughness, high temperature resistance, substantially improved antifriction capability of the surface, scaling resistance of the surface, cleaning convenience, and increased service life; at the same time, prior ceramic preparation technology is optimized, suitable technological parameters are selected, so that performance of the material is more stable.

Owner:上海秉丰生物科技有限公司

Preparation method for aluminium alloy radiator passivation solution before lacquering

InactiveCN104328415AImprove corrosion resistanceImprove adhesionMetallic material coating processesAcetic acidSodium molybdate

The invention discloses a preparation method for an aluminium alloy radiator passivating solution before lacquering. The passivating solution comprises 6-8 g / L of sodium molybdate, 4-6 g / L of potassium tetrafluoroborate, 3-5 g / L of magnesium titanate, 8-10 g / L of sodium zirconate, 16-18 g / L of aqueous polyurethane, 12-14g / L of boric acid, 4-6 g / L of acetic acid, 1-2g / L of thiourea and the balance water. The preparation method comprises: weighing all raw materials according to the above proportions, putting in a reaction kettle, heating to 35-45 DEG C, then starting a stirrer, controlling the rotation speed to be 160-180 r / min, stirring for 15-25 min, then cooling to room temperature and putting for 10-12 h.

Owner:无锡永发电镀有限公司

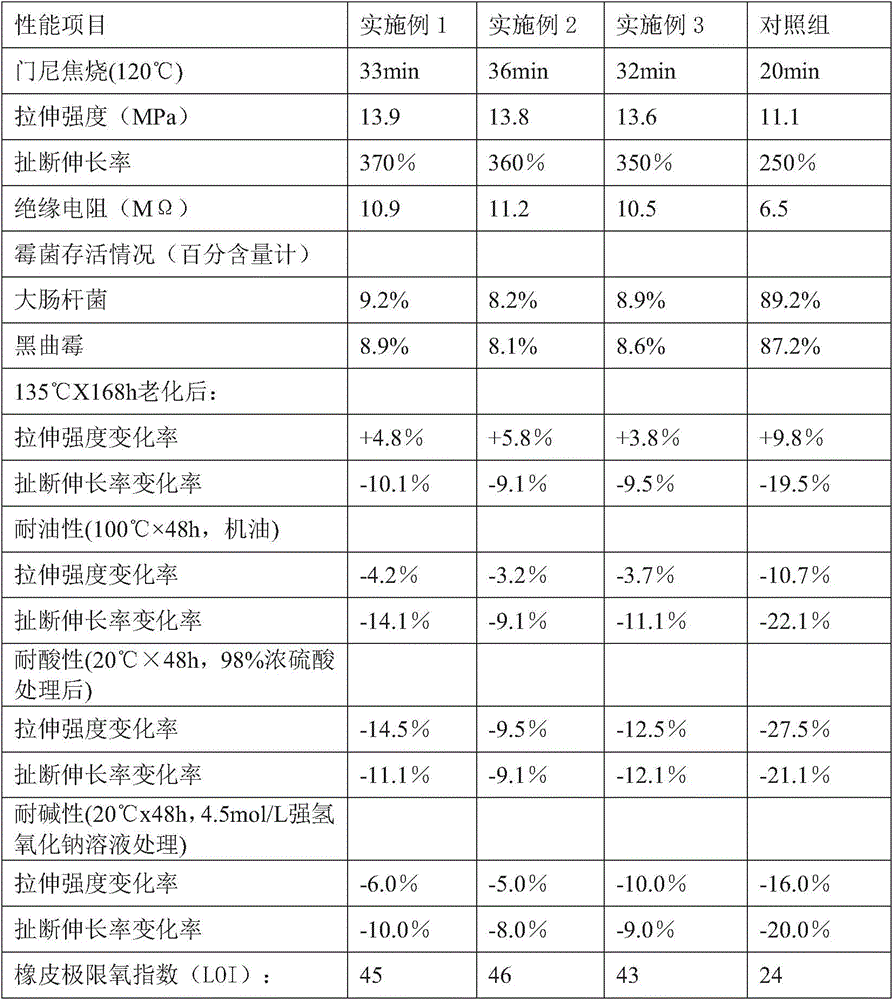

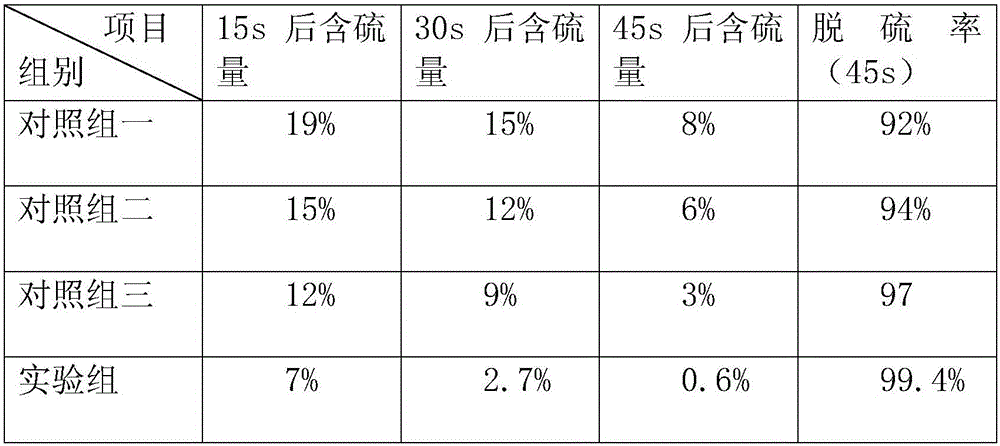

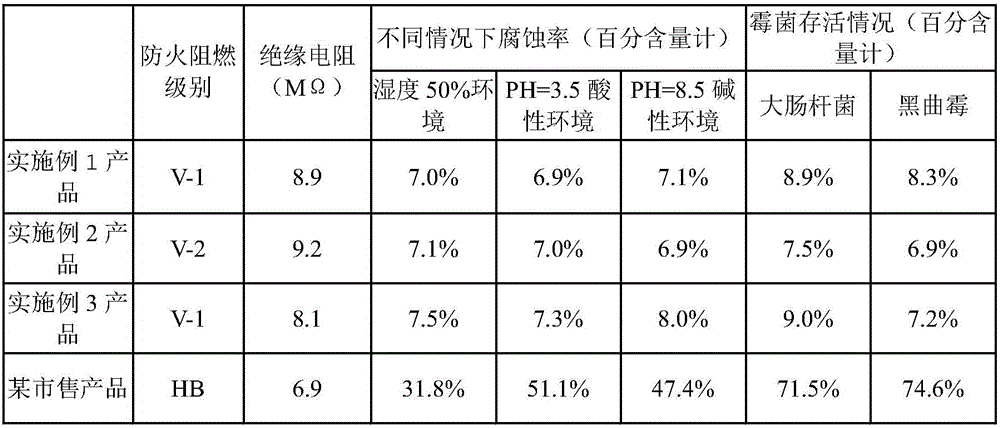

Installation cable for electric power distribution cabinet

InactiveCN106084479ASoft textureExcellent flame retardantPlastic/resin/waxes insulatorsClimate change adaptationDiacetone alcoholPhosphate

The invention relates to an installation cable for an electric power distribution cabinet. The installation cable comprises a plurality of copper alloy wires and protective sheaths, wherein the copper alloy wires are arranged in parallel to each other, and the outer layer of each copper alloy wire is coated with the protective sheath; each protective sheath comprises the following components: polypropylene resin, aldehyde resin, brominated bisphenol A epoxy resin, Litsea cubeba oil, 4-hydroxy-4-methyl-2-pentanone, castor oil, amyl propionate, propiconazole, sodium monofluorophosphate, carbendazim, tetramethyl thiuram disulfide, tourmaline powder, molybdenum disilicide powder, titanium dioxide powder, weathered coal, corundum powder, sodium zirconate powder, strontium chromate powder, silica gel powder, tris(2-chloroethyl) phosphate, hexabromo-benzene, modacrylic, decabrominated iphenyl ethane, diaminodiphenyl methane, diphenyl silanediol, diphenylmethane bismaleimide, diacetone alcohol, dibutyltin dilaurate, diethylene glycol dibenzoate, and dimethyl ketoxime. The installation cable provided by the invention has the advantage of improving the operation performance of a product.

Owner:虞永华

Impact-resistant ceramic coating layer for metal-based thermal spraying and spraying method thereof

InactiveCN104862634AStable currentImprove the accuracy of useMolten spray coatingTitanium oxideCalcium lignosulfonate

The invention discloses an impact-resistant ceramic coating layer for metal-based thermal spraying. The impact-resistant ceramic coating layer comprises the following raw materials in parts by weight: 25-32 parts of basalt, 13-20 parts of kaolin, 8-10 parts of clay, 3-8 parts of silicon dioxide, 2-5 parts of titanium oxide, 1-4 parts of sodium oxide, 4-8 parts of calcium lignosulphonate, 2-4 parts of zirconium oxide, 6-8 parts of assistant, 4-8 parts of glass fibers, 2-7 parts of nickel sulfate, 1-2 parts of rare earth, 1-2 parts of sodium zirconate, and 5-10 parts of de-ionized water, wherein the rare earth comprises the following components in percentage by mass: 8.8-9.4% of erbium, 3.7-4.6% of holmium, 9.2-10.8% of neodymium, 4.5-5.5% of promethium, 13.2-15.5% of gadolinium, 10.2-10.8% of europium, and the balance of lanthanum and inevitable impurities. The impact-resistant ceramic coating layer in proper in ceramic powder components and ratios; the average grain size of the ceramic coating layer is 52.8 nm; a molten shell adopts a columnar crystal structure with stronger directivity; the ceramic coating layer is excellent in impact resistance, high in hardness, wider in temperature resistance, excellent in ablation resistance, excellent in mechanical performance and high in strength; adopted plasma spraying equipment is stable in current; a formed aluminum oxide coating layer is smooth and compact; and the bonding strength with a metal matrix is high.

Owner:SUZHOU TONGMING MACHINERY

Carbon nano tube conductive silver paste for filter and manufacturing method thereof

InactiveCN104143383AImprove conductivitySilver conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteAcrylic resin

The invention discloses carbon nano tube conductive silver paste for a filter. The carbon nano tube conductive silver paste is characterized by being composed of the following raw materials, by weight, 40-50 parts of silver powder, 3-4 parts of carbon nano tubes, 1-2 parts of boric oxide, 2.1-3.4 parts of precipitated barium sulphate, 0.4-0.9 part of sodium zirconate, 0.2-0.4 part of a titanate coupling agent, 0.4-0.7 part of sodium diacetate, 1.2-2.3 parts of methylimidazoline, 4-6 parts of ethylene glycol butyl ether, 3-5 parts of acrylic resin, 30-40 parts of assistants and appropriate water. Various effective constituents are combined in an optimized mode, the production process is simplified, and compared with the prior art, implementation and operation are convenient, after a substrate is coated with the carbon nano tube conductive silver paste for the filter and sintered, a silver conductive layer which is high in compactness, high in adhesive force, good in conductive performance and good in weldability is formed, and the market prospects are wide.

Owner:滁州恒恩光电科技有限公司

Vitrified agent and preparation method thereof

InactiveCN101629286BImprove stabilityNo sedimentMetallic material coating processesPhosphatePotassium

The invention discloses a vitrified agent which is prepared by the following raw materials according to the parts by weight: 20-30 parts of potassium fluorozirconate or sodium fluorozirconate, 5-10 parts of fluoride, 5-10 parts of complexing agent and 40-60 parts of water. The vitrified agent prepared by the technology has good stability, no sediment and no phosphates, can form a vitrification layer on the surface of steel, zinc and aluminum, has strong binding force with various types of coatings, is applicable to the spraying and soaking at room temperature, does not need a heating device and can reach the aim of saving energy and simplifying the production.

Owner:岑添祥

Environmental-friendly water treatment material and preparation method thereof

InactiveCN106495306AAccelerated settlementFunction increaseOther chemical processesWater/sewage treatment using germicide/oligodynamic-processPolyvinyl alcoholSulfate

The invention discloses an environmental-friendly water treatment material and a preparation method thereof. The environmental-friendly water treatment material comprises the following components in parts by weight: 45 to 60 parts of polyvinyl alcohol, 6 to 8 parts of montmorillonite, 3 to 6 parts of tourmaline powder, 2 to 3 parts of polyaluminosiloxane, 1 to 2 parts of calcium sulfate, 1 to 2 parts of ethanol amine, 0.8 to 1.5 parts of sulfuric acid, and 0.4 to 0.8 part of sodium zirconate. The invention further provides a preparation method of the environmental-friendly water treatment material.

Owner:江苏悠谷未来科技有限公司

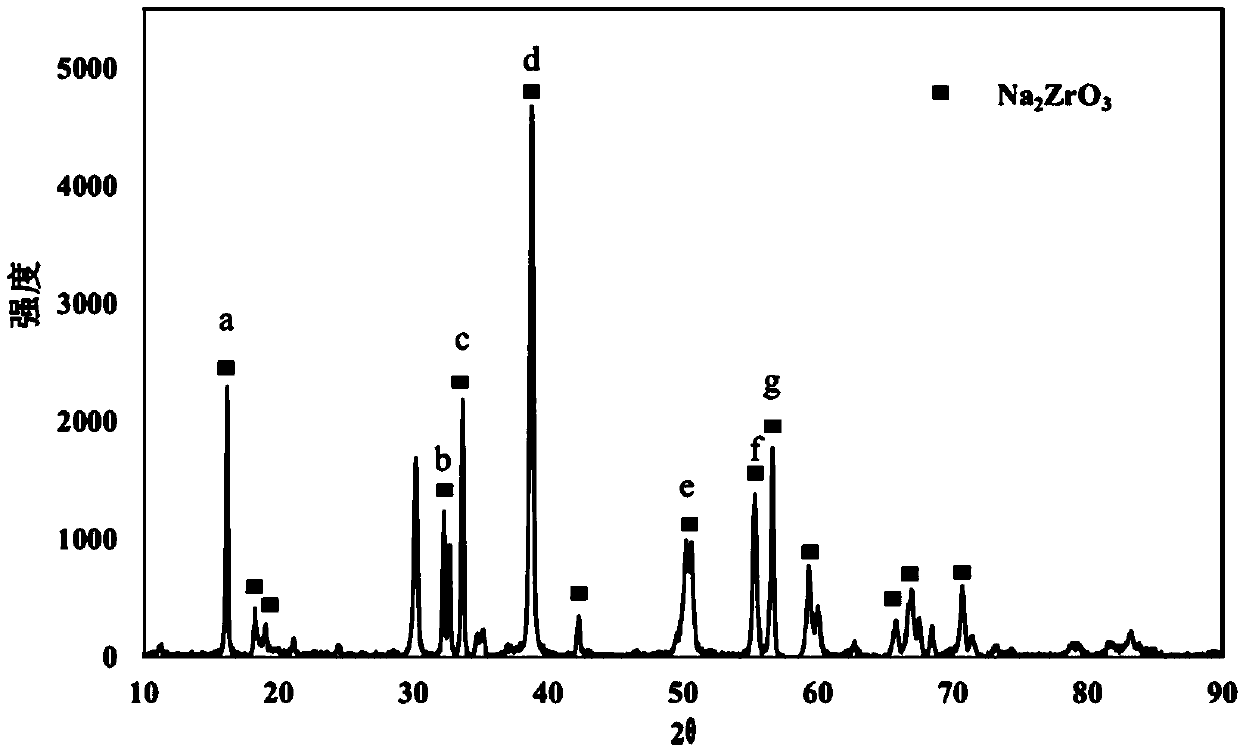

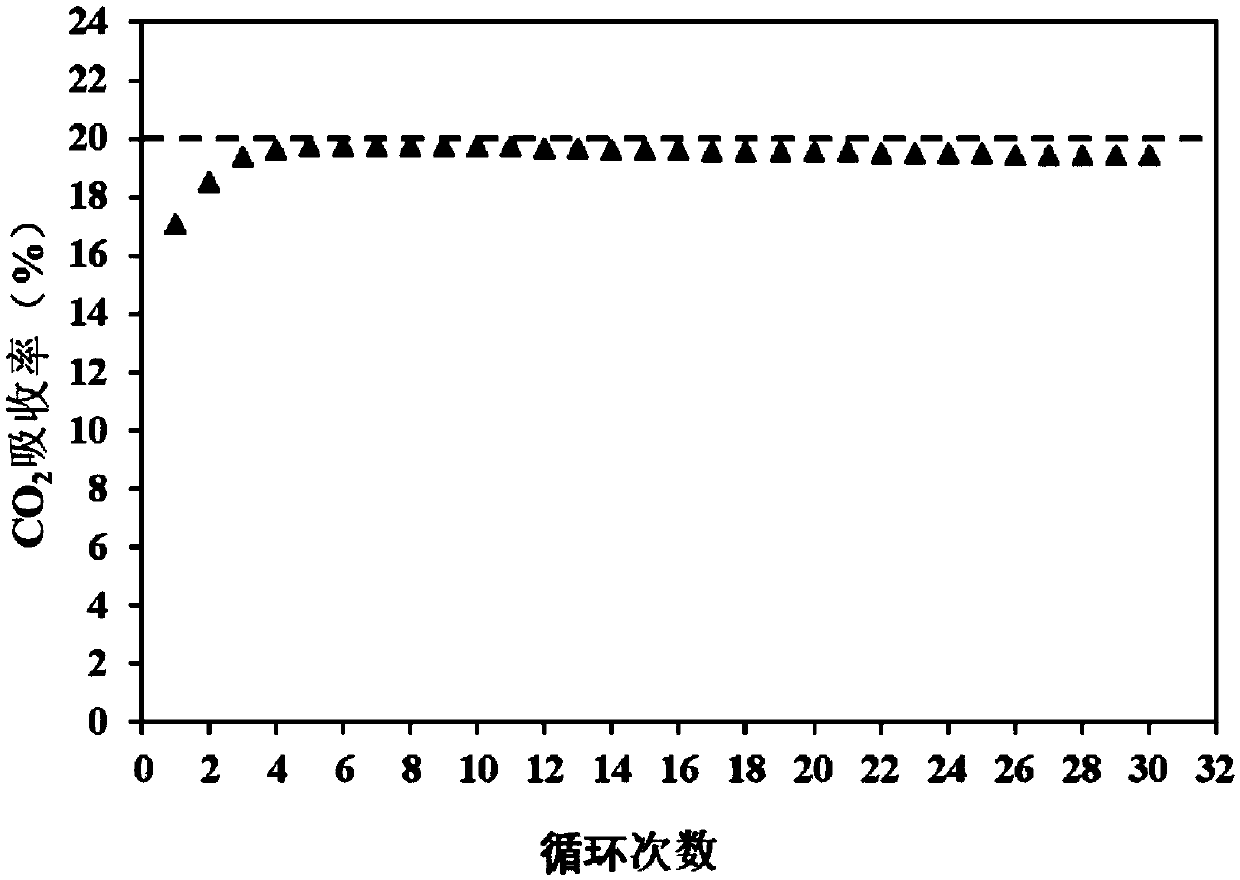

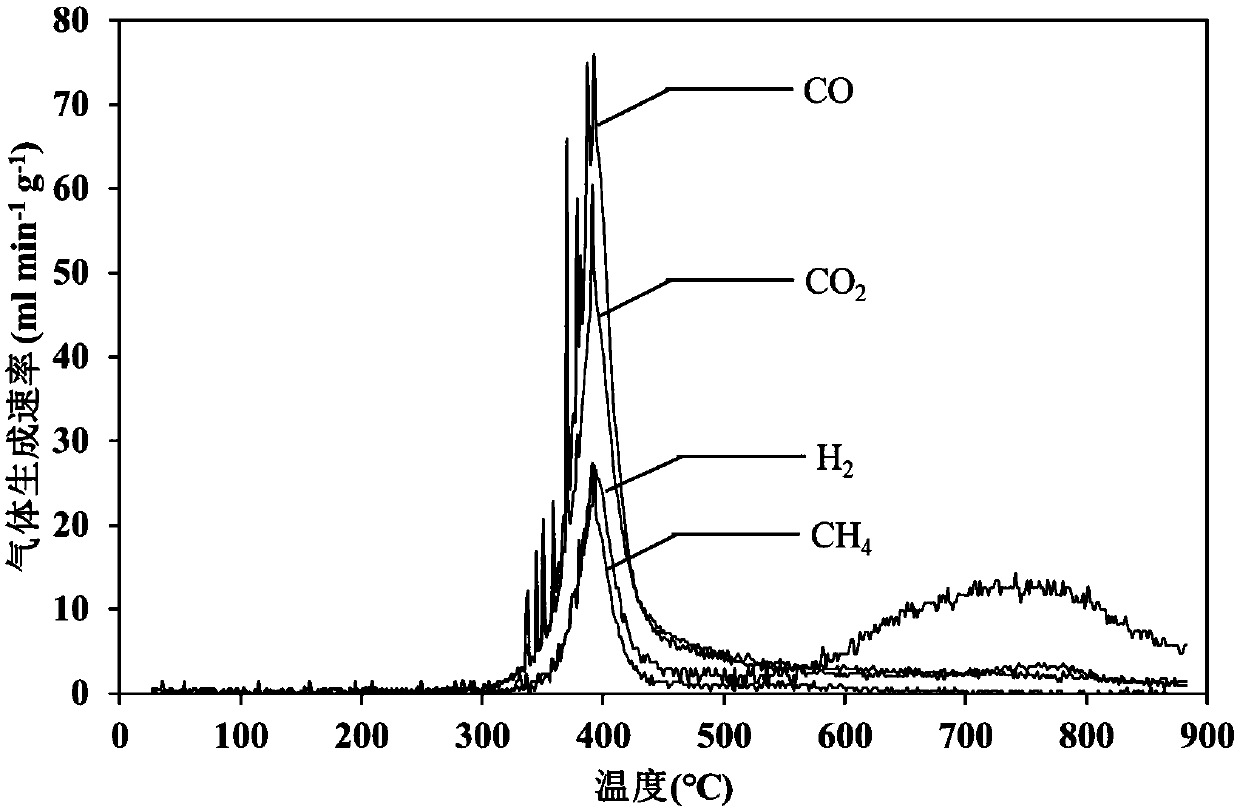

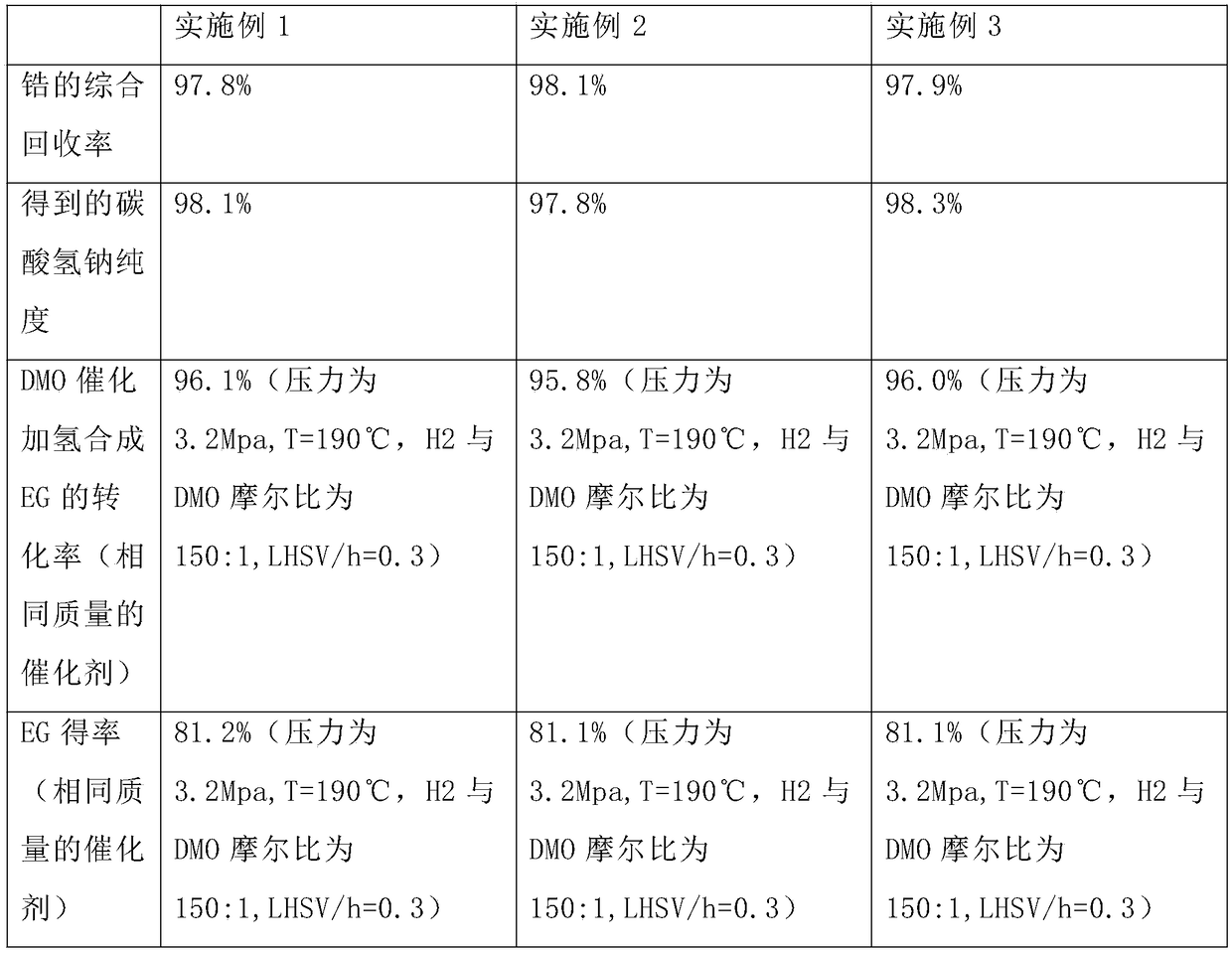

Synthesizing and application methods of sodium zirconate

The invention discloses synthesizing and application methods of sodium zirconate and belongs to the field of resource utilization of solid wastes. The synthesizing method of the sodium zirconate comprises the following steps of (1) mixing YSZ (yttria-stabilized zirconia) solids and sodium carbonate solids at a certain weight; (2) calcinating the products obtained in the step (1) at a temperature of 750-850 DEG C for 5-8 hours. The synthesizing method of the sodium zirconate can not only complete recycling of dental crown material wastes to achieve reduction and resource utilization of solid dental wastes, but also synthesize the sodium zirconate in a simple and easily-operated mode, which can serve as a carbon dioxide absorbent with good carbon dioxide absorbency or be applied to pyrolysishydrogen production of biomass and biomass waste.

Owner:TSINGHUA UNIV +1

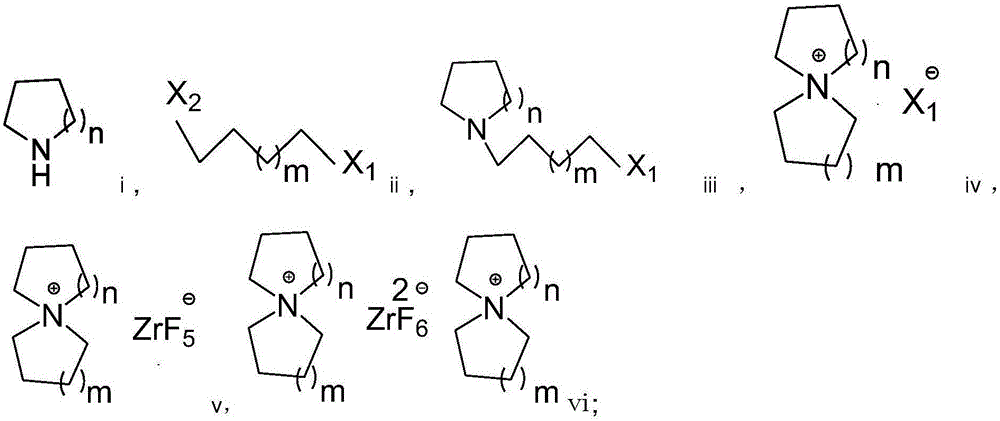

Preparation method of fluorozirconate

ActiveCN106117217ARaw materials are cheap and easy to getThe reaction steps are simpleHybrid capacitor electrolytesOrganic chemistryAlkaneOrganic solvent

Owner:NANJING YUANSHU MEDICAL TECH CO LTD

Zirconia production process

The invention discloses a zirconia production process. The zirconia production process comprises the following steps of: placing zircon in a smelting furnace, adding caustic soda into the smelting furnace, performing real-time mixing and stirring on the mixture, leaching molten liquid by using hot water, putting first mixed liquid in a stirrer, then adding sodium zirconate into the stirrer, performing real-time stirring, then adding an acid solution into the stirrer to obtain second mixed liquid, performing impurity removal, putting the second mixed liquid which is subjected to impurity removal in a vessel again, performing mixing and stirring at 60-80 DEG C, adding a precipitating agent into the vessel while stirring is conducted, then placing treated zirconium hydroxide in the smelting furnace, performing second melting at 500-600 DEG C, and adding a catalyst into the solution to obtain the zirconia. Through the zirconia production process, not only can the quality of the zirconia beimproved, but also the melting point of the zirconia can be increased, so that the obtained zirconia is adaptive to different environments, and the needs of present development are met.

Owner:淄博松阳锆业科技有限公司

Multi-arc ion physical plating paint used for replacing chemical electroplating

InactiveCN104774558AIncrease brightnessIncrease surface expansion forceCoatingsOrganic solventAcrylic resin

The invention discloses a multi-arc ion physical plating paint used for replacing chemical electroplating. The multi-arc ion physical plating paint is composed of following raw materials, by weight, 30 to 38% of organic silicon resin, 15 to 22% of hydroxy acrylic resin, 8 to 13% of polytetrafluoroethylene liquid resin, 3 to 8% of phosphorus silicon sodium zirconate, 0.5% of a fluorine carbon leveling auxiliary agent, and 30 to 40% of an organic solvent. Compared with the prior art, the multi-arc ion physical plating paint is capable of avoiding defects of conventional multi-arc ion plating; conventional chemical electroplating is completely replaced by physical multi-arc ion physical plating; and environmental protection is realized.

Owner:JINJIANG DANER COATING CO LTD

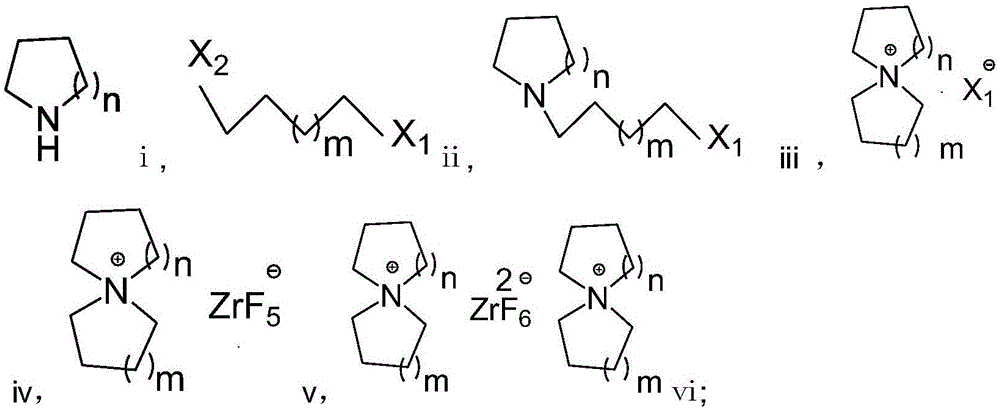

Quick waste gas desulphurization agent and preparation method thereof

InactiveCN105944553AGood desulfurization effectFast desulfurizationDispersed particle separationPotassium hydroxideManganese oxide

The invention discloses a quick waste gas desulphurization agent and a preparation method thereof. The agent is prepared from raw materials in parts by weight as follows: 25-27 parts of cobalt chloride, 18-20 parts of sodium carbonate, 15-17 parts of cobalt carbonyl, 6-8 parts of basic nickel carbonate, 20-22 parts of basic aluminum sulfate, 20-22 parts of potassium hydroxide, 6-8 parts of activated carbon, 4-6 parts of calcium lactate, 12-14 parts of iron oxide, 6-8 parts of manganese oxide, 6-8 parts of zirconium dioxide, 2-4 parts of sodium zirconate, 6-8 parts of praseodymium-neodymium oxide, 18-20 parts of lanthanum oxide, 26-28 parts of acetic acid, 5-7 parts of sodium hydroxide and 4-6 parts of magnesium perchlorate. The quick waste gas desulphurization agent has the high desulphurization speed and the good use effect.

Owner:张锐

Multifunctional power construction tube stock

The invention relates to a multifunctional power construction tube stock which comprises the following components: fluororubber, keto-aldehyde resin, PVC resin powder, polyester carbamate resin, polypropylene resin, dimethyl formamide, polyvinyl acetate emulsion, polyglycerol polyricinoleate, di-butyl cellosolve, polyvinyl acetate emulsion, tea polyphenol, bromo-dimethyl hydantoin, carbendazim, cyanoethyl cellulose, di-octadecyl dimethyl ammonium chloride, sodium zirconate powder, strontium carbonate powder, magnesium silicate powder, starch acrylamide, alginic acid, aluminum sulfate, sodium humate, ammonium diacid phosphate, decabrominated dipheny ethane, hexahydrophthalic anhydride, triethylene glycol di-2-ethylhexoate, tricresyl phosphate, sodium lignin sulfonate, anhydride maleique, methacrylic glycerol trilaurate and fatty glyceride. According to the invention, various materials are mixed with each other so as to form a novel compound toughening enhancing system; the performance indexes of toughness, rigidity and elasticity modulus are better; the ageing resistance and usability of the products are greatly promoted.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

Aluminum alloy profile surface treatment process

ActiveCN109317382BFast growthHigh mechanical strengthPretreated surfacesMetallic material coating processesTungstateStrong acids

The invention discloses an aluminum alloy profile surface treatment process, which includes the following steps: (1) pretreatment: adding the aluminum alloy profile into a cleaning solution for ultrasonic cleaning for 3-5 minutes; (2) passivation treatment: under nitrogen conditions, the pretreated Aluminum alloy profiles are preheated to 60-80°C, first brushed with passivation solution, after 5-10 minutes of reaction, brushed with nitrate film-forming accelerator solution, and after 3-5 minutes of reaction, then painted with passivation solution; The passivation solution is composed of the following components by weight percentage: 5-10% formic acid, 1-3% hydrofluoric acid, 5-10% sodium fluozirconate, 3-6% potassium tungstate, and 1-5% potassium phytate , organic corrosion inhibitor 2-4%, the balance is water; (3) electrostatic spraying. The invention adopts non-aluminum oxide film-type passivation sealing "two-in-one" surface treatment technology to form a crystalline dense composite passivation film on the surface of aluminum alloy profiles, which has a fast film forming speed and is resistant to strong acid and strong alkali corrosion.

Owner:安徽安铝铝业有限公司

Abrasion-resistant daily ceramic product and preparation method thereof

The invention discloses an abrasion-resistant daily ceramic product and a preparation method thereof. The ceramic product includes, by weight, 30-40 parts of kaolin, 15-25 parts of albite, 10-20 partsof vermiculite, 5-15 parts of hollow microspheres, 5-14 parts of black mud, 5-10 parts of water-based acrylic emulsion, 6-10 parts of talcum powder, 5-10 parts of bamboo carbon fibers, 2-4 parts of sodium zirconate, 3-5 parts of rice hull powder, 10-20 parts of epoxy resin, 1-4 parts of polyester resin and 1-2 parts of a dispersing agent. A production technology is simple, there is no pollution in the process of the technology, the cost for raw materials is low, and the ceramic product prepared through a scientific raw material formula is low in cost, high in hardness, resistant to abrasion,high in ductility and durable.

Owner:福建省德化县鹏欣陶瓷有限公司

Process for separating zirconium, silicon and aluminum from AZS solid wastes

InactiveCN105174294ANo emissionsReduce pollutionSilicaZirconium compoundsAluminateAluminium hydroxide

The invention relates to a process for separating zirconium, silicon and aluminum from AZS solid wastes, which belongs to the technical field of cyclic utilization of refractory solid wastes. AZS solid wastes are subjected to alkali fusion and roasting firstly so as to obtain a sintered material; the sintered material is subjected to water leaching for separating out zirconium, so that lixiviums of water-soluble metasilicate and meta-aluminate are obtained; and acid liquor is added into the lixiviums to react, so that an aluminum salt solution and a silica gel are obtained finally, thereby realizing the separation of silicon and aluminum, and solving the problems of low recovery and utilization rates and low added value of products existing in current recovery and utilization technologies of AZS solid wastes. Sodium zirconate obtained in the invention can be used for preparing zirconium oxychloride or zirconium sulfate, the silica gel can be used for preparing white carbon black, aluminum can be directly converted into aluminium hydroxide products, and the recovery rates of zirconium dioxide, aluminium oxide and silicon dioxide are all greater than or equal to 98%, therefore, the process has the characteristics of high recovery and utilization rates and high added value of products; and washing wastewater produced in the process can be recycled, thereby achieving the effect of no wastewater discharge, and reducing the environmental pollution.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

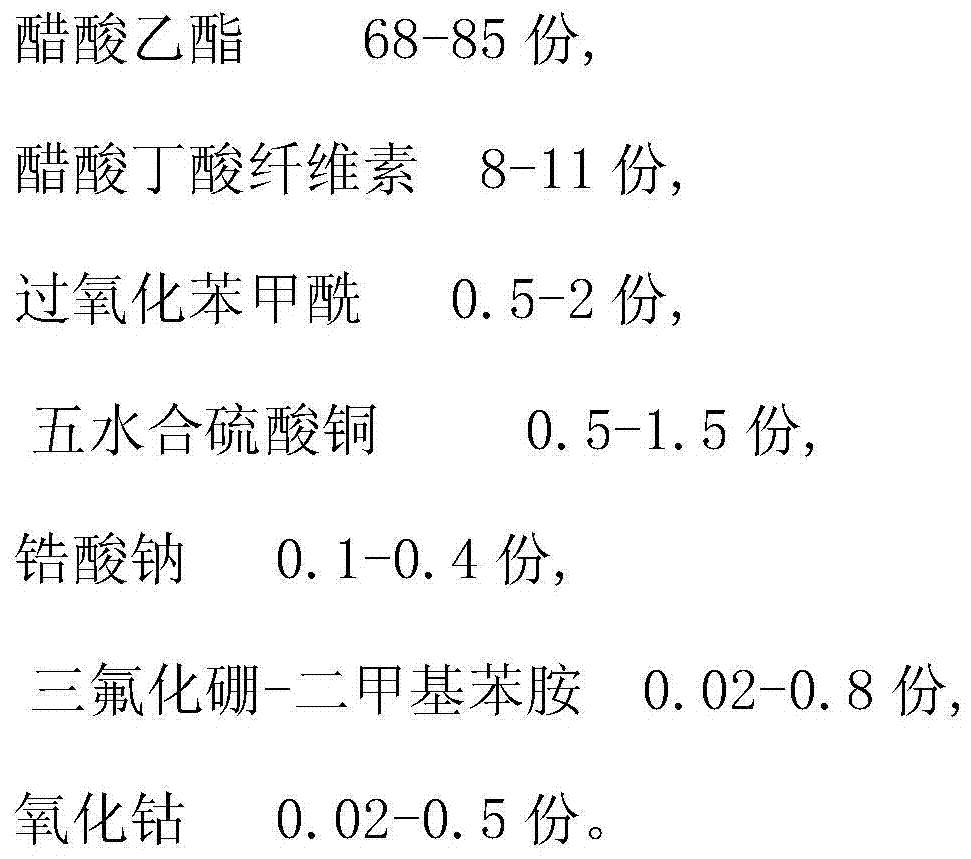

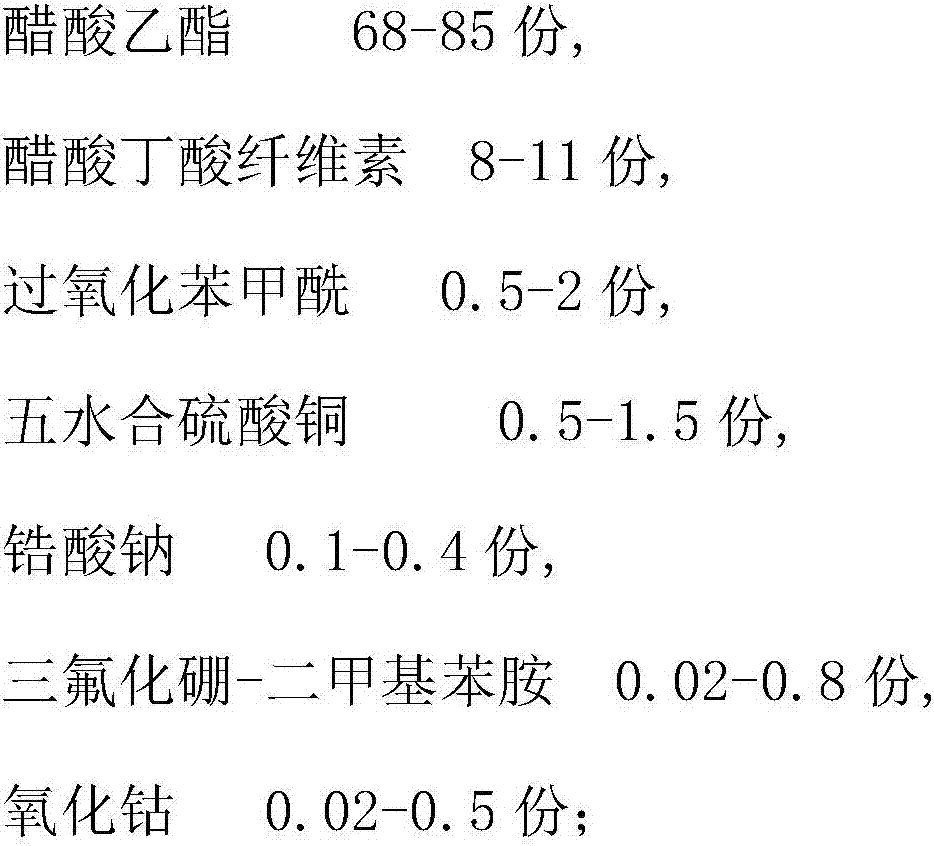

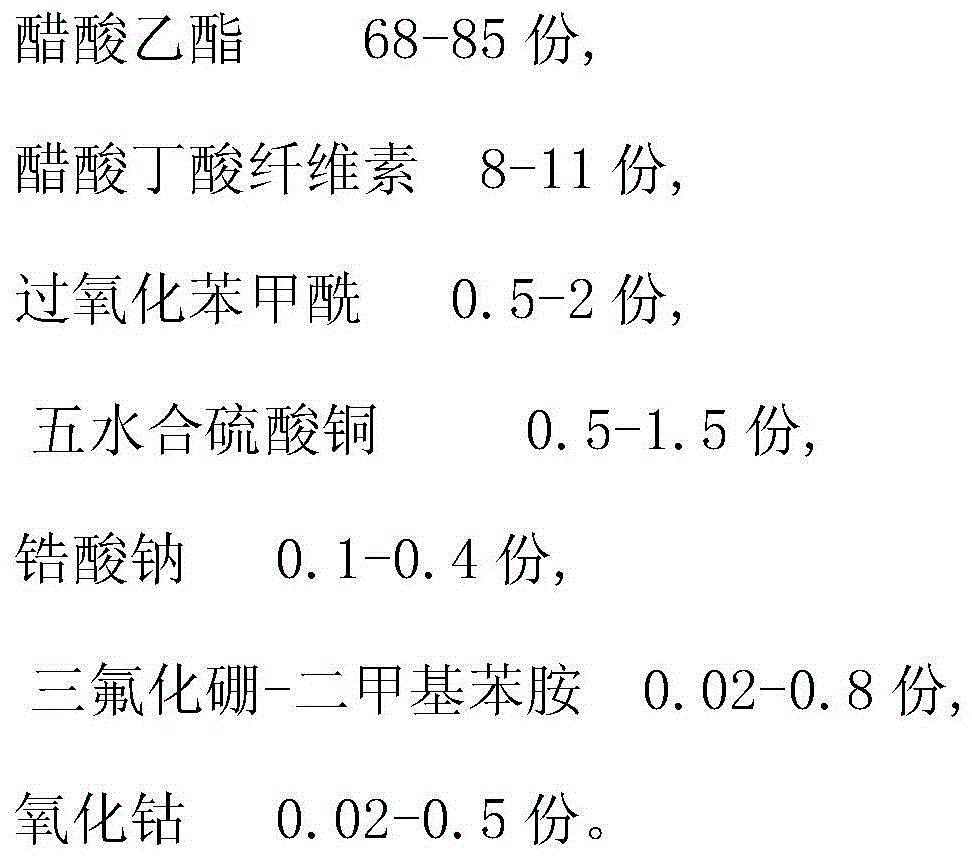

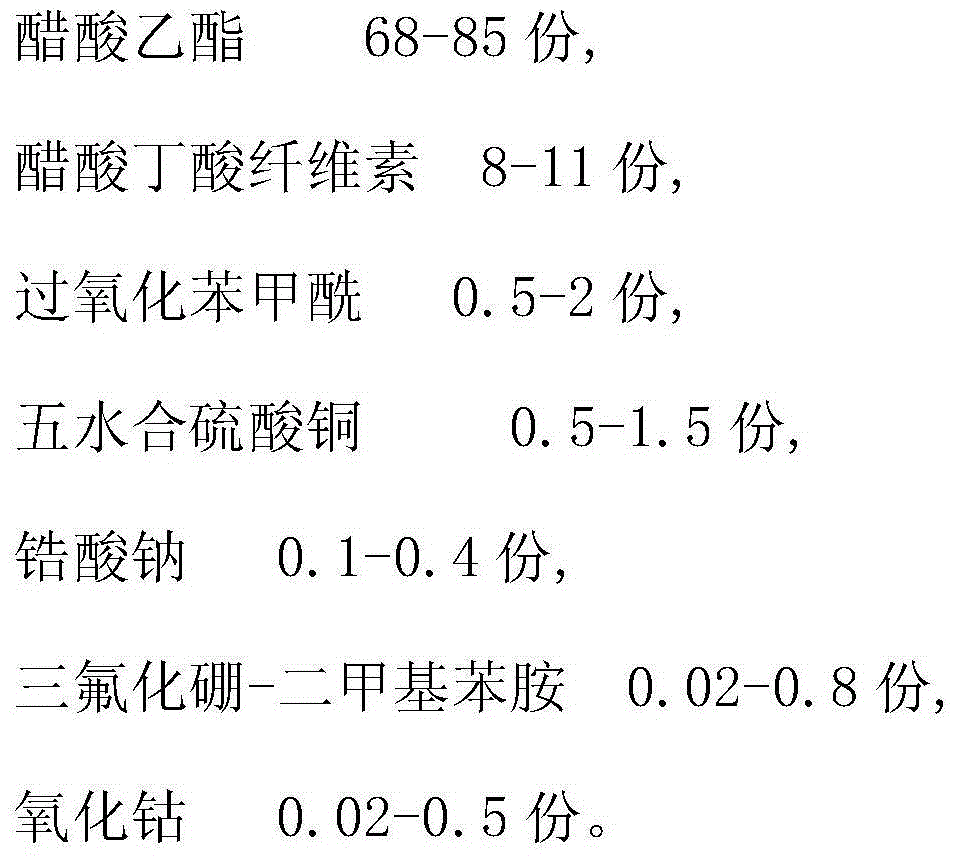

A kind of anti-fog film material and preparation method thereof

ActiveCN104893430BGood film formingImprove high temperature resistanceCoatingsDimethylaniline N-oxideBenzoyl peroxide

The invention relates to an anti-fog film material and a preparation method thereof. The above-mentioned anti-fog film material is made of the following components by weight: 68-85 parts of ethyl acetate, 8-11 parts of cellulose acetate butyrate, 0.5-2 parts of benzoyl oxide, 0.5-1.5 parts of copper sulfate pentahydrate, 0.1-0.4 parts of sodium zirconate, 0.02-0.8 parts of boron trifluoride-dimethylaniline, and 0.02-0.5 parts of cobalt oxide. The invention also provides a preparation method of the above-mentioned anti-fog film material.

Owner:YANCHENG FENGYING PLASTIC PROD CO LTD

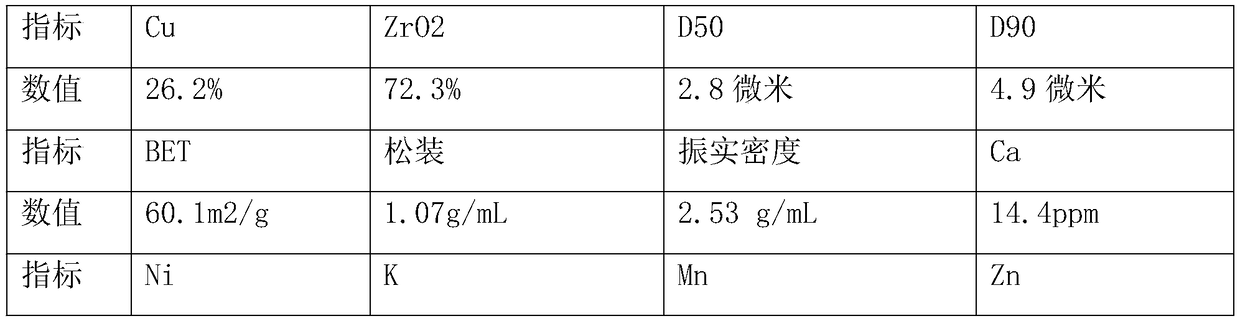

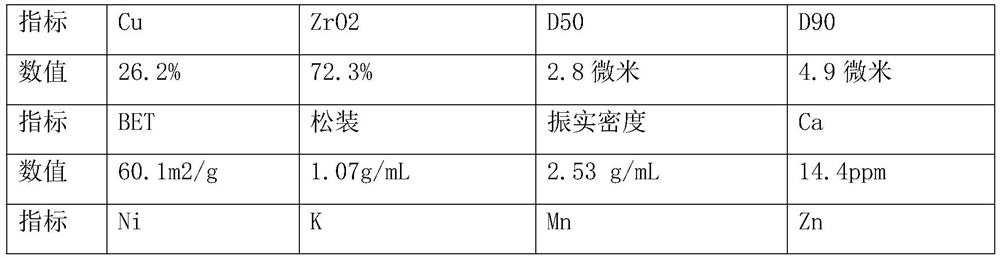

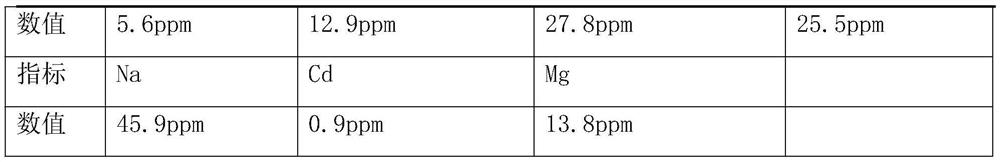

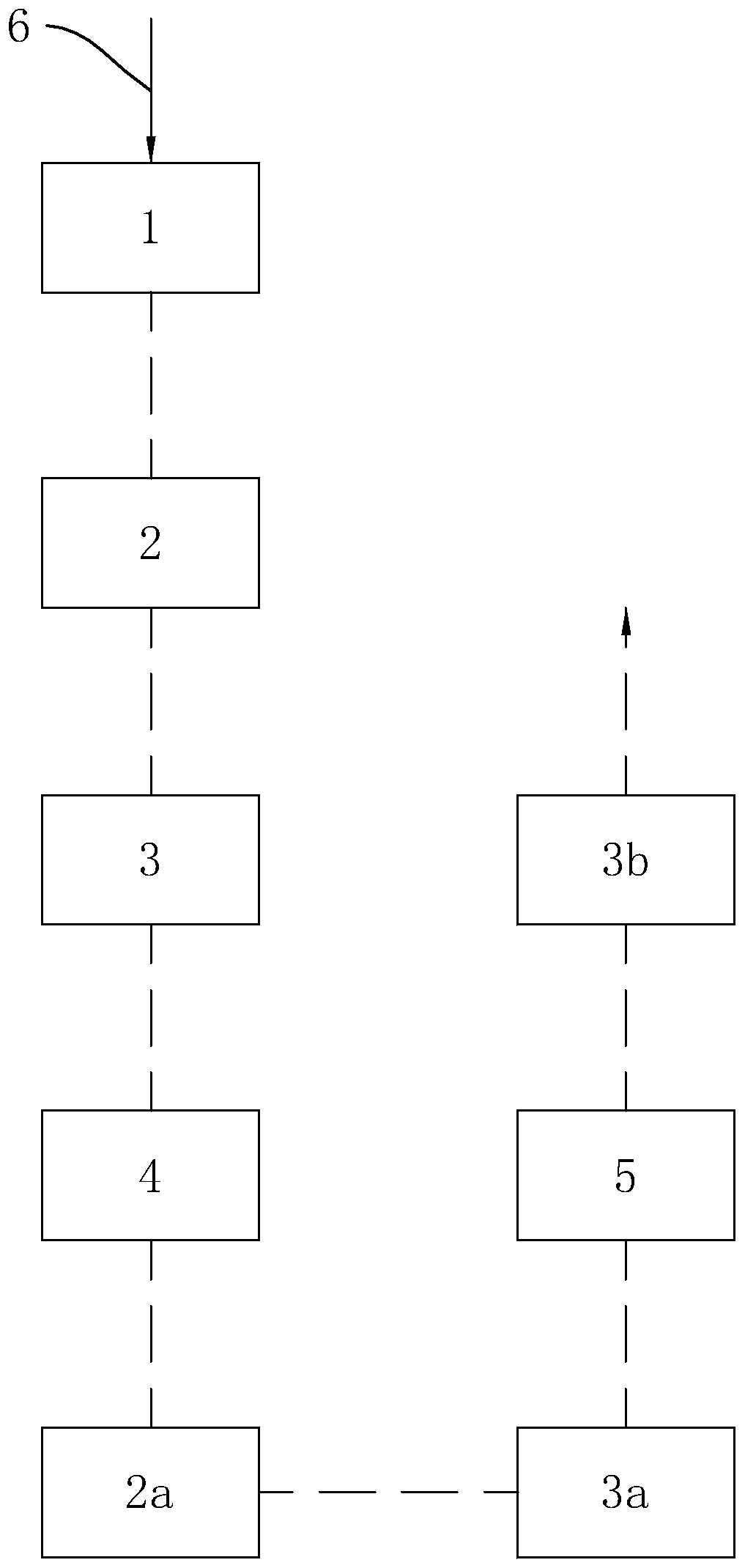

Method for preparing high-activity copper zirconium catalyst by utilizing zirconium oxide ball milling chips

ActiveCN108636406ARealize resource utilizationIncrease added valueCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiltrationResource utilization

The invention discloses a method for preparing a high-activity copper zirconium catalyst by utilizing zirconium oxide ball milling chips. The method comprises the following steps: adding sodium hydroxide into the zirconium oxide ball milling chips, performing calcination, wherein calcination temperature is 385 DEG C and calcination time is 2.5 h, taking out a calcination product, adding hot pure water, performing washing, and performing filtration to obtain a sodium zirconate solution; introducing carbon dioxide into the sodium zirconate solution obtained in the step (1) until a pH of the solution is 7.85, performing filtration, performing washing, adding a copper acetate solution, performing slurrying, and performing spray drying on the slurry material to obtain dried powder; and puttingthe dried powder obtained in the step (2) into a hydrogen reduction furnace, performing reduction, wherein reduction temperature is 458 DEG C and reduction time is 1.95 h, performing gas flow crushingunder nitrogen protection, performing sieving, and performing vacuum packaging to obtain the copper zirconium catalyst. The method disclosed by the invention reduces costs, realizes resource utilization of waste; and the catalyst has stable components, a large specific surface area and strong catalytic activity.

Owner:方嘉城

Antifogging film material and preparation method thereof

ActiveCN104893430AGood film formingImprove high temperature resistanceCoatingsDimethylaniline N-oxideBoron trifluoride

The invention relates to an antifogging film material and a preparation method thereof. The antifogging film material is prepared from the following components in parts by weight: 68-85 parts of ethyl acetate, 8-11 parts of cellulose acetate butyrate, 0.5-2 parts of benzoperoxide, 0.5-1.5 parts of blue copperas, 0.1-0.4 part of sodium zirconate, 0.02-0.8 part of boron trifluoride-dimethylaniline and 0.02-0.5 part of cobalt oxide. The invention also relates to a preparation method of the antifogging film material.

Owner:YANCHENG FENGYING PLASTIC PROD CO LTD

Potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and its growth method

ActiveCN107268084BSmall sizeReduce crackingPolycrystalline material growthFrom frozen solutionsCrucibleZirconate

The invention relates to a potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal and a growing method thereof. The chemical formula of the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is (1-y)(KxNa(1-x))NbO(3-y)(Bi0.5Na0.5)ZrO3, wherein x is larger than or equal to 0.4 and smaller than or equal to 0.6, and y is larger than or equal to 0 and smaller than or equal to 0.1. According to the method, raw materials and a growth auxiliary are mixed and presintered, and the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal is obtained by growing with a Bridgman-Stockbarger method; the potassium sodium niobate-bismuth sodium zirconate lead-free piezoelectric single crystal growing with the Bridgman-Stockbarger method after addition of the growth auxiliary has the advantages that a nucleus is formed easily, the crystal size is larger (2-20 mm), fewer cracks are formed and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

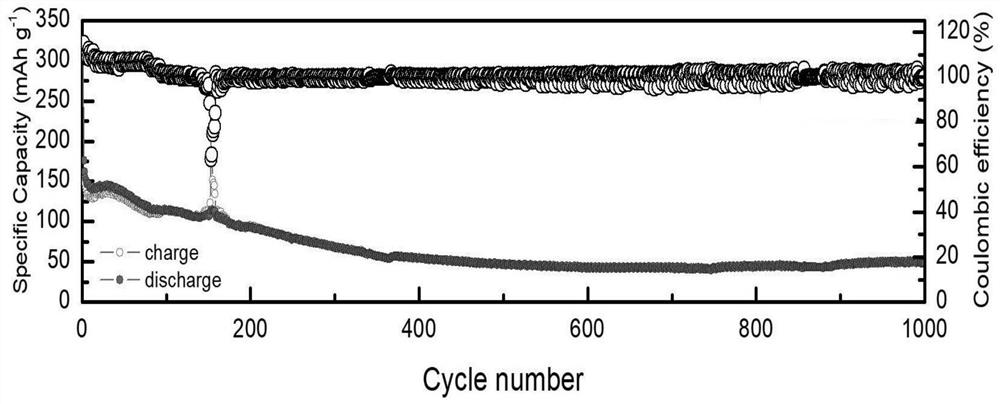

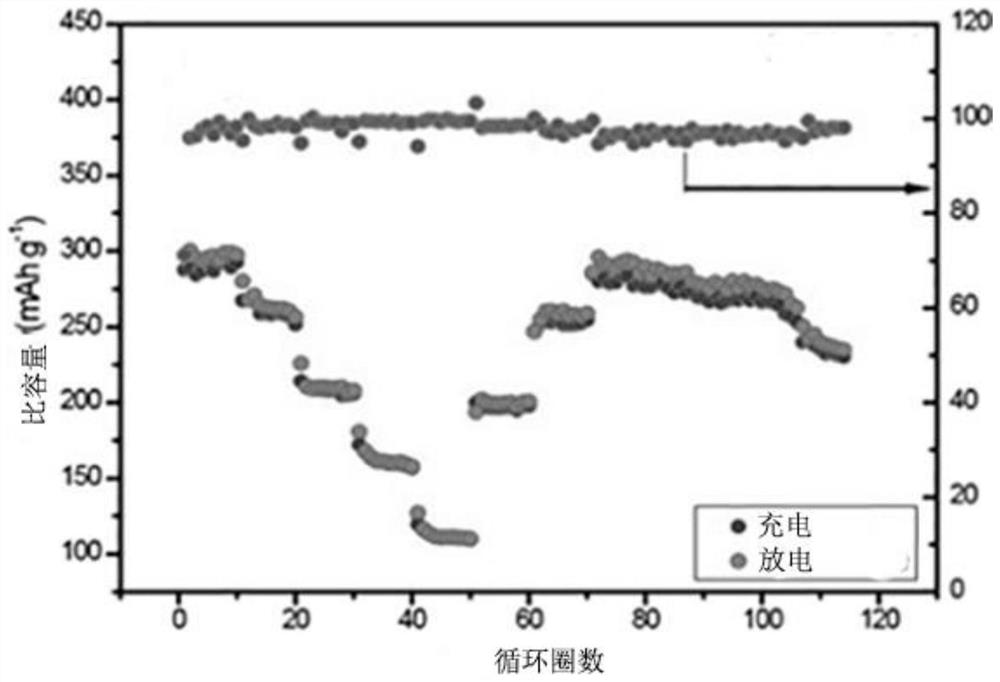

A kind of sodium ion solid-state battery and its preparation process

InactiveCN111969243BImproved magnification performanceImprove heat drying effectMaterial nanotechnologyFinal product manufactureSolid state electrolytePolyethylene terephthalate glycol

The invention relates to a sodium ion solid-state battery, which is composed of a battery shell, a current collector, a positive electrode material, a negative electrode material and a solid electrolyte. The negative electrode material is a metal sodium electrode, the positive electrode material is a metal sulfide material, and the solid electrolyte is a sodium salt metal oxide. Composite material, including the following components: 60-100 parts of phenolic resin, 80-100 parts of silica / silicon nanoparticles, 0.1-0.5 parts of N, B-doped graphite microparticles, 650-730 parts of sodium zirconate, niobium 1-3 parts of sodium, 2-5 parts of polyethylene terephthalate, 3-7 parts of azobenzene, silica / silicon particles provide a stable channel for ion transmission, which can improve its rate performance, The addition of azobenzene can enhance the interconnection between lattices and increase the diffusion and migration channels of sodium ions. The graphite microparticles are doped with N and B, and the doping of N and B elements makes the thermal dryness, lubricity and electrical conductivity of graphite. It is improved, thereby improving the cycle performance of the sodium-ion solid-state battery, which is beneficial to industrial production.

Owner:山西穿越光电科技有限责任公司

Kaolin-modified paint for hot-blast furnaces and preparation method thereof

InactiveCN106189824AImprove high temperature resistanceAccelerated corrosionFireproof paintsAnti-corrosive paintsFiberCarbon fibers

The invention discloses a kaolin-modified paint for hot-blast furnaces and a preparation method thereof. The preparation method comprises the following steps: 1) immersing river mud in acid liquor, filtering, and taking the filter cake to obtain modified river mud; 2) dispersing silica gel, sodium zirconate, rare-earth oxides and modified river mud in an organic solvent under ultrasonic conditions, filtering, and taking the filter cake to obtain an activated substance; and 3) carrying out contact reaction on organic silicon, an acrylonitrile-ethylene-styrene copolymer, maleic anhydride, an organic solvent, carbon fibers, kaolin, cyclodextrin and the activated substance under high-pressure closed conditions to obtain the kaolin-modified paint for hot-blast furnaces. The paint prepared by the method has excellent high temperature resistance and corrosion resistance, thereby prolonging the service life of the hot-blast furnace.

Owner:WUHU CHANGQI FURNACE

A method for preparing highly active copper-zirconium catalysts using zirconia ball grinding debris

ActiveCN108636406BRealize resource utilizationIncrease added valueCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEthylic acid

Owner:方嘉城

Anti-corrosion coating applied to hot-blast stove and preparation method of anti-corrosion coating

InactiveCN106118335AImprove high temperature resistanceAccelerated corrosionFireproof paintsAnti-corrosive paintsFiberCyclodextrin

The invention discloses an anti-corrosion coating applied to hot-blast stove and a preparation method of the anti-corrosion coating. The preparation method comprises: (1), placing canal mud in acid liquid to soak, filtering, and taking out a filter cake to prepare modified cannal mud; (2), dispersing silica gel, sodium zirconate, rare-earth oxide and modified canal mud in an organic solvent under an ultrasonic condition, performing filtration and taking a filter cake, thereby obtaining activators; and (3), performing contact reactions on the organic silicon, acrylonitrile-butadiene-styrol copolymer, phthalic anhydride, organic solvent, carbon fiber, expanded vermiculite, cyclodextrin and the activators under high-pressure and sealing conditions, thereby preparing the anti-corrosion coating applied to the hot-blast stove. The coating prepared by the method has excellent high-temperature resistance and high-corrosion resistance, thereby improving the service life of the hot-blast stove.

Owner:WUHU CHANGQI FURNACE

High-temperature resistant paint for hot-blast stoves and preparation method of high-temperature resistant paint

InactiveCN106189437AImprove high temperature resistanceAccelerated corrosionFireproof paintsAnti-corrosive paintsFiberCarbon fibers

The invention discloses high-temperature resistant paint for hot-blast stoves and a preparation method of the high-temperature resistant paint. The preparation method includes 1), soaking river mud in acid liquor, and picking filter cakes after filtration to obtain the modified river mud; 2), dispersing silica gel, sodium zirconate, rare earth oxide and the modified river mud in organic solvent ultrasonically, and picking filter cakes after filtration to obtain an activator; 3), allowing contact reaction among organosilicone, acrylonitrile-butadiene-styrol copolymers, maleic anhydride, organic solvent, carbon fibers, kieselguhr, cyclodextrin and the activator under a high-pressure closed condition to obtain the high-temperature resistant paint for the hot-blast stoves. The high-temperature resistant paint prepared according to the method has excellent high-temperature and corrosion resistance performance, so that service life of the hot-blast stoves can be prolonged.

Owner:WUHU CHANGQI FURNACE

Preparation method of vitrification agent and vitrification liquid and vitrification process

ActiveCN108754471BImprove corrosion resistanceImprove rust resistanceMetallic material coating processesMetal coatingNano silicon

The invention relates to pretreatment before metal coating, discloses a pottery agent, a preparation method thereof and a pottery process, and solves the problem of fast easy re-rusting time caused byweak corrosion resistance of pottery films obtained by a traditional pottery process. The pottery agent comprises the following components in parts by mass: 5-10 parts of sodium hexafluorozirconate,3-5 parts of potassium fluotitanate, 5-10 parts of silane coupling agent, 5-8 parts of tartaric acid, 62-77 parts of de-ionized water, and 10-15 parts of nanometer silicon powder. Water and an adjusting agent are added in the pottery agent for dilution to prepare pottery liquid; metal workpieces are conveyed by a conveying lifting frame to move through a phosphorus-free cleaning chamber, a first ultrasonic cleaning tank and a first water washing tank in sequence for cleaning and degreasing, are derusted and cleaned by an acid washing tank, a second water washing tank and a second ultrasonic cleaning tank, and enter a first pottery pool with the pottery liquid for pottery to form pottery films on the surfaces; and the obtained pottery films improve the corrosion resistance, and achieve excellent rust resistance.

Owner:厦门力九化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com