Novel special ceramic material and preparation method thereof

A special ceramic and a new type of technology, applied in the field of ceramic materials, can solve the problems of high processing cost, low product benefit, small heat resistance, etc., and achieve strong corrosion resistance and oxidation resistance, stable performance, and friction resistance The effect of ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

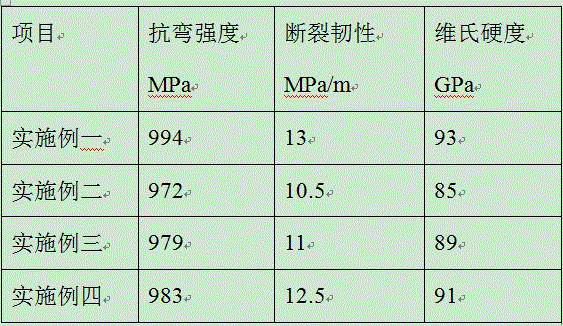

Examples

Embodiment 1

[0020] A new type of special ceramic material, the new type of special ceramic material is made of the following raw materials in parts by weight: 45 parts of red clay, 2 parts of albite, 6 parts of nano-scale aluminum oxide, 2 parts of nickel oxide, 2 parts of zinc oxide 6 parts, 6 parts of niobium pentoxide, 6 parts of boron nitride, 6 parts of wollastonite, 3.2 parts of sodium zirconate, 6.5 parts of additives; the components of the additives are calculated in parts by weight: nano silicon nitride 0.9 parts, 0.7 parts of nano-boron fiber, 0.65 parts of silane coupling agent kh-5500, 0.36 parts of polyethylene glycol, 23 parts of deionized water, 14 parts of kaolinite, and 6 parts of titanium dioxide.

[0021] In this example, the preparation method of the auxiliary agent is as follows: pulverize kaolinite, pass through a 40-mesh sieve to obtain kaolinite powder, add polyethylene glycol into deionized water, stir evenly, and sieve the Add kaolinite powder, stir for 20 minute...

Embodiment 2

[0027] A new type of special ceramic material, the new type of special ceramic material is made of the following raw materials in parts by weight: 40 parts of red clay, 1 part of albite, 5 parts of nano-scale aluminum oxide, 1 part of nickel oxide, 1 part of zinc oxide 5 parts, 5 parts of niobium pentoxide, 5 parts of boron nitride, 5 parts of wollastonite, 3 parts of sodium zirconate, 5 parts of additives, and the special additives are made of the following raw materials in parts by weight: nano silicon nitride 0.8 parts, 0.6 parts of nano-boron fiber, 0.6 parts of silane coupling agent kh-5500, 0.3 parts of polyethylene glycol, 20 parts of deionized water, 12 parts of kaolinite, and 5 parts of titanium dioxide.

[0028] In this example, the preparation method of the auxiliary agent is as follows: pulverize kaolinite, pass through a 40-mesh sieve to obtain kaolinite powder, add polyethylene glycol into deionized water, stir evenly, and sieve the Add kaolinite powder, stir for...

Embodiment 3

[0034] A new type of special ceramic material, the new type of special ceramic material is made of the following raw materials in parts by weight: 50 parts of red clay, 3 parts of albite, 7 parts of nano-scale aluminum oxide, 3 parts of nickel oxide, 3 parts of zinc oxide 7 parts, 7 parts of niobium pentoxide, 7 parts of boron nitride, 7 parts of wollastonite, 4 parts of sodium zirconate, and 7 parts of additives; the special additives are made of the following raw materials in parts by weight: nano silicon nitride 1.2 parts, 0.9 parts of nano-boron fiber, 0.8 parts of silane coupling agent kh-5500, 0.4 parts of polyethylene glycol, 25 parts of deionized water, 17 parts of kaolinite, and 7 parts of titanium dioxide.

[0035] In this example, the preparation method of the auxiliary agent is as follows: pulverize kaolinite, pass through a 40-mesh sieve to obtain kaolinite powder, add polyethylene glycol into deionized water, stir evenly, and sieve the Add kaolinite powder, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com