Cement kiln co-treatment process for urban dried sludge

A drying sludge and co-processing technology, applied in water/sludge/sewage treatment, sludge treatment, incinerator, etc., can solve the problem that sludge cannot be sprayed into the decomposition furnace, etc., to achieve sufficient combustion and particle uniformity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

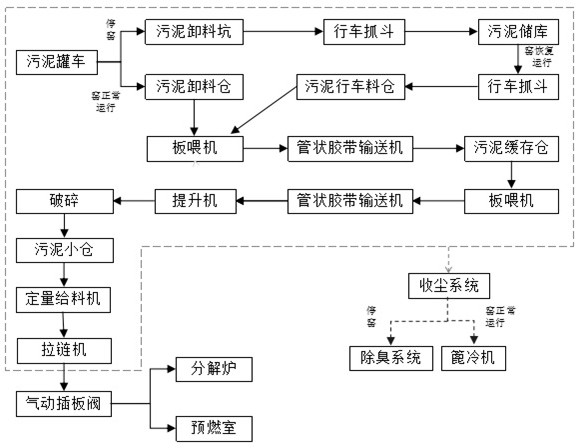

[0016] refer to figure 1 , the specific implementation mode adopts the following technical scheme: a kind of urban dry sludge cement kiln co-processing process, comprising the following steps:

[0017] 1. The sludge is transported to the unloading platform of the sludge disposal workshop with a closed sludge tanker, and the sludge truck is reversed into place. When the kiln is in normal operation, the sludge is directly unloaded to the sludge discharge bin; when the kiln is shut down for maintenance , the sludge is unloaded to the sludge discharge pit, and transported to the sludge storage by the driving grab bucket. After the kiln resumes operation, it is transported to the sludge truck silo by the driving grab bucket for processing;

[0018] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com