Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Weighing bottle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weighing bottles are glass laboratory equipment used for precise weighing of solids. Most of the glass used in the bottles is thin and fragile glass, but sometimes they are also made of ceramics or plastics.

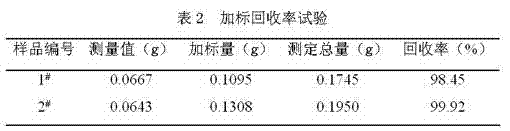

Rubber film separant

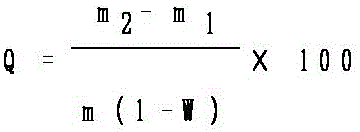

The invention provides a rubber film separant. The rubber film separant is prepared from raw materials in parts by weight as follows: 10-40 parts of calcium stearate, 20-50 parts of inorganic filler, 5-20 parts of a surfactant, 1-10 parts of inorganic gel, 1-10 parts of hydroxymethyl cellulose and 1-10 parts of a defoaming agent. The rubber film separant is white or off-white fine powder, the PH value of a 2% aqueous dispersion is 8-10, and the solid content is calculated in the following steps: a sample in the weight of 2 g (accurate to 0.01 g) is taken from a low weighing bottle with a decrement method, and the weighing bottle with the opening open is put into an oven at the temperature of 105 DEG C and baked for 2 h, then taken out, put into a dryer to be cooled for 30 min and then weighed. The percent of remaining of the rubber film separant is higher than 80%, the dispersity is good in cold water or hot water in the concentration being 2%-6% at the temperature of 10-90 DEG C, the rubber film separant does not settle after being dissolved or diluted in water, no cakes are left on the surface of a rubber film, so that smooth progressing of following compositing is guaranteed, and the rubber film separant which guarantees non-viscosity and increases the cooling and drying speed of the rubber film can uniformly cover the surface of the rubber film.

Owner:NANTONG XINBANG CHEM

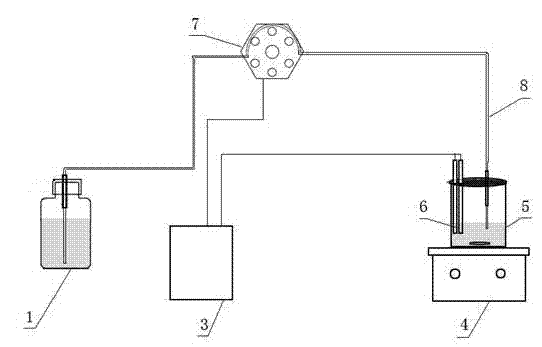

Peristaltic pump type weighing titrator and titration method thereof

InactiveCN102507856AIncrease dosageReduce wasteChemical analysis using titrationElectrode potentialPeristaltic pump

The invention discloses an analytical chemistry instrument, in particular to a peristaltic pump type weighing titrator and a titration method thereof. The titrator comprises a titration unit, a measure and control unit and a weighing bottle. The titration unit comprises a titration tank, a peristaltic pump and capillaries, and an inlet and an outlet of the peristaltic pump are respectively communicated with the weighing bottle and the titration tank through the capillaries. An electrode is installed in the titration tank, an electric signal input end of the measure and control unit is connected with the electrode in the titration tank, and a control output end of the measure and control unit is connected with the peristaltic pump. The peristaltic pump type weighing titrator drives titrating solution through the peristaltic pump, determines titration progress through changes of electrode potentials measured by the measure and control unit, controls the peristaltic pump, acquires mass of the titrating solution through a weighing method, and accordingly improves titration accuracy. Simultaneously, the peristaltic pump type weighing titrator is simple in structure, convenient to use and low in cost, and a titration pipeline is small in volume, so that washing is facilitated.

Owner:方原民

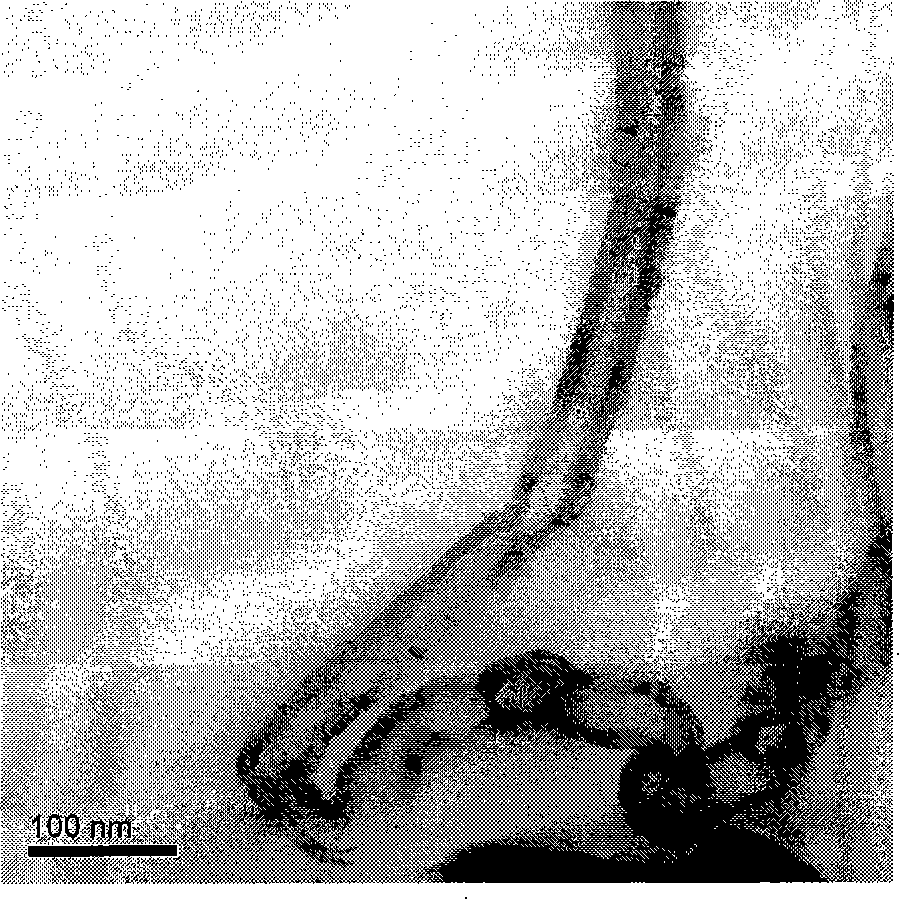

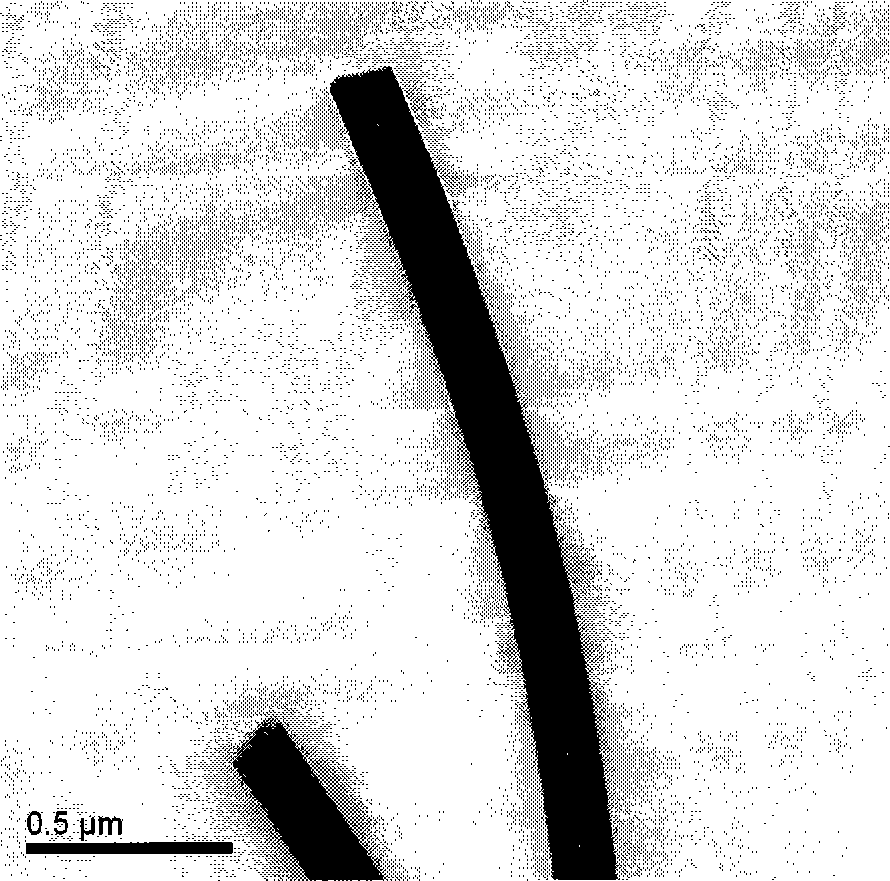

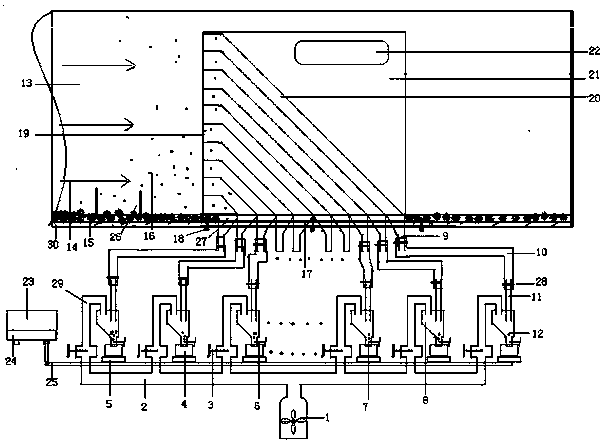

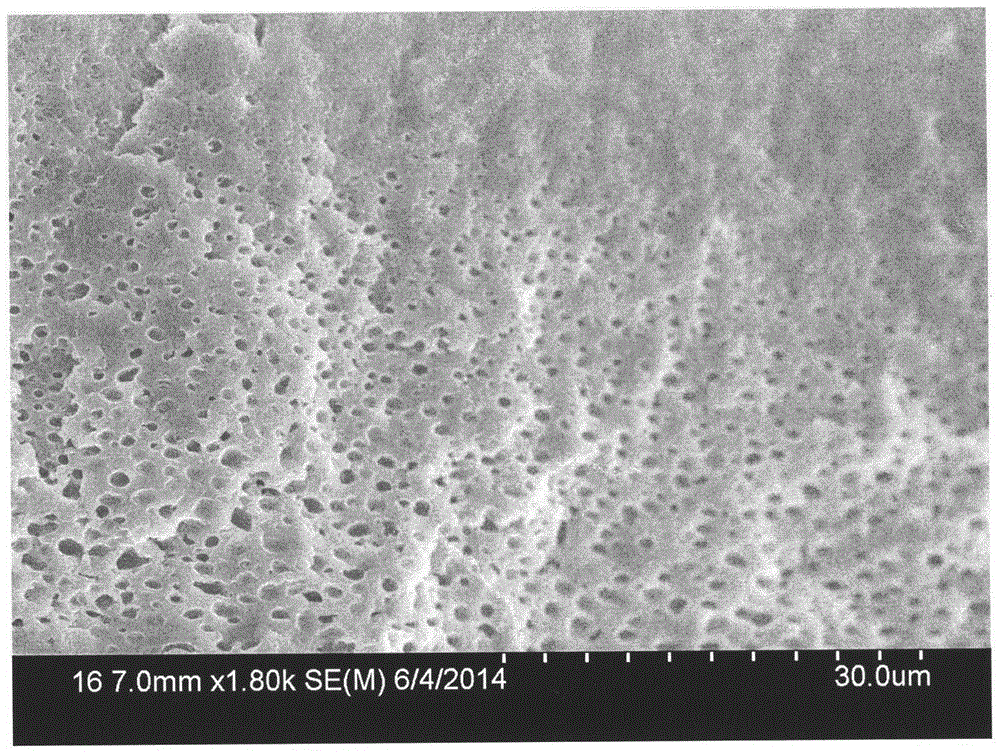

Production of nano-carbon tube

InactiveCN101244817AEasy post-processingSimple processNanostructure manufactureCarbon nanotubeWeighing bottle

The invention belongs to the technical field of the nanometer material preparation, particularly related to the preparation method of a carbon nano-tube (CNT), comprising the following steps: dissolve the complex block ferrocene of 0.002g / mL to 0.04g / mL into the xylene; put the solution into the quartz weighing bottle and put the weighing bottle into the hydrothermal reactor; put the reactor into a box resistor-stove to be heated to 600 DEG C to 800 DEG C for 12 to 18 minutes to get black product, which is carbon nano-tube (CNT). The preparation method of the carbon nano-tube (CNT) has the advantages of simple technology, easy operation in the whole preparation process, easy controlling condition and convenient post treatment, thus applicable to mass production. The material of the preparation method of the carbon nano-tube (CNT) is easy to get, without need of any special addition agent or catalyst, thus characterized in economic and low cost. The preparation method of the carbon nano-tube (CNT) does not produce by-product which pollutes the environment during preparation, meeting the demand of sustainable development, thus being an environment-friendly synthesis craft.

Owner:TONGJI UNIV

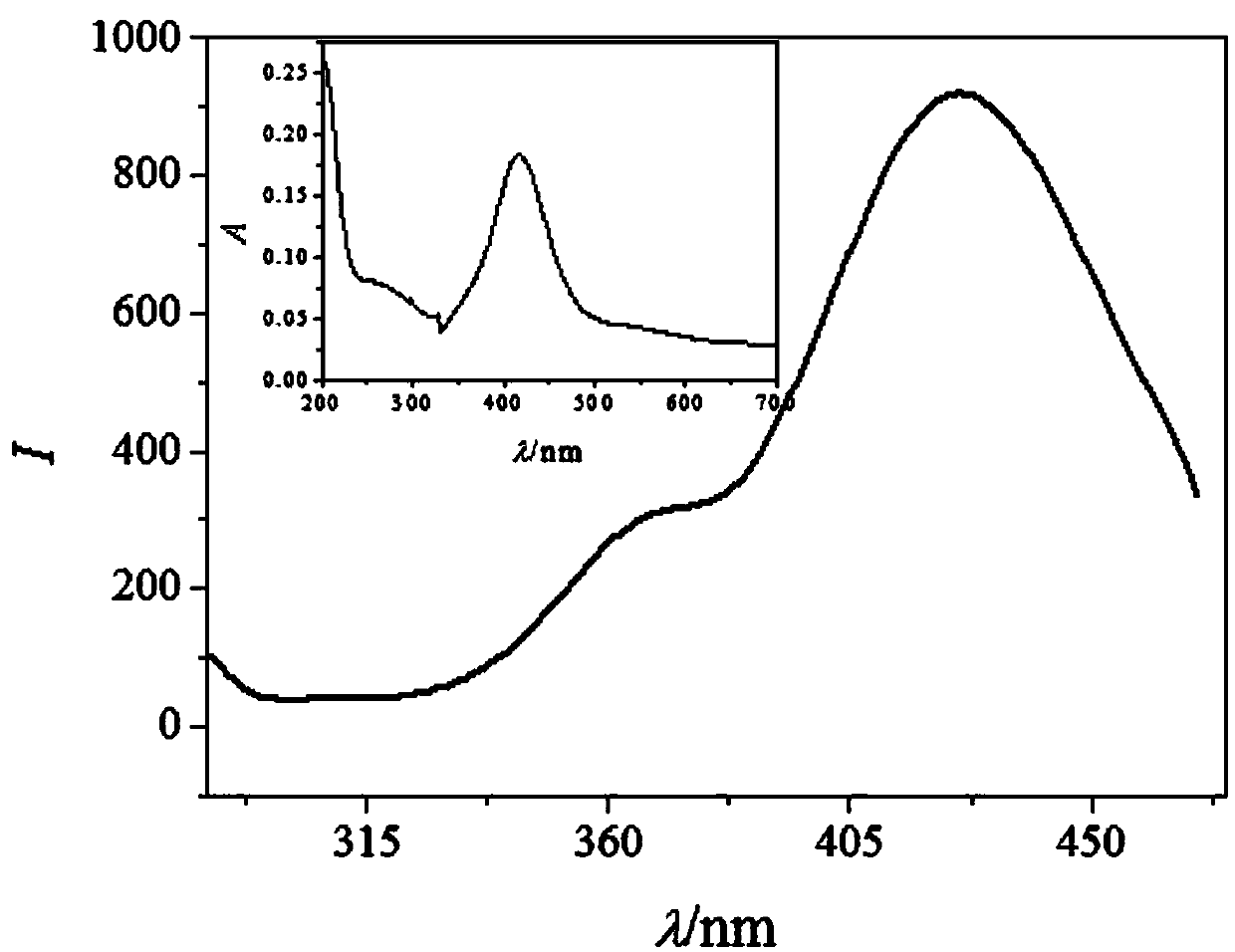

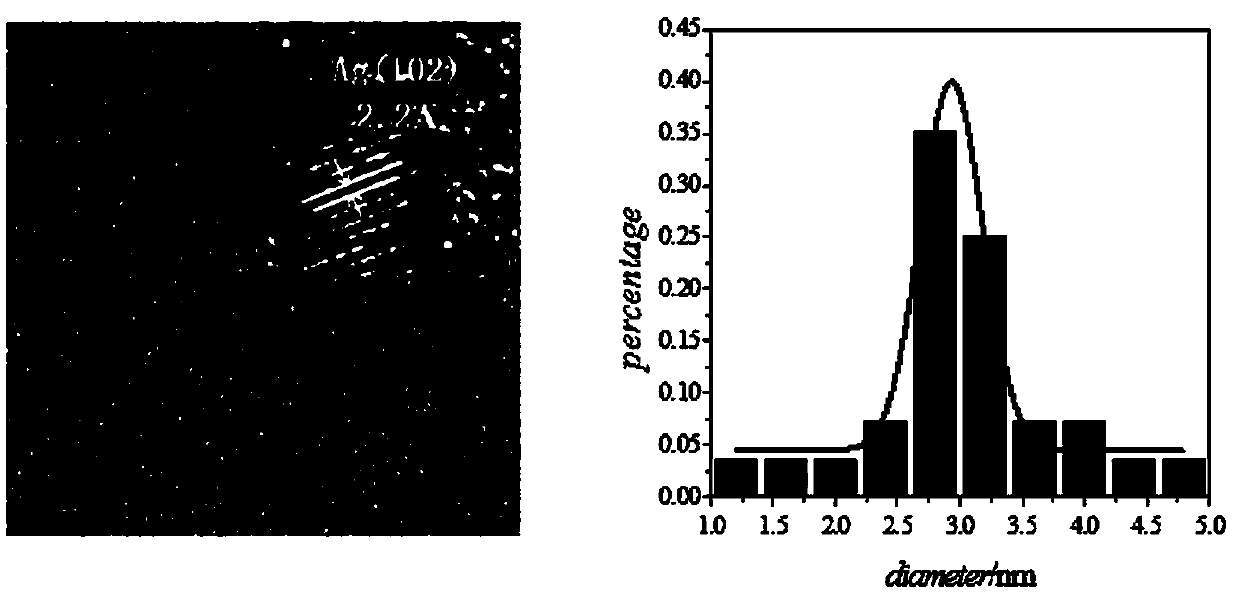

Method for restoring silver ammonia solution with ultraviolet light to prepare water-soluble silver nano-clusters

ActiveCN104174868ASimple reaction systemEasy to operateMaterial nanotechnologyFluorescenceUltraviolet lights

The invention provides a method for restoring a silver ammonia solution with ultraviolet light to prepare water-soluble silver nano-clusters. The method includes: adding an AgNO3 solution to a reaction vessel, slowly adding a NaOH solution to the vessel in oscillation, after sediment is generated, dropwise adding NH3.H2O to the vessel in oscillation till the sediment is fully dissolved, and adding redistilled water to prepare a silver ammonia stock solution with the concentration of 5.0*10<-3>M; dropwise adding carboxymethyl dextran to a weighing bottle, adding the silver ammonia stock solution in stirring, adding secondary water till volume of the solution reaches 5 to 10 times of that of the carboxymethyl dextran, stirring the solution with a magnetic stirrer for 5 to 10 minutes, and placing the solution in an exposure manner at the normal temperature under an ultraviolet lamp prior to stirring while light the solution for 2 to 4 hours. The carboxymethyl dextran is taken as a stabilizer and a reducing agent, and the water-soluble silver nano-clusters can be synthesized from the silver ammonia solution under irradiation of the ultraviolet light.

Owner:HUNAN UNIV OF SCI & TECH

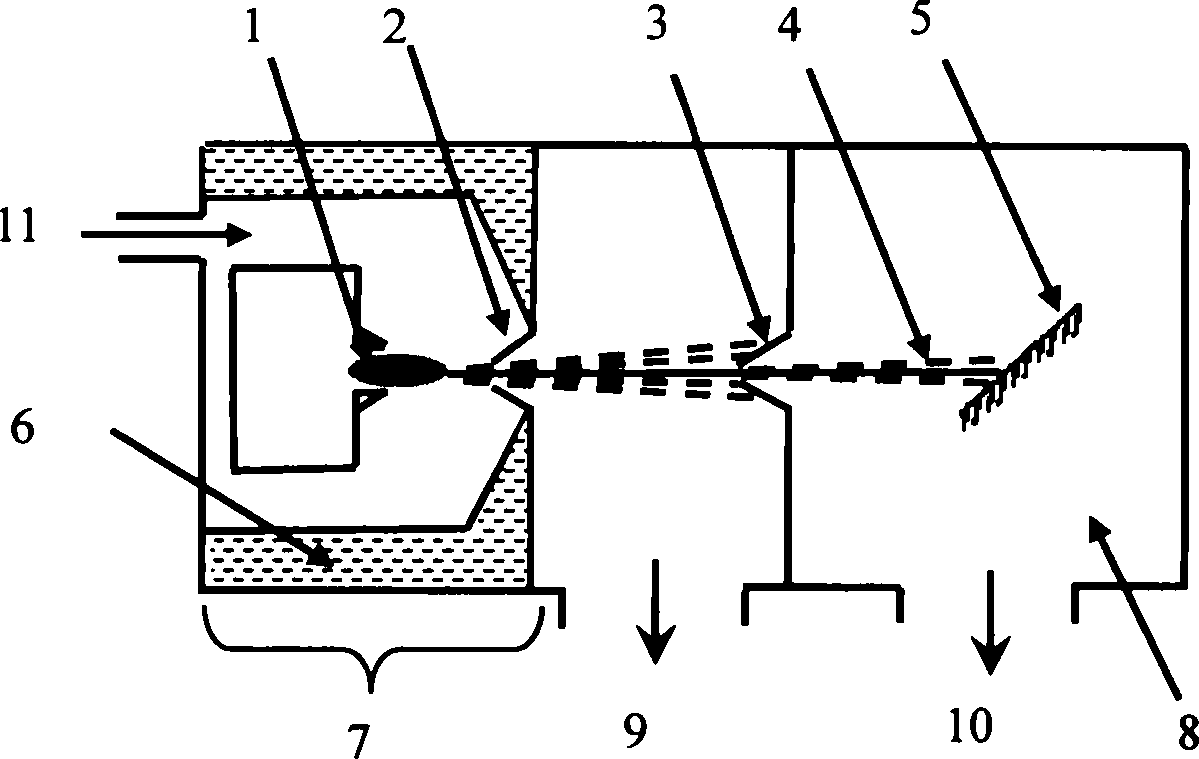

Method for preparing interval and configuration adjustable and controllable nano particle ordered array

InactiveCN1884042AOvercome the disadvantages of difficult regulationGood long-range orderNanostructure manufacturePolymer dissolutionEvaporation

The invention relates to preparation method of space and configuration-adjustable nano granule ordered array. The method comprises steps of dissolving block polymer in solvent, rotably coating the substrate(5) with solution, placing substrate in weighing bottle with toluene drop, sealing the bottle with aluminum foil or cotton cloth, and making ordered pattern template, fixing it on substrate, placing it in settling chamber (8), exhausting air to vacuum, filling inert gas into condense chamber (6). Atomizer (1) produce atom gas through magnetron sputtering or high temperature evaporation. The atom gas is condensed by inert gas to form into nano particle and form highly-oriented nano particle beam current (4) through spray nozzle . The nano particle beam current is deposited on template substrate. The deposit is stopped when covering rate is not more than 100%, thus linear nano particle array or two-dimensional ordered nano particle array is obtained. The invention has simple process, low cost, high efficiency, easy to achieve scaled production.

Owner:NANJING UNIV

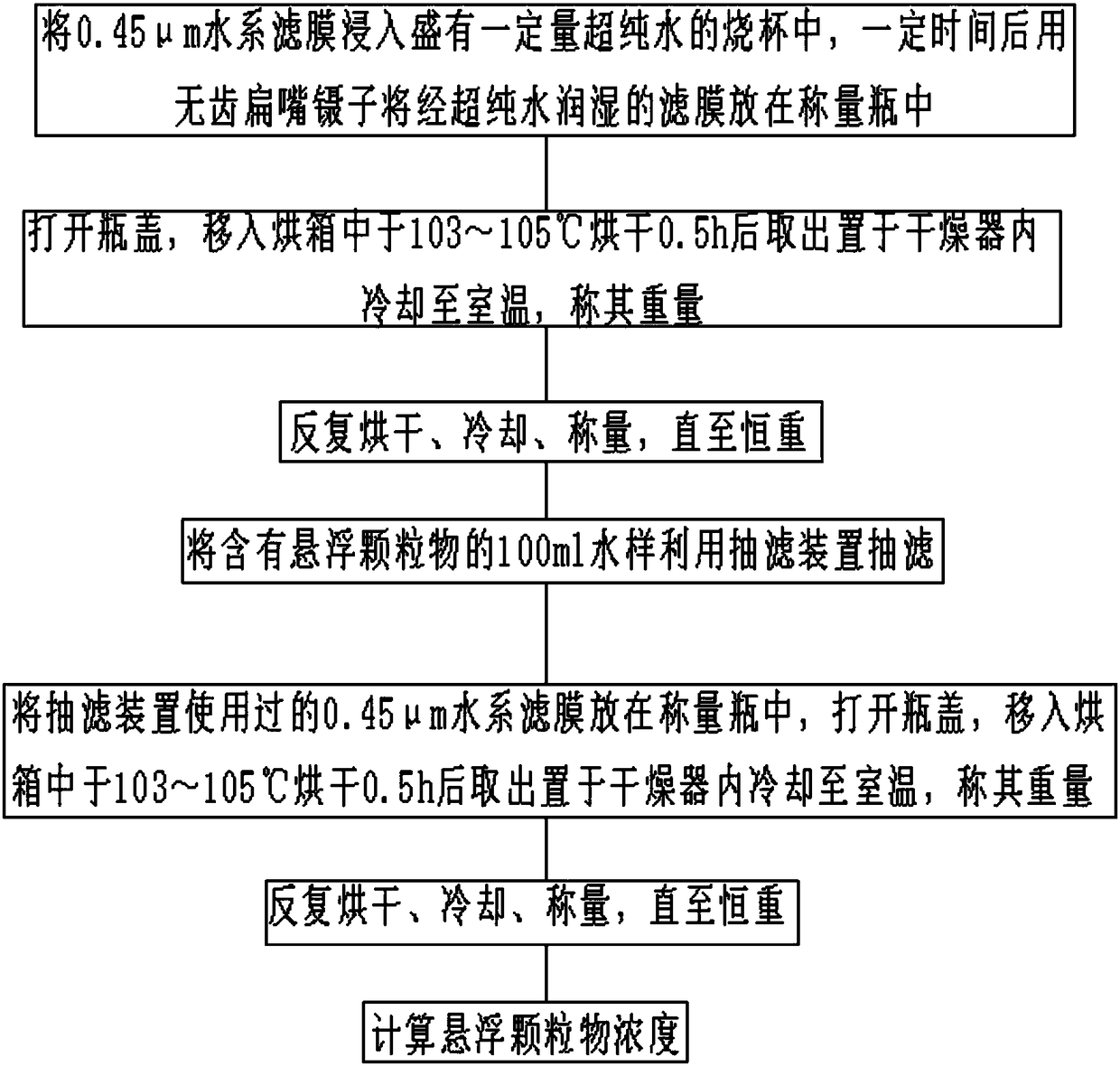

Filtering method for suspended matters in water

InactiveCN104155204AExtended drying timeReduce drying timesWeighing by absorbing componentFiltrationDrying time

Owner:广州衡创测试技术服务有限公司

Illegal cooking oil moisture detection method

InactiveCN108760562AImprove accuracyGood repeatabilityWeighing by removing componentOil and greaseRoom temperature

The invention provides an illegal cooking oil moisture detection method which comprises the following steps: putting an illegal cooking oil sample into a constant-weight weighing bottle, together witha flask filled with phosphorus pentoxide, putting into a vacuum drying tank, exhausting the air by controlling pressure to 300-400mmHg, heating to 60-65 DEG C, carrying out constant-temperature drying, introducing dry air after completing drying, taking out the weighing bottle after recovering the pressure in the vacuum drying tank to normal pressure, putting into a dryer, cooling to the room temperature, weighing, and repeating operation till the illegal cooking oil sample is constant in weight. By adopting the method, oxidation weight increase or thermal decomposition phenomenon of grease in the illegal cooking oil can be effectively avoided, deviation can be reduced, the accuracy of illegal cooking oil moisture content detection is high, the stability of the detection method can be achieved, the quality of the illegal cooking oil can be controlled or evaluated, and good application of the illegal cooking oil can be promoted.

Owner:海南澄迈神州车用沼气有限公司

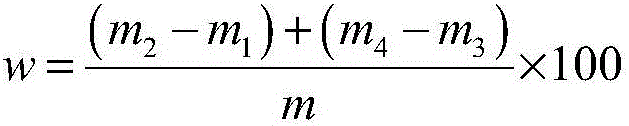

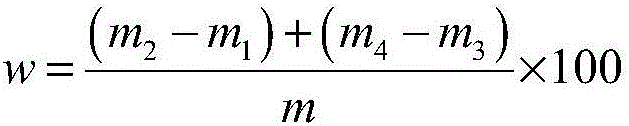

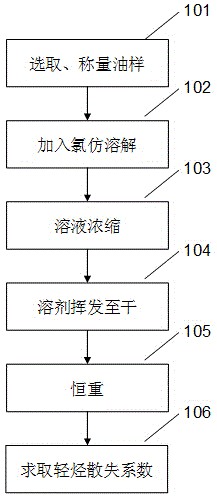

Method for testing content of oil sludge in phosphate fire-resistant oil

ActiveCN105891042ALow kinematic viscosityEasy to separateWeighing by removing componentCentrifugationOil sludge

The invention discloses a method for testing the content of oil sludge in phosphate fire-resistant oil. The method includes the following steps that 20 g of the to-be-tested phosphate fire-resistant oil is added into a constant-weight centrifugal tube, n-pentane is added into the centrifugal tube, an opening of the centrifugal tube is plugged through a first plug, and then the material is mixed to be uniform; 50 mL of n-pentane is added into the centrifugal tube, after a second plug is plugged into the opening of the centrifugal tube, shaking is conducted, the centrifugal tube is put in a centrifuge for centrifugation, and after centrifugation, an upper solution of liquid in the centrifugal tube is poured into filter paper for filtering; the liquid in the centrifugal tube is put in a flask; the filter paper is washed with petroleum ether till no oil sample trace exists on the filter paper, and then the filter paper is put in a weighing bottle; the flask and the weighing bottle are dried and then cooled, the cooled flask and the cooled weighing bottle are weighed, and the content w of the oil sludge in the to-be-tested phosphate fire-resistant oil is obtained. The content of the oil sludge in the phosphate fire-resistant oil can be accurately tested.

Owner:XIAN THERMAL POWER RES INST CO LTD

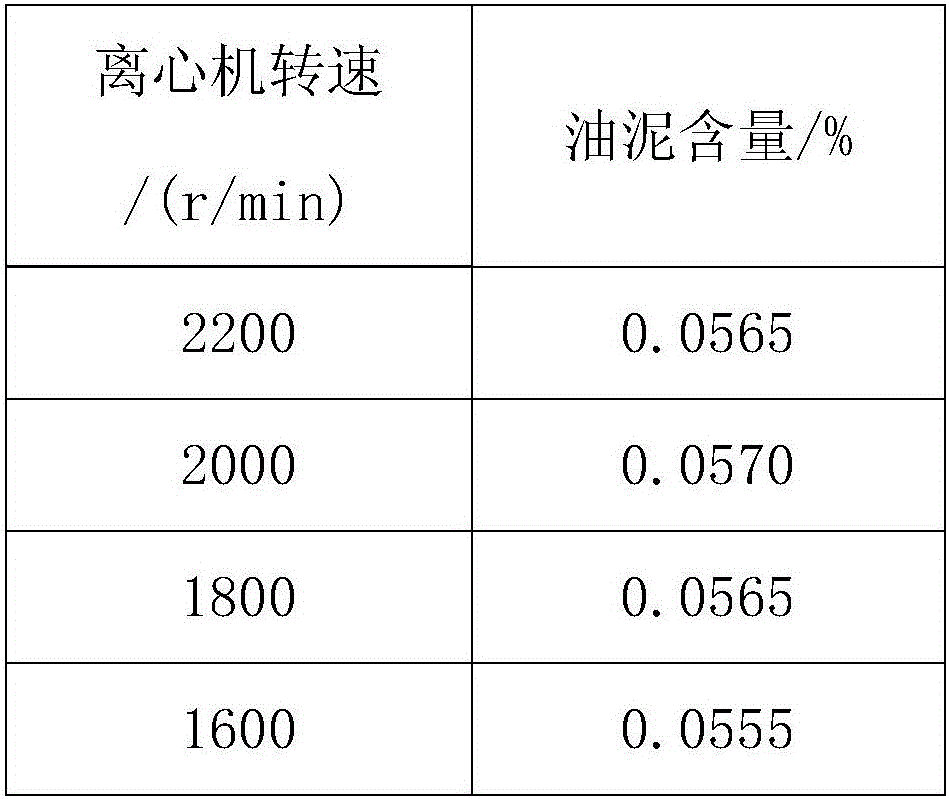

Method for evaluating occluded hydrocarbon content of shale with chloroform bitumen A

The invention provides a method for evaluating the content of retained hydrocarbons in shale by using chloroform bitumen A. The method comprises: step 1, selecting and weighing a crude oil sample of a certain quality; step 2, adding chloroform to the crude oil sample and dissolving it into a mixed solution ; Step 3, concentrate the mixed solution in a distiller lower than or equal to 85°C; Step 4, transfer the concentrated solution to a weighing bottle with constant weight, and volatilize to dryness at a temperature less than or equal to 40°C ; Step 5, carry out the constant weight of the volatilized crude oil that is contained in the weighing bottle; The amount of crude oil taken above is its light hydrocarbon loss coefficient. The method of using chloroform bitumen A to evaluate the content of retained hydrocarbons in shale can conveniently and quickly express the loss of light hydrocarbons in shale with chloroform bitumen A in shale with similar organic parent material and similar evolution degree, and quantitatively describe the content of retained hydrocarbons in shale.

Owner:CHINA PETROLEUM & CHEM CORP +1

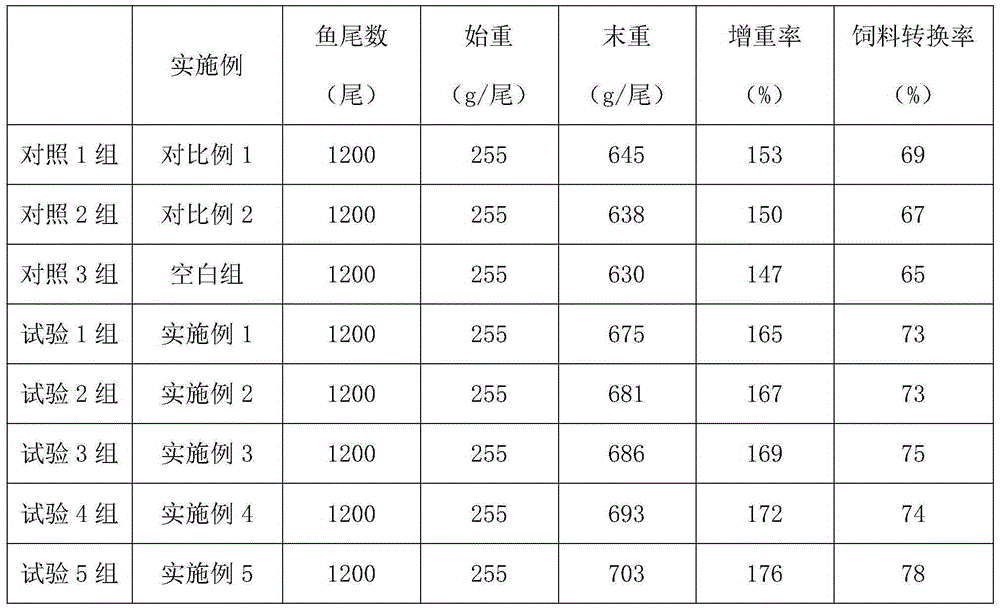

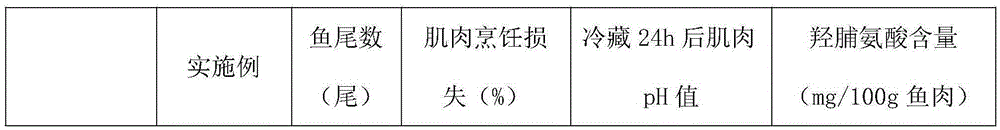

Additive capable of improving fish meat quality as well as preparation method and application of additive

ActiveCN105231098AImprove utilization efficiencyHigh in calciumFood processingAnimal feeding stuffBottle gourdFodder

The invention discloses an additive capable of improving fish meat quality as well as a preparation method and application of the additive. The additive consists of the following raw materials in parts by weight: 1-5 parts of bottle gourd peel, 3-8 parts of haws, 13-18 parts of lotus leaves, and 5-10 parts of glycerine. The preparation method comprises the following steps of weighing the bottle gourd peel, the haws and the lotus leaves, soaking the weighed bottle gourd peel, the weighed haws and the weighed lotus leaves with an ethanol solution so as to obtain a mixture A, wherein the soaking time is 5-6 hours; boiling over the mixture A, decocting the boiled mixture A for 3.5-4 hours, and adding water which is 4-6 times as much as the total weight of the bottle gourd peel, the haws and the lotus leaves, decocting the water and the mixture A for 4-4.5 hours, and filtering the decocted mixture A so as to obtain filtrate; adding the glycerine to the filtrate, decocting the filtrate and the glycerine once again until the water is drained in the boiling manner, and drying the decocted filtrate and the decocted glycerine in shade so as to obtain the additive. According to the additive as well as the preparation method and the application thereof, disclosed by the invention, the content of fish muscle calcium can be increased, the cooking loss of muscle is reduced, the chewy degree of fish meat is increased, the pH value of the muscle after being refrigerated for 24 hours is increased, and the mouth feel of the fish meat is improved; the growth and the development of fish can also be promoted, and the feed utilization efficiency is improved. The additive as well as the preparation method and the application thereof have the advantages that materials are wide to take; the additive is simple to prepare, convenient to use, low in cost, non-toxic and safe, and industrialized production is facilitated.

Owner:佛山百洋饲料有限公司

High-accuracy testing method of oil content of polyester staple fibers

InactiveCN105758762AAdd transfer stepsImprove the accuracy of oil content testWeighing by removing componentPolyesterFiber

The invention relates to a high-accuracy testing method of oil content of polyester staple fibers. The method is characterized in that with the adoption of an optimized extraction method, an extraction oil agent transferring step is added, an oil agent in a distillation flask in an original extraction method is transferred to a weighing bottle, drying and weighing are performed after evaporation in a water bath, the absolute dry weight of residues is calculated, and the influence of environmental temperature and humidity changes on the oil content testing result is reduced to the lower level. With the adoption of the transferring extraction method, the oil content of the polyester staple fibers can be accurately detected; compared with an original method, the testing accuracy of the method is greatly improved.

Owner:江阴市纤维检验所

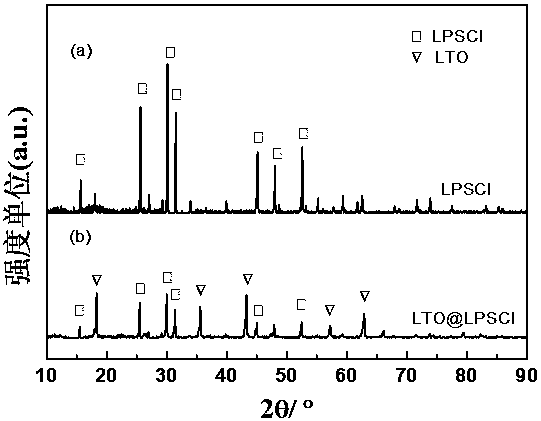

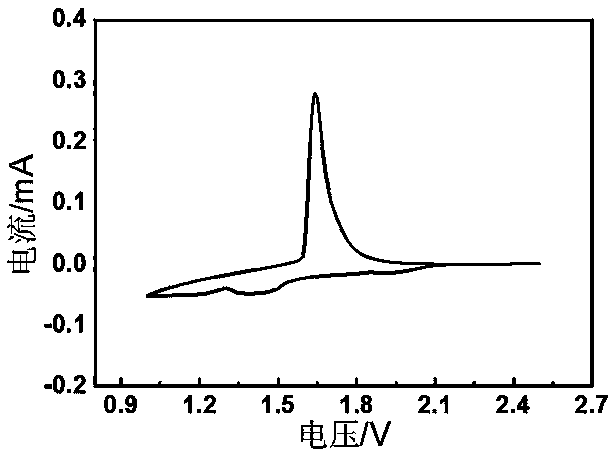

All-solid-state lithium battery composite positive electrode and preparation method thereof

InactiveCN107910523AEasy to prepareLow costElectrode rolling/calenderingSecondary cellsFiberArgon atmosphere

An all-solid-state lithium battery composite positive electrode and a preparation method thereof belong to the technical field of a lithium ion battery. The composite positive electrode is prepared from lithium titanate, vapor-phase growth carbon fiber VGCFs and a binary sulfide electrolyte LPSCI according to a mass ratio being (1-5):(1-5):1. The method comprises the following steps of (1) taking10-100mL of 200# gasoline in a weighting bottle, weighing and adding lithium titanate powder, VGCFs and the LPSCI electrolyte in an amount of 10-50g according to a mass ratio into the weighing bottle,and performing mixing and stirring for 12-24 hours; (2) drying the obtained mixed solution to obtain Li4Ti5O12 and Li6PS5Cl mixed powder, wherein the temperature is 50-100 DEG C, the time is 10-24 hours, and the drying atmosphere is argon atmosphere; and (3) pressing the obtained mixed powder to form a ceramic sheet per 1-30mg, thereby obtaining the composite positive electrode, wherein the pressing pressure is 100-550MPa, and the pressing time is 1-60 minutes. The preparation method has the advantages of simplicity and low cost, and the obtained composite positive electrode material is relatively good in particle uniformity, relatively high in lithium ion conductivity and excellent in electrochemical performance.

Owner:HARBIN INST OF TECH

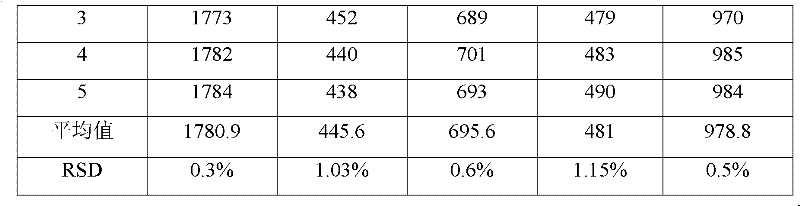

Liquid chromatography method for purity of rubber vulcanization accelerator MBT

The invention discloses a liquid chromatography method for purity of a rubber vulcanization accelerator MBT. The method comprises the following processes: using a high-angle weighing bottle to weigh 10 to 100 milligrams of an MBT sample, adding 5 to 200 milliliters of 95 to 99 percent alcohol solution into the MBT sample, putting the mixture into an ultrasound cleaner and oscillating the mixture for 2 to 20 minutes, then taking the mixture out and transferring the mixture to a volumetric flask of 100 to 1,000 milliliters, using 95 to 99 percent alcohol to dilute the mixture to the scale, and shaking up and filtering the mixture; and keeping the mixture for 20 to 30 DEG C at room temperature, then injecting 10 to 50 mu l of sample into liquid chromatography by using a trace sample injector, and obtaining the purity of the sample MBT after 30 minutes, wherein the liquid chromatography is a VWD detector, the model of a chromatographic column is EXTEND-C18, the liquid chromatography uses water and methanol as flow phases, the flow rate is 0.5 to 5.0 milliliters per minute, the wavelength of the VWD detector is 100 to 400 nanometers, and the precision is + / -0.2 percent. The method has the advantages of simple process, high analysis result accuracy and small error.

Owner:KEMAI CHEM

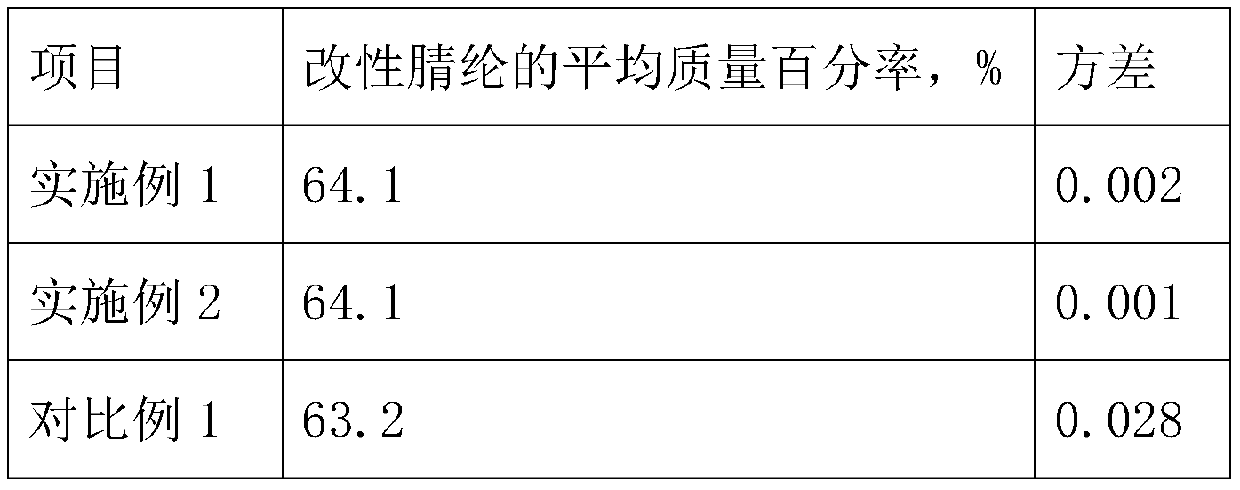

Method for measuring modified acrylic and acrylic blended fabric fiber contents

The invention discloses a method for measuring modified acrylic and acrylic blended fabric fiber contents. The method comprises the following steps of (1) taking all samples, then splitting the samples into a yarn shape, placing in a weighing bottle, drying and cooling, and then weighing to obtain dry mass m0 of the samples; (2) putting the weighed samples into a conical flask, adding a solution,plugging a glass stopper, shaking the flask to fully wet the samples, placing the flask in a constant temperature oscillating water bath kettle, and carrying out continuous violent oscillation; (3) pouring the dissolved samples into a glass sand core crucible, carrying out vacuum suction and liquid drainage, cleaning and then carrying out vacuum suction, finally, drying the crucible and residues,cooling, and weighing to obtain the mass m1 of the residues, and calculating and acquiring a mass percentage P of modified acrylic fibers, wherein the P satisfies the following formula: P=100%-m1*d*100% / m0. By using the method for measuring the modified acrylic and acrylic blended fabric fiber contents, the measuring method is rapid and convenient, cost is low and a measured result is real and accurate.

Owner:莱茵技术-商检(青岛)有限公司

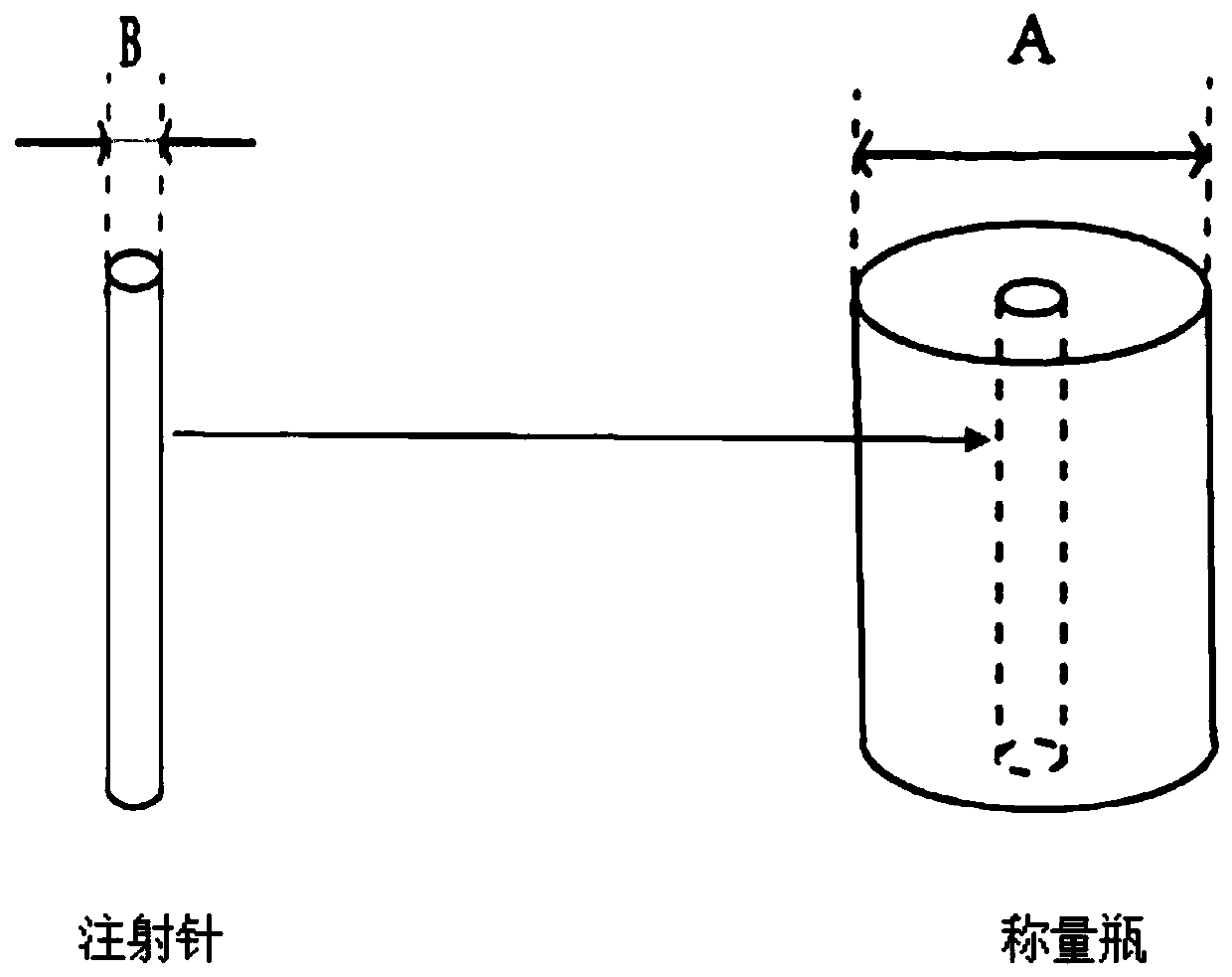

Micro flow and ultrafine flow measuring device and method

InactiveCN110057417AImprove accuracyStable flowStationary measuring chambersEngineeringHigh pressure

Owner:SHANGHAI WUFENG SCI INSTR

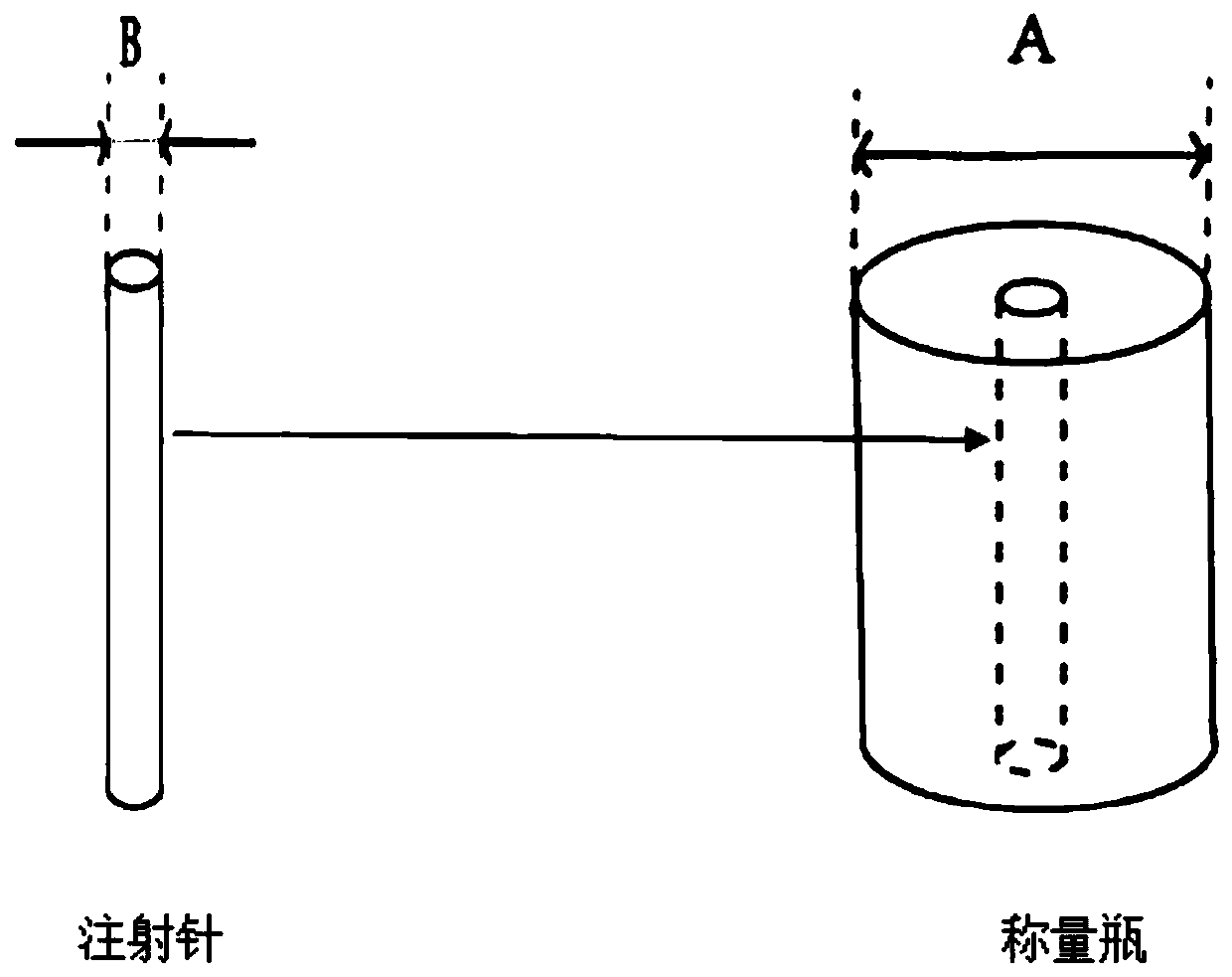

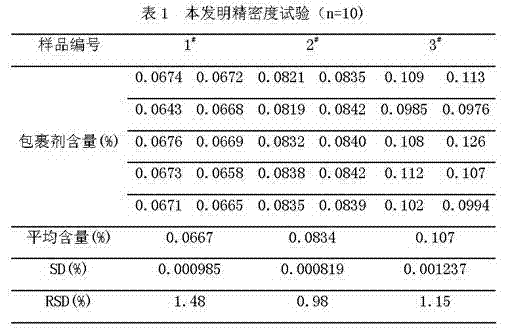

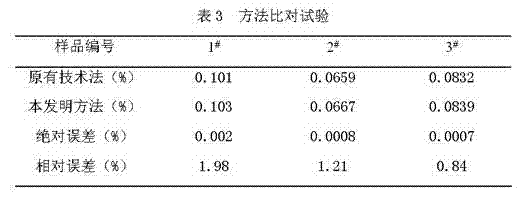

Measuring method for encapsulating agent in porous granular ammonium nitrate

ActiveCN102759490AImplement batch processingDetection speedWeighing by removing componentBatch processingOil water

A measuring method for an encapsulating agent in porous granular ammonium nitrate includes the steps as follows: dissolving a sample in water; still standing the solution and forming layered oil and water; abandoning the water layer; transferring the oil layer through acetone or cyclohexane into a constant-weight weighing bottle; volatilizing almost all the acetone or cyclohexane, and drying the weighing bottle to reach a constant weight; and calculating the mass percentage content of the encapsulating agent in the porous granular ammonium nitrate. The method provided by the invention is simple to operate, has a high detection speed, and realizes the batch processing of samples.

Owner:TIANJI COAL CHEM IND GROUP

Test method for physical property of viscose colourant

InactiveCN101587051AEasy to joinSatisfy filterabilityWeighing by removing componentPreparing sample for investigationColourantWeighing bottle

The invention discloses a test method for the physical property of a viscose colourant, comprising the following steps: calculating the percentage composition of the solid colourant; weighing a certain amount of the colourant and adding a certain volume of demineralized water, collocating the diluted colourant and homogeneously stirring and mixing the colourant for standby; putting a microporous filtering film in the weighing bottle and roasting with the weighing bottle in the oven until the weight is constant, and recording the weight of the microporous filtering film and then weighing the bottle; measuring the filtering time of the colour paste and calculating the percentage of the residue filtered by the colourant. The production of the coloured thread with good quality is guaranteed by using the present invention.

Owner:YIBIN HIEST FIBER +1

An uncertainty detecting method in heating loss measurement of dibasic lead phosphite

An uncertainty detecting method in heating loss measurement of dibasic lead phosphite is disclosed. The uncertainty detecting method includes: a first step of weighing 10 g of a dibasic lead phosphite sample to a constant-weight weighing bottle at 105-110 DEG C according to a heating loss method in HG / T 2339-2005 dibasic lead phosphite, transferring to a drying oven, opening a bottle cap, allowing the layer of the sample to be detected in the weighing bottle and a layer of a mercury bulb of a thermometer in the drying oven to be at the same horizontal plane and to have a transverse distance not more than 100 mm, maintaining the temperature at 105-110 DEG C for 1 h, closing the bottle cap, taking the weighing bottle out, putting into a dryer, cooling to room temperature, and weighing; a second step of determining a mathematical model to be detected; a third step of determining main sources of uncertainty; and a fourth step of determining values of components of the uncertainty.

Owner:PROD QUALITY SUPERVISING & INSPECTING INST OF TAIZHOU CITY

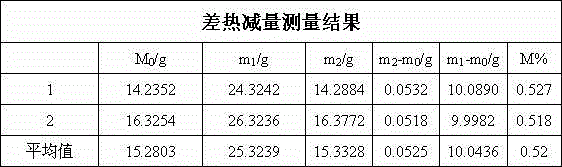

Air-exhaust-type wind-sand flow gradient high sand-collecting rate device for wind-sand environment wind tunnel

The invention relates to an air-exhaust-type wind-sand flow gradient high sand-collecting rate device for a wind-sand environment wind tunnel. The air-exhaust-type wind-sand flow gradient high sand-collecting rate device is characterized in that a sand dust gradient collector is provided with wind-sand flow sand inlets, gradient channels communicate with the wind-sand flow sand inlets, collector placing openings are connected with the gradient channels, air-exhaust connecting pipes are mounted on gradient leaking nozzles exposed out of the collector placing openings correspondingly, the gradient leaking nozzles are perpendicular to the bed surface downwards and are connected with the air-exhaust connecting pipes, the air-exhaust connecting pipes are connected with wind-sand flow air-exhaust branch pipes, wind-sand flow separating tanks of the respective channels sleeve outlets of the wind-sand flow air-exhaust branch pipes, the wind-sand flow separating tanks communicate with weighingbottles, high-precision weighing sensors are placed at the bottoms of the weighing bottles, and the sand delivery amounts in the weighing bottles are measured by the high-precision weighing sensors. According to the air-exhaust-type wind-sand flow gradient high sand-collecting rate device, the measured sand delivery amounts are precise and errorless, and data support is provided for disclosing thechange law that a wind-sand flow passes through a flow field and for researching the relation between the wind speed and a soil structure as well as the relation between the soil water content and soil wind erosion.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Method used for determining water content of capsule shell

InactiveCN104914002AIngenious and reasonable designEasy to operateWeighing by removing componentLoss rateSolvent

The invention discloses a method used for determining water content of capsule shell. The method comprises following steps: (1) substances in soft capsules is removed using a suction part so as to obtain soft capsule shell; (2) the soft capsule shell is cut open with a knife, and residue substances on the inner and the outer surfaces of the soft capsule shell are moved with a solvent; (3) precision weighing of a soft capsule shell sample with a certain weight is carried out, the soft capsule shell sample is delivered into a platode weighing bottle which is dried to constant weight, and then the platode weighing bottle together with the sample are dried to constant weight, and drying loss rate, i.e. water content of the soft capsule sample, is calculated according to drying loss and the weight of the soft capsule shell, wherein drying temperature is controlled to be 115 DEG C. According to the method, direct cutting of the soft capsule shell, which may lead to leakage of the substances in the soft capsule and sticking of the substances onto laboratory coat or arms of operators, in the prior art is abundant; the substances in the soft capsules is removed via suction firstly, and then water content of the capsule shell is determined; design is reasonable and artful, and simple and effective; operation is simple; working efficiency can be increased effectively; and rapid determination of water content of the capsule shell can be realized.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

Liquid chromatography method for purity of rubber vulcanization accelerator MBTS

The invention discloses a liquid chromatography method for purity of a rubber vulcanization accelerator MBTS. The method comprises the following processes: using a high-angle weighing bottle to weigh 10 to 100 milligrams of an MBTS sample, adding 5 to 200 milliliters of 95 to 99 percent trichloromethane into the MBT sample, putting the mixture into an ultrasound cleaner and oscillating the mixture for 2 to 20 minutes, then taking the mixture out and transferring the mixture to a volumetric flask of 100 to 1,000 milliliters, using the 95 to 99 percent trichloromethane to dilute the mixture to the scale, and shaking up and filtering the mixture; and keeping the mixture for 20 to 30 DEG C at room temperature, then injecting 10 to 50mu l of sample into liquid chromatography by using a trace sample injector, and obtaining the purity of the sample MBTS after 35 minutes, wherein the liquid chromatography is a VWD detector, the model of a chromatographic column is 20RBAXRX-C18, the liquid chromatography uses water and methanol as flow phases, the flow rate is 0.5 to 5.0 milliliters per minute, the wavelength of the VWD detector is 100 to 400 nanometers, and the precision is + / -0.2 percent. The method has the advantages of simple process, high analysis result accuracy and small error.

Owner:KEMAI CHEM

Multi-walled carbon nano-tube/polystyrene composite material film preparation method

The present invention relates to a method for preparing a polystyrene-multi-walled carbon nano-tube composite material through a solution blending aqueous solution film forming method. The preparation method comprises: 1, adding a certain amount of polystyrene, various functionalized multi-walled carbon nano-tubes and a surfactant triton into a weighing bottle filled with a certain amount of tetrahydrofuran, placing onto a magnetic roton stirrer, and carrying out mechanical stirring until the polystyrene is completely dissolved and the multi-walled carbon nano-tubes are uniformly dispersed; 2, carrying out an ultrasonic treatment, wherein the dissolved and dispersed composite material solution is subjected to an ultrasonic treatment for a certain time until the carbon nano-tubes are further completely and uniformly dispersed; and 3, forming a film, wherein the composite material solution is poured into a particular container to form a film, and after a certain time, the container is placed into deionized water to completely form the film. The method of the present invention has advantages of simple process, low energy consumption, high film forming efficiency, less pollution, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

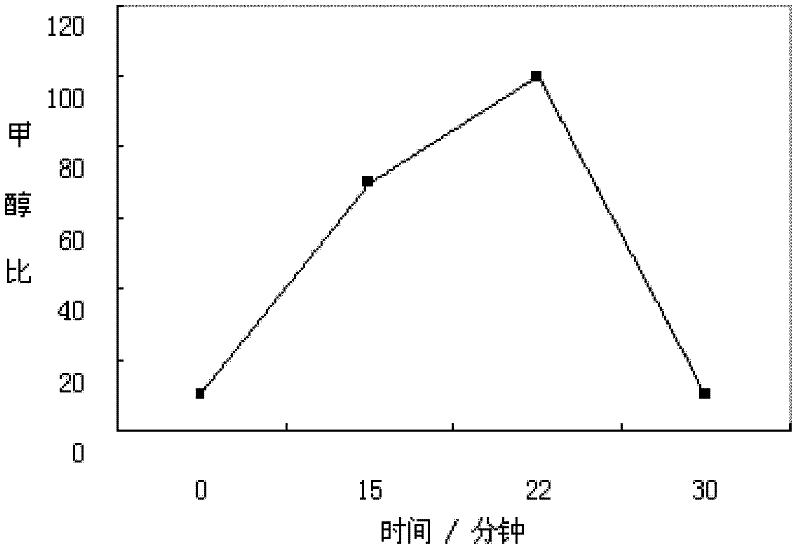

Liquid phase chromatography analysis method for active ingredient content of crude product M

InactiveCN102375036AEasy to operateImprove accuracyComponent separationMegasonic cleaningColumn temperature

The invention relates to a liquid phase chromatography analysis method for the active ingredient content of a crude product M. The method comprises the following steps of: weighing crude MBT (2-Mercaptobenzothiazole) with a weighing bottle, preparing a 0.1-0.5 mg / mL sample with a chromatographically pure methanol solution, and putting the sample into an ultrasonic cleaner for oscillating for 2-20 minutes; filtering the sample solution with 0.2 mum of filtering film before sampling; keeping the column temperature at 20-30 DEG C, wherein a liquid phase chromatogram is a VWD (Variable Wavelength Detector), the model of the chromatogram column is EXETEND-C18, and water and methanol are taken as a flowing phase of the liquid phase chromatogram; and injecting 5 mu l of sample into liquid phase chromatogram with a trace sampler, wherein the gradient process is that: when the sampling time is 0 minute, the ratio of water in the flowing phase is 90 percent while the ratio of methanol is 10 percent; when the sampling time is 15 minutes, the ratio of the water in the flowing phase is gradually decreased to 30 percent while the ratio of the methanol is 70 percent; when the sampling time is 22 minutes, the ratio of the water in the flowing phase is 0 percent while the ratio of the methanol is 100 percent; and when sampling time is 30 minutes, the ratio of the water in the flowing phase is increased gradually to 90 percent while the ratio of the methanol is 10 percent. Under the analyzing condition, each active ingredient can be effectively separated.

Owner:KEMAI CHEM

Method for improving determination efficiency of moisture content of coal

InactiveCN107764690ASolve problems that do not meet expectationsSimple stepsWeighing by removing componentAnalytical balanceRoom temperature

The invention discloses a method based on improving the measurement efficiency of moisture content in coal. A drying box, a drier, a glass weighing bottle and an analytical balance are selected; 1 ± 0.1g air-dried coal sample, spread it in a weighing bottle, open the weighing bottle cap, put it into a drying oven that has been heated to 105-110°C in advance, and keep the air blowing , dry the bituminous coal for 1 hour, and dry the anthracite for 1 to 1.5 hours. Put the weighing bottle containing the coal sample into the desiccator to cool to room temperature, and then weigh it; take the weighing bottle out of the drying box, and immediately cover it. After cooling to room temperature in a desiccator, weigh and carry out inspection drying, each time for 30 minutes, until the mass reduction of two consecutive dried coal samples does not exceed 0.001g or the mass increases; calculate the results. The method has simple and convenient steps, high efficiency and high detection accuracy, and can ensure that the coal achieves the expected target during subsequent use.

Owner:郭莉

Liquid chromatogram analysis method for rubber sulfuration accelerant MBTS

InactiveCN101464435AImprove accuracyEasy to operateComponent separationMethylene DichlorideUv detector

The invention discloses a liquid chromatographic method of a thiofide MBTS, which comprises the steps as follows: 10 to 100mg of MBTS samples are weighed with a high angle weighing bottle, and methylene dichloride of 5 to 200ml is added in, wherein, the concentration of methylene dichloride is 95 to 99 percent; the mixed liquid is put in a supersonic cleaner and is oscillated for 2 to 20 minutes, then is taken out and transferred to a volumetric flask whose volume capacity ranges from 100 to 1000ml, and is shook up and filtered after being diluted to reach the scale by using methylene dichloride whose concentration is 95 to 99 percent; and the room temperature is kept from 20 to 30 DEG C, a liquid chromatogram takes water and methanol as a mobile phase, the flow rate is 0.5 to 5.0ml / min, the wavelength of a UV detector ranges from 100 to 500nm, samples of 10 to 50 mul are injected to the liquid chromatogram through a trace sample injector, the purity quotient of the samples MBTS is obtained after 10 to 50 minutes, and the precision error is within 0.2 percent. The liquid chromatographic method has the advantages of simple process, high accuracy rate of analysis results and small errors.

Owner:KEMAI CHEM

Method for determining moisture of soft capsule rubber

InactiveCN104359788AIngenious and reasonable designEasy to operateWeighing by removing componentMedicineSolvent

The invention discloses a method for determining the moisture of soft capsule rubber. The method comprises the following steps: (1) extracting content in a rubber capsule by virtue of a suction element to obtain hollow soft capsule rubber; (2) splitting the soft capsule rubber by virtue of a knife, and wiping the residual content on the inner and outer surfaces by virtue of a solvent; and (3) precisely weighing a certain weight of rubber, putting into a flat weighing bottle with constant weight, drying until reaching constant weight, and calculating weight loss on drying of the rubber, namely the moisture of the soft capsule rubber, according to the reduced weight and the weight of the rubber before being dried. According to the method disclosed by the invention, the practice that the capsule rubber is directly cut off in the traditional method and the content in the capsule easily flows to and sticks to a laboratory coat or arms of an operator is abandoned; and the content is firstly extracted and then is subjected to rubber moisture determination, so that the method is reasonable and ingenious in design, simple, effective, and convenient to operate; and the work efficiency can be effectively improved, and thus the moisture content of the rubber is quickly determined.

Owner:JIANGSU ZODIAC MARINE BIOTECH

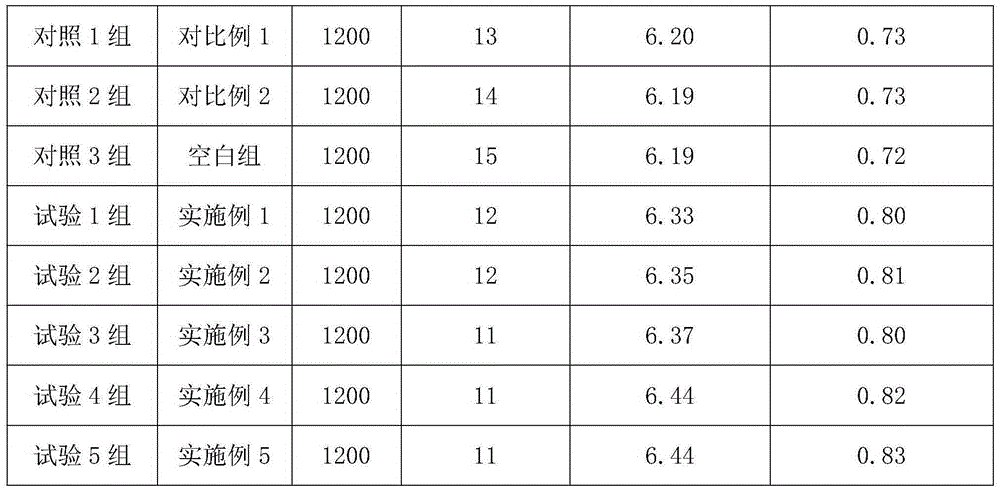

Method for measuring solid content of hydroxamic acid type polyacrylamide

InactiveCN102466602AQuickly measure the solid contentHigh measurement accuracyWeighing by removing componentMeasurement costHydroxamic acid

The invention discloses a method for measuring the solid content of hydroxamic acid type polyacrylamide. The method comprises the steps of: weighing Mg of a polymer test sample; drying under the condition of a certain temperature; taking out a weighing bottle and cooling to room temperature, wherein the weight is weighed to be m; calculating the solid content S according to M and m; and the like. The method disclosed by the invention can be used for rapidly measuring the solid content of the hydroxamic acid type polyacrylamide, has high measurement precision and simple measurement steps, is beneficial to reduction of the measurement cost and provides good data support for use of the hydroxamic acid type polyacrylamide.

Owner:袁俊海

Microflow and ultramicro flow determination device and method

Owner:SHANGHAI WUFENG SCI INSTR

Method for efficiently and accurately detecting content of silicon dioxide and aluminum oxide in glass

InactiveCN104280306ATo achieve the purpose of separate detectionImprove accuracyMaterial weighingHydrofluoric acidPlatinum

The invention discloses a method for efficiently and accurately detecting the content of silicon dioxide and aluminum oxide in glass. The method comprises the following steps: A, adding to-be-detected glass powder into a weighing bottle, and drying the glass powder in a drying box; B, weighing the same amount of dried glass powder into a group of platinum crucibles, adding diluted hydrochloric acid, heating till each solution is slightly boiling, filtering, firing each solution with filter paper until obtained residual filtrate reaches constant weight, weighing and recording the mass as m0; C, heating and leaching each residual filtrate with diluted hydrofluoric acid, filtering, firing each filtrate with filter paper until an obtained aluminum oxide residue reaches constant weight, weighing, recording the mass as m1, calculating the content of aluminum oxide according to the difference between m1 and the mass of each crucible, and taking the average value of the values obtained be measuring the samples of the platinum crucibles as the final content value of aluminum oxide; and D, taking the average value of the values obtained by measuring the samples of the platinum crucibles as the final content value of silicon oxide according to the difference between m0 and m1 weighed twice. According to the method disclosed by the invention, the relative deviation is small, and the detection result is real and reliable; and moreover, the reliability of the detection result obtained by the method disclosed by the invention is higher than that of a detection result obtained by a traditional method.

Owner:TUNGHSU GRP

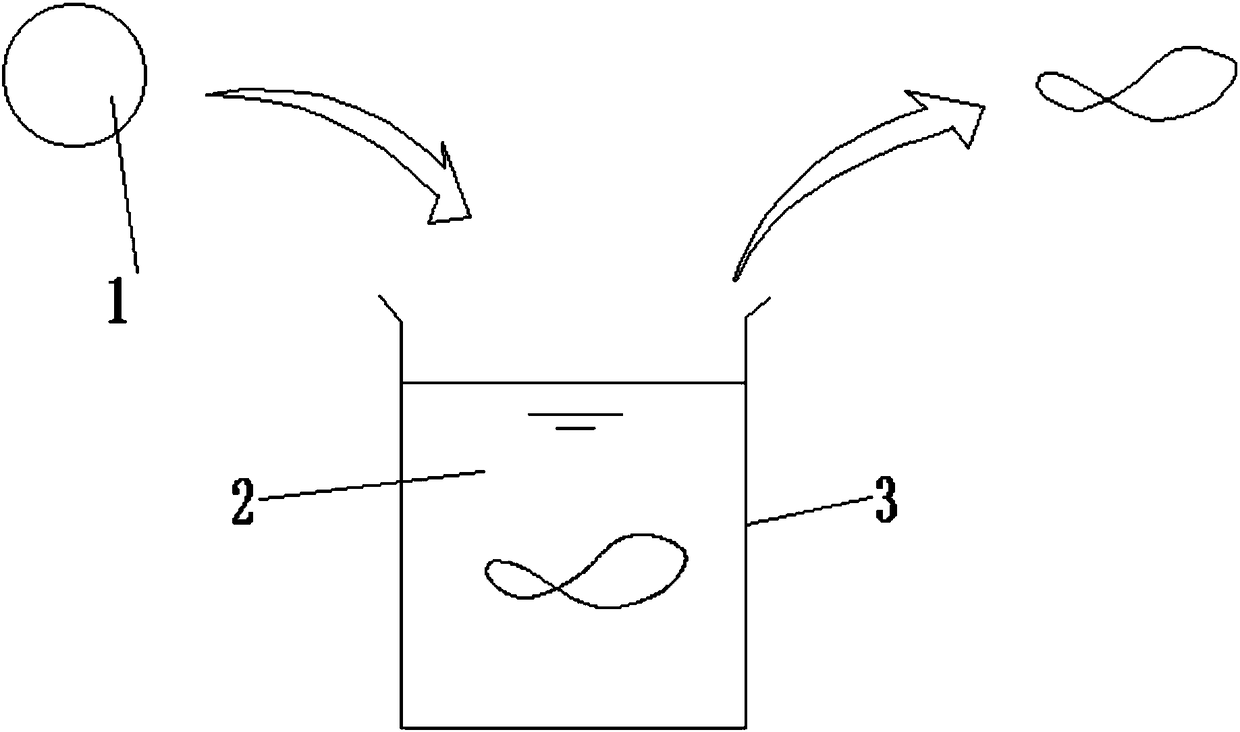

Method for improving detection accuracy of concentration of suspended particulates in water

InactiveCN108444860AAccurate concentration determinationReduce experimental errorWeighing by removing componentFiltrationRoom temperature

The invention discloses a method for improving the detection accuracy of the concentration of suspended particulates in water. The method comprises the following steps: immersing a 0.45 [mu]m hydrophilic filter membrane in a beaker containing a certain amount of ultrapure water, placing the ultrapure water wetted filter membrane in a weighing bottle by dressing flat-bit forceps a certain time later, taking off a bottle cap, transferring the filter membrane into an oven, drying the filter membrane at 103-105 DEG C for 0.5 h, taking out the filter membrane, placing the filter membrane in a drier, cooling the filter membrane to room temperature, and weighing the filter membrane; repeatedly drying, cooling and weighing the filter membrane until the weight is constant; performing suction filtration on 100 ml of a water sample containing suspended particulates by a suction filtration device; placing the suction filtered 0.45 [mu]m hydrophilic filter membrane in the weighing bottle, taking off the bottle cap, transferring the filter membrane into the oven, drying the filter membrane at 103-105 DEG C for 0.5 h, taking out the filter membrane, cooling the filter membrane to room temperature, and weighing the filter membrane; repeatedly drying, cooling and weighing the filter membrane until the weight is constant; and calculating the concentration of suspended particulates. The method has the characteristics of convenience, fastness, simplicity in operation, and high accuracy.

Owner:北京中科乾和环保科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com