All-solid-state lithium battery composite positive electrode and preparation method thereof

A composite positive electrode and lithium battery technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., to achieve the effects of good uniformity, simple preparation method, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific Embodiment 1: This embodiment describes a composite positive electrode of an all-solid-state lithium battery. The raw materials for preparing the composite positive electrode are composed of lithium titanate, vapor-phase grown carbon fiber VGCFs and Binary sulfide electrolyte LPSCI composition.

specific Embodiment approach 2

[0029] Embodiment 2: A preparation method of the all-solid-state lithium battery composite positive electrode described in Embodiment 1 is prepared by a liquid phase method, and the specific steps of the method are as follows:

[0030] Step 1: First, take 10~100 mL of 200# gasoline in a 40mm×70mm weighing bottle, weigh lithium titanate powder, VGCFs, and LPSCl electrolyte in total according to the mass ratio, and add 10~50 g into the weighing bottle, and mix and stir for 12~ 24 hours;

[0031] Step 2: Dry the mixed solution obtained in Step 1, the drying temperature is 50-100 ° C, the drying time is 10-24 hours, and the drying atmosphere is an argon atmosphere to obtain Li 4 Ti 5 o 12 and Li 6 P.S. 5 Cl (LTO@LPSCl) mixed powder;

[0032] Step 3: Press 1-30 mg of the mixed powder obtained in Step 2 into a ceramic sheet, the pressing pressure is 100-550 MPa, and the pressing time is 1-60 min, and the composite positive electrode is obtained.

Embodiment 1

[0034] First, take 50mL of 200# gasoline in a 40mm×70mm weighing bottle, weigh lithium titanate powder, VGCFs, and LPSCl electrolyte 5 g, 4 g, and 1 g into the weighing bottle at a mass ratio of 5:4:1, respectively. After stirring for 20 h, the obtained mixed solution was dried in an argon atmosphere at 60 °C for 20 h, and 10 mg of the dried mixed powder was weighed and pressed at 330 MPa for 30 min to obtain a composite positive electrode.

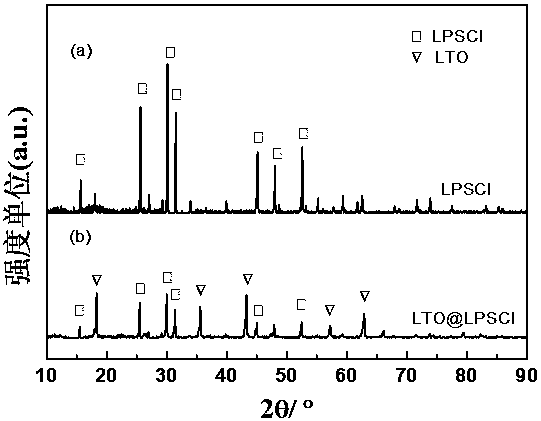

[0035] The obtained composite cathode material was characterized by XRD, such as figure 1 As shown, it can be seen that the characteristic peaks of LTO and LPSCl are sharp and independent of each other, without missing. Therefore, in the process of mixing, there is no side reaction between the two phases, and the original crystal form and state are maintained. The obtained electrolyte was characterized by SEM, and the results were as follows: figure 2 As shown, it can be seen that the particle size of the composite dielectric particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com