Preparation method and use method of high-resilience TPU hot-melt adhesive tape

A hot-melt tape and high-resilience technology, which is applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problem of not being able to adapt to the large-scale expansion and contraction of high-resilience textiles and weak cohesion and other problems, to achieve the effect of improving granulation efficiency, improving quality, and high particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

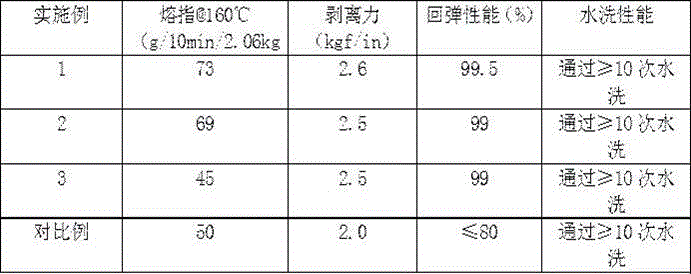

Embodiment 1

[0032] A preparation method of high-resilience TPU hot-melt adhesive tape, taking the hot-melt adhesive film whose product model is LQ361-05 and whose specification is 152cm*500m / r as an example, the specific steps of its preparation are as follows:

[0033] The first step, masterbatch raw material: it is composed of the following raw materials in weight ratio, TPU 50 parts, petroleum resin 40 parts, processing aid 10 parts, the melt index of the masterbatch raw material at 160 °C is 73g / 10min;

[0034] The second step, granulation: before the granulator works, it is necessary to clean the screw with PE pure material, and then put the masterbatch raw material in the first step into the mixer for mixing. The mixer adopts a high-speed mixer with a stirring speed of 300-500rpm. The time is 10 minutes; then put the mixed masterbatch raw materials into a granulator for granulation. The granulator adopts a twin-screw granulator with a host current of 80A, a melt pressure of 2MPa, a h...

Embodiment 2

[0039] The first step, masterbatch raw materials: it is composed of the following raw materials in the weight ratio, TPU55 parts, petroleum resin 40 parts, processing aids 15 parts, the melt index of masterbatch raw materials at 160°C is 69g / 10min;

[0040] The second step, granulation: before the granulator works, it is necessary to clean the screw with PE pure material, and then put the masterbatch raw material in the first step into the mixer for mixing. The mixer adopts a high-speed mixer with a stirring speed of 350rpm and a stirring time of 10 minutes ; Then put the mixed masterbatch raw material into the granulator for granulation, the granulator adopts a twin-screw granulator, the main engine current is 80A, the melt pressure is 2MPa, the main engine speed is 400r / min, and the feeding speed is 210r / min. Heat the heating zone at 150°C along the extrusion direction of the screw; after the granulation is completed, dry to obtain the masterbatch, the drying temperature is 4...

Embodiment 3

[0045] A method for preparing a high-resilience TPU hot-melt adhesive film, taking the hot-melt adhesive film whose product model is LQ361-15 and whose specification is 152cm*500m / r as an example, the specific steps of its preparation are as follows:

[0046] The first step, masterbatch raw material: it is composed of the following raw materials in weight ratio, TPU60 parts, petroleum resin 30 parts, processing aid 10 parts, the melt index of the masterbatch raw material at 160 ℃ is 25-25g / min;

[0047] The second step, granulation: before the granulator works, it is necessary to clean the screw with PE pure material, and then put the masterbatch raw material in the first step into the mixer for mixing. The mixer adopts a high-speed mixer with a stirring speed of 350rpm and a stirring time of 10 minutes ; Then put the mixed masterbatch raw material into the granulator for granulation, the granulator adopts a twin-screw granulator, the main engine current is 80A, the melt pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com