Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

272results about How to "Improve granulation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

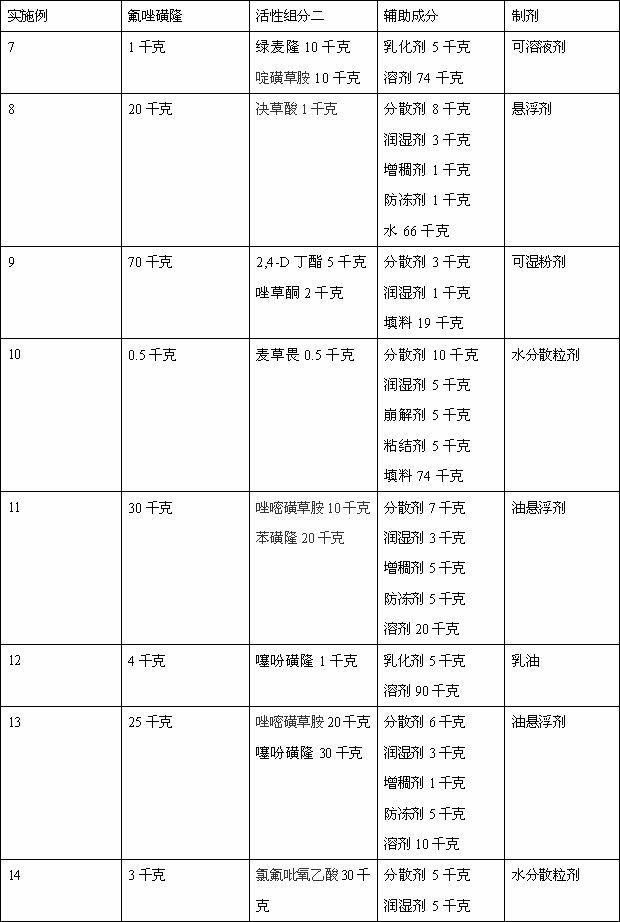

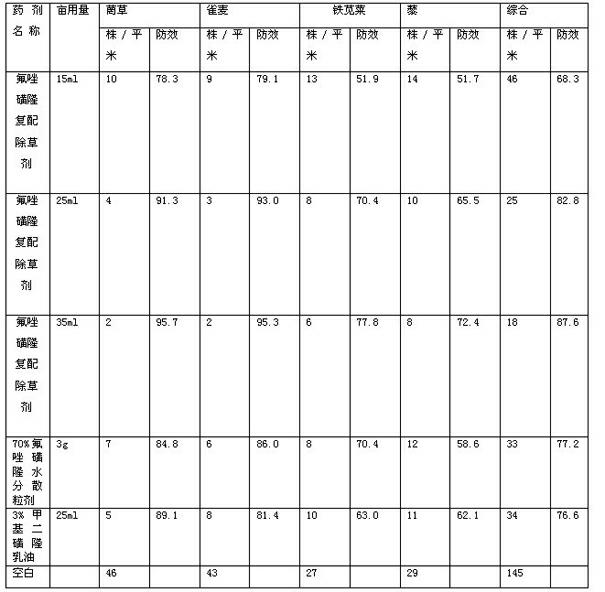

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

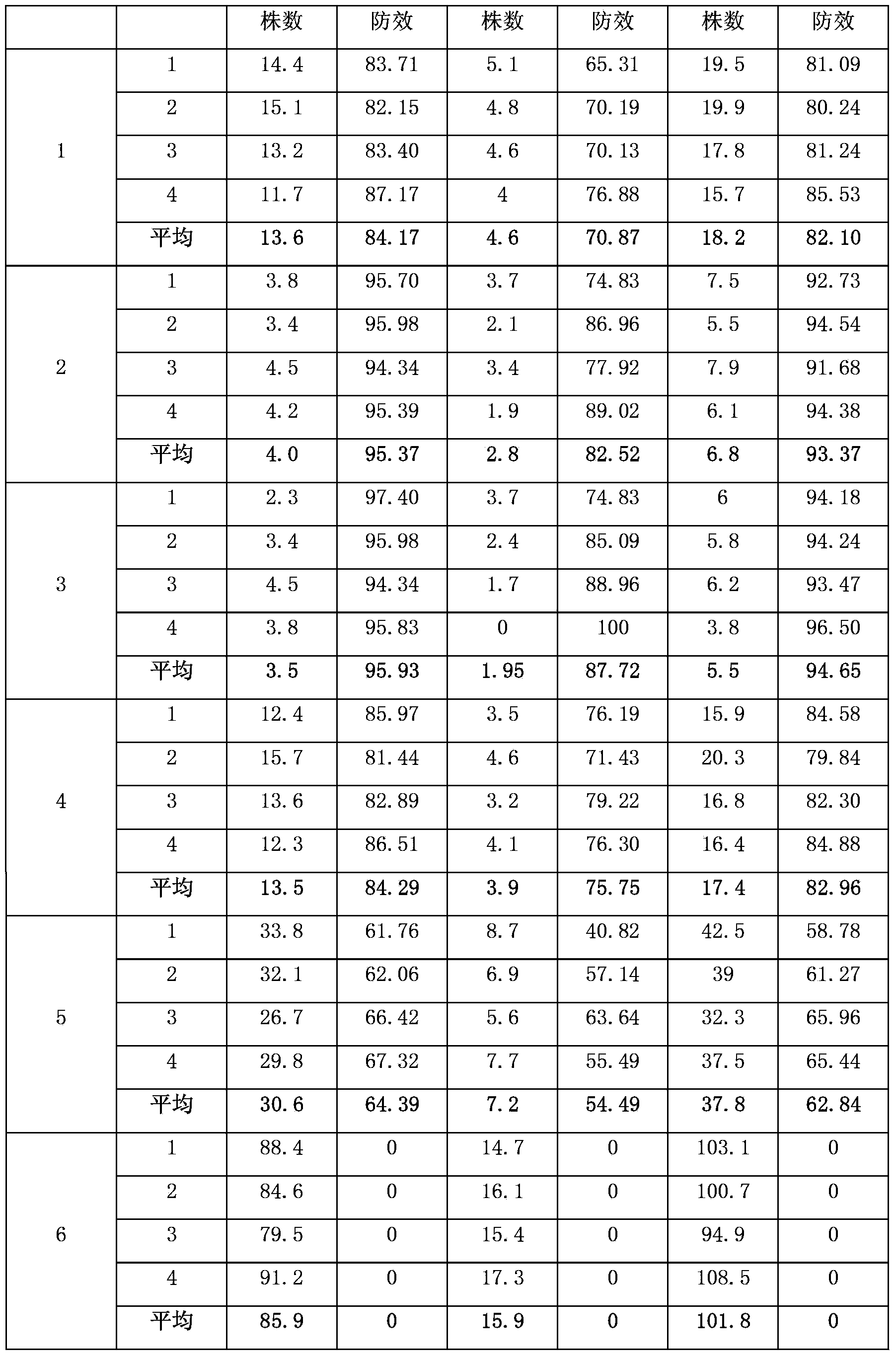

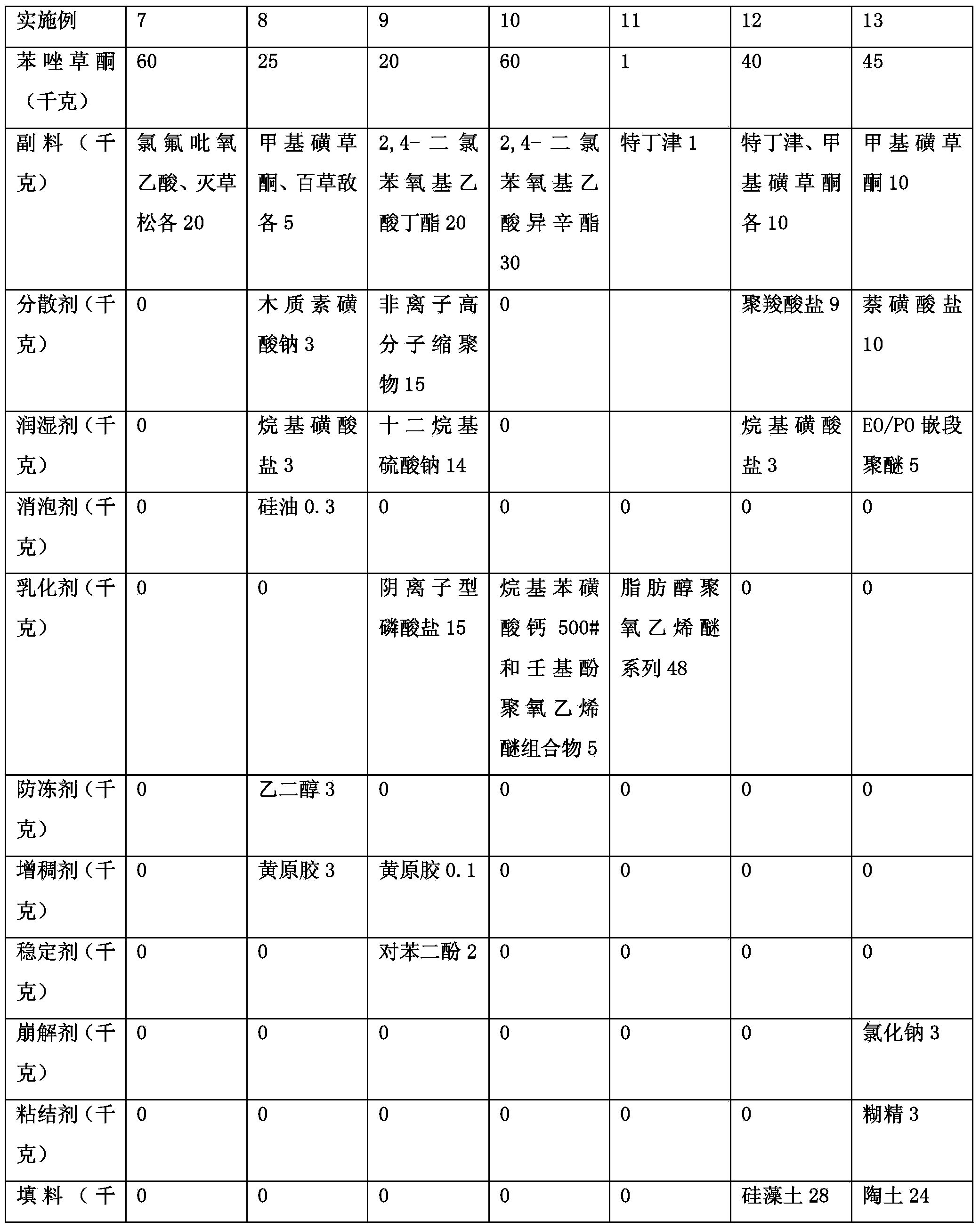

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

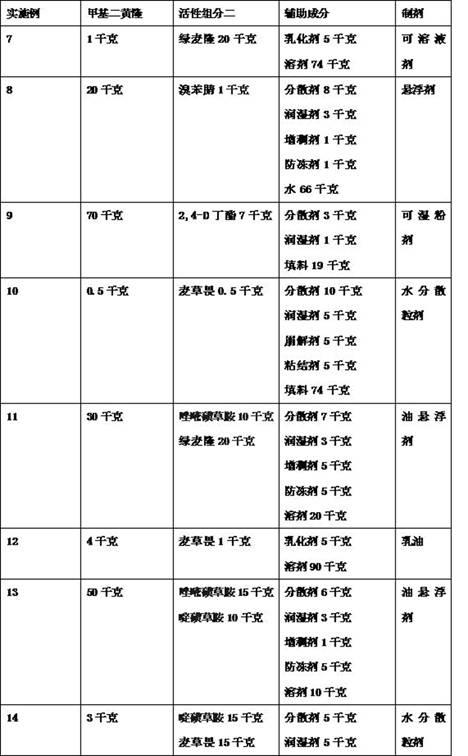

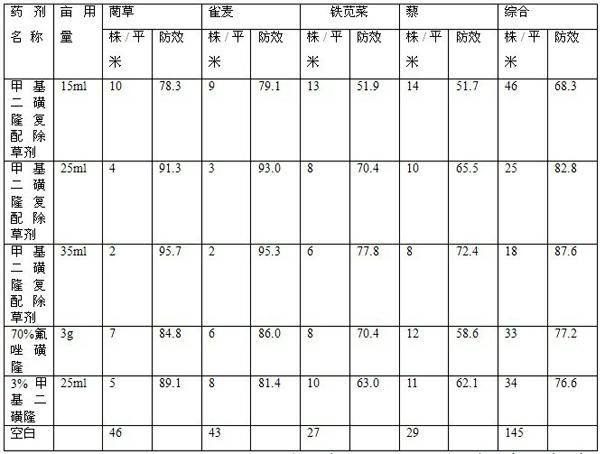

Mesosulfuron-methyl compound herbicide

InactiveCN102550585APrevent flocculationAvoid layeringBiocideAnimal repellantsAdjuvantAdditive ingredient

The invention discloses a mesosulfuron-methyl compound herbicide which consists of mesosulfuron-methyl as active ingredient I, active ingredient II and auxiliary ingredients; the active ingredient II is the combination of one or more of flucarbazone-Na, isoproturon, chlortoluron, pyroxsulam, 2-methyl-4-chlorophenoxy acetic acid, 2,4-D butyl ester, dicamba, bromoxynil, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary ingredients consists of adjuvant and one of filler and solvent, and the adjuvant is the combination of one or more of emulsifying agent, dispersing agent, wetting agent, disintegrant, binding agent, antifreezing agent and thickening agent; the sum of the weight of the mesosulfuron-methyl as the active ingredient I and the weight of the active ingredient II is 1 to 85 percent of the total weight of the mesosulfuron-methyl compound herbicide; and the weight ratio of the active ingredient I to the active ingredient II is 1:20 to 20:1. The mesosulfuron-methyl mixed herbicide is novel herbicide for wheatlands.

Owner:河北博嘉农业有限公司

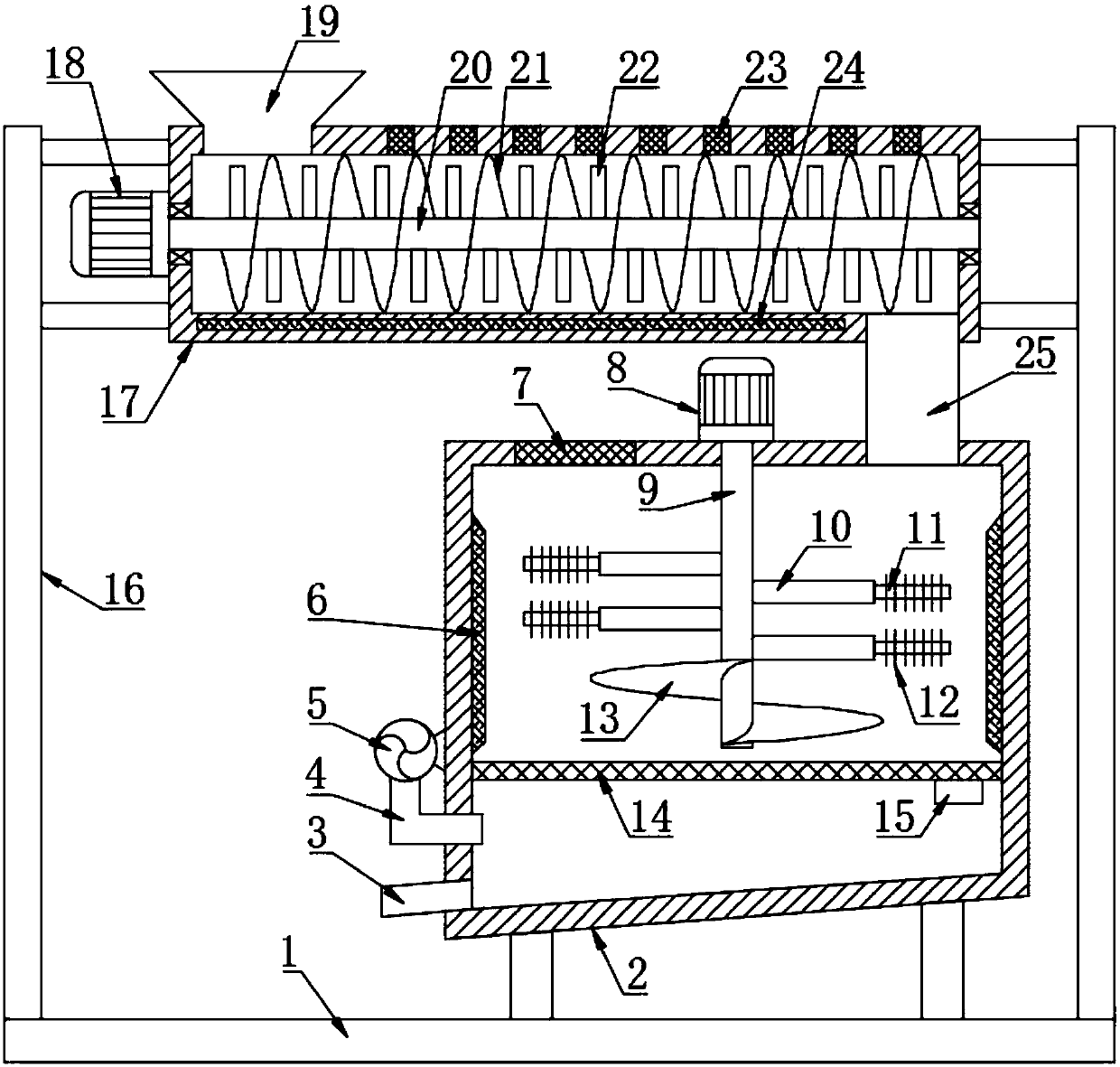

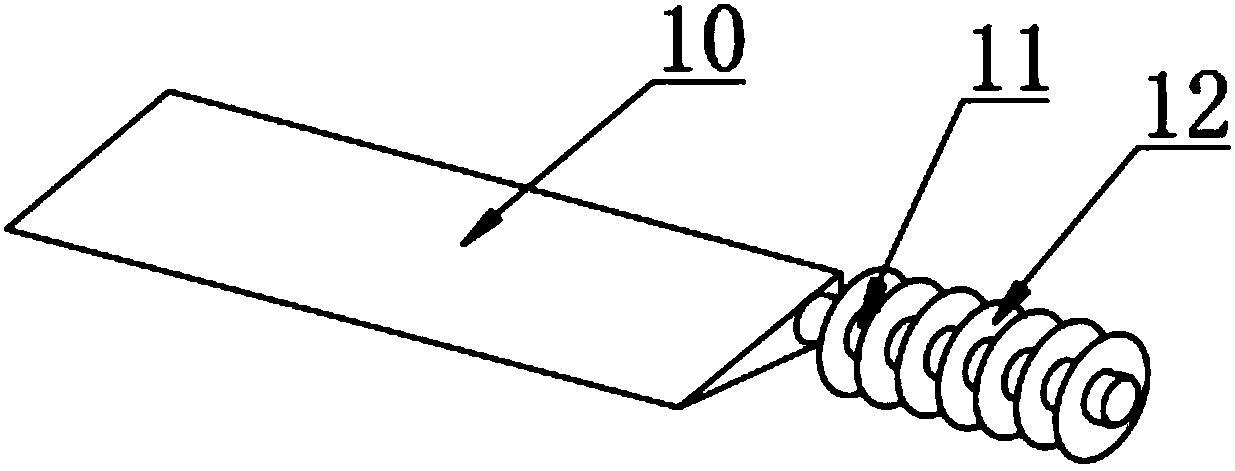

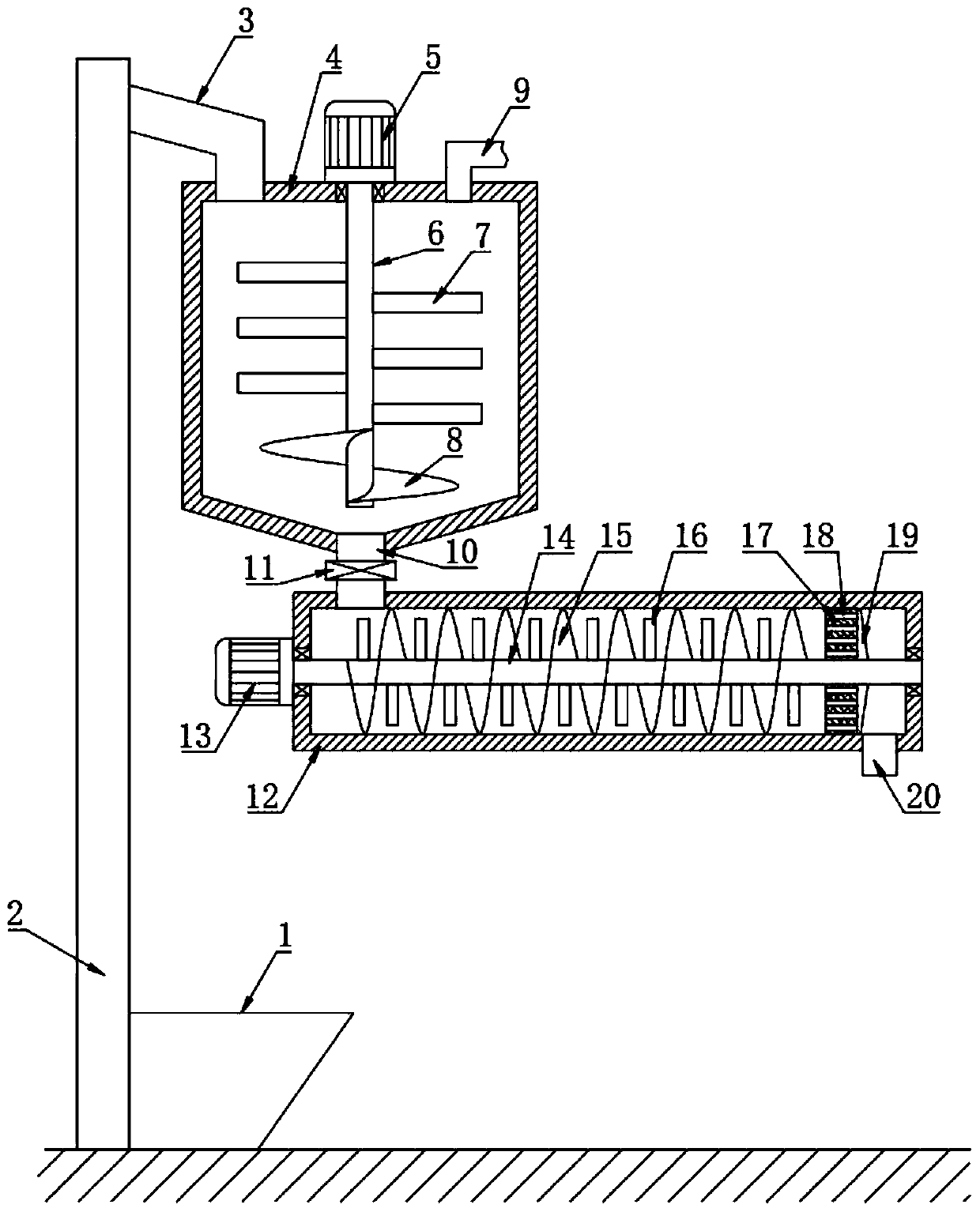

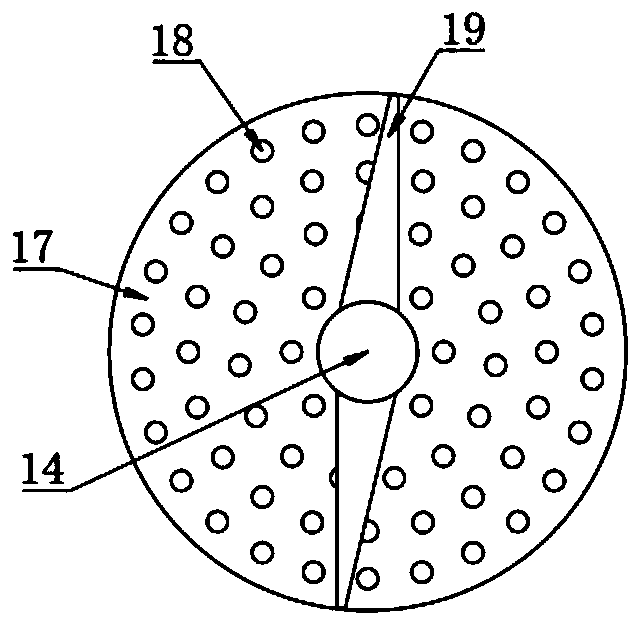

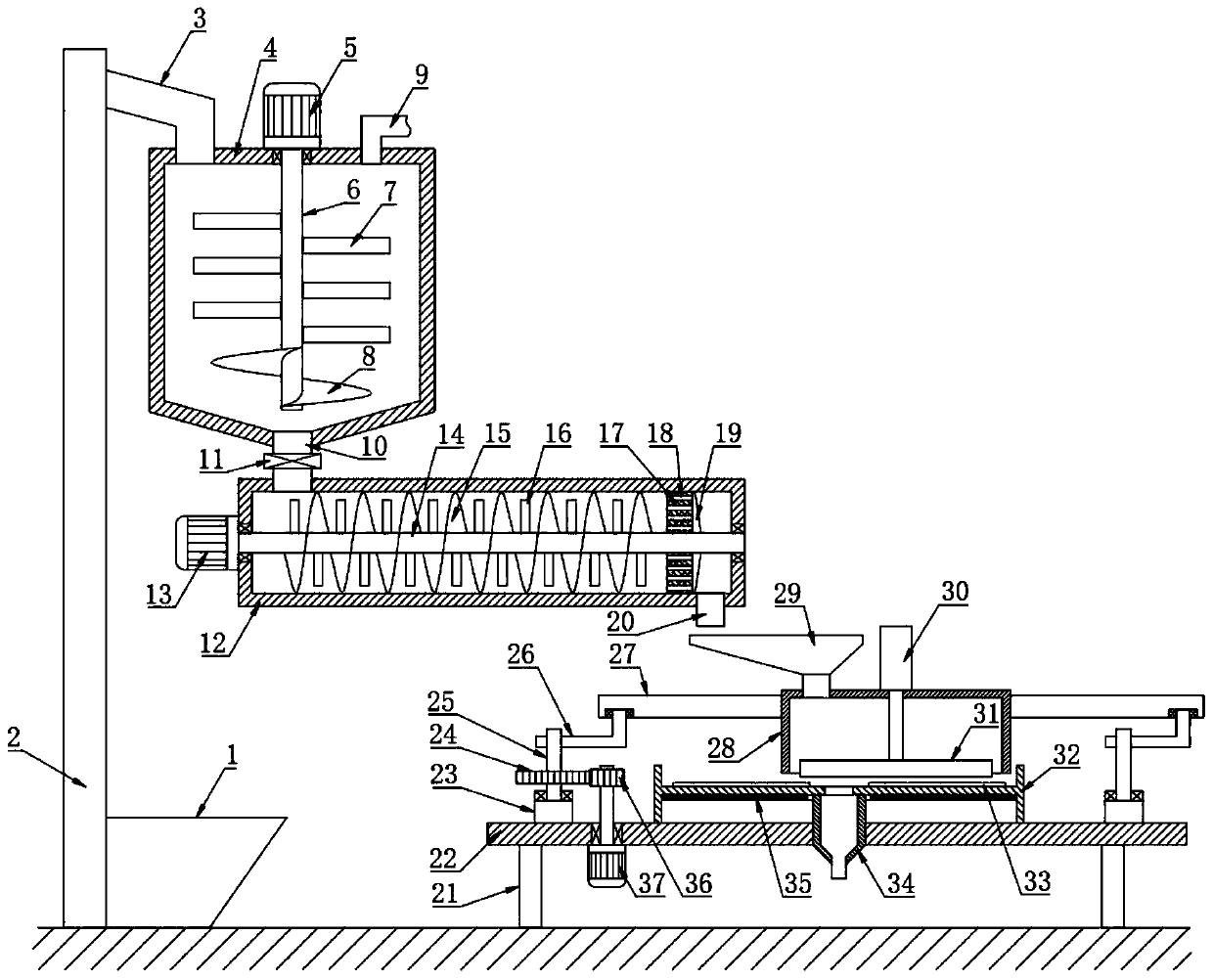

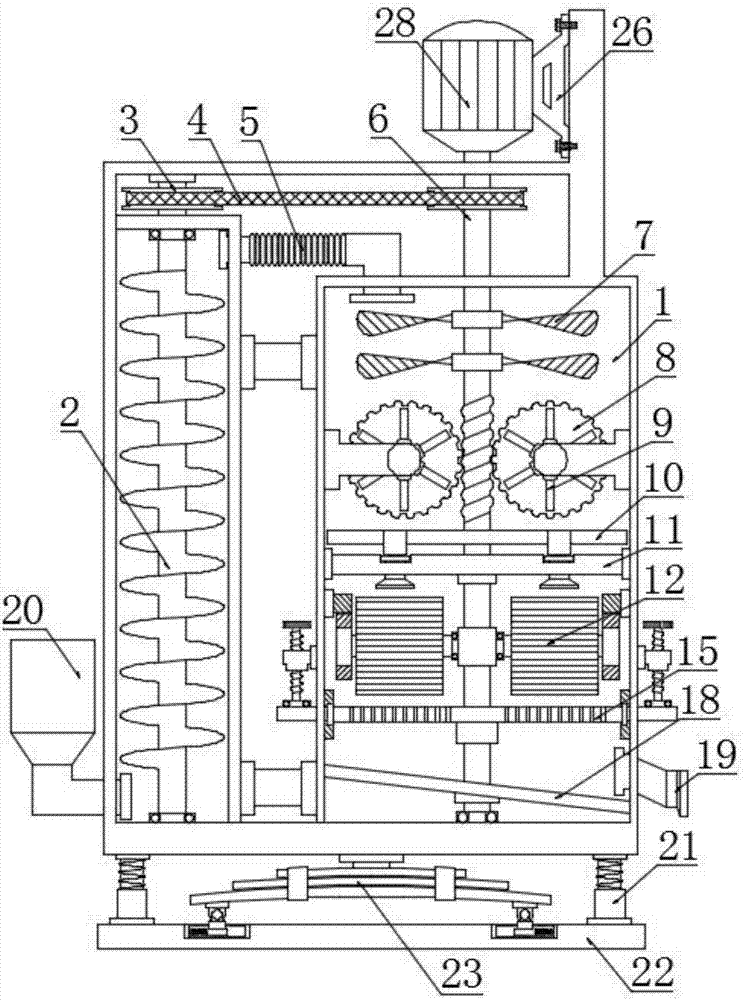

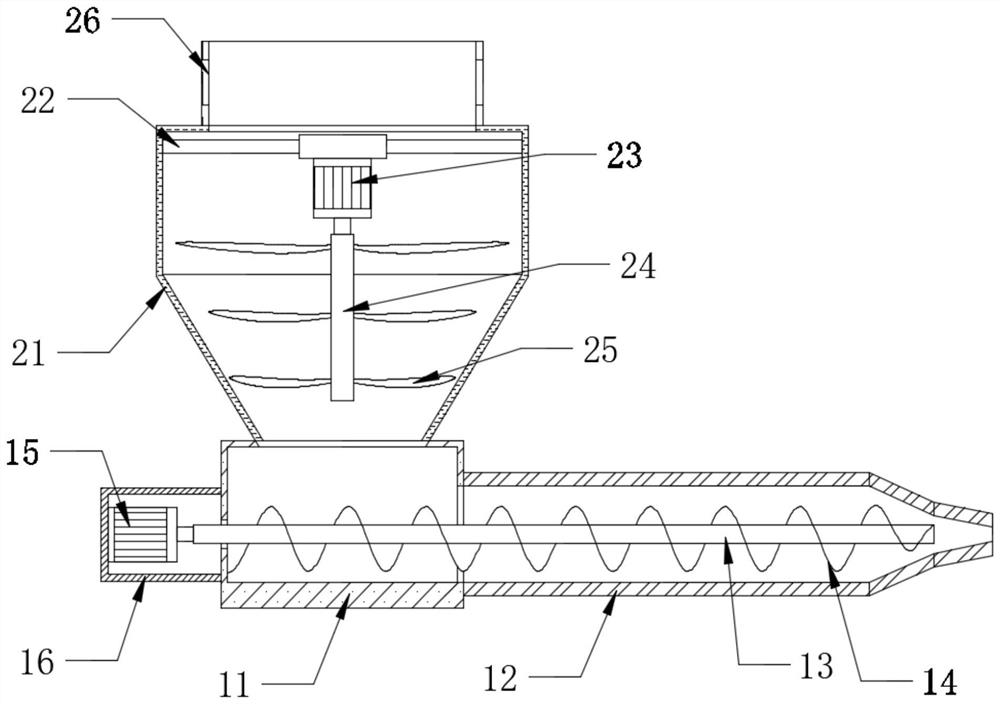

Feed mixing granulation screening device

InactiveCN108041657AFast speedImprove granulation efficiencyFeeding-stuffDrying gas arrangementsElectric machineryMotor shaft

The invention discloses a feed mixing granulation screening device. The device comprises a base; a granulation box is fixedly arranged above the base through a bracket; the bottom of the granulation box is inclined to lower left; the lower left corner of the granulation box is connected to a discharging pipe; the top center of the granulation box is fixedly provided with a motor; the motor shaft at the bottom of the motor penetrates the top wall of the granulation box and is fixedly connected to a first rotating shaft; the side wall of the first rotating shaft is fixedly connected to a plurality of crushing blades, and the crushing blades are staggered; the end face of each crushing blade is fixedly connected to a round rod; and the round rod is fixedly sleeved by a plurality of granulation blades, and the granulation blades are in a round sheet shape. According to the invention, the crushing blades and the granulation blades rotate to carry out crushing and granulation on agglomeratedfeed; the rotating speed of the crushing blades and the granulation blades is high; granulation efficiency is high; the cutting edges of the crushing blades are inclined downwards; and when the crushing blades rotate, an upward force is fed to the feed, so that the feed is driven to move upwards, and crushing effect is better.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Method for preparing non-sintered ceramsite by adding dredged sludge

The invention relates to a method for preparing non-sintered ceramsite by adding dredged sludge. The method comprises the following steps: (1) pre-treatment of the dredged sludge; (2) material preparation: mixing and stirring smashed dredged sludge, cement, quick lime, gypsum and coal ash to prepare a dry mixture; the mass portions of the smashed dredged sludge, cement, quick lime, gypsum and coal ash are as follows: 60 to 80 parts of the dredged sludge, 1 to 6 parts of the cement, 1 to 6 parts of the quick lime, 1 to 6 parts of the gypsum and 3 to 15 parts of the coal ash; then uniformly mixing water glass with water to obtain a mixed solution of the water glass and the water, wherein the mass ratio of the adding amount of the water glass to the dredged sludge is 3 to 15: 60 to 80, and the adding amount of the water accounts for 40 to 60 percent of the total mass of the dry mixture and the water glass; (3) disc granulation; (4) primary curing of a product; (5) waterproofing work; (6) ultimate curing of the product, namely obtaining a finish product of the non-sintered ceramsite. According to the method provided by the invention, a large amount of dredged sludge can be added, the purpose of utilizing waste materials is realized, the requirements of a dredging Industry are met, the production energy consumption is low, and the produced non-sintered ceramsite can meet the demands of construction market.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

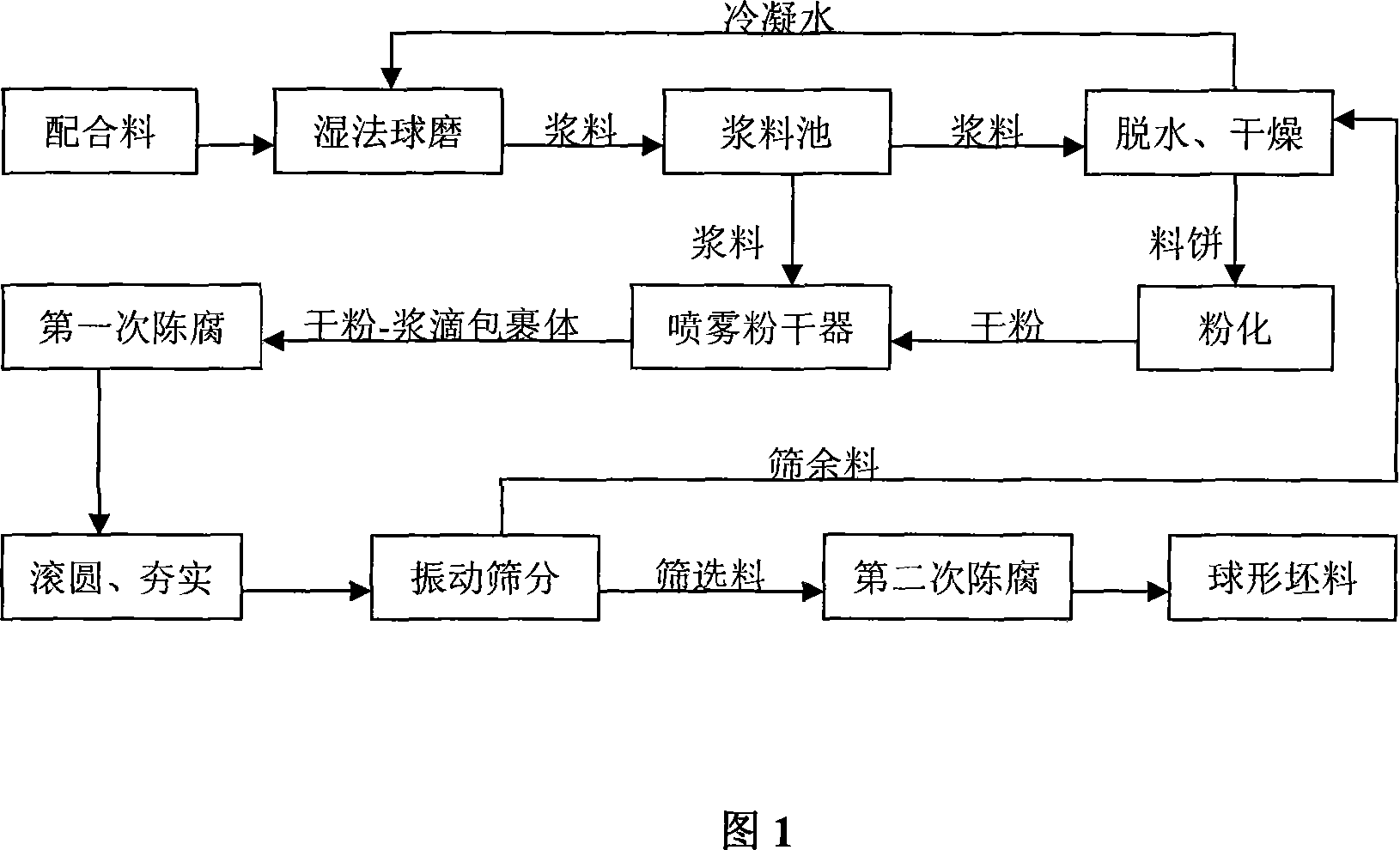

Technology for preparing blank for constructive ceramic with semi-drying method

ActiveCN101121282AReduce energy consumptionHigh energy consumptionClay processing apparatusLight pollutionRegular Production

The present invention relates to a technology for manufacturing the blank of architectural ceramics. The technology is a semi-dry one for manufacturing the blank of architectural ceramics; the technology is characterized in that the technology comprises the following steps: materials batching that materials are quantified according to regular production materials proportion of architectural ceramics and the materials is put into a ball grinder; wet ball grinding; the iron material is sifted out; the dry powder is manufactured: a part of the pulp manufactured through the process (3) is made into dry powder; spraying powder dry grain manufacturing: one share of the pulp made through the process (3) is sprayed into a spraying powder drier to form pulp fogdrop, i.e. wet core; 4 to 7.5 shares of dry powder are sprayed into the spraying powder drier made through the process (4) to form a dispersed distribution state; the wet core contacts and fully absorbs the dispersed dry powder to from grains of dry powder-pulp drop inclusion which is wet inside and dry outside; rolling and solidifying of the grains to form ball blank; vibrating and sifting out; water content is modulated and fossilized to form the blank used for architectural ceramics. The present invention boasts of low energy consumption, light pollution, material evenness and no iron pollution.

Owner:浙江中地大科技有限公司

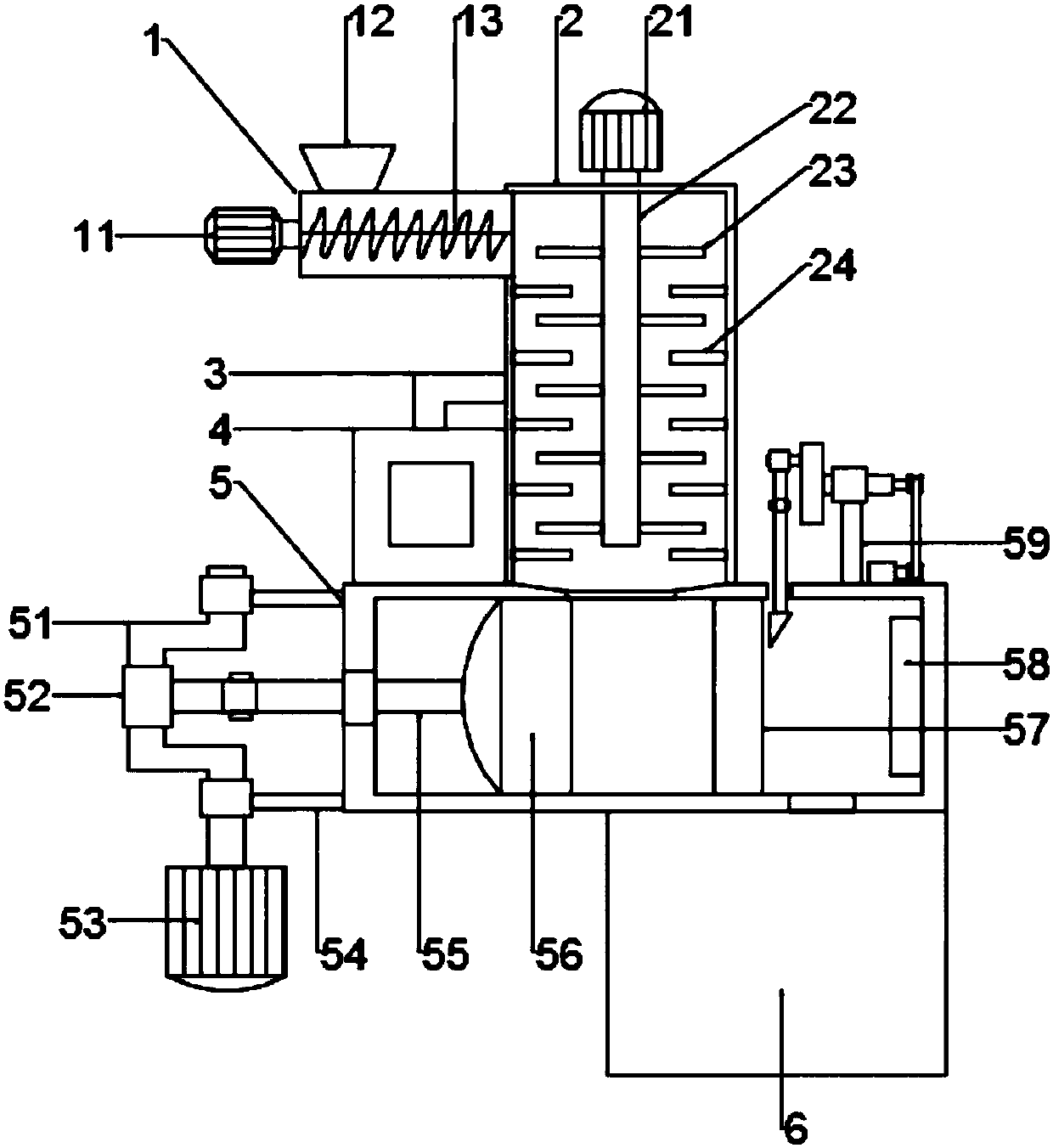

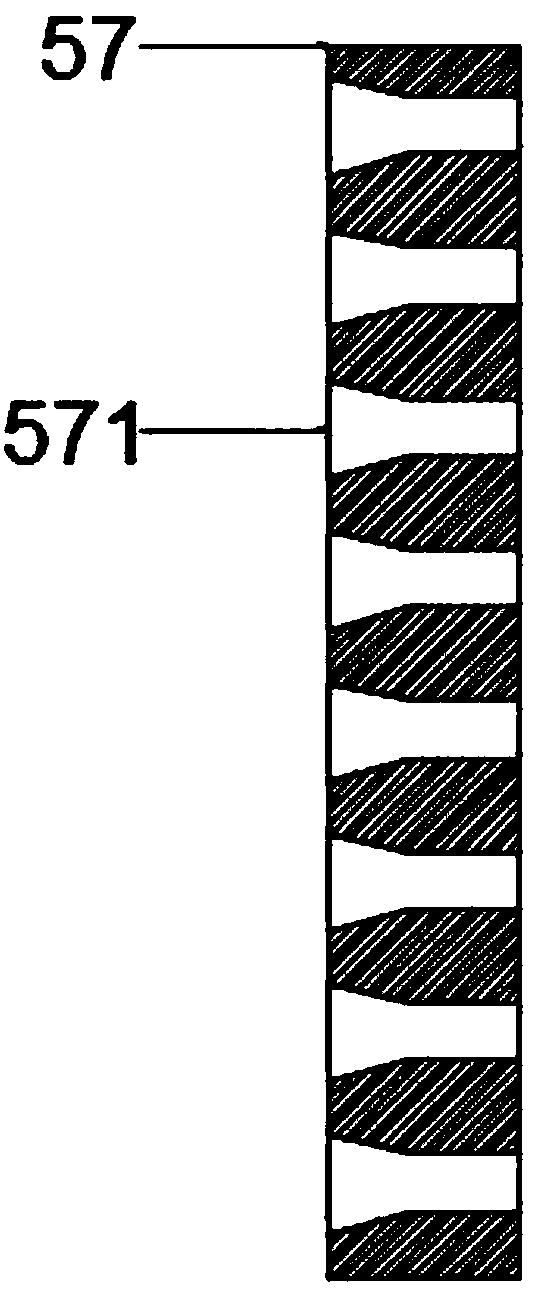

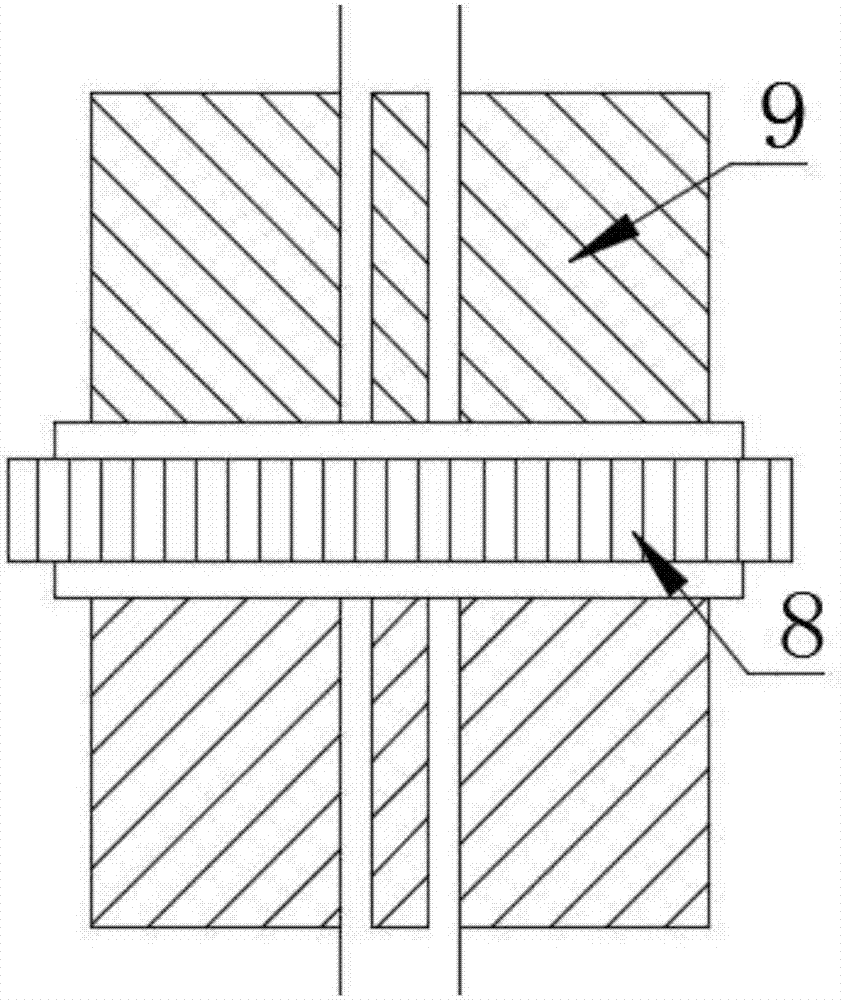

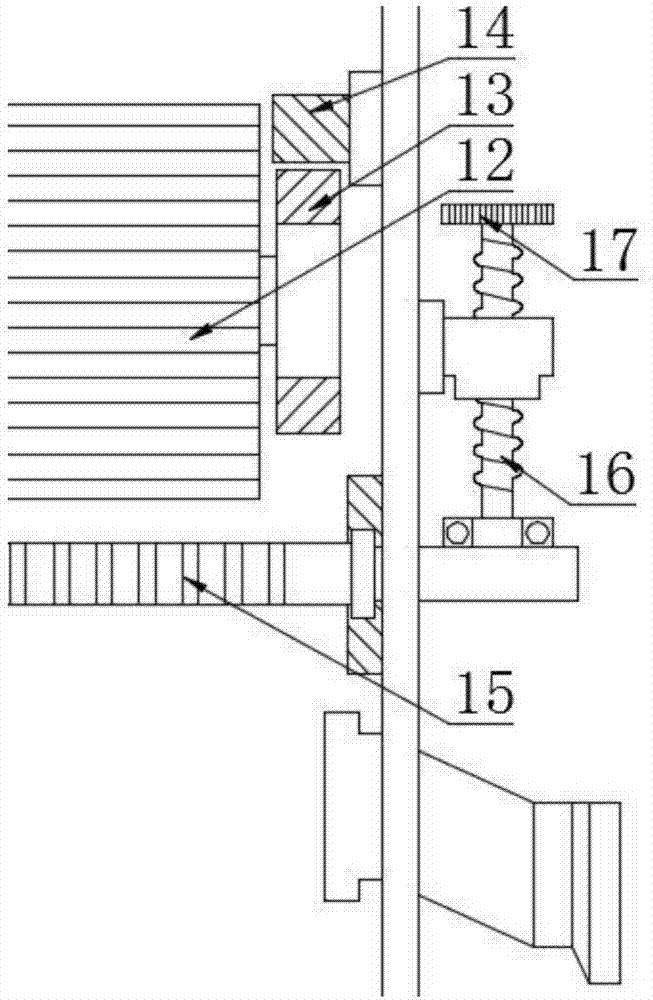

Dry method pelletizing machine

InactiveCN103861525ACompact structureFully automatedGranulation by material expressionEngineeringMechanical engineering

The invention discloses a dry method pelletizing machine. The dry method pelletizing machine is characterized by comprising a loading mechanism, a vertical feeding mechanism, an inclined feeding mechanism, a tabletting mechanism, a granulating mechanism, a straightening mechanism and a screening mechanism, wherein the loading mechanism comprises a charging basket which is communicated with a vacuum system, the vertical feeding mechanism comprises a vertical feeding motor and a vertical feeding screw rod, the inclined feeding mechanism comprises a feeding cylinder, a feeding screw rod and a feeding motor, the tabletting mechanism comprises an upper pinch roller and a lower pinch roller which rotate reversely, the granulating mechanism comprises a granulating wheel, the straightening mechanism comprises a straightening wheel, a straightening device and a screen straightening device, the screening mechanism comprises a screening barrel, a sieve tray and a powder receiving tray, and a feeding hole, a fine powder discharging hole and a finished product discharging hole are formed in the wall of the screening barrel. The dry method pelletizing machine is compact in structure, reliable in sealing and high in working efficiency, high quality finished product particles can be produced, fine powder ratio of finished product is controlled to be less than 4%, the dry method pelletizing machine can be applicable to various powders with different flowabilities, and automatic production can be completely realized.

Owner:ZHEJIANG FUTURE MACHINERY

Granulating and screening machine for feed production

InactiveCN107581643AMalleableImprove granulation qualityFeeding-stuffAgricultural engineeringWater pipe

The invention discloses a granulating and screening machine for feed production. The granulating and screening machine comprises a charging device, a conditioning mechanism, a granulating box and a screening box, wherein a charging opening is formed in the upper end of the charging device, a first rotating shaft is arranged in the conditioning mechanism, stirring paddles distributed in arrays arearranged on the first rotating shaft, water filling pipes distributed in arrays are arranged on the conditioning mechanism on the left and right sides of the stirring paddles, a squeezing plate is arranged in the granulating box, a granulating plate is arranged in the granulating box on the right side of the squeezing plate, a cutting device is arranged on the granulating box on the right side ofthe granulating plate, a charging pipe is arranged on the upper end of the screening box, a screening plate is arranged in the screening box on the lower side of the charging pipe, and a discharging pipe is arranged on the screening box on the right side of the screening plate. According to the granulating and screening machine for feed production disclosed by the invention, the contact area between water and feed is large, the conditioning effect is good, the conditioning mechanism is provided with vertical conditioning for solving the problems of insufficient stirring and water addition anddifficulty in discharging of a transverse conditioning mechanism, the granulating efficiency is high, and the feed granulating quality is high.

Owner:遂昌县宏创技术开发有限公司

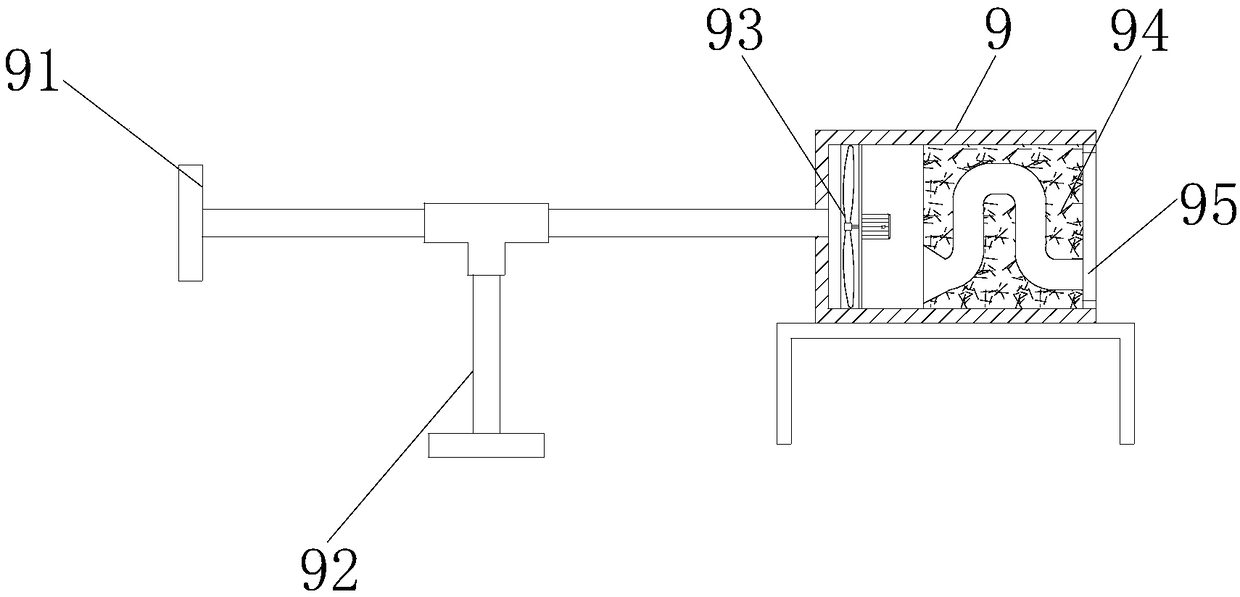

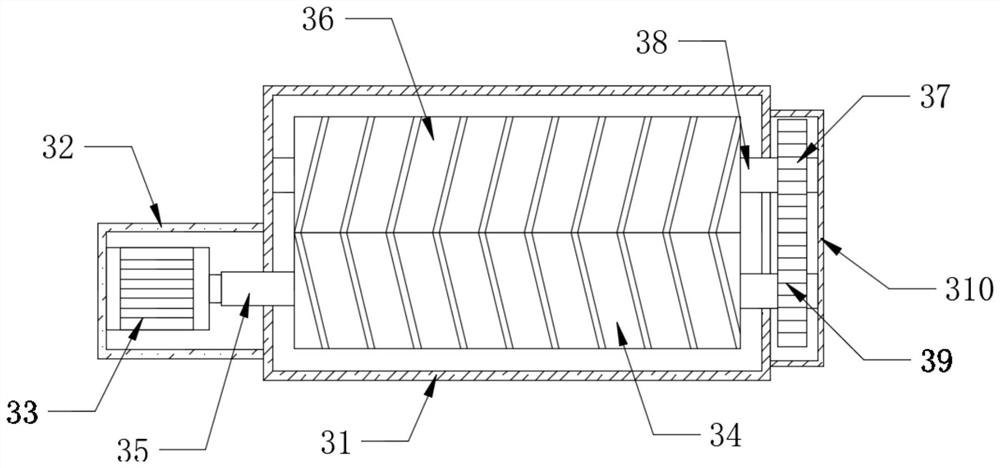

Gradient alloying granulation method of diamond abrasive grain surface binding agent

ActiveCN104592938AImprove performanceThe preparation method is efficientOther chemical processesAbrasion apparatusSprayerCarbide

The invention discloses a gradient alloying granulation method of a diamond abrasive grain surface binding agent. The diamond abrasive grains with a gradient alloying binding agent layer comprise diamond grains; an inner binding agent, a middle binding agent and an outer binding agent are arranged on the surfaces of the diamond grains in sequence; and the content of carbide forming elements in the binding agent is gradually decreased layer by layer. A gradient alloying granulation device of the diamond abrasive grain surface binding agent is used for preparing the diamond abrasive grains and comprises a roller, a slurry feeding sprayer, a power feeding sprayer and an ultrasonic stirrer. The gradient alloying granulation method of the diamond abrasive grain surface binding agent uses at least three sets of above devices, and comprises the following steps: a, wrapping the inner binding agent on the surfaces of the diamond grains; b, wrapping the middle binding agent on the surfaces of the diamond grains; and c, wrapping the outer binding agent on the surfaces of the diamond grains. The prepared abrasive grains have relatively good performance and the preparation method is high in efficiency.

Owner:GUANGDONG UNIV OF TECH

Fosaprepitant dimeglumine injection composition and preparation method thereof

InactiveCN103156813ALow costNo side effectsPowder deliveryOrganic active ingredientsFormularyDisodium Edetate

The invention relates to the field of medicament preparation, and particularly relates to a fosaprepitant dimeglumine injection composition and a preparation method thereof. The pharmaceutical active ingredients of the fosaprepitant dimeglumine injection composition include the following components in parts by weight: 180-250 parts of fosaprepitant dimeglumine, 12.0-20.0 parts of disodium edetate, 50.0-80.0 parts of polysorbate-80, 250-400 parts of lactose and 2000-3000 parts of water for injection. The preparation method comprises the following steps: dissolving, preparing, adsorbing, pre-freezing, performing sublimation drying and mounting an injection piston. The fosaprepitant dimeglumine injection composition provided by the invention is prepared from the low low-cost auxiliary materials according to a self-developed formula, has the same medicament effect in comparison with the existing fosaprepitant medicament available in America, is low in medicament cost and has no side effect basically; and the lactose used as excipient resists infection and is easy to absorb, so that favorable pharmaceutical effect can be achieved, and crushing of the medicament during storage can be avoided.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

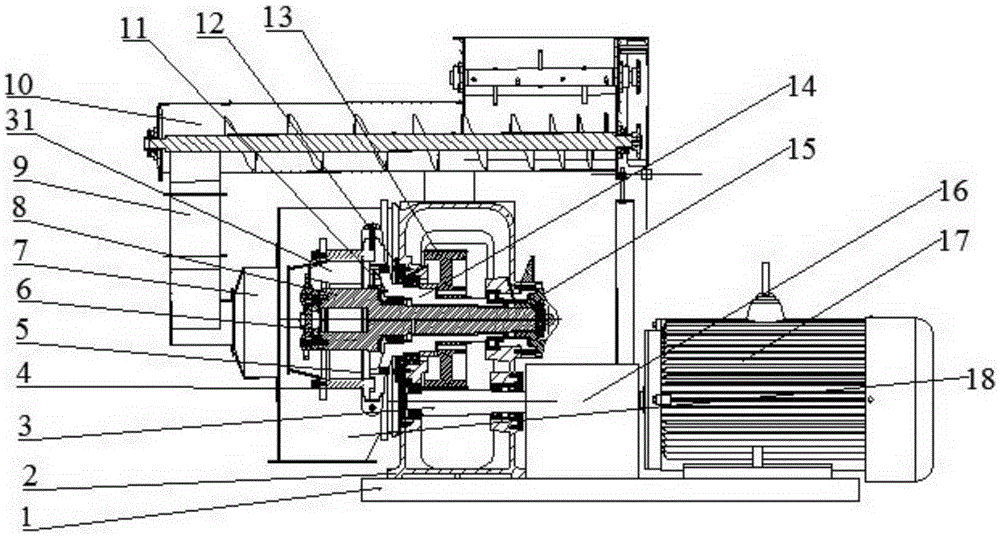

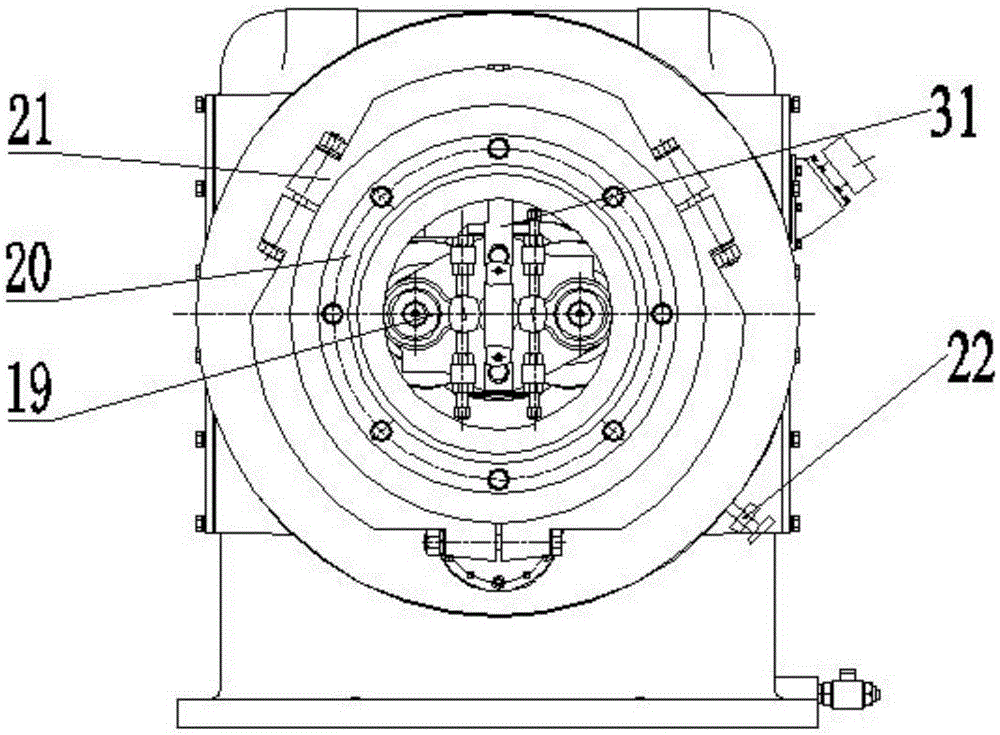

Ring-die granulator, and operating method and application thereof

InactiveCN105413586AReduce cloggingImprove granulation efficiencyGranulation by pressingFeed devicesMechanical engineering

The invention provides a ring-die granulator. The ring-die granulator comprises a frame, a feeding part arranged on the frame, a die-roller system, a motor used for driving the die-roller system, a discharge outlet, and a granulating chamber arranged outside the die-roller system, wherein the die-roller system comprises a ring die with internal teeth, and pressure rollers which have external teeth and are arranged inside the ring die. According to the invention, the ring die rotates clockwise at a certain rotational speed around a hollow shaft of the granulator, and the pressure rollers start to rotate clockwise by utilizing the force of friction between the ring die, the pressure rollers and materials, so the materials are extruded and compressed; meanwhile, a discharge hole of the ring die is substantially improved, so the granulator is suitable for rolling compaction of various materials; thus, granulation efficiency is greatly improved, and machine halt factors like blockage of the materials are reduced.

Owner:UNIV OF JINAN

Drying-free processing method for granular fertilizer

InactiveCN107162800AShort reaction timePromote absorptionMagnesium fertilisersSolid/semi-solid fertilisersFertilizerElectric heating

The invention aims to design a drying-free processing method for a granular fertilizer, the granular fertilizer is granulated by a method of high temperature melting and cooling curing or a method of hot air drying, dehydration and curing of a granulated wet material. Heating is needed in the process, environmental pollution is caused by coal-fired heating, cost and energy consumption are increased by oil, gas and electric heating, according to the drying-free processing method, 3-15% by mass of calcined magnesium-carbonate-containing ore is added, main component magnesium oxide is used as a curing agent, a curing reinforcer accounted for 15-20% of the mass of the curing agent is added, the curing agent can fast react to form crystals when meeting water in the presence of the curing reinforcer, large quantity of water is absorbed in the reaction process, material temperature is improved, water evaporation in the granulation material is promoted, the crystals are formed by curing in the air, and the crystals have a certain strength to ensure the particles are not broken.

Owner:YANTAI GOODLY BIOTECH

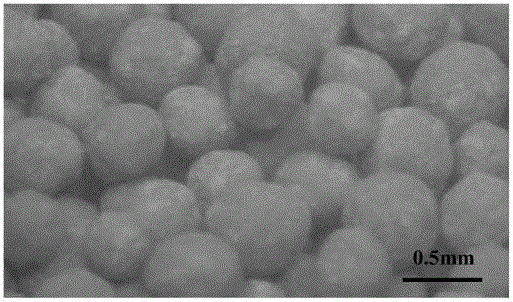

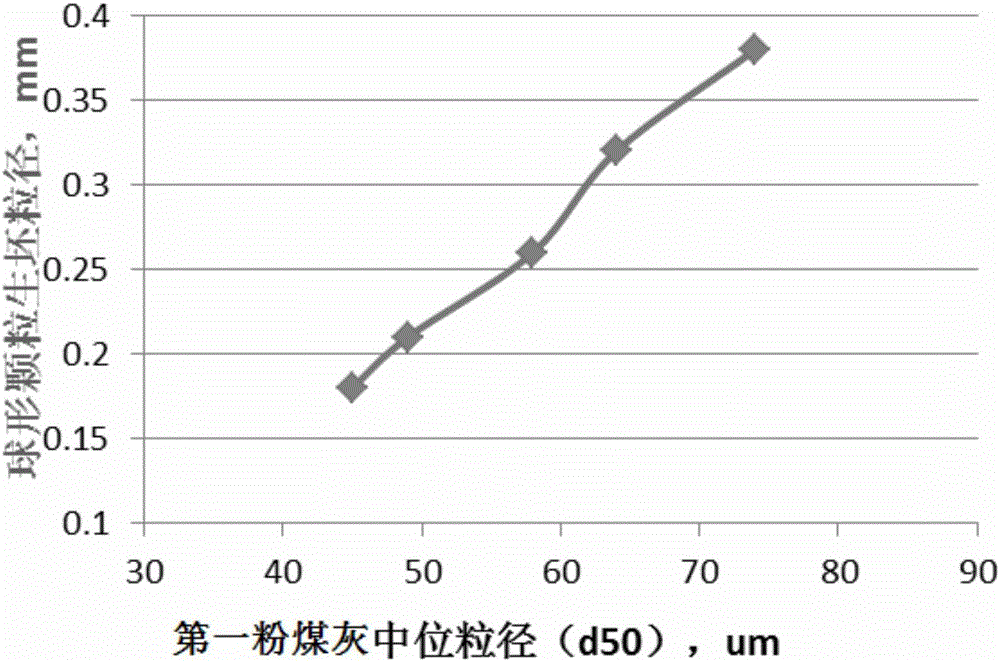

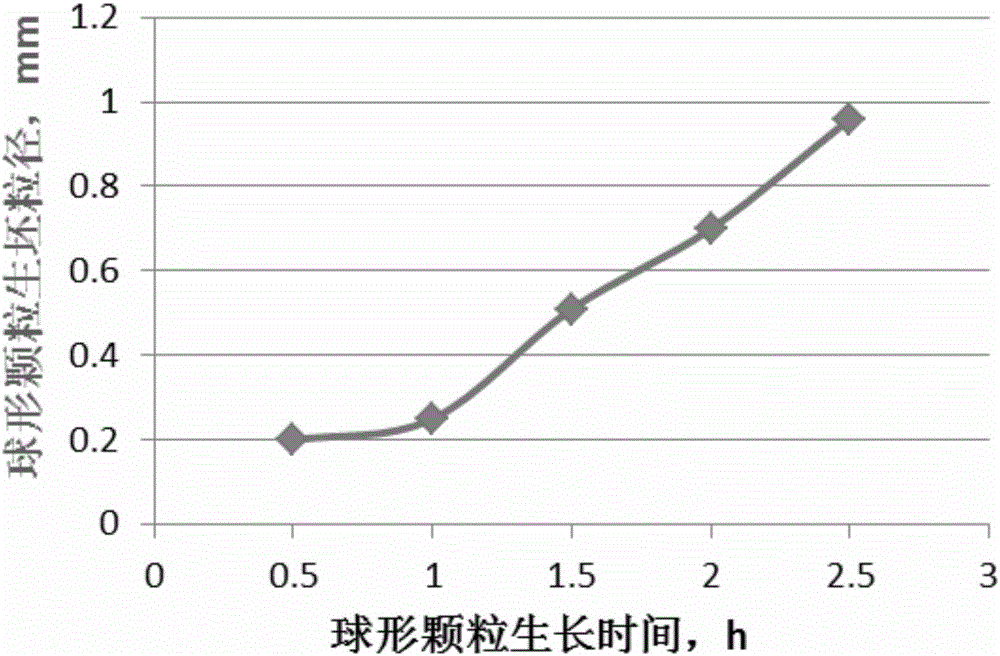

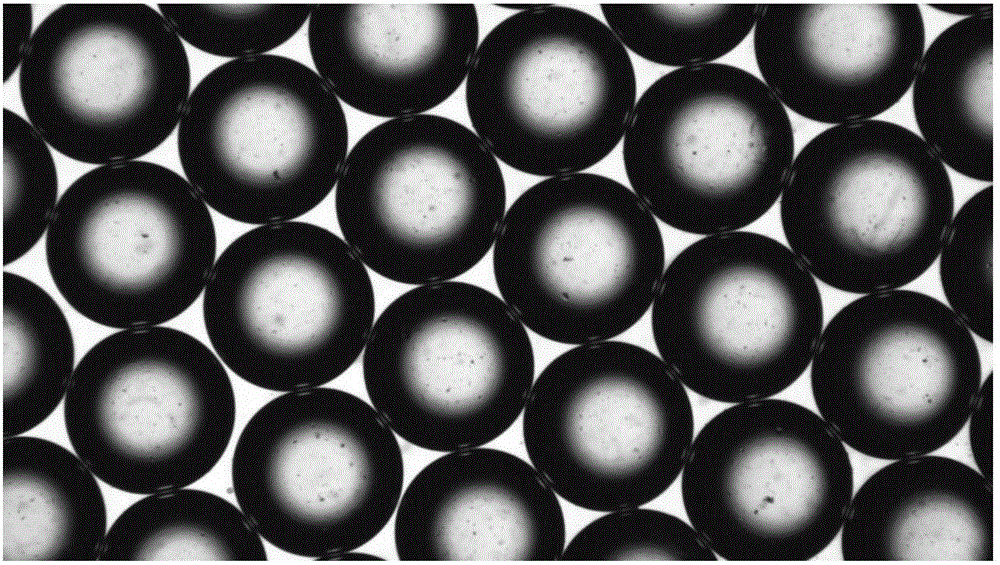

Composition for preparing spherical ceramic particles, and spherical ceramic particles as well as preparation method and application thereof

InactiveCN106565210ASimple recipeLow costCeramic materials productionClaywaresMetallurgyExpanded clay aggregate

The invention relates to the field of ceramic materials, in particular to a composition for preparing spherical ceramic particles, and the spherical ceramic particles as well as a preparation method and application thereof. The composition comprises a nucleating primer, growing fine powder, a binding agent and a selectable solvent, wherein the nucleating primer comprises first coal ash; the growing fine powder comprises second coal ash, and the grain size of the first coal ash is greater than that of the second coal ash. The composition provided by the invention is simple in formula of raw materials, green and environmental-friendly, low in cost and convenient for industrial production on a large scale. Meanwhile, the treatment energy consumption of the raw materials can be reduced and the forming time of the spherical particles can be shortened, so that the production cost of the spherical ceramic particles is lowered. The typical properties of the spherical particles prepared by the method provided by the invention are as follows: the diameter is greater than 0.1mm, the bulk density is 1.30-1.80g / cm<3>, and the true density is 2.3-3.0g / cm<3>. The spherical ceramic particles can be used in the field of a petroleum fracturing supporting agent, a grinding medium, casting sand, chemical packing spheres, building materials and light ceramsite for water treatment and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Topramezone and terbuthylazine compounded herbicide

InactiveCN103430947APrevent flocculationAvoid layeringBiocideAnimal repellantsSuspending AgentsToxicology

The invention discloses a topramezone and terbuthylazine compounded herbicide which comprises an oil suspended agent mainly prepared from topramezone, terbuthylazine, an assistant and a solvent, wherein the mass percent of the topramezone is 1-60%, the mass percent of terbuthylazine is 1-40%, and the mass sum of the topramezone and terbuthylazine takes 2-90% of the total mass of theherbicide. The topramezone and terbuthylazine compounded herbicide provided by the invention is a novel herbicide composition with a good weeding effect.

Owner:河北博嘉农业有限公司

Granulating equipment for making molten liquid into spherical granule product

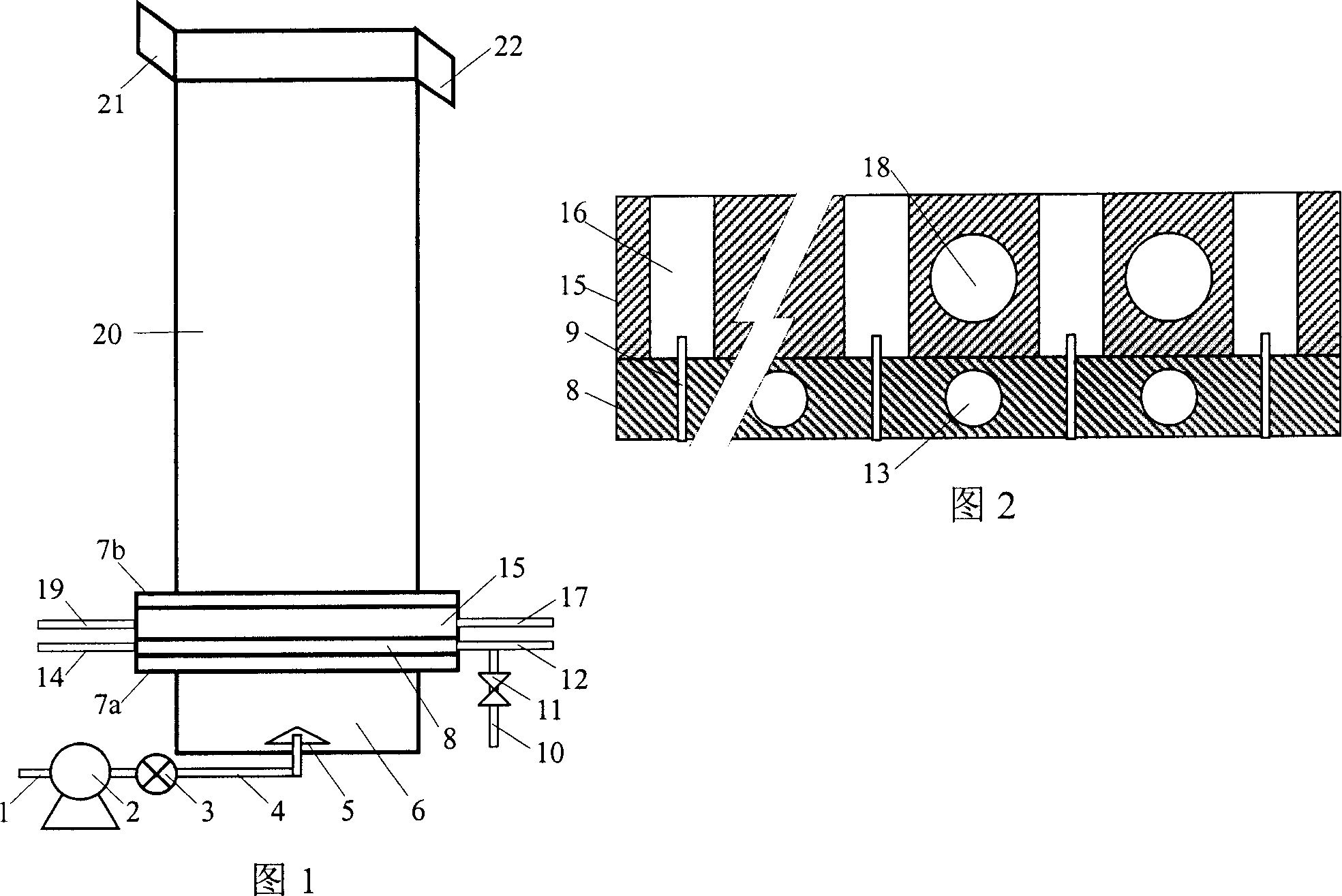

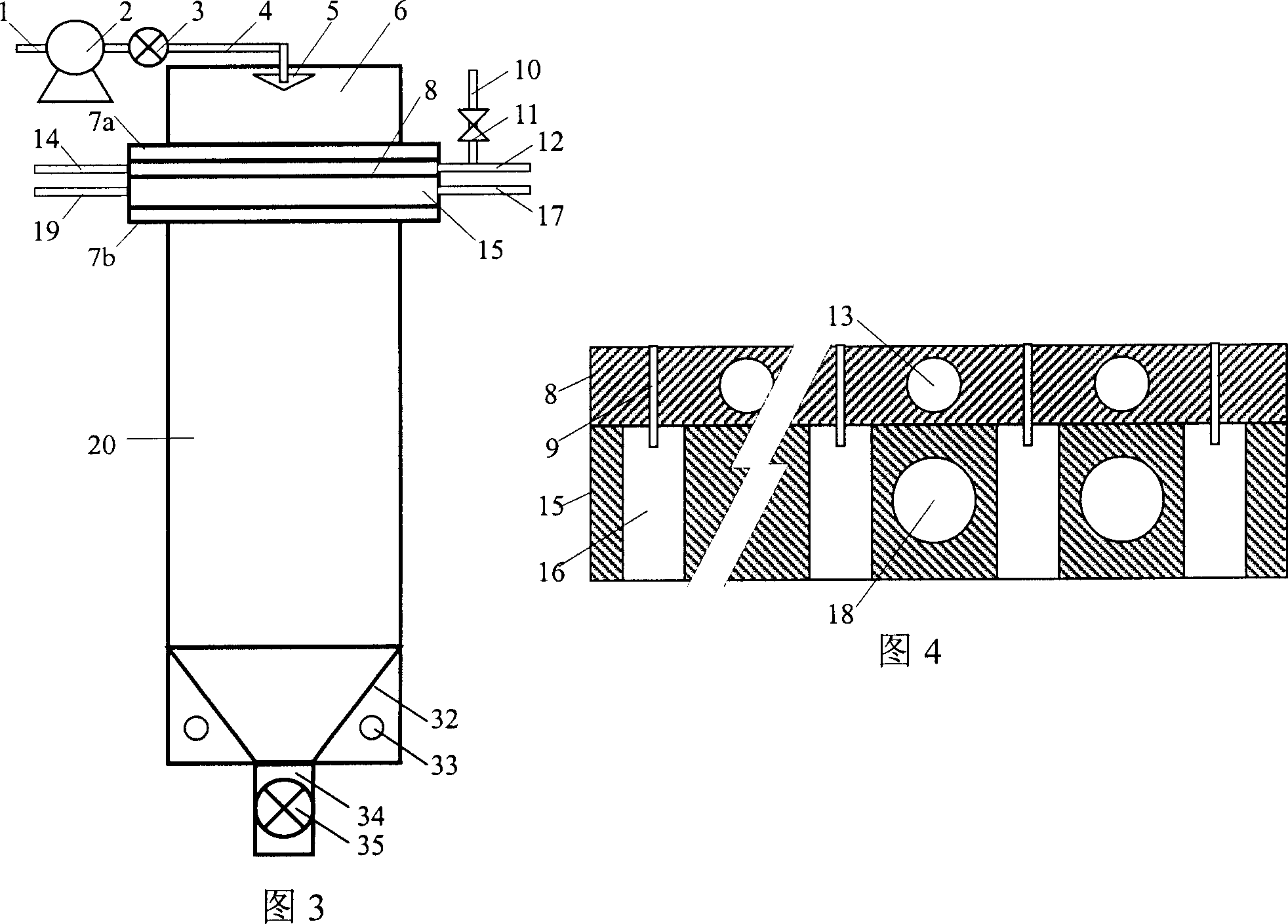

InactiveCN1515350AImprove granulation efficiencyLess investmentGranulation by liquid drop formationSpherical granulePrill

The present invention relates to a granulating equipment for making the molten liquid into spherical granular product. When the density of molten liquid is less than density of cooling liquid, it contains pressure-equalizing molten liquid chamber, distribution plate positioned over the molten liquid chamber and equipped with several nozzles along its longitudinal direction, heat-insulating plate positioned over the distribution plate and equipped with heat-insulating holes correspondent to the above-mentioned nozzles and heating medium channel opening from side surface, tower body, nozzle opening and closing component, valve mechanical switch, cooling liquid inlet and product discharge outlet. When the density of molten liquid is greater than that of cooling liquid, it contains the components of molten liquid chamber, distribution plate, heat-insulating plate, tower body, cooling liquid inlet distributing device and product discharge device.

Owner:TSINGHUA UNIV

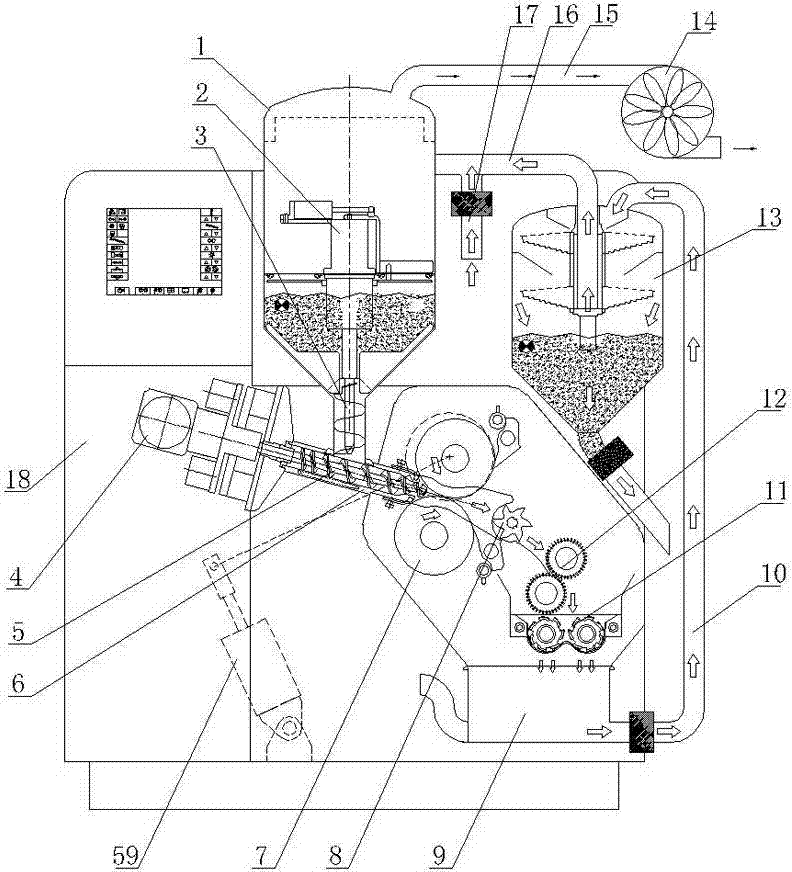

Aluminum oxide ball production line

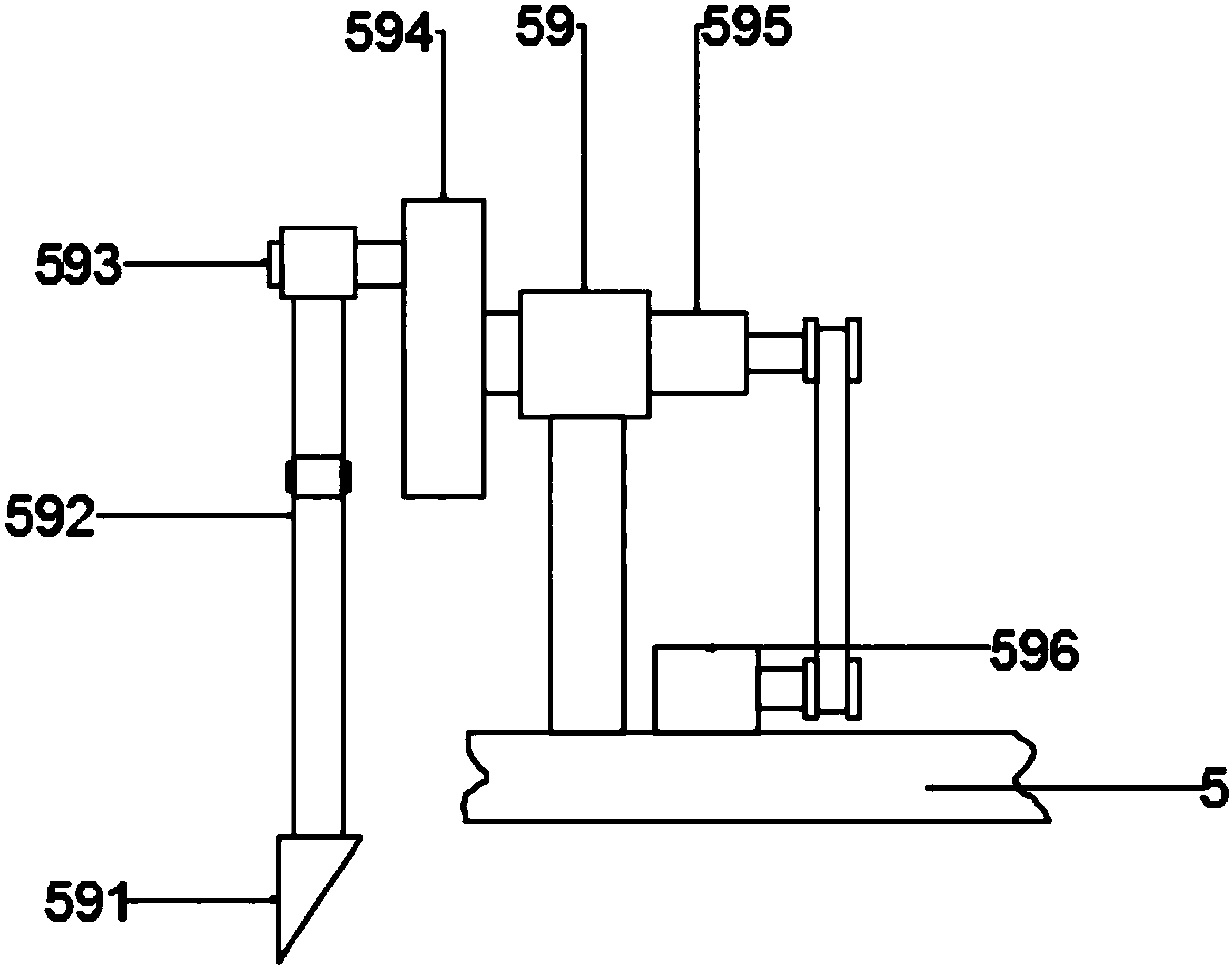

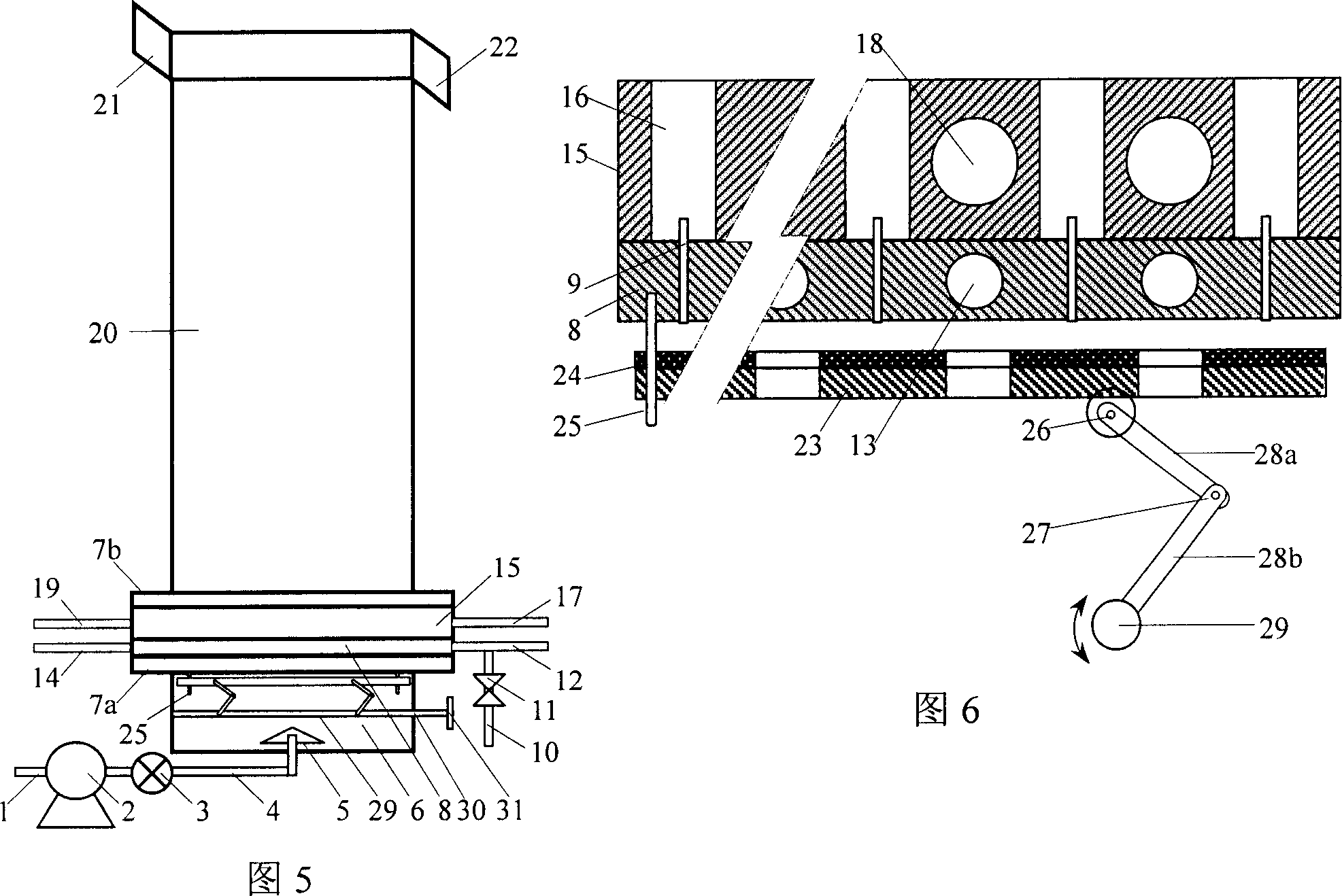

PendingCN110756117AImprove granulation efficiencyReduce manual labor intensityTransportation and packagingMixersCrankEngineering

The invention discloses an aluminum oxide ball production line, and relates to the field of aluminum oxide ball production machineries, the aluminum oxide ball production line comprises a support plate and a storage barrel, a rubbing disc is fixedly arranged at the top of the support plate; a plurality of supporting arms are fixedly connected to the outer surface of the storage barrel, cranks areconnected to the bottoms of the supporting arms through bearings, a plurality of third rotating shafts matched with the cranks are rotatably connected to the top of the support plate through plummer blocks, and the top ends of the third rotating shafts are fixedly connected with the corresponding cranks respectively; an electric push rod is fixedly arranged in the center of the top of the storagebarrel, and a push rod of the electric push rod penetrates through the top of the storage barrel to be fixedly connected with a rubbing plate; a circular through hole is formed in the center of the rubbing disc, and a discharging hopper is fixedly connected to the lower portion of the circular through hole in the top of the rubbing disc. Aluminum oxide particles gradually fall into the rubbing disc through a gap between the storage barrel and the rubbing plate to be rubbed, new raw material particles are supplemented after aluminum oxide balls are discharged, accordingly, the aluminum oxide balls can be continuously produced, and the production efficiency is higher.

Owner:山东中金金石科技股份有限公司

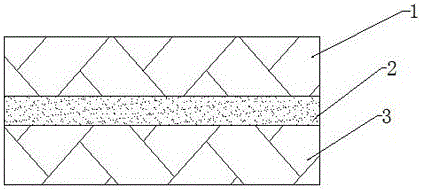

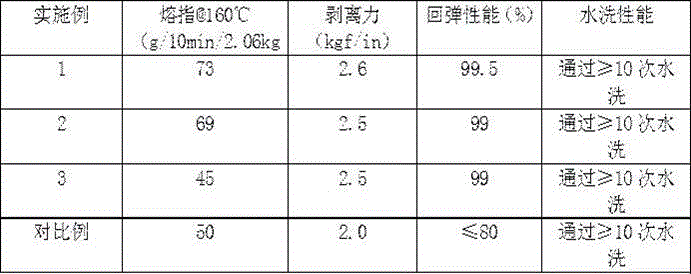

Preparation method and use method of high-resilience TPU hot-melt adhesive tape

ActiveCN105778810AHigh bonding strengthIncrease elasticityMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolymer scienceHot melt

The invention relates to a preparation method and a use method of a high-resilience TPU hot-melt adhesive tape. The preparation method mainly comprises five steps of selection of master batch raw materials, granulation, tape casting, compounding and splitting. In the tape casting step, master batches are fed into a tape casting machine in a mixing manner according to a weight ratio of 100:(5-15) for tape casting molding and rolling. When the high-resilience TPU hot-melt adhesive tape prepared by the preparation method is in use, one surface without release paper is in contact with a base material, and certain temperature and pressure are applied to pressing equipment; after adhesion is completed, the other surface is adhered to another adhered base material. The preparation method of the high-resilience TPU hot-melt adhesive tape has the advantages that the adhesion strength and the resilience of a hot-melt adhesive tape film are improved; when the prepared high-resilience TPU hot-melt adhesive tape film is in use, the equipment process is simple, and the working efficiency is high.

Owner:江苏和和新材料股份有限公司

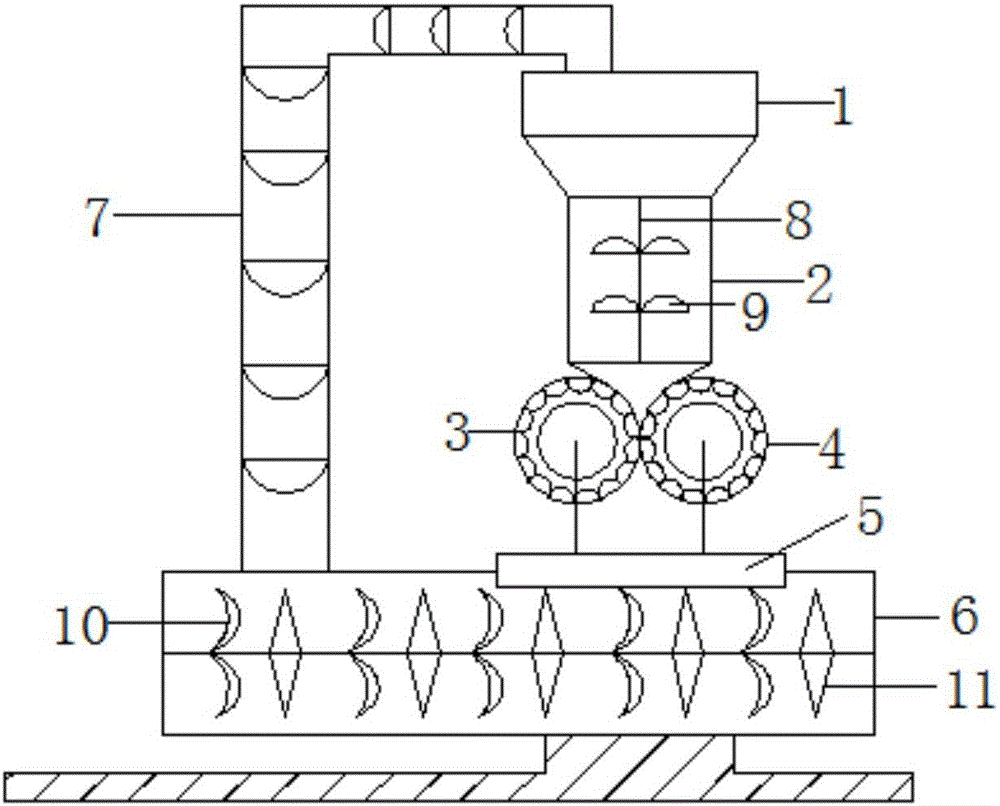

Pelletizing machine

InactiveCN106237929AImprove granulation efficiencyAids in granulation operationsGranulation by pressingDrive motorBucket elevator

The invention belongs to the field of pelletizing equipment, and especially relates to a pelletizing machine. According to the pelletizing machine, a storage hopper is arranged above a pedestal; a feeding device is arranged on the lower part of the storage hopper; a compacting mechanism is arranged in the feeding device; a left pelletizing rolling cutter and a right pelletizing rolling cutter are arranged under the feeding device, wherein the rotating direction of the left pelletizing rolling cutter and the rotating direction of the right pelletizing rolling cutter are opposite to each other; the pelletizing rolling cutters are driven by a drive motor; a grading screen is arranged below the pelletizing rolling cutters; a waste material recycling bin is arranged under the grading screen; the waste material recycling bin is arranged on the pedestal; a material returning screw conveyer is arranged in the waste material recycling bin; a bucket elevator is arranged between the material returning screw conveyer and the storage hopper; the feeding device comprises a feeding hopper and a feeding pipe; the compacting mechanism comprises a rotating shaft and compacting slices arranged on the rotating shaft; the compacting slices are arranged on the rotating shaft in the feeding pipe; and the rotating shaft is connected with the drive motor. The pelletizing machine is high in pelletizing efficiency; and the rotating shaft and the compacting slices are capable of providing raw materials with certain pressure, so that it is beneficial for subsequent pelletizing operation, and pelletizing efficiency is increased.

Owner:扬州日发干燥工程有限公司

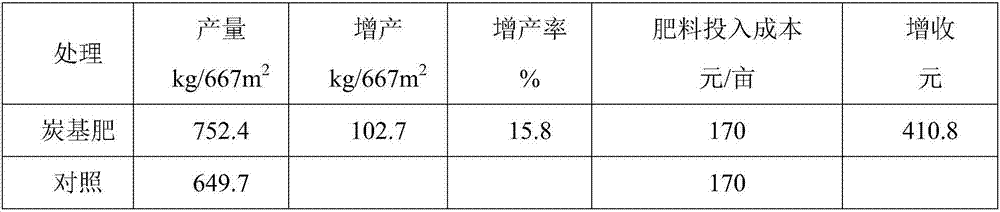

Charcoal matrix compound fertilizer and preparation method thereof

PendingCN107032895APromote growthPromote growth and developmentSuperphosphatesAlkali orthophosphate fertiliserSodium BentonitePlant growth

The invention relates to a charcoal matrix compound fertilizer and a preparation method thereof and solves the problems that existing charcoal base fertilizer preparation is tedious, the cost is high, the fertilizer utilization efficiency is low and the energy consumption is high in the straw charcoal powder processing process and the pollution in the preparation process is serious. The fertilizer is formed by carbomite, calcium superphosphate or diammonium phosphate, potassium chloride, bentonite, microelements, water, a binder and straw charcoal; the preparation method comprises the steps that one, the charcoal is smashed; two, urea, the diammonium phosphate and the potassium chloride are taken out, smashed and mixed with the straw charcoal, the bentonite, the microelements and the binder and put into a mixer; three, pelleting and drying are performed; four, the urea, the diammonium phosphate and the potassium chloride are mixed. According to the fertilizer, the plant growth and development can be promoted, the production and the income are increased, release of nitrogen, phosphorus and potassium is slowed, and the valid time limit of the fertilizer is prolonged. The method is applicable to preparation of charcoal matrix compound fertilizers.

Owner:黑龙江省农业科学院农村能源研究所

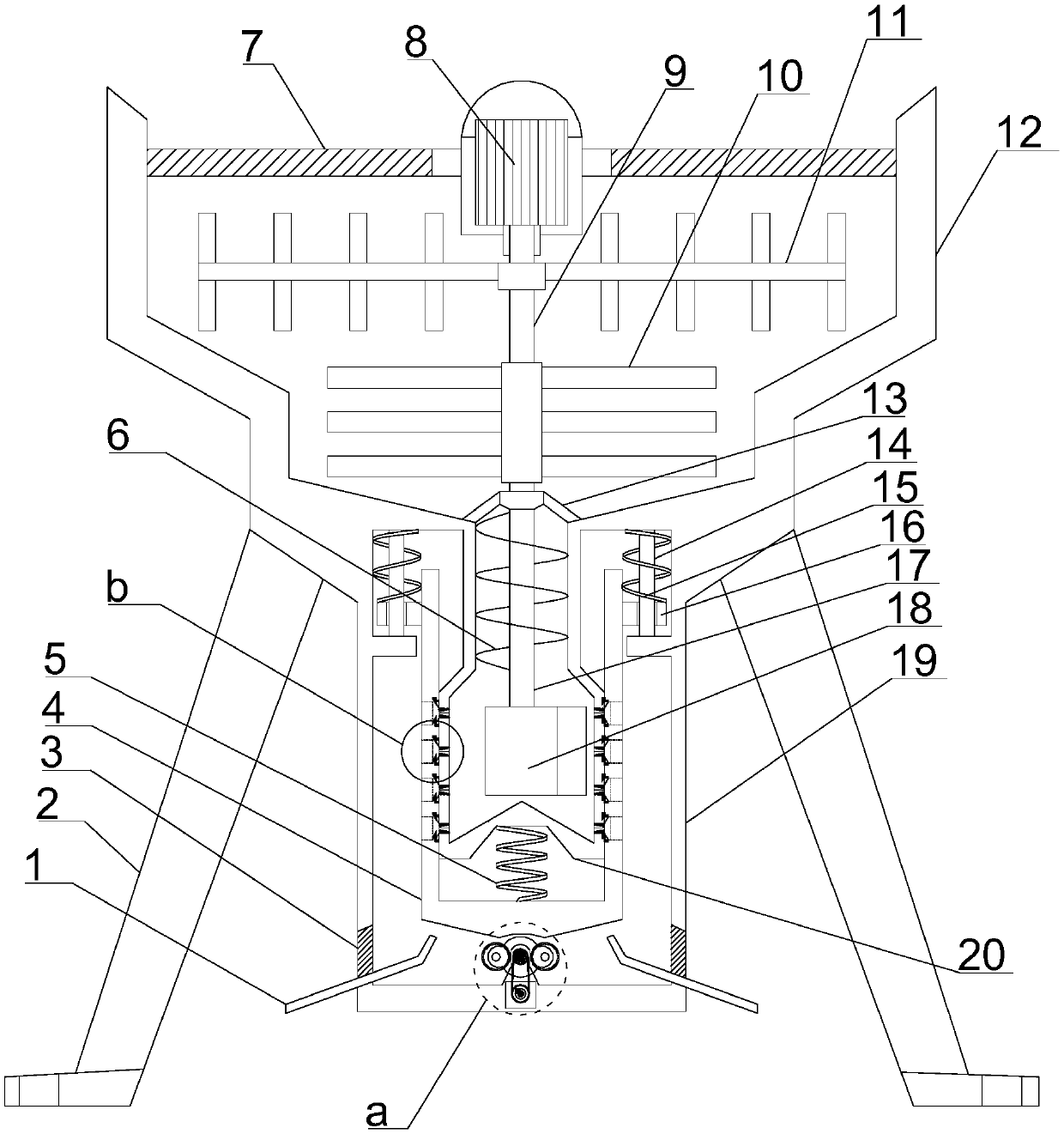

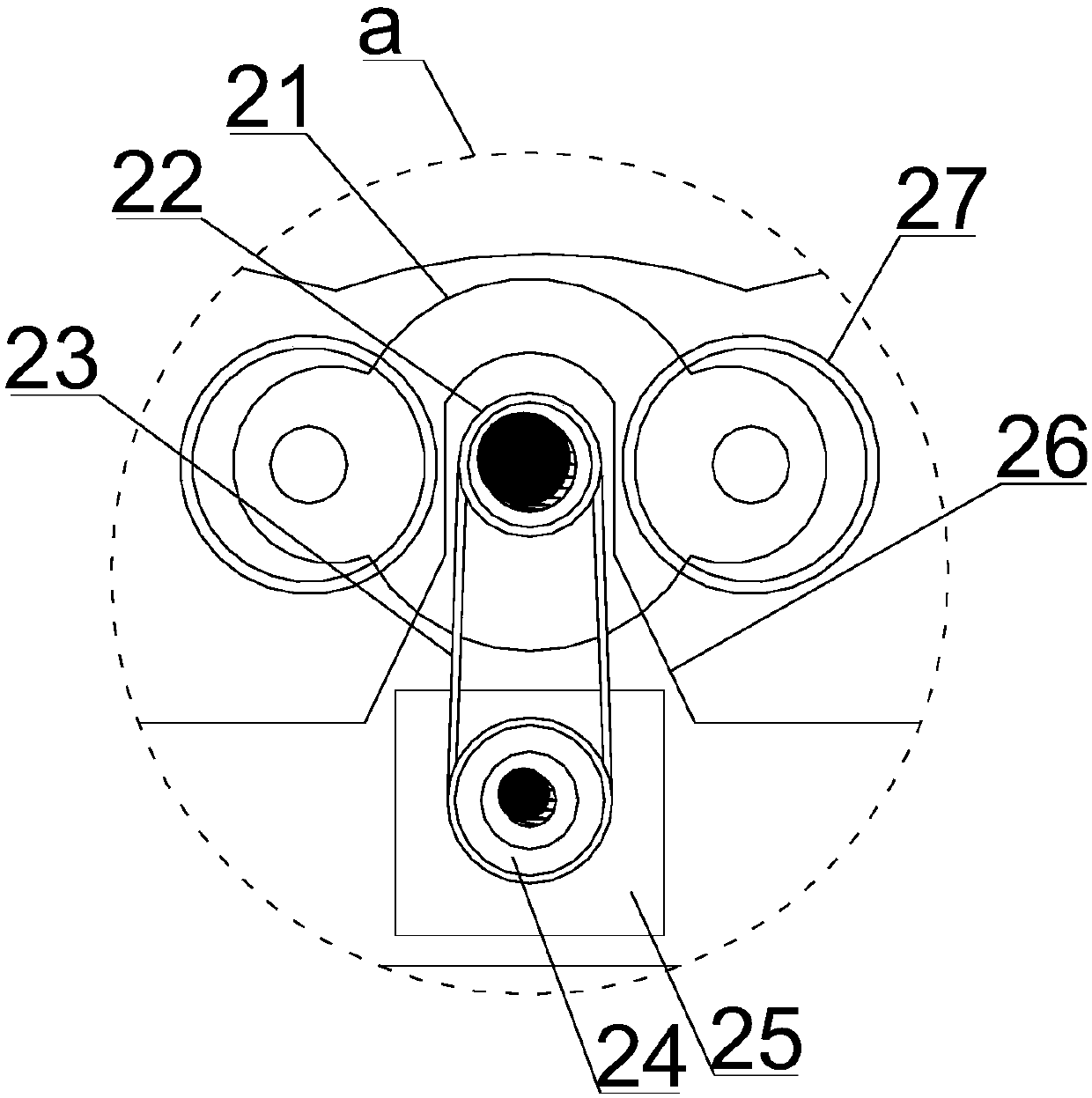

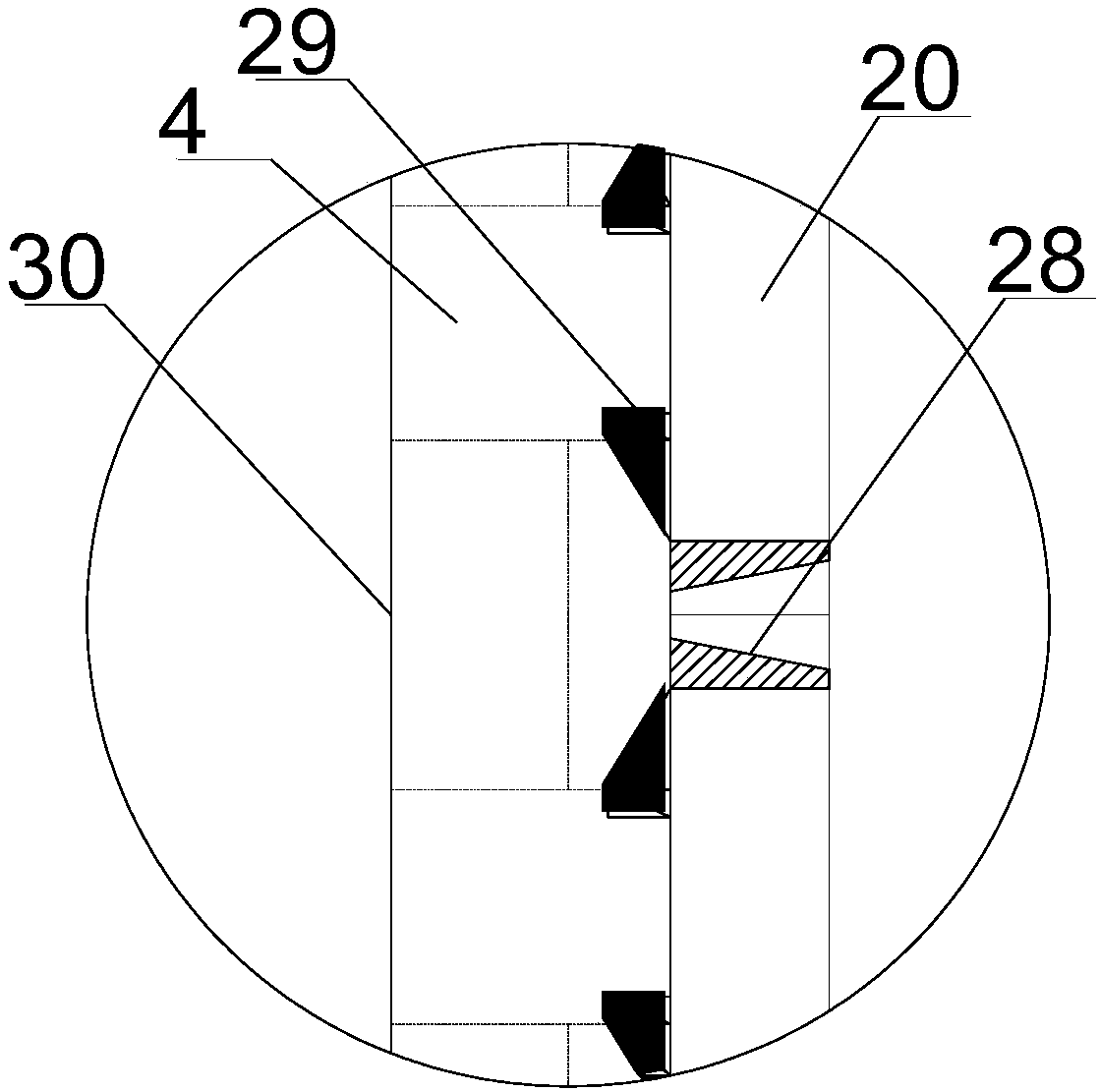

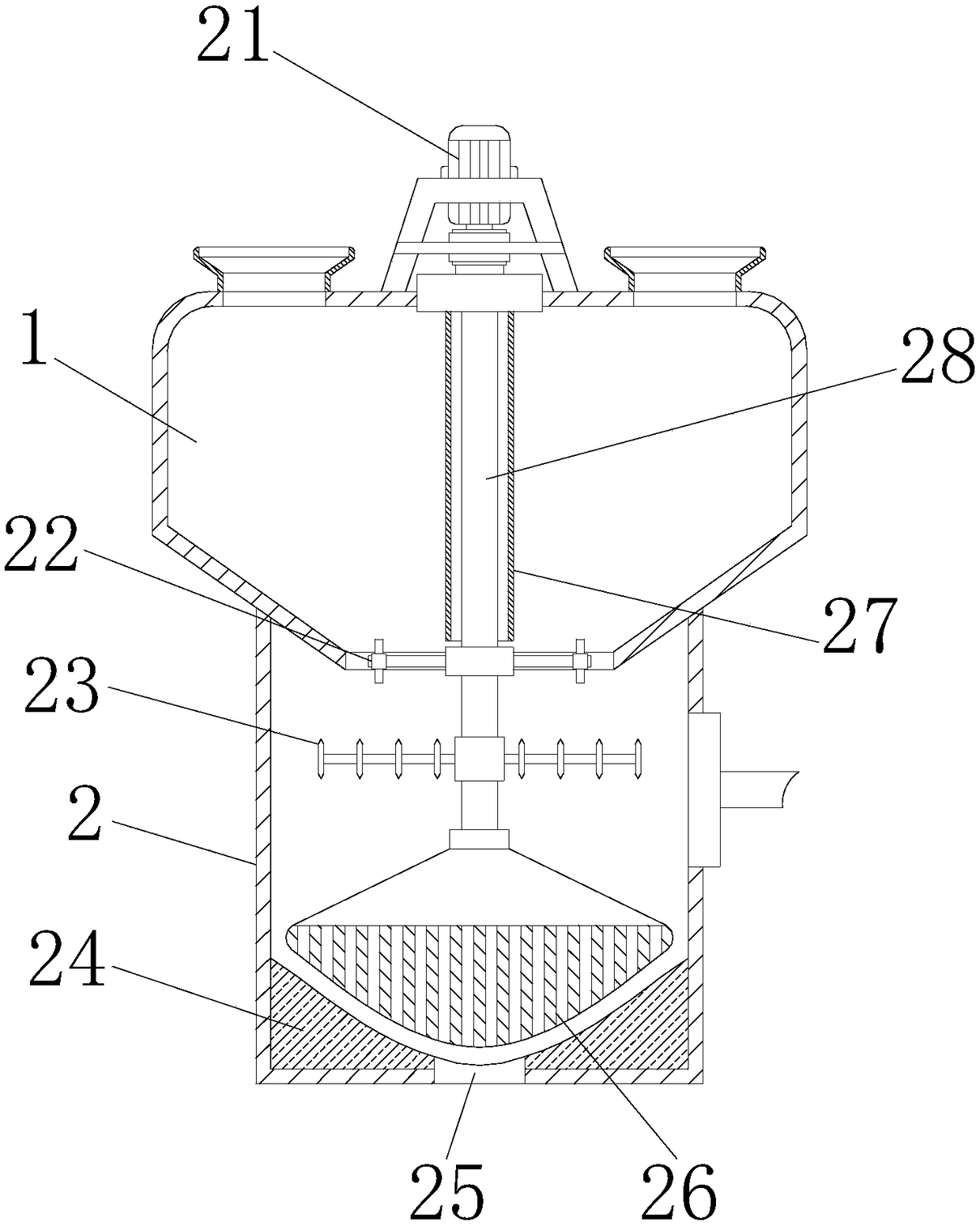

Feed stirring and pelletizing device

InactiveCN107583492AImprove granulation efficiencyLoose structural designFeeding-stuffRotary stirring mixersDrive motorBilateral symmetry

The invention discloses a feed stirring and pelletizing device. The feed stirring and pelletizing device comprises a supporting stirring module and a reciprocating pelletizing module, wherein the supporting stirring module comprises a diameter-variable stirring mounting barrel which is vertically arranged; supporting mounting columns are obliquely arranged at the lower end of the diameter-variablestirring mounting barrel in a bilateral symmetry manner; a material guide mounting plate is horizontally embedded into the upper end of the diameter-variable stirring mounting barrel; a motor mounting frame is mounted at the middle position of the material guide mounting plate in a vertical penetration manner; a driving motor is vertically embedded into the motor mounting frame; a driving rotaryshaft is vertically and downward arranged at the bottom of the motor mounting frame through a bearing sleeve; the material guide mounting plate and the motor mounting frame are matched and are provided with a material guide ring net in a concentric embedding manner. The feed stirring and pelletizing device disclosed by the invention has the advantages of compact structural design, simple and efficient transmission, stable transmission, high pelletizing efficiency, reasonable device shape, energy saving and high efficiency and the like.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

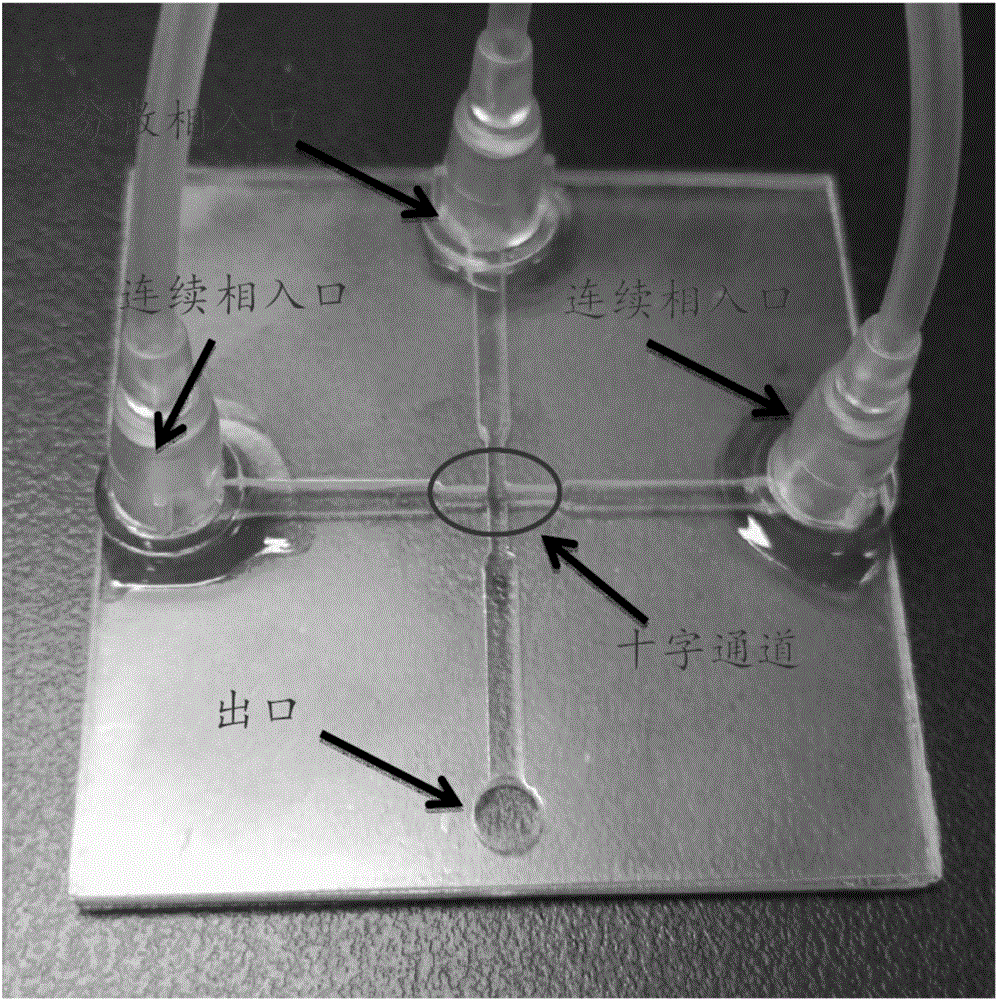

Microfluidic one-step synthesis method of chitosan microspheres for heavy metal wastewater treatment

InactiveCN105709696AShort manufacturing processSimple methodOther chemical processesWater contaminantsMicrofluidic chipAqueous solution

The invention provides a chitosan microsphere microfluidic one-step synthesis method for heavy metal wastewater treatment, the method comprising the following steps: a. preparing chitosan aqueous solution as the dispersed phase; b. preparing the oil added with cross-linking agent phase as the continuous phase; c. passing the obtained continuous phase and the dispersed phase into the microfluidic chip for shearing, forming chitosan droplets, and cross-linking and curing; and d. the obtained cross-linking and curing chitosan particles After washing, dry to obtain chitosan microspheres.

Owner:EAST CHINA UNIV OF SCI & TECH

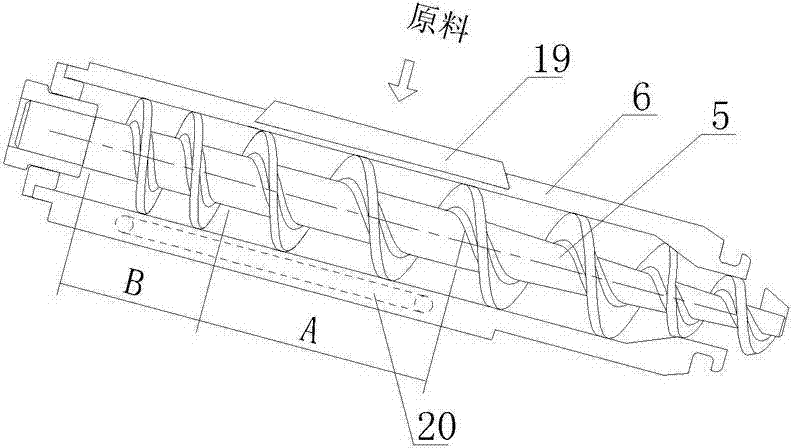

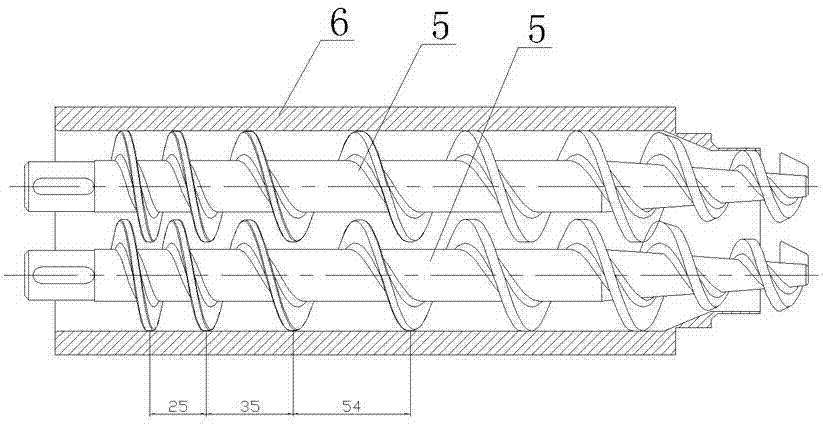

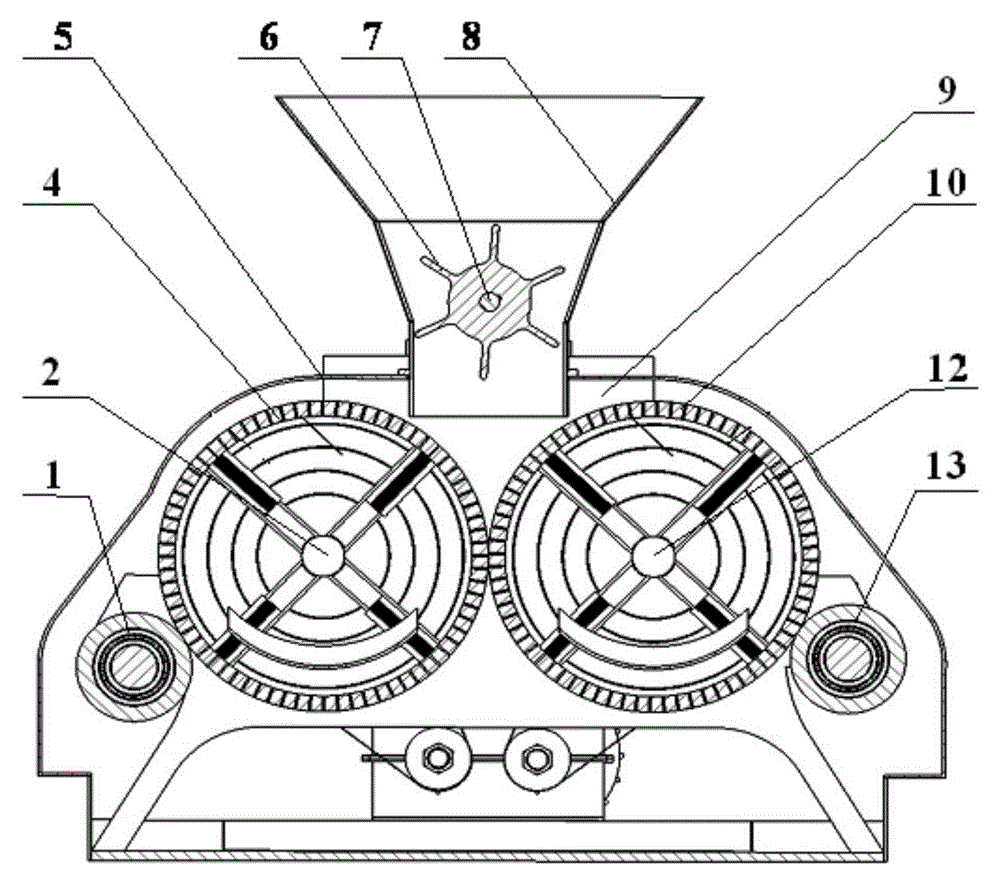

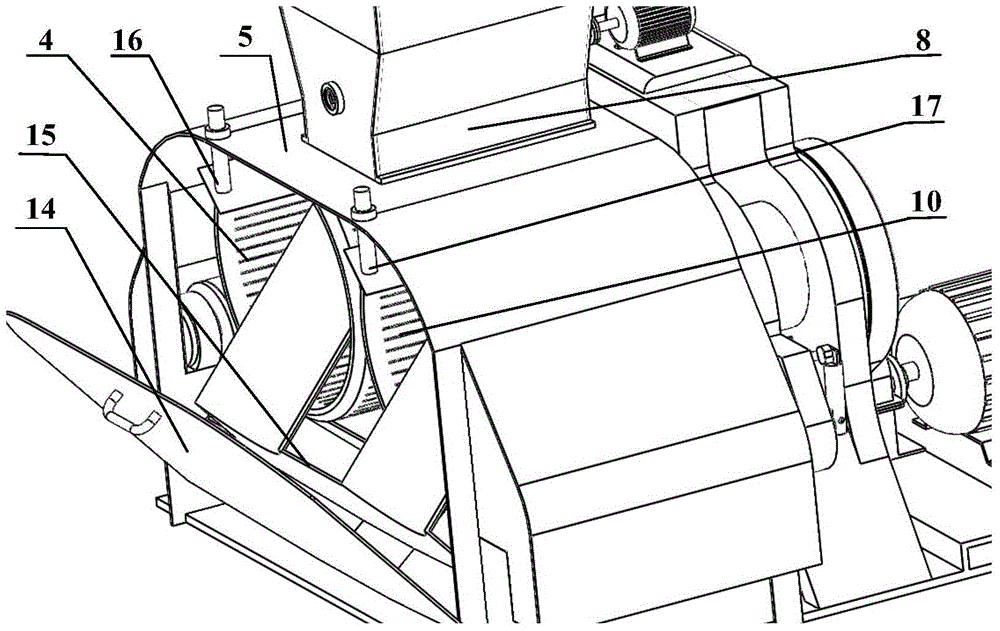

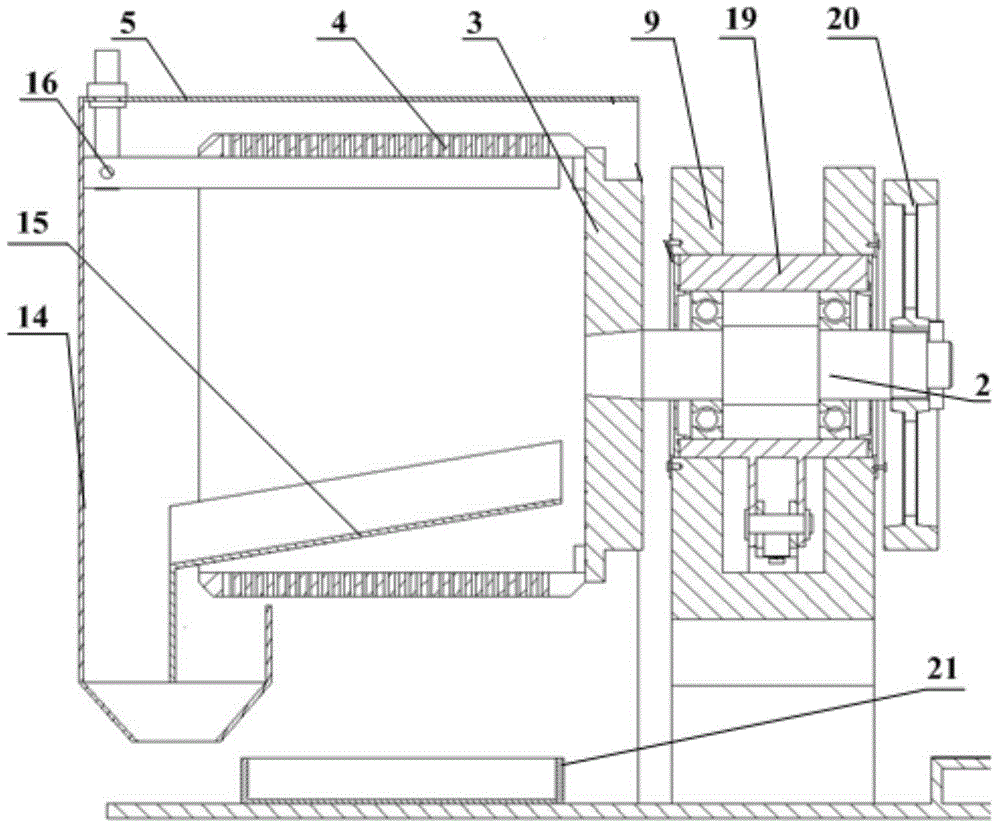

Feed mixing double-roll pellet pressing device

InactiveCN107997214AQuality improvementImprove granulation efficiencyFeeding-stuffGear wheelSprocket

The invention discloses a feed mixing double-roll pellet pressing device. The upper end of a worm is fixedly connected with a chain wheel; the chain wheel is engaged with the right end of a chain; theleft end of the chain is engaged with the other chain wheel; the upper part of the worm is fixedly connected with stirring blades; worm gears are arranged at the lower ends of the stirring blades andare engaged with the worm; the surface of each worm gear is fixedly connected with connection overturning plates; a rotary table is arranged at the lower ends of the worm gears and is fixedly connected with the middle part of the worm; the surface of the rotary table is fixedly connected with intermittent discharge pipes; the middle part of each rotary shaft is fixedly connected with a pressure roll; the end part of each rotary shaft is fixedly connected with a gear; the upper end of each gear is engaged with an annular rack; and the lower end of each pressure roll is provided with a flat template. By adopting the device, a raw material is conveyed upward through rotation of a spiral material lifting roll, so that manual lifting and pouring are omitted; the worm drives the overturning plates and the stirring blades to longitudinally and laterally rotate, so that the raw material is fully and uniformly stirred in a device body; and the pressure rolls which perform revolution around theworm while performing rotation are matched with the flat temperature to extrude the feed raw material. The device is reasonable and applicable in structure design, greatly improves the pelleting efficiency of an agricultural feed, saves the labor and is better in quality of the feed.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

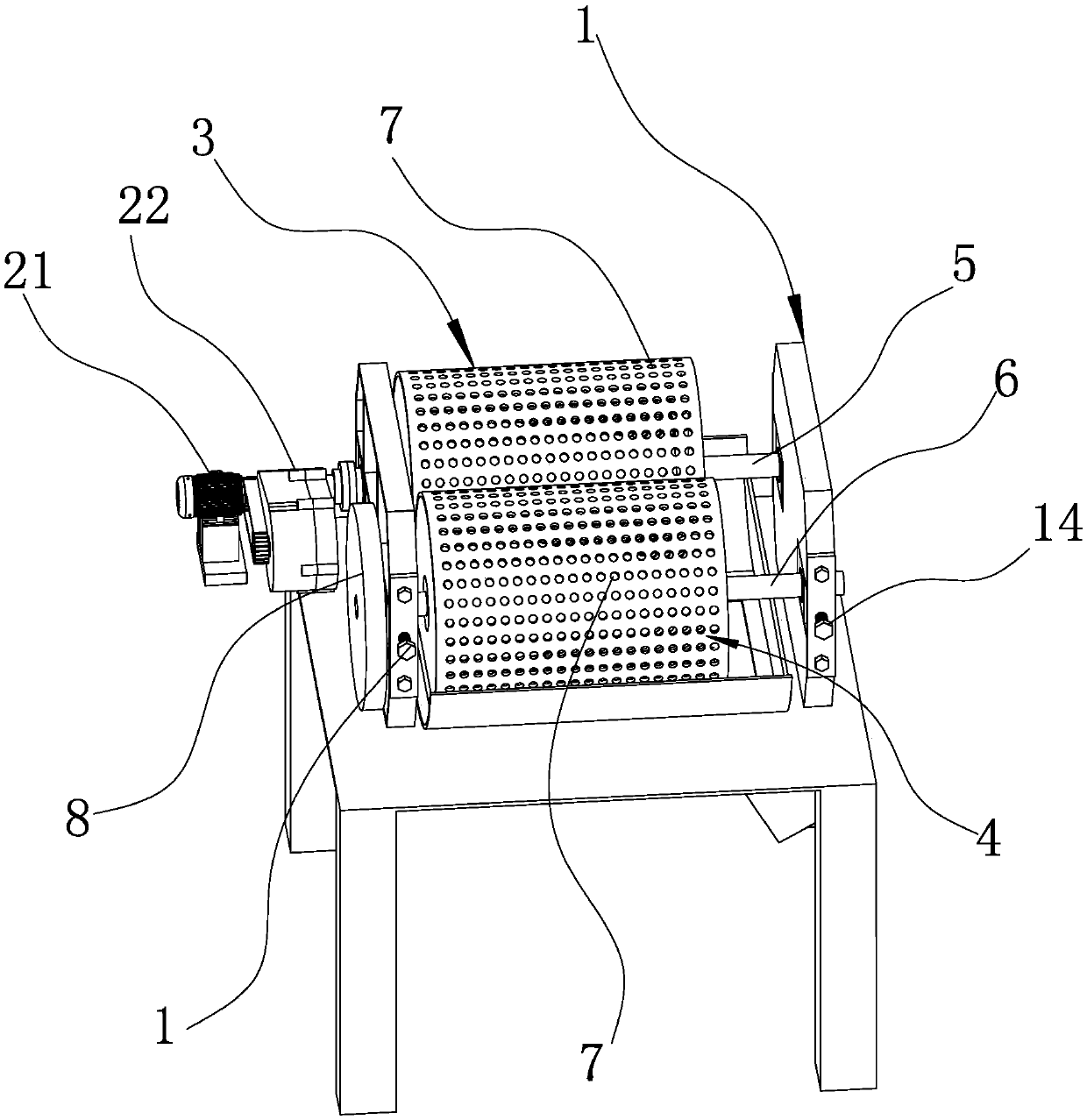

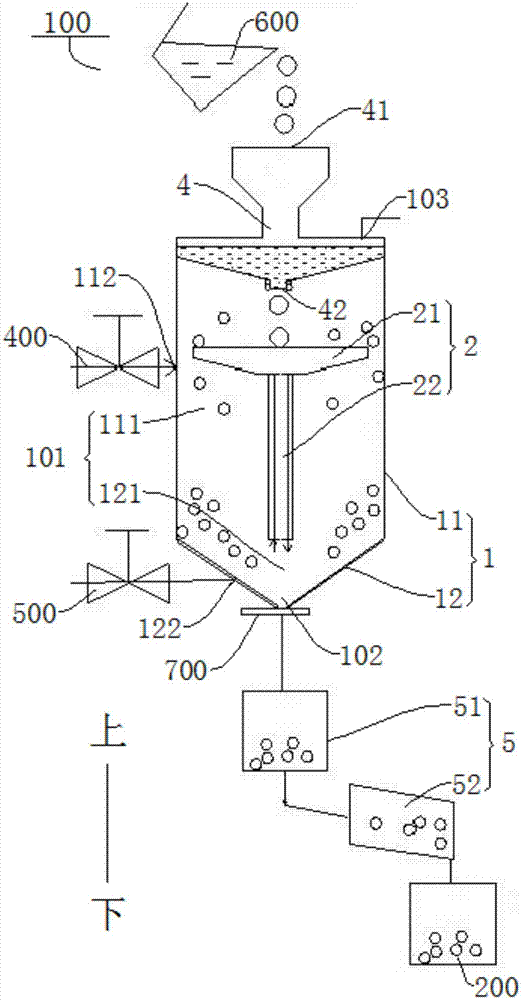

Roller pelletizer for sludge ceramsite granulation

PendingCN107551953AAvoid overload damageAvoid stickingCeramic shaping apparatusGranulation by pressingHigh energySludge

The invention relates to a roller pelletizer for sludge ceramsite granulation and belongs to the technical field of pelletizing equipment. In order to solve the problems of low efficiency and high energy consumption at present, the invention provides the roller pelletizer for sludge ceramsite granulation. The roller pelletizer comprises a frame, a driving mechanism, a driving roller and a driven roller, wherein the driving roller is arranged on the frame in a rotatable form through a first rotating shaft; the driven roller is arranged on the frame in the rotatable form through a second rotating shaft; the driving roller and the driven roller are horizontally arranged; a plurality of through holes are formed along the circumferential directions of the roller walls of the driving roller andthe driven roller; the driving mechanism is capable of driving the first rotating shaft to drive the driving roller to rotate; a flywheel is fixed on the second rotating shaft of the driven roller; the flywheel is located on the outer side of the driven roller. The through holes and the flywheel are arranged, so that the overload damage of the power source, such as a motor, in the driving mechanism can be avoided, the energy-saving effect can be achieved, the sludge ceramsite can be prevented from attaching to the through holes, the pelletizing efficiency is increased and the performance of quickly pelletizing can be realized.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

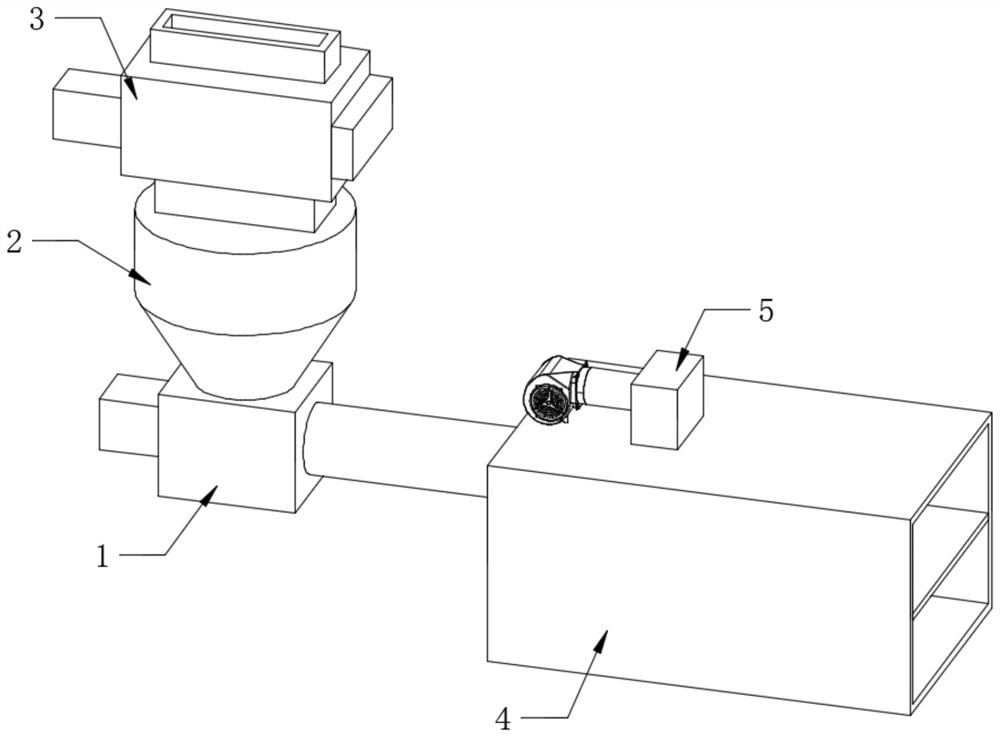

High-efficiency granulator for organic fertilizer production

InactiveCN108855540AImprove granulation efficiencyImprove the processing environmentGas treatmentDispersed particle separationSpiral bladeElectric machinery

The invention discloses a high-efficiency granulator for organic fertilizer production. The high-efficiency granulator for organic fertilizer production comprises an unloading hopper, a driving motor,a base, a conveying cylinder, a spiral rotating shaft, spiral blades and a discharge port; the conveying cylinder is mounted at the upper end of the base; the spiral rotating shaft is mounted in theconveying cylinder; the spiral blades are arranged on the surface of the spiral rotating shaft; and the driving motor is mounted at one end of the conveying cylinder opposite to the spiral rotating shaft. A crushing hopper is mounted on the unloading hopper; a stepper motor drives a connecting shaft to rotate; through an anti-blockage unloading rod, materials fall into the crushing hopper from theunloading hopper; the falling raw materials are contacted with a rotated crushing blade for primary crushing; the raw materials after primary crushing fall into a gap between a grinding base and a grinding disc; through rotation of the grinding disc, the materials are further crushed and refined; the crushed raw materials are discharged into the conveying cylinder from an unloading port; and through dual crushing, the raw materials are fined, and the granulation efficiency of organic fertilizers is improved.

Owner:福州立农环保科技有限公司

Multifunctional automatic vertical straw granulation equipment

PendingCN113230977AAvoid diversionRealize automatic integrated granulationBiofuelsDrying gas arrangementsElectric machineProcess engineering

The invention discloses multifunctional automatic vertical straw granulation equipment. The equipment comprises an extrusion mechanism, a crushing mechanism, a rolling mechanism, a storage mechanism, a hot air mechanism and a pelletizing mechanism. Straw is preliminarily ground through the extruding mechanism, the ground straw falls into the crushing mechanism, a crushing motor drives a crushing cutter to crush the straw, the crushed straw falls into the extrusion mechanism, the crushed straw is extruded into straw strips, an output shaft of a pelletizing motor drives a pelletizing cutter to rotate to make the straw strips pelletized, the pelletized straw falls into a net plate in an inner cavity of a storage box, then a fan is started, a heating wire is electrified, the heating wire adds air conveyed into the heating box through a branch pipe, hot air is blown into the storage box through an air outlet cover, straw particles in the inner cavity of the storage box are dried, the situation that the straw is manually transferred can be avoided, automatic integrated granulation is achieved, and the granulation efficiency is greatly improved.

Owner:郭荣阳

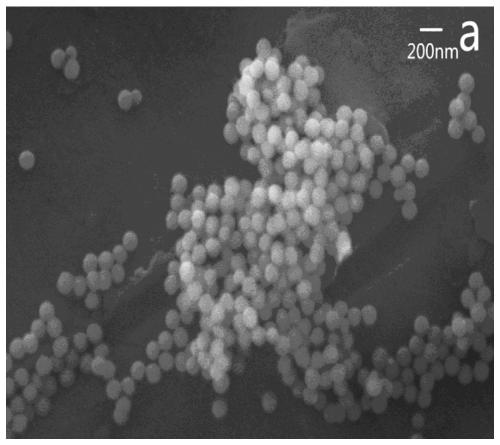

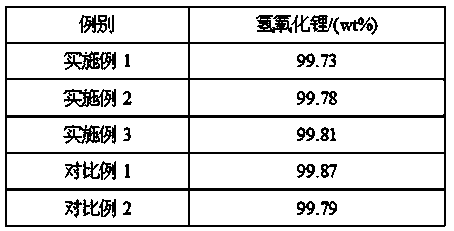

Nano spherical lithium hydroxide and preparation method thereof

ActiveCN111115663AGood dispersionPrevent compactionLithium oxides/hydroxidesMicroballoon preparationLithium oxideDispersity

The invention discloses nano spherical lithium hydroxide and a preparation method thereof. The nano spherical lithium hydroxide and the preparation method thereof are characterized in that the particle size of primary particles of the lithium hydroxide nanospheres is 10-600nm, the particle size D50 of laser particle size test is 50-2000nm, the purity of the lithium hydroxide nanospheres is greaterthan 99.7%, and the balance is 0.01-0.2% of non-polar organic matters and a proper amount of impurities. According to the nanospheres, a lithium hydroxide solution is matched with a non-polar organicsolvent and an ionic surfactant with a hydrophobic group according to a certain proportion to form stable water-in-oil, namely the structure is a structure that an organic matter wraps a water phase(W / O), the solution system is enabled to form emulsion liquid beads with nanometer and micrometer sizes, then, the lithium hydroxide of the liquid beads can be dried in the spraying process to separate out spherical nanoparticles, and in the drying process, a small amount of non-polar organic matters are remained, so that the dispersity of the lithium hydroxide nanospheres is improved, the hardening of the lithium hydroxide particles is favorably prevented, and the better physical morphology and size of the lithium hydroxide nanospheres are maintained.

Owner:苏州众鑫凯能源科技有限公司

Disc granulator

InactiveCN107175041AEasy to granulateUniform grainGranulation in rotating dishes/pansHydraulic cylinderProduction rate

The invention discloses a disc granulator, which comprises a base, and a control device is arranged on the top of the base, and the control device includes a signal receiver, a signal processor and a first signal transmitter. A hydraulic cylinder, one side of the hydraulic cylinder is connected with a movable piston rod, one end of the piston rod is provided with a bracket, one end of the bracket is provided with a partition, one end of the partition is fixedly connected to the base, and the top of the partition is provided with a motor, The top of the bracket is provided with an electromagnetic heater, the bottom of the electromagnetic heater is provided with a disk, the surface of the disk is provided with a corresponding disk cover, the top of the disk is provided with a feed port, and the disk A water storage chamber is provided on one side of the disc, a first discharge port is provided at the bottom of the disc, a second discharge port is provided at one side of the disc, and a disc bracket is provided outside the disc. The invention has the advantages of uniform granulation, stable quality, high yield and high productivity, safety and environmental protection.

Owner:JIANGSU SELF ENVIRONMENTAL SCI & TECHCO

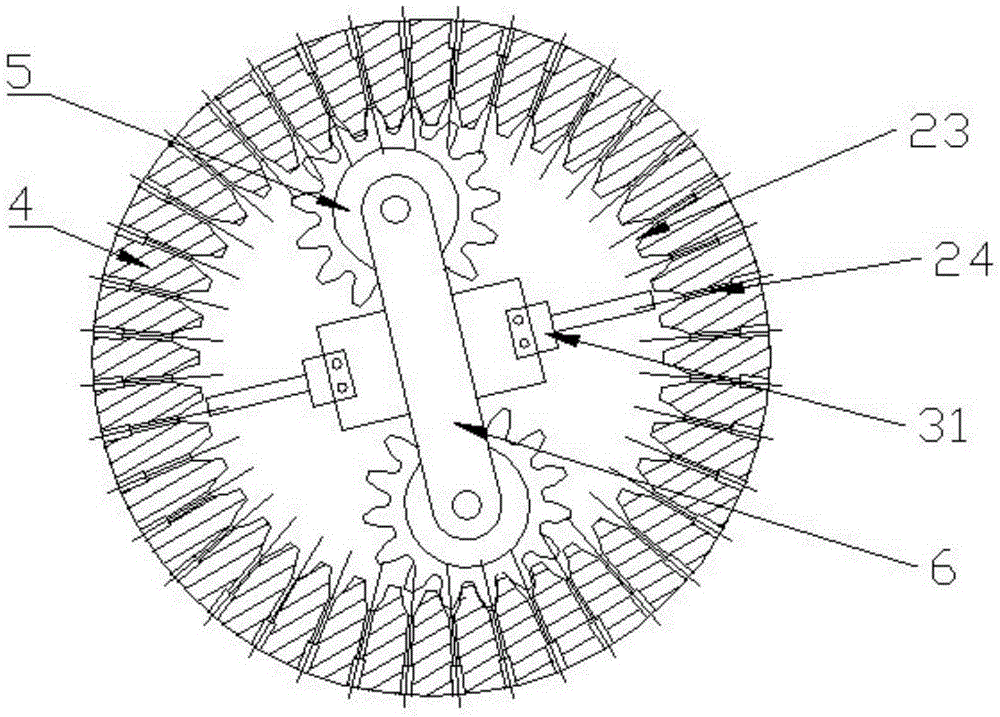

Double supporting rollers-type double circular molds granulator

InactiveCN105013397AEasy to disassemble and replaceImprove support stiffnessGranulation by pressingImpellerReducer

The invention discloses a double supporting rollers-type double circular molds granulator, which comprises a first supporting roller, a first rotating shaft, a first circular mold, a casing, an impeller, an impeller shaft, a hopper, a support, a second circular mold, a second rotating shaft, a second supporting roller, a door cover, a material collecting trough, a first scraper, a second scraper, a first bearing sleeve, a first belt wheel, a residual material groove, a gear reducer, a main motor, a second belt wheel, a second bearing sleeve, a first synchronous belt, a third belt wheel, a first compaction wheel, a second compaction wheel, a fourth belt wheel, a second synchronous belt, and an impeller motor. The double circular molds granulator has the advantages that dismounting and replacing of the circular molds are convenient and fast, the supporting rollers support the circular molds, support rigidity of the circular molds can be greatly increased, the granulator can be used for extruding the difficultly-extruded materials, width of the circular molds can be increased greatly, granulation efficiency is greatly increased; the scraper is employed for cooperating the material collecting trough for collecting the material, the material collecting trough is arranged on the door cover, when the door cover is opened, a cutter on the scraper is dismounted so that the circular molds can be rapidly replaced.

Owner:NANJING UNIV OF SCI & TECH

Liquid calcium carbide granulating device

PendingCN107117617AImprove cooling efficiencyImprove granulation efficiencyCalcium carbidePollutionCalcium carbide

The invention discloses a liquid calcium carbide granulating device. The liquid calcium carbide granulating device comprises a granulating tower, a first air blowing device, a second air blowing device and a granulating machine, wherein a granulating cavity is formed in the granulating tower; an outlet and an inlet are respectively formed in the bottom part and the top part of the granulating cavity; a first air inlet and a second air inlet are formed in the side wall of the granulating cavity; the first air blowing device is connected with the first air inlet; the second air blowing device is connected with the second air inlet; the granulating machine is arranged in the granulating cavity; the granulating machine is configured in a way that liquid calcium carbide entering from the inlet is converted into a liquid calcium carbide film and the liquid calcium carbide film is thrown away from the granulating machine; the first air blowing device is configured in a way that the liquid calcium carbide film thrown away from the granulating machine is divided into multiple liquid calcium carbide drops by division air entering the granulating cavity and the multiple liquid calcium carbide drops are discharged from the outlet after being cooled into calcium carbide granules by cooling air entering the granulating cavity. According to the liquid calcium carbide granulating device disclosed by the invention, the production efficiency is high, the utilization rate of factory area is high, and environment pollution caused by a smashing process can be avoided.

Owner:SHENWU TECH GRP CO LTD

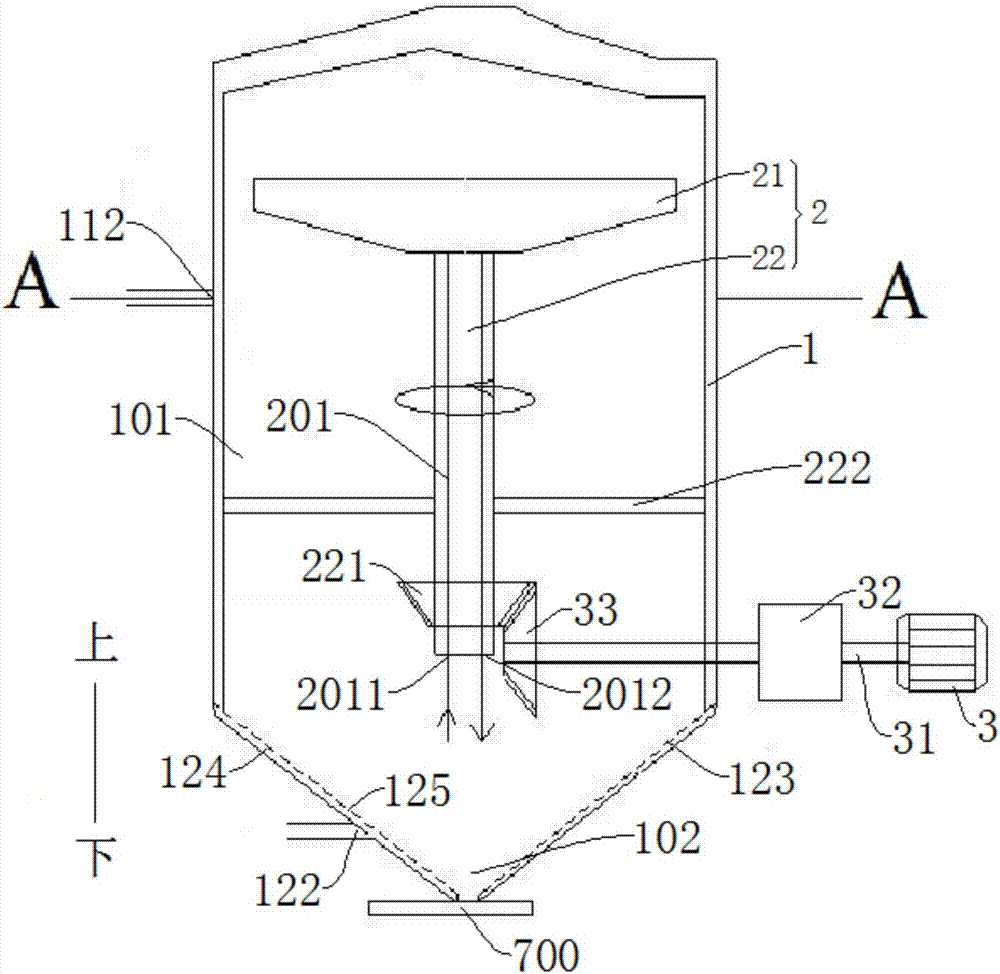

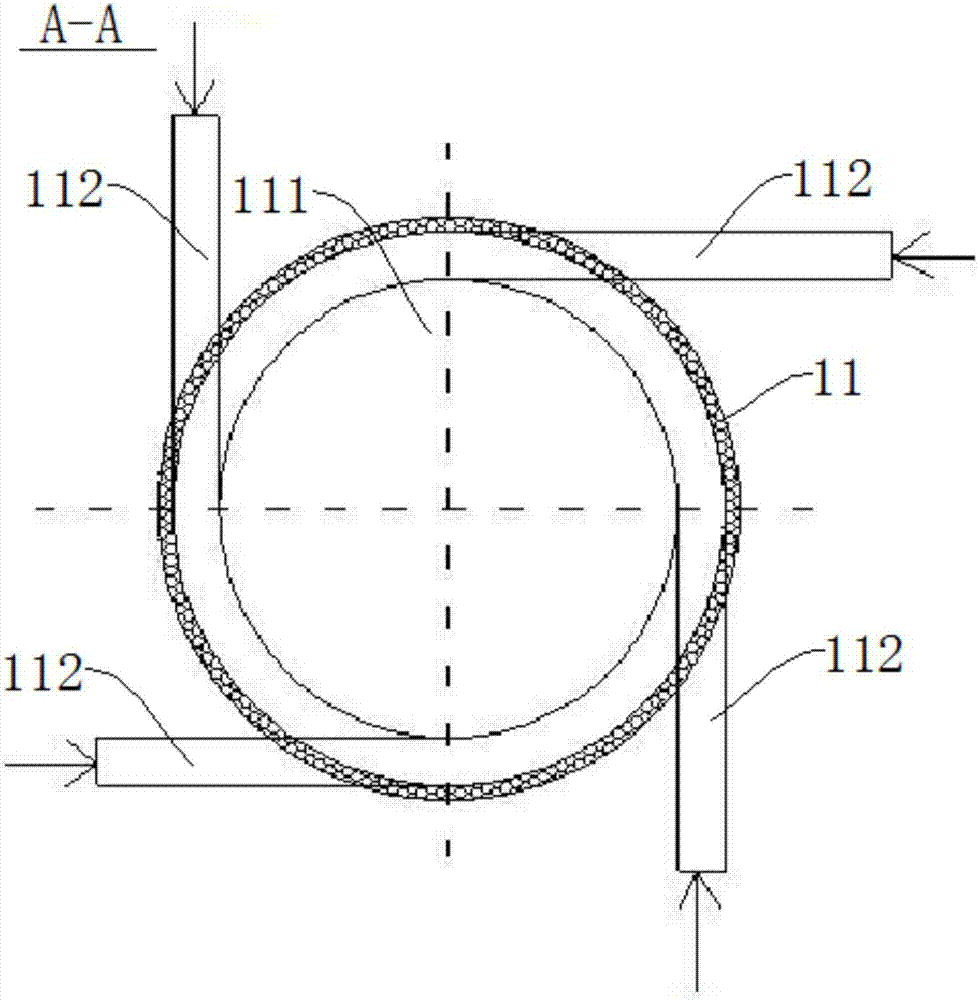

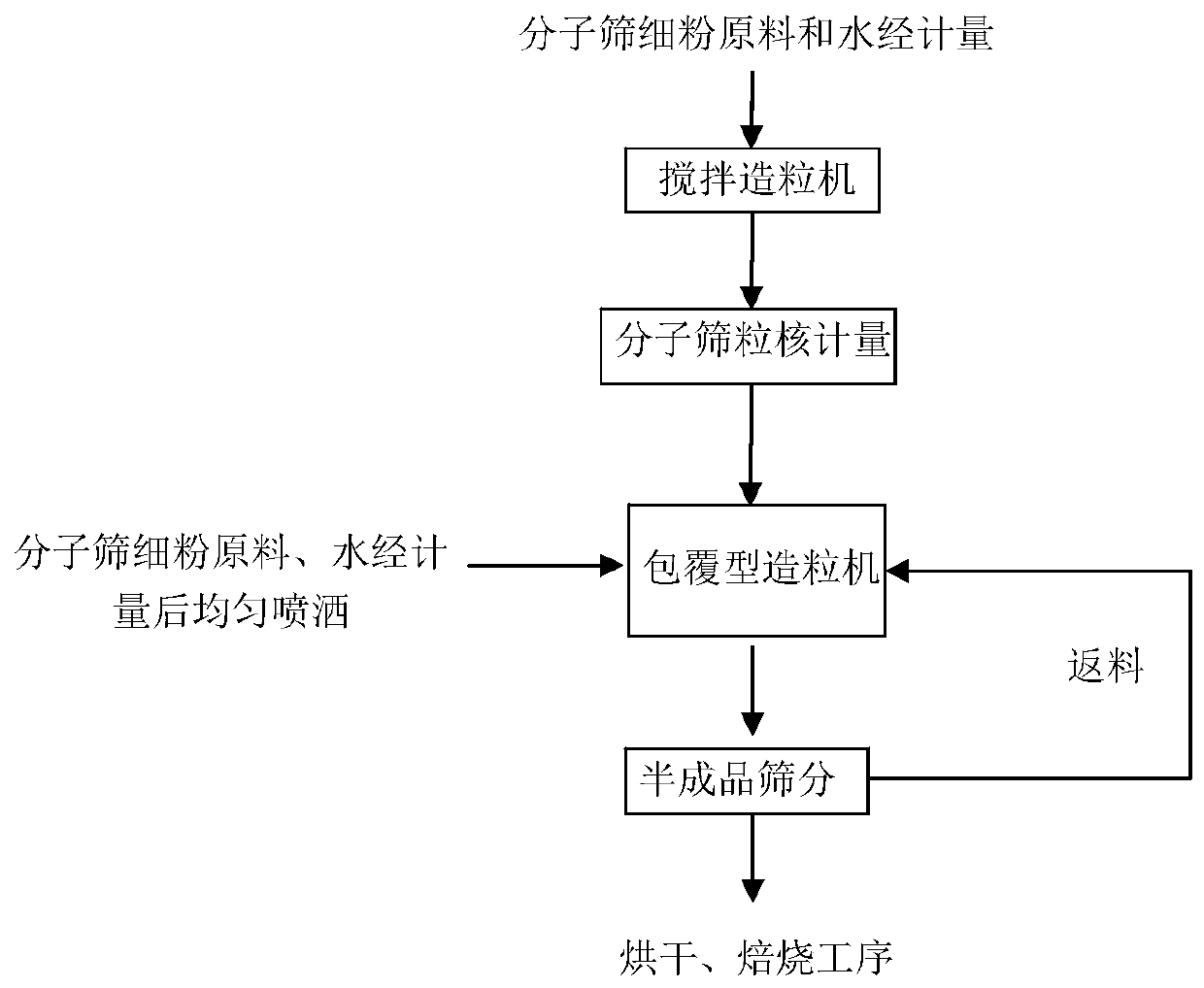

Method for preparing spherical molecular sieve

InactiveCN110237771AImprove ball forming efficiencyDense grainGranulation in stationary drums/troughsMolecular sieveSpherical shaped

The invention relates to a method for preparing a spherical molecular sieve. The method comprises the steps: (1) preparation of small-particle nuclei: adding a molecular sieve fine powder raw material and water to a stirring granulator, and performing stirring and granulation so as to obtain the small-particle nuclei with a particle diameter of 0.5-2.0 mm; (2) preparation of molecular sieve spherical particles: adding the small-particle nuclei, the molecular sieve fine powder raw material and water to a coating granulator so as to form the molecular sieve spherical particles; and (3) preparation of the finished product: performing sieving, drying and calcination on the molecular sieve spherical particles so as to obtain the spherical molecular sieve product. Compared with the prior art, the method has the advantages of a high pelletization rate of nuclei, energy saving, environmental protection and a simple preparation process, and the molecular sieve particles are compact, and has a rounded appearance and smooth appearance.

Owner:SHANGHAI RES INST OF CHEM IND

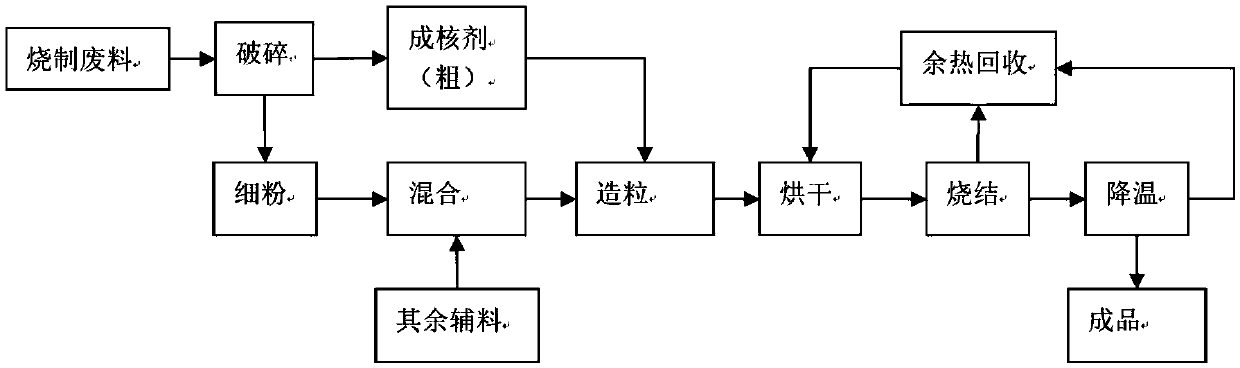

Application of ceramic waste in preparation of high-strength light aggregate and prepared high-strength light aggregate

InactiveCN110950558AReduce manufacturing costLow thermal conductivityThermal insulationExpanded clay aggregate

The invention belongs to the technical field of treatment and resource utilization of environment-friendly building, building material and solid waste, particularly relates to application of ceramic waste in preparation of high-strength light aggregate, and further discloses high-strength light aggregate prepared from ceramic waste and fly ash, and a preparation method thereof. According to the light aggregate disclosed by the invention, fly ash and solid waste such as ceramic wastes generated in each stage of a ceramic production process are used as raw materials, and the high-strength lightaggregate is prepared from different additives based on the interaction of the characteristics of the ceramic wastes generated in different stages, and has good performance advantages, so that the production cost of the light aggregate is reduced, and the solid waste utilization is maximized so as to obtain building ceramsite with the advantages of light weight, high strength, low heat conductioncoefficient, high refractoriness, good chemical stability, good durability and good thermal insulation and sound insulation performances.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com