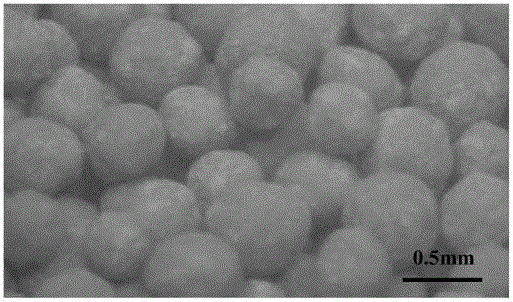

Composition for preparing spherical ceramic particles, and spherical ceramic particles as well as preparation method and application thereof

A technology of ceramic particles and compositions, applied in the field of special ceramics, can solve the problems of reducing the molding efficiency of spherical green bodies, energy loss, etc., and achieve the effects of facilitating large-scale industrial production, low production energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] According to the composition of the present invention, the type of the binding agent can be selected in a wide range, and the binding agents conventionally used in the art can be used in the present invention. According to a preferred embodiment of the present invention, the binding agent One or more of polyvinyl alcohol, dextrin and starch.

[0047] According to the composition of the present invention, the type of the solvent can be selected in a wide range, and solvents commonly used in the field can be used in the present invention. According to a preferred embodiment of the present invention, the solvent is water.

[0048] The use of the aforementioned composition of the present invention to prepare spherical ceramic particles can reduce the energy consumption of processing raw materials, shorten the molding time of spherical particles, and thereby reduce the production cost of spherical ceramic particles. The raw material formula of the invention is simple, enviro...

Embodiment 1

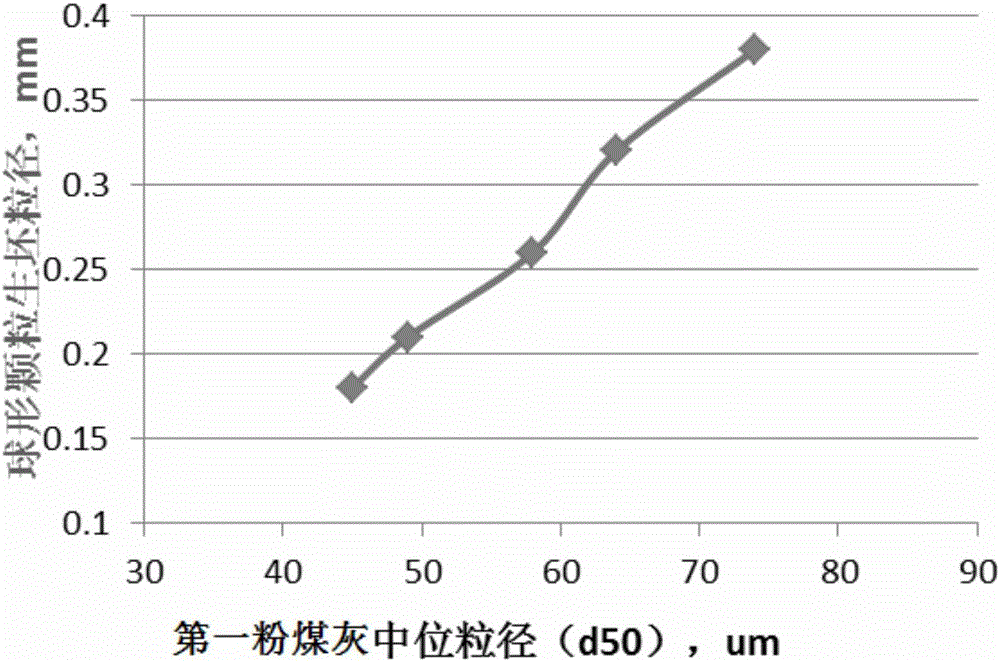

[0092] Add 6 kilograms of coarse-grained fly ash (the first fly ash) of d50=45 micron, d10=31 micron, d90=65 micron into a disc-type ball forming machine with a diameter of 1.5 meters, and rotate at a speed of 15 rpm to form For ball disks, spray 1.3kg of PVA solution with a concentration of 0.5wt% evenly in 15 minutes, so that the surface of the coarse-grained fly ash is fully wetted, and there is no bonding between the particles, and there is a good particle size in the ball disk. fluidity;

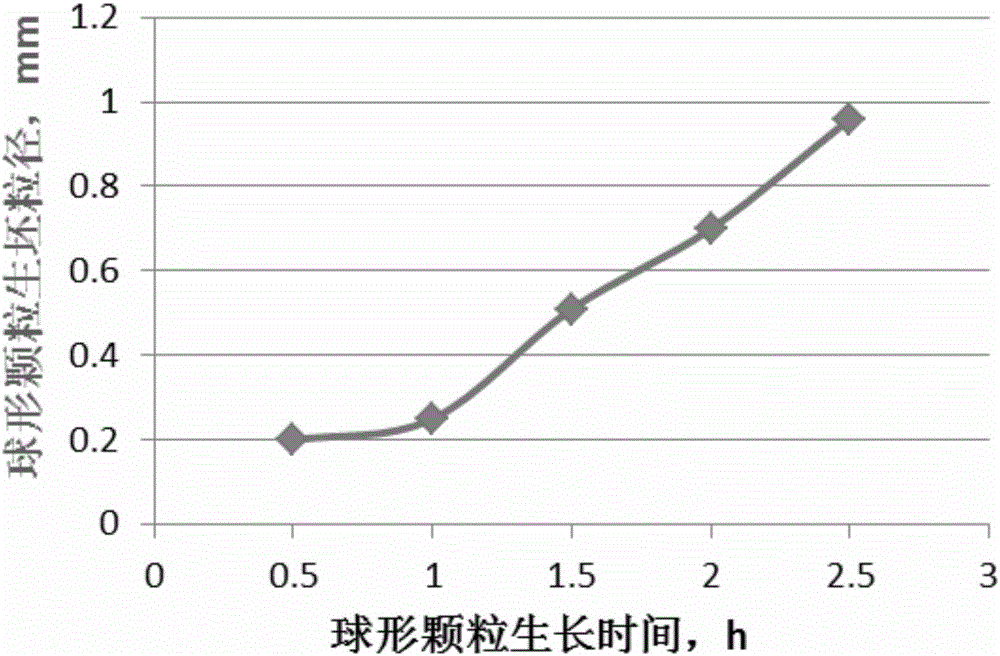

[0093] Add d50=1.6 micron, d10=0.2 micron, d90=6.3 micron fine particle size fly ash (second fly ash) and PVA solution into the coarse particle size fly ash after wetting evenly, and continuously Repeat the steps of adding fine powder and adding binder solution to make spherical particles grow up constantly, and grow to 0.18 millimeters through 50 minutes. At this stage, the add-on of PVA solution is 53.7 kilograms, and the add-on of the second particle size fly ash is 270kg;

[0094]...

Embodiment 2

[0096] Add 2 kg of fly ash with a coarse particle size of d50=58 microns, d10=53 microns, and d90=73 microns into a disc-type ball forming machine with a diameter of 1.5 meters, turn it into a ball disc at a speed of 20 rpm, and spray it with mist in 10 minutes. Spray evenly 0.43kg of PVA binder solution with a concentration of 10wt% into the chemical nozzle, so that the surface of the coarse-grained fly ash is fully wetted, and there is no bonding between the particles, and it has good fluidity in the ball-forming disk;

[0097] Add d50=3 micron, d10=1.1 micron, d90=9.5 micron fine particle size fly ash and binder solution evenly into the wetted coarse particle size fly ash, and repeat adding fine powder and adding The step of binding agent solution makes spherical particle grow up constantly, and grows to 0.25 millimeter through 76 minutes, and the add-on of binding agent solution is 39.57 kilograms at this stage, and the add-on of the second particle size fly ash is 190 kilo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com