Ring-die granulator, and operating method and application thereof

A granulator and ring die technology, which is applied in the direction of manufacturing tools, mold extrusion granulation, chemical instruments and methods, etc., can solve the problem of unfavorable material granulation due to combined structure, short service life of ring die and pressure roller, and increased workpiece work Pressure and other issues to achieve the effect of improving the practicality and economy of use, easy heat dissipation, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

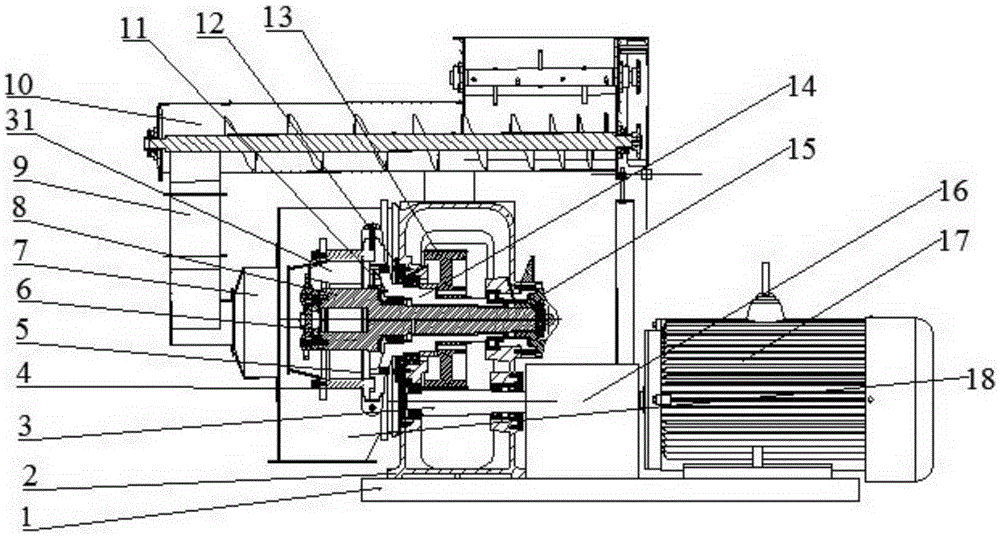

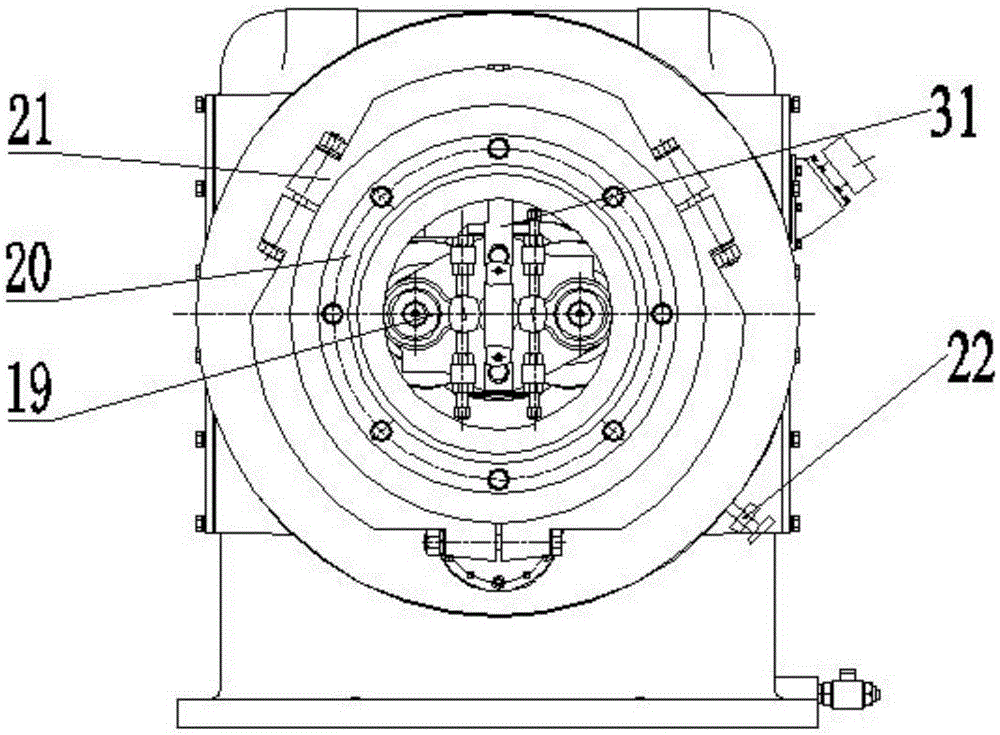

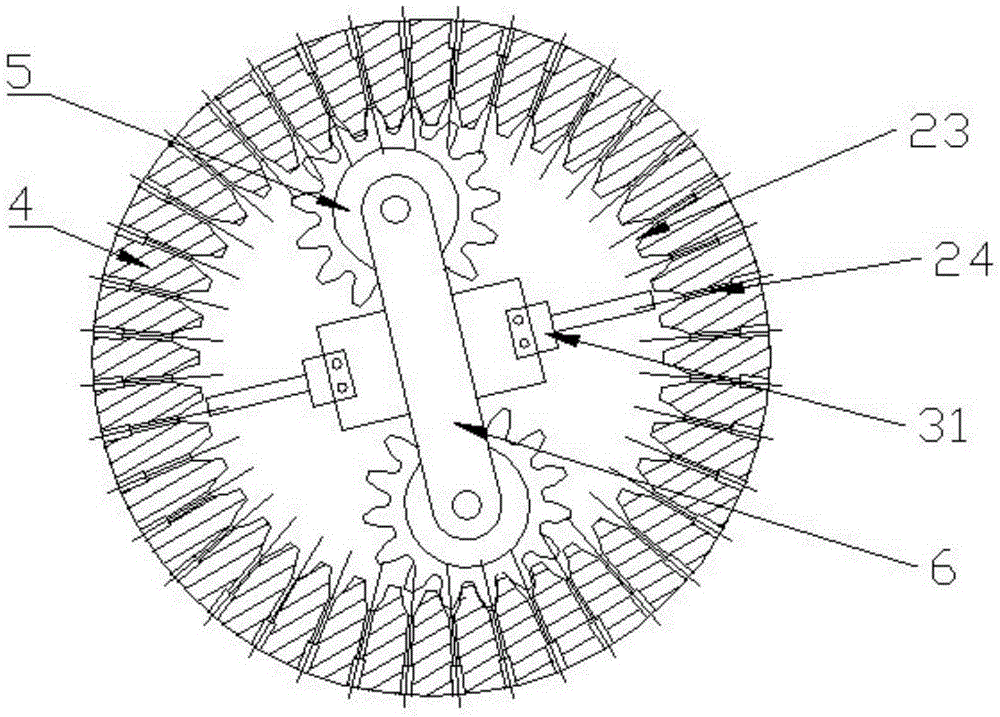

[0045] A kind of ring die granulator, comprises frame 1, the feeding part that is arranged on described frame 1, mold roller system, the motor 17 that drives described mold roller system, discharge port 18 and the mold roller The granulation chamber 20 provided outside the system, the feed part is connected with the mold roll system, and the granulation chamber 20 is connected with the discharge port 18; the mold roll system includes a ring die 4 with internal teeth, The pressure roller 5 with external teeth arranged in the ring die 4, the internal teeth 23 cooperate with the external teeth 28; the internal teeth 23 are arranged axially along the inner wall of the ring die 4, and A plurality of discharge holes 24 are radially arranged in the tooth grooves between the teeth 23; the discharge holes 24 include a pressing channel 30 and a diameter-expanding hole 32 connected radially from the inside to the outside and connected to the tooth grooves. The inner diameter of the press...

Embodiment 2

[0049] Ring die granulator as described in embodiment 1, the difference is that the feed section includes an auger 10 along the feed direction, a forced feeder 9 and the feed section of the feed section connected to the die roll system. Material mouth 7.

Embodiment 3

[0051] As in the ring die granulator described in Embodiment 1, the difference lies in that a small scraper 11 is arranged on the main shaft 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com