Charcoal matrix compound fertilizer and preparation method thereof

A biochar substrate and compound fertilizer technology, which is applied to organic fertilizers, inorganic fertilizers, urea compound fertilizers, etc., can solve the problems of cumbersome preparation process of biochar base fertilizers, poor granulation effect of fertilizer particles, and low utilization efficiency of chemical fertilizers. Extend the effective time limit, improve the granulation efficiency, and reduce the effect of Chen Ben

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: present embodiment a kind of biochar matrix compound fertilizer, this biochar matrix compound fertilizer is made up of 15~25 parts of carboxamides, 15~30 parts of superphosphate or diammonium hydrogen phosphate, 8 parts by mass. 20 parts of potassium chloride, 5 to 10 parts of bentonite, 0 to 2 parts of trace elements, 0 to 8 parts of water, 1 to 3 parts of binder and 15 to 30 parts of straw biochar.

[0020] This embodiment has the following beneficial effects:

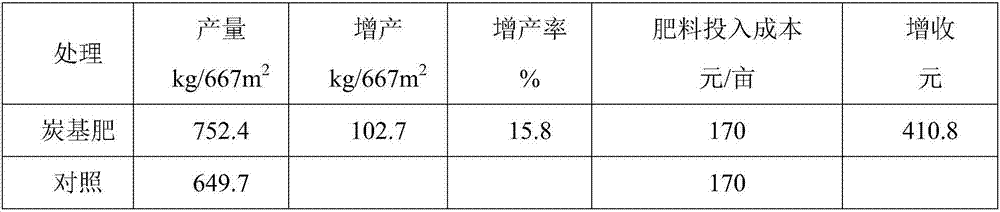

[0021] 1. The water content of the biochar-based compound fertilizer in this embodiment is 0-8%, the mechanical strength is greater than 85%, and the pH value is 6.4-7.2, which meets the corresponding national standards; the fertilizer can promote the growth and development of plants and promote the growth and development of rice seedlings. growth, improve tillering; at the same time, it can increase yield by more than 5%, increase income by 80 yuan / mu, and reduce aging cost by 10 yuan...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: the trace element is a mixture obtained by mixing chelated zinc and ferrous sulfate in any mass ratio. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the binder is a mixture of bentonite and vegetable starch. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com