Granulating equipment for making molten liquid into spherical granule product

A spherical particle and granulation device technology, which is applied in the direction of liquid separation into beads and granulation, can solve the problems of low thermal conductivity of paraffin wax, large footprint, and unreported device, and achieve good product quality, easy operation, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

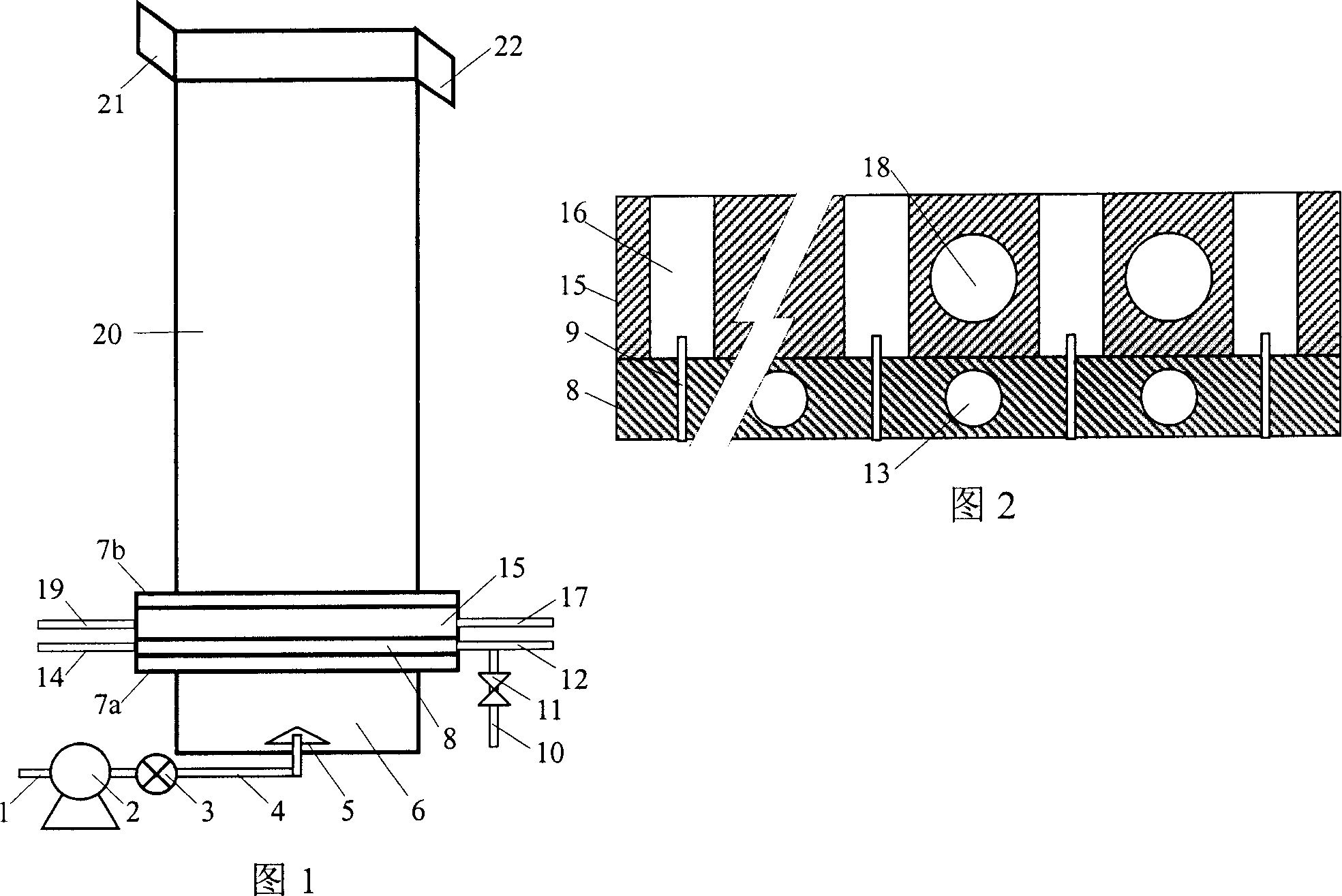

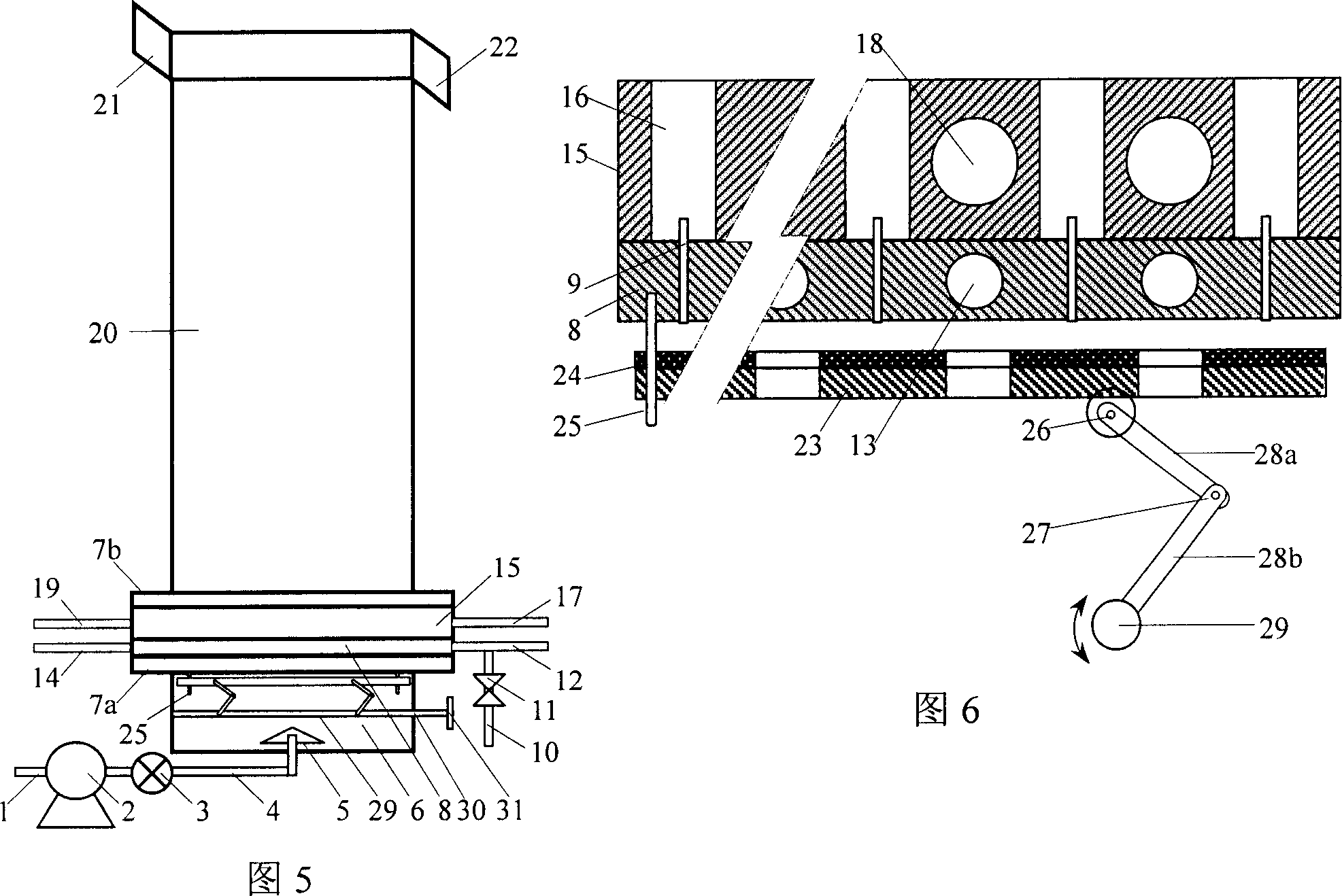

[0027] Embodiment 1: The present invention is carried out in the granulation of paraffin melt liquid, and the density of melt liquid is less than the density of cooling liquid, and its basic parameters and implementation effect are as follows:

[0028] The melting point of paraffin is 58°C, and the density of the molten liquid is about 776kg / m 3 , the density of solid paraffin is about 916kg / m 3, the temperature of the paraffin melt is 80°C, and cooling water is used as the cooling liquid. Use the device shown in Figure 1. The heating medium of the insulation board is steam, the heating medium of the switch is steam, and the cooling medium of the switch is cooling water. The cooling water is recycled after being cooled by the refrigeration device.

[0029] 1. When the diameter of the nozzle is 0.5mm, spherical paraffin particles with a diameter of 2-3mm are obtained. After draining and centrifugal fluidized bed dehydration, the water content is lower than 0.03%, and the pro...

Embodiment 2

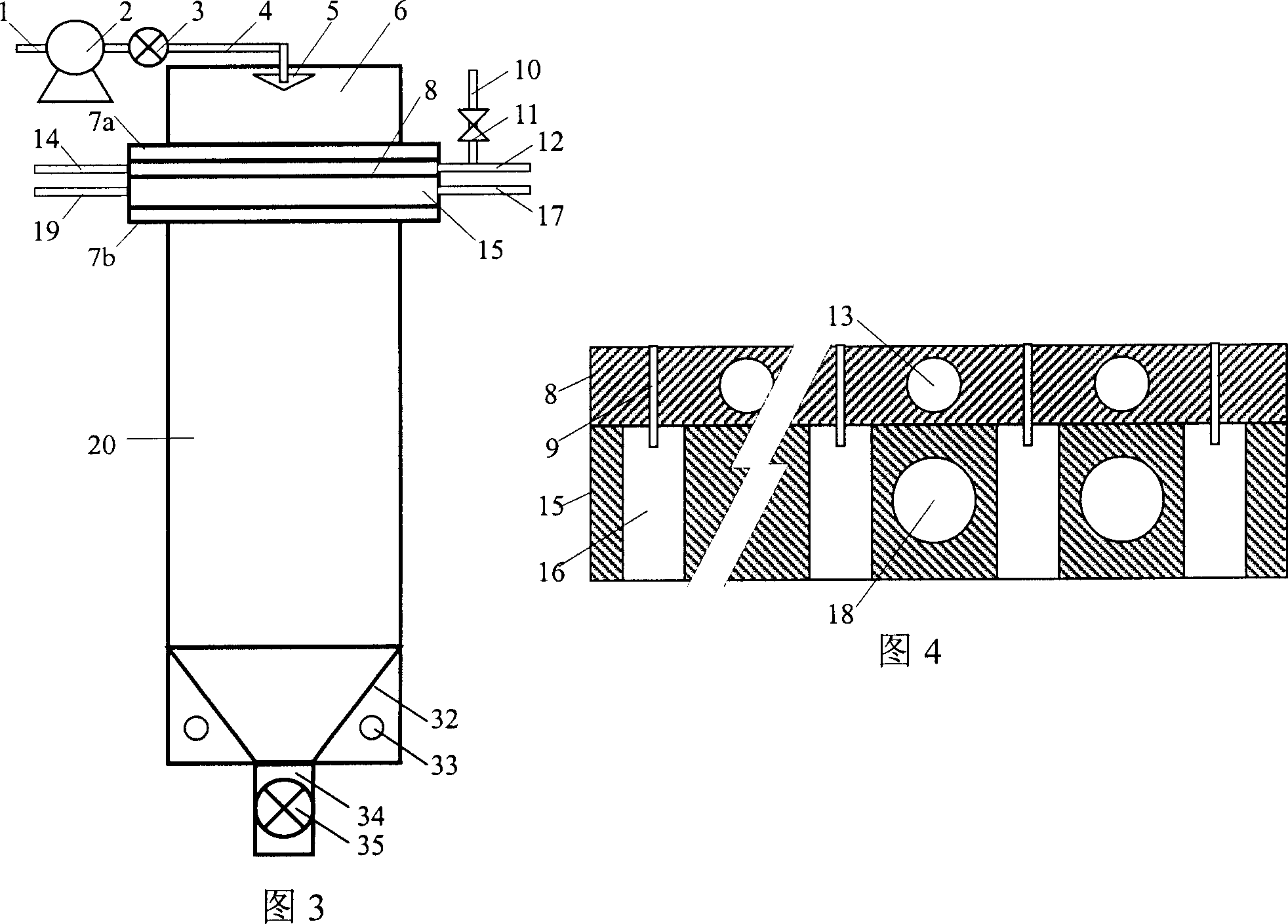

[0031] Embodiment two: the present invention has carried out granulation to urea molten liquid in liquid paraffin, and the density of molten liquid is greater than the density of cooling liquid, and its basic parameters and implementation effect are as follows:

[0032] The melting point of urea is 132.7°C, and the density of urea melt is 1335kg / m 3 , liquid paraffin is used as cooling liquid, and the density of liquid paraffin is about 845kg / m 3 , using the device shown in Figure 3. The heating medium of the insulation board is steam, the heating medium for switching is steam, and the cooling medium for switching is liquid paraffin. The liquid paraffin is recycled after being cooled by a refrigeration device. When the nozzle diameter is 1.2mm, spherical urea particles with a diameter of 3-6mm are obtained, and after draining and centrifugal fluidized bed dewaxing, the product quality is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com