Processing equipment for lithium battery cathode material

A cathode material and processing equipment technology, applied in the field of lithium battery cathode material production equipment, can solve problems such as low production efficiency, difficulty in large-scale production, and poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

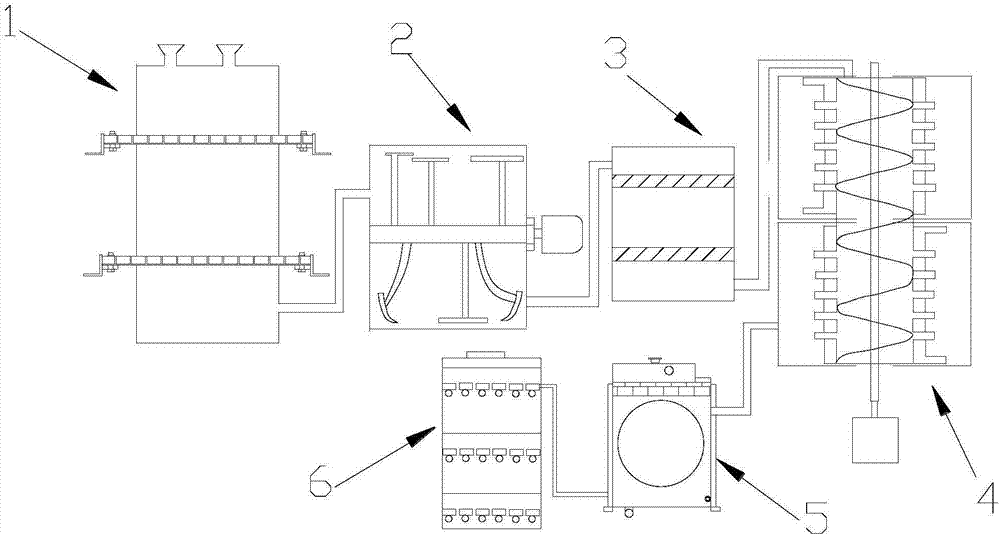

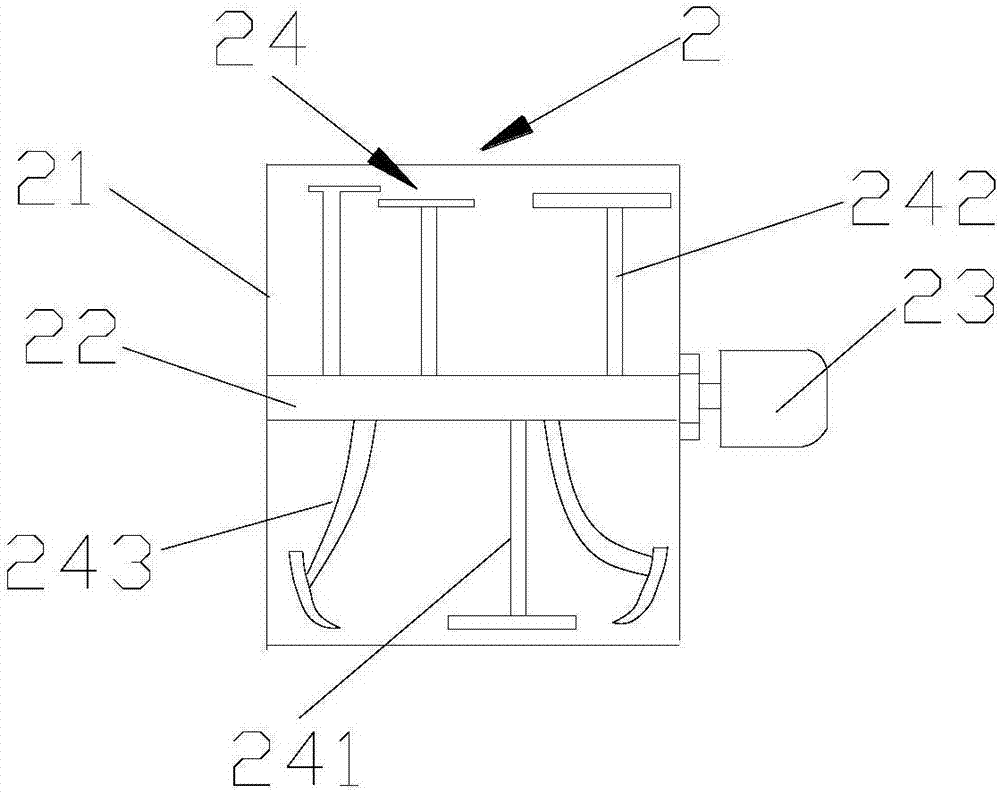

[0036] Such as Figure 1 to Figure 7 As shown, the processing equipment of lithium battery cathode material of the present invention comprises feeding device 1, mixing device 2, filter 3, reaction device 4, cooler 5 and drier 6, feeding device 1, mixing device 2, filter 3. The reaction unit 4, the cooler 5 and the drier 6 are sequentially connected by pipelines, wherein:

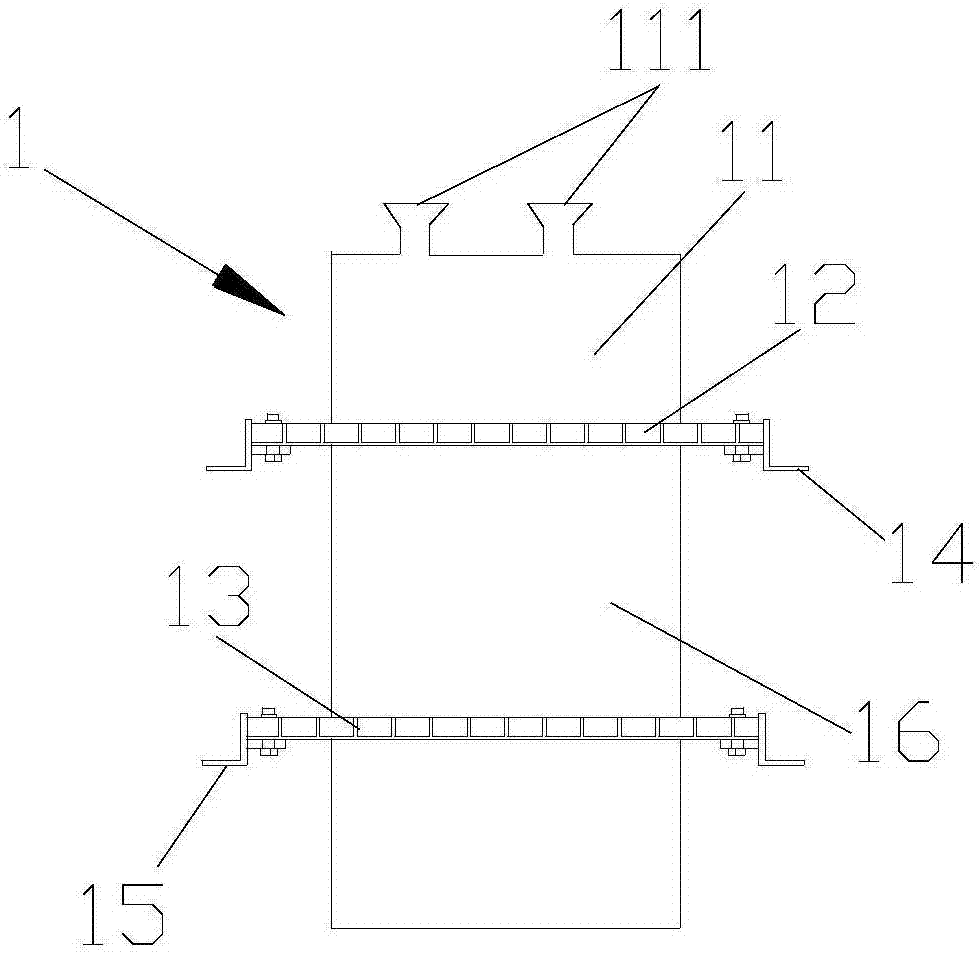

[0037]The feeding device 1 includes a feeding channel 11, a first valve plate 12 and a second valve plate 13. The upper end of the feeding channel 11 is provided with two raw material inlets 111, and the two raw material inlets 111 are funnels with a large opening at the upper end and a small opening at the lower end. shape, the first valve plate 12 and the second valve plate 13 are installed in the upper and lower positions with each other on the feeding channel 11, the first valve plate 12 and the second valve plate 13 are gate-type manual valve plates, and the feeding channel 11 is provided with a first ...

Embodiment 2

[0045] Such as Figure 8 As shown, in order to optimize Embodiment 1, on the basis of Embodiment 1, a temperature sensor 431 is provided on the spiral feeding device 43, and there are two temperature sensors 431, and the two temperature sensors 431 are respectively arranged on the spiral feeding device 43. The upper end and the lower end of the device 43, the temperature sensor 431 at the upper end is used to detect the temperature of the preheating section 41, when the temperature sensor 431 detects that the temperature of the preheating section 41 reaches the requirement, the screw feeding device 43 is started to prepare the raw materials into the reaction section 42. The temperature sensor 431 at the lower end is used to detect the temperature of the reaction section 42. When the temperature sensor 431 detects that the temperature of the reaction section 42 reaches the requirement, the screw feeding device 43 is started to transport the reacted raw material lithium manganate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com