Preparation method for InN/GaN/glass structure

A technology for glass and glass substrates, applied in the field of deposition and preparation of new optoelectronic materials, can solve the problems of high price of sapphire substrates, hinder the development of InN material devices, and difficult to reduce device costs, achieve good electrical performance and stability, and solve the problems of crystal Grid mismatch, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

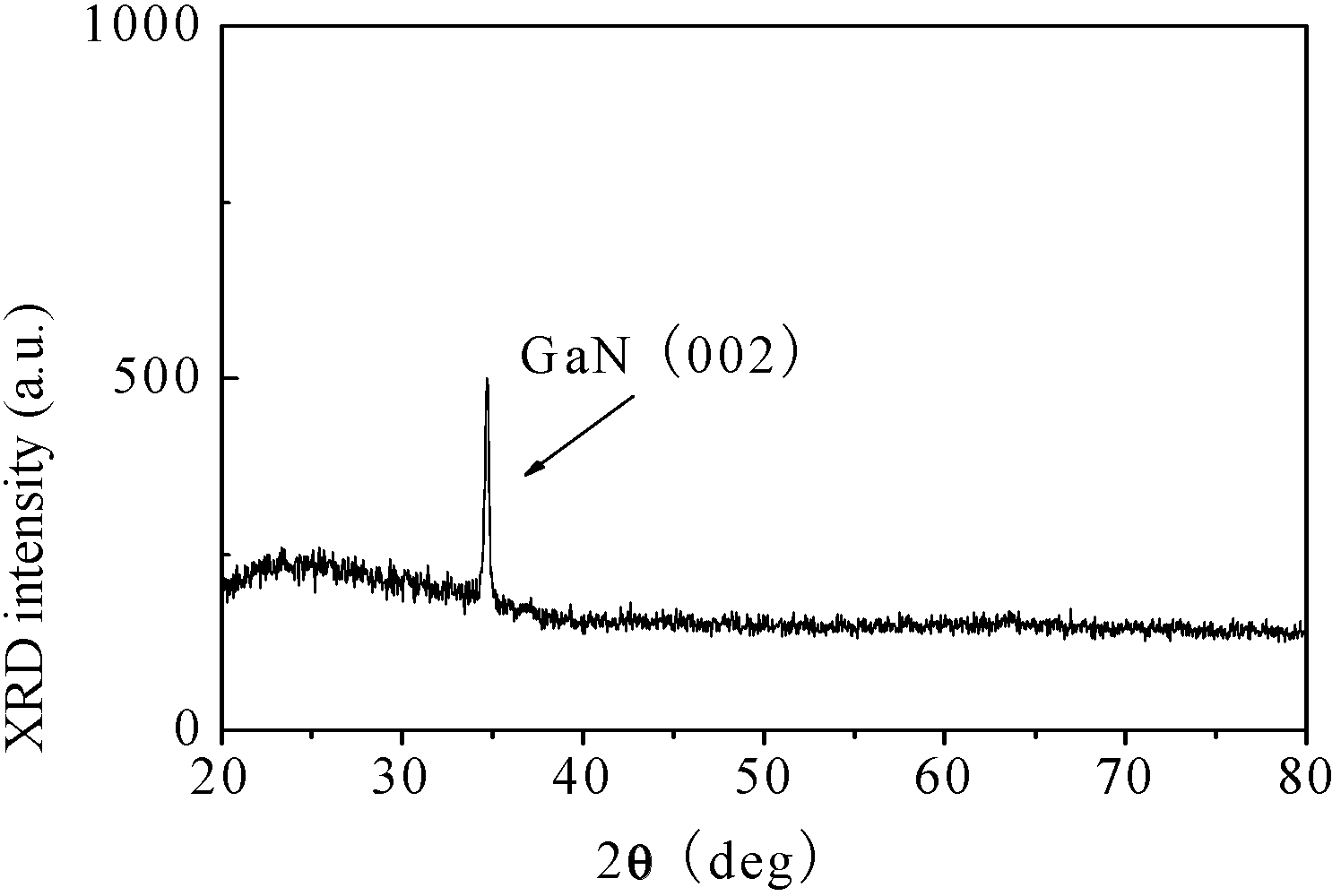

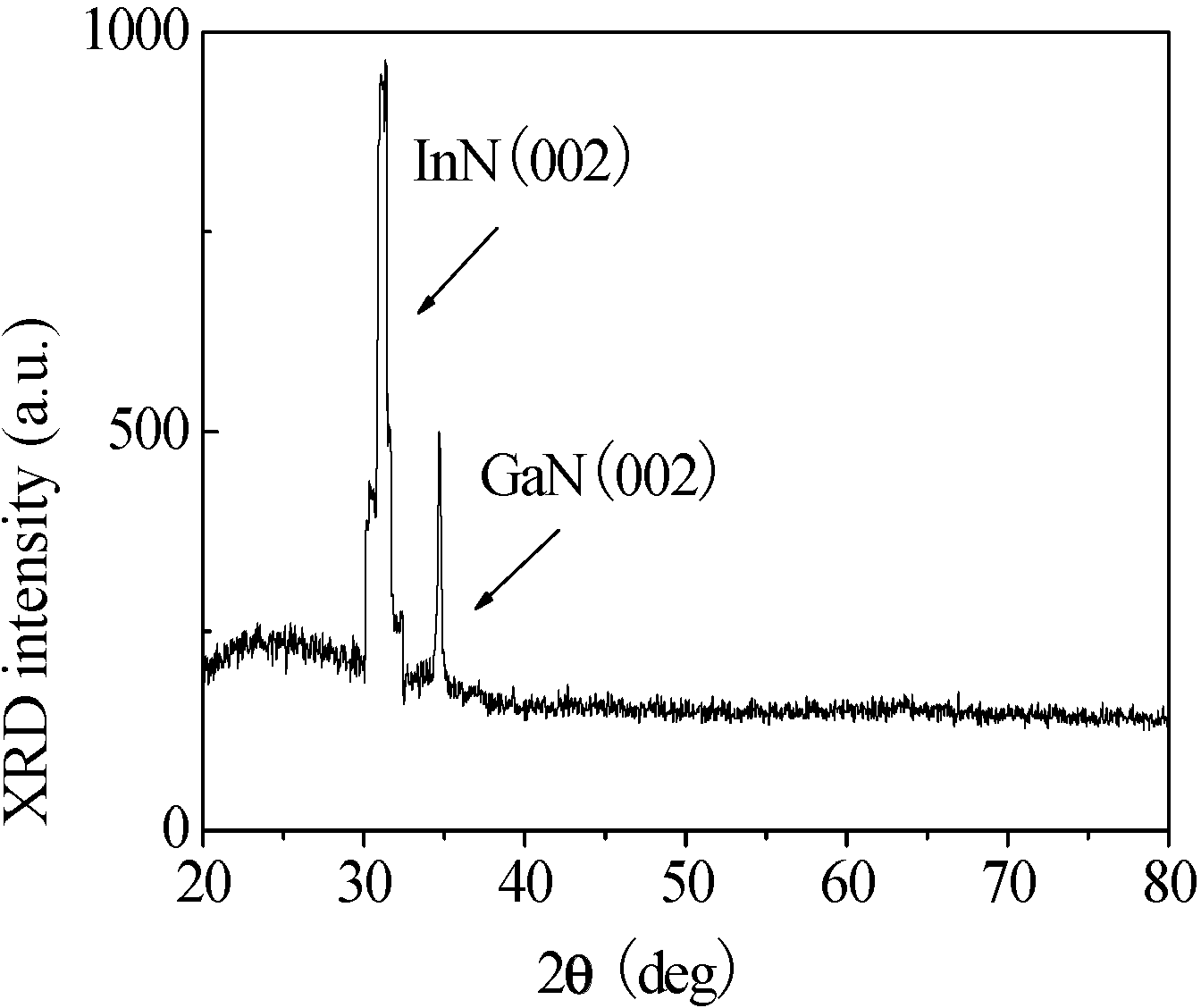

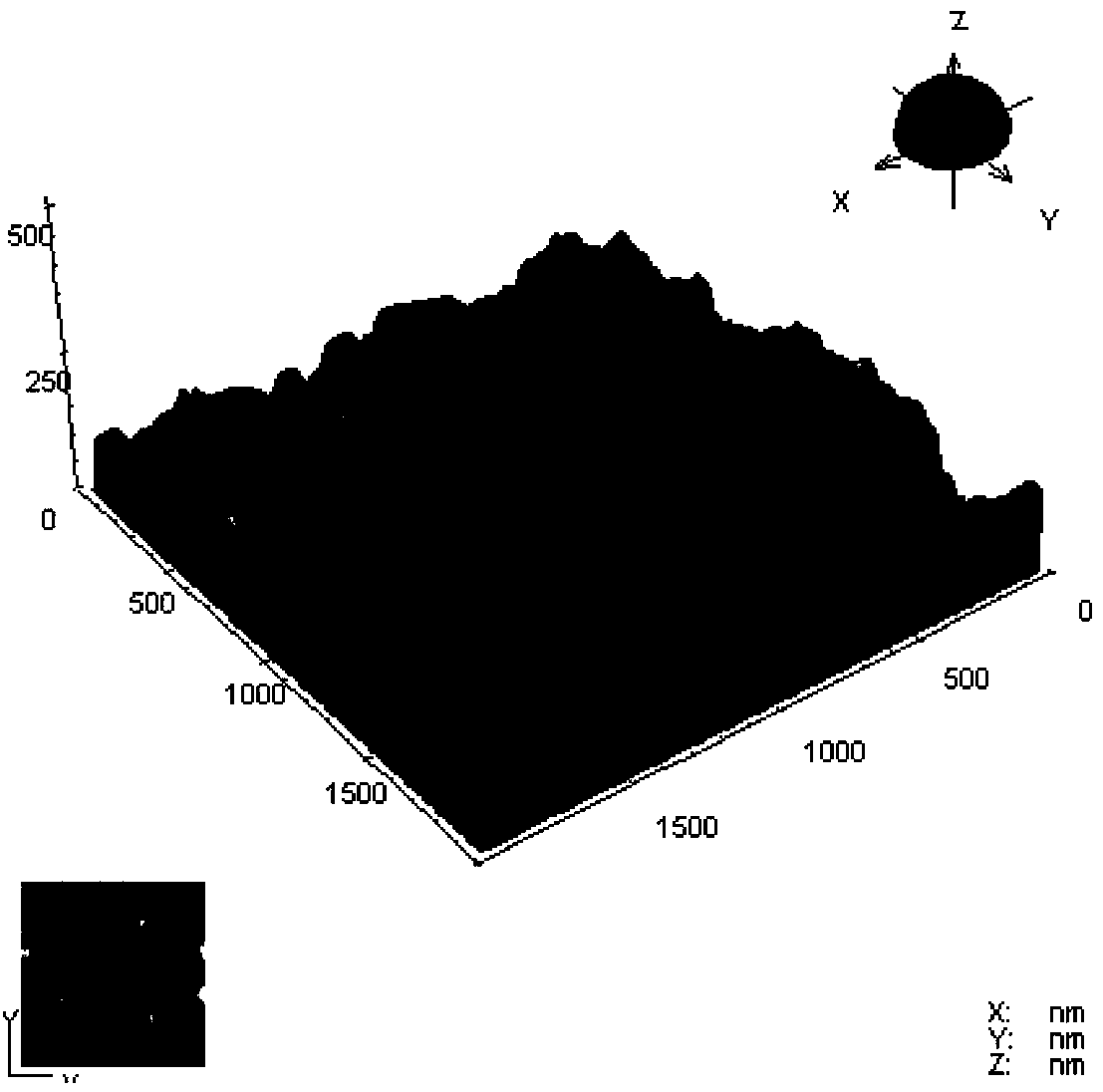

Embodiment 1

[0051] The Corning glass substrate was ultrasonically cleaned with acetone, ethanol and deionized water for 5 minutes, then dried with nitrogen and sent to the reaction chamber; the reaction chamber was evacuated to 9.0×10 -4 Pa, the substrate is heated to 485°C, trimethylgallium and nitrogen carried by hydrogen are introduced into the reaction chamber, and the flow rates of the two are 0.5sccm and 80sccm, controlled by a mass flow meter; the total pressure of the control gas is 1.2Pa; The electron cyclotron resonance power is 650W, and the reaction is 30min, and the GaN buffer layer film on the Corning glass substrate is obtained. Then continue to use the ECR-PEMOCVD system to evacuate the reaction chamber to 8.0×10 -4 Pa, the substrate is heated to 300°C, trimethylindium and nitrogen carried by hydrogen are introduced into the reaction chamber, the flow ratio of the two is 4:150, and the flow is 4sccm and 150sccm, controlled by a mass flow meter; control gas The...

Embodiment 2

[0054] The Corning glass substrate was ultrasonically cleaned with acetone, ethanol and deionized water for 5 minutes, then dried with nitrogen and sent to the reaction chamber; the reaction chamber was evacuated to 9.0×10 -4 Pa, the substrate is heated to 485°C, trimethylgallium and nitrogen carried by hydrogen are introduced into the reaction chamber, and the flow rates of the two are 0.6sccm and 90sccm, controlled by a mass flow meter; the total pressure of the control gas is 1.2Pa; The electron cyclotron resonance power is 650W, and the reaction is 30min, and the GaN buffer layer film on the Corning glass substrate is obtained. Then continue to use the ECR-PEMOCVD system to evacuate the reaction chamber to 8.0×10 -4 Pa, the substrate is heated to 200°C, trimethylindium and nitrogen carried by hydrogen are introduced into the reaction chamber, the flow ratio of the two is 4:120, and the flow rate is 4sccm and 120sccm, controlled by a mass flow meter; control gas...

Embodiment 3

[0056] The Corning glass substrate was ultrasonically cleaned with acetone, ethanol and deionized water for 5 minutes, then dried with nitrogen and sent to the reaction chamber; the reaction chamber was evacuated to 9.0×10 -4 Pa, the substrate is heated to 485°C, trimethylgallium and nitrogen carried by hydrogen are introduced into the reaction chamber, and the flow rates of the two are 0.5sccm and 120sccm, controlled by a mass flow meter; the total pressure of the control gas is 1.2Pa; The electron cyclotron resonance power is 650W, and the reaction is 30min, and the GaN buffer layer film on the Corning glass substrate is obtained. Then continue to use the ECR-PEMOCVD system to evacuate the reaction chamber to 8.0×10 -4 Pa, the substrate is heated to 100°C, trimethylindium and nitrogen carried by hydrogen are introduced into the reaction chamber, the flow ratio of the two is 5:120, and the flow is 5 sccm and 120 sccm, controlled by a mass flow meter; control gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com