Ultra-low-sulfur diesel lubricating property improver and preparation method thereof

A technology of ultra-low sulfur diesel oil and lubricating performance, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of fuel filter clogging, high acid value, increased cost, etc., and achieves low production cost and short process. , the effect of cleaning the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

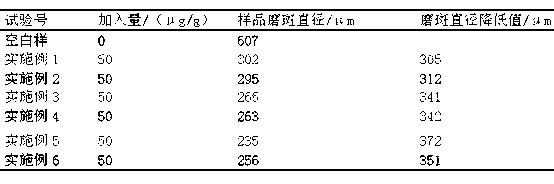

Examples

Embodiment 1

[0020] Weigh 186 g of glycerin (chemically pure), 140 g of mixed fatty acids (that is, the mixed fatty acids produced by hydrolysis of animal and vegetable oils, carbon number range C12-C22, average molecular weight 280), 3.7 g of isobutanol (chemically pure), namely glycerin, The molar ratio of mixed fatty acid to isobutanol is 4:1.0:0.1; add imidazole cationic ionic liquid catalyst (self-made) 13.19g, accounting for 4% of the total mass of the reaction mixture; react in a stainless steel kettle with a volume of 1000 ml, The reaction temperature is 100°C, the stirring speed is 800 revolutions per minute, the reaction pressure is 0.1MPa, and the reaction time is 2 hours; after the reaction is completed, the reaction mixture is lowered to room temperature and allowed to stand for stratification, the upper layer is the target product, and the lower layer is unreacted glycerin , the catalyst ionic liquid and the by-product water generated by the reaction; the upper reactant was an...

Embodiment 2

[0022] Weigh 232.5 g of glycerin (chemically pure), 156 g of mixed fatty acids (same as Example 1, carbon number range C12-C22, average molecular weight 280), 4.5 g of isopropanol (chemically pure), that is, glycerin, mixed fatty acids and isopropanol The molar ratio is 5:1.1:0.15; add 31.44g of imidazole cationic ionic liquid catalyst (self-made), accounting for 8% of the total mass of the reaction mixture; react in a stirred stainless steel tank with a volume of 1000 ml, and the reaction temperature is 120°C. The stirring speed is 800 revolutions per minute, the reaction pressure is 0.1MPa, and the reaction time is 2 hours; after the reaction, the reaction mixture is lowered to room temperature and allowed to stand for stratification. The upper layer is the target product, and the lower layer is unreacted glycerin, catalyst ionic liquid and reaction mixture. The generated by-product water; the upper reactant was subjected to gas chromatography analysis and acid value and lubr...

Embodiment 3

[0024] Weigh 279 g of glycerin (chemically pure), 168 g of mixed fatty acids (same as Example 1, carbon number range C12-C22, average molecular weight 280), 7.4 g of isobutanol (chemically pure), namely glycerin, mixed fatty acids and isobutanol The molar ratio is 6:1.2:0.2; add 54.53g of imidazole cationic ionic liquid catalyst (self-made), accounting for 12% of the total mass of the reaction mixture; react in a stirred stainless steel tank with a volume of 1000 ml, and the reaction temperature is 150°C. The stirring speed is 800 revolutions per minute, the reaction pressure is 0.2 MPa, and the reaction time is 1 hour; after the reaction, the reaction mixture is lowered to room temperature and allowed to stand for stratification. The upper layer is the target product, and the lower layer is unreacted glycerin, catalyst ionic liquid and reaction mixture. The generated by-product water; the upper reactant was subjected to gas chromatography analysis and acid value and lubricatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com