Glued groove-and-tongue floor

A floor, tongue and groove technology, applied in the direction of floor, building, building structure, etc., can solve the problems of inability to achieve non-destructive separation, easy pollution of the floor surface, troublesome application and construction, etc., to improve the glue application installation process and reduce service costs. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

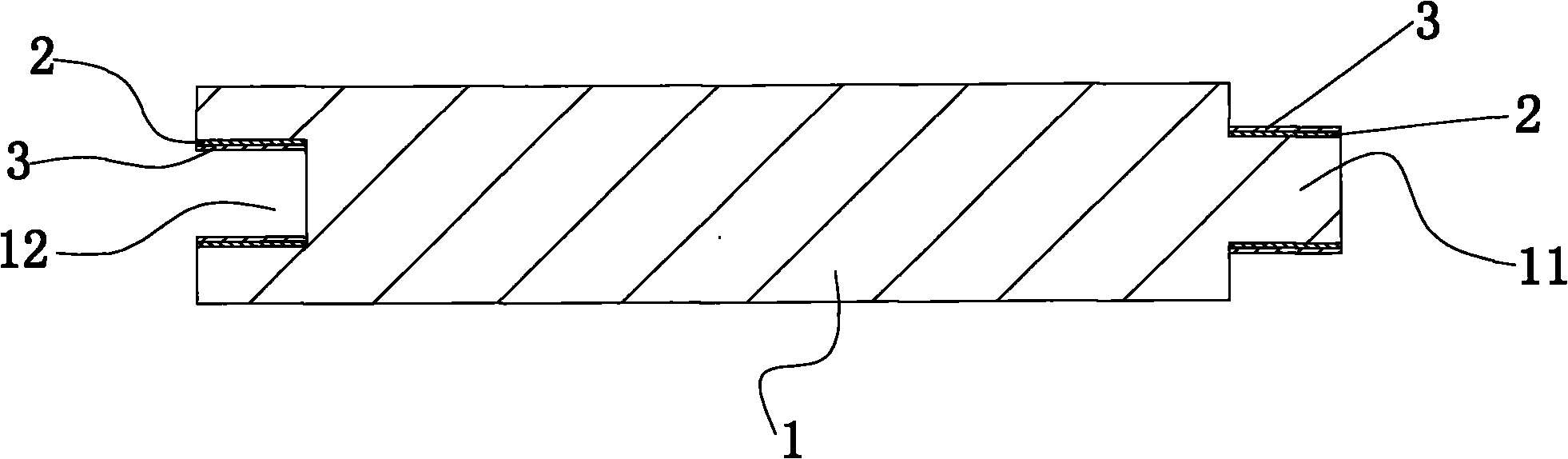

[0011] Embodiment one: if figure 1 As shown, a glued tongue-and-groove floor includes a floor body 1, the floor body 1 is a solid wood floor, a solid wood composite floor, a laminate floor, a cork floor or a PVC floor, and the floor body 1 is provided with a connecting tenon 11 and a connecting groove 12, The connecting tenons 11 and the connecting grooves 12 are coated with a pressure-sensitive adhesive layer 2 , and wax paper 3 is provided on the surface of the pressure-sensitive adhesive layer 2 .

[0012] The pressure-sensitive adhesive is a type of adhesive that is sensitive to pressure. It has the feature of peeling, given a certain force, the adhesive surface can be peeled off, and can be glued again after peeling off. Pressure-sensitive adhesives can be divided into two types: rubber type and resin type according to the main resin composition. The pressure-sensitive adhesives currently used are mainly acrylic and rubber-based solvent-based or latex-based adhesives. ...

Embodiment 2

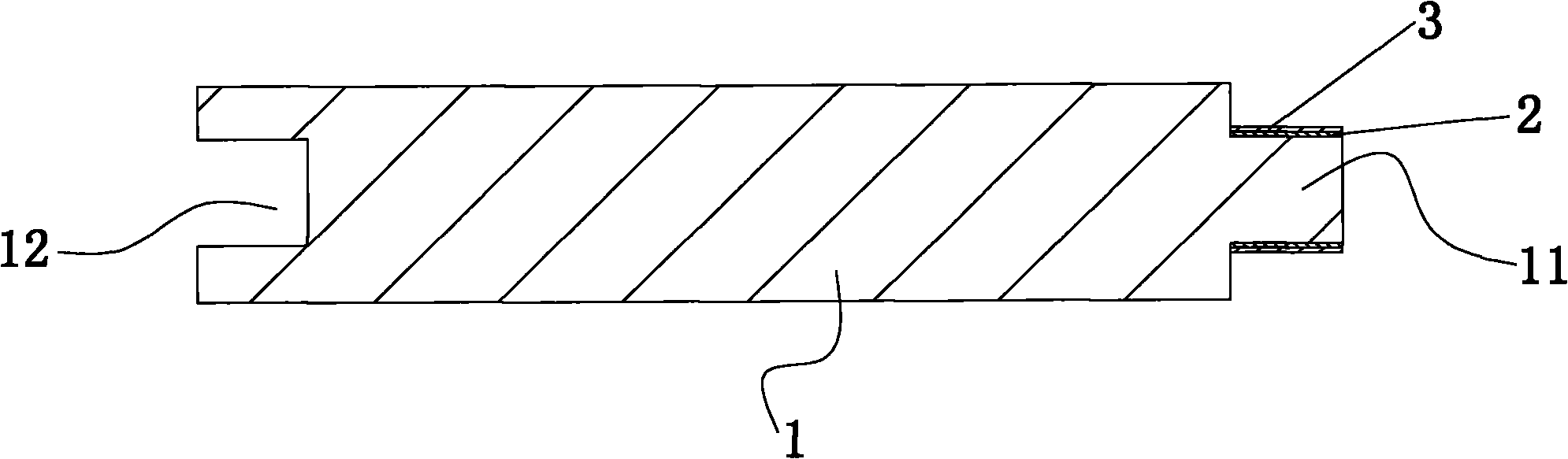

[0013] Embodiment two: if figure 2 As shown, the difference from the first embodiment is that the pressure-sensitive adhesive layer 2 is only coated on the connecting tenons 11 .

Embodiment 3

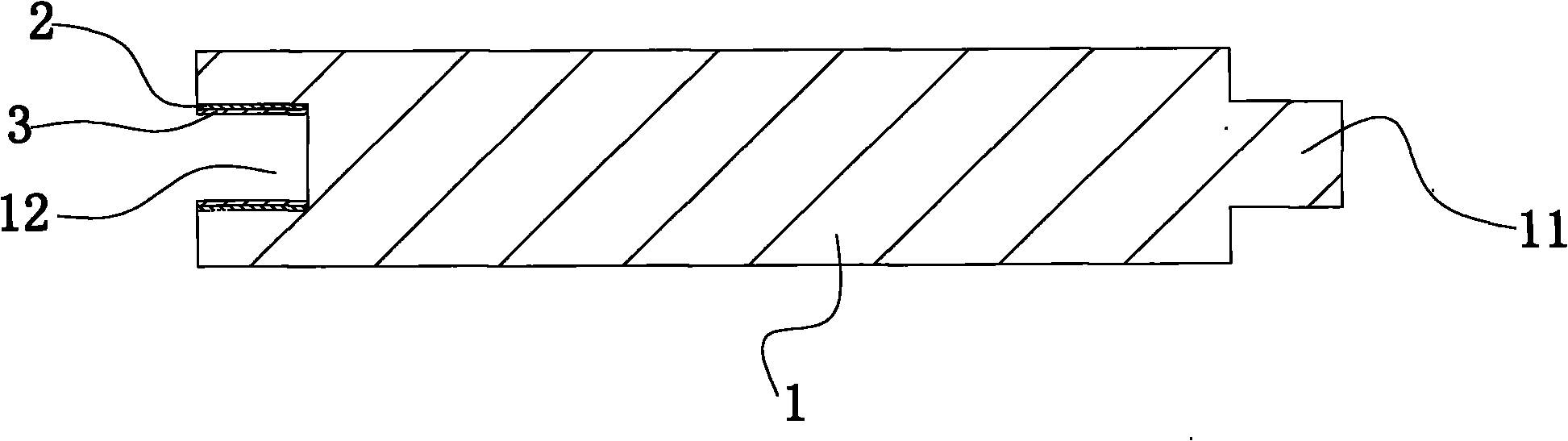

[0014] Embodiment three: as image 3 As shown, the difference from the first embodiment is that the pressure-sensitive adhesive layer 2 is only coated on the connection groove 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com