Casting mold and forming method for box body of gearbox

A molding method and gearbox technology, which are applied in the casting mold of gearbox casing and its molding, and the casting mold and molding of gearbox, can solve the problems of difficulty in meeting requirements, low brushing efficiency, and easy generation of brush marks, etc. Achieve the effect of good appearance consistency, good surface quality and clear outline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

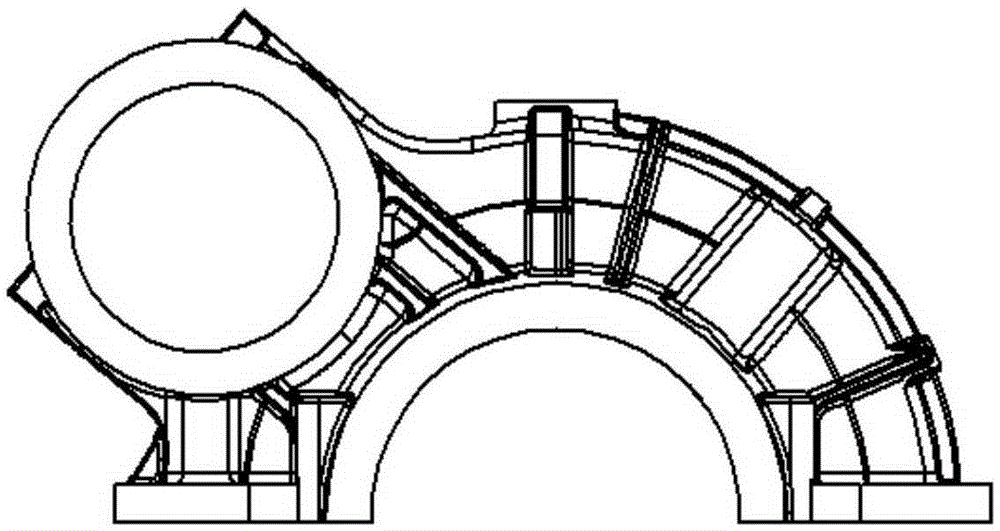

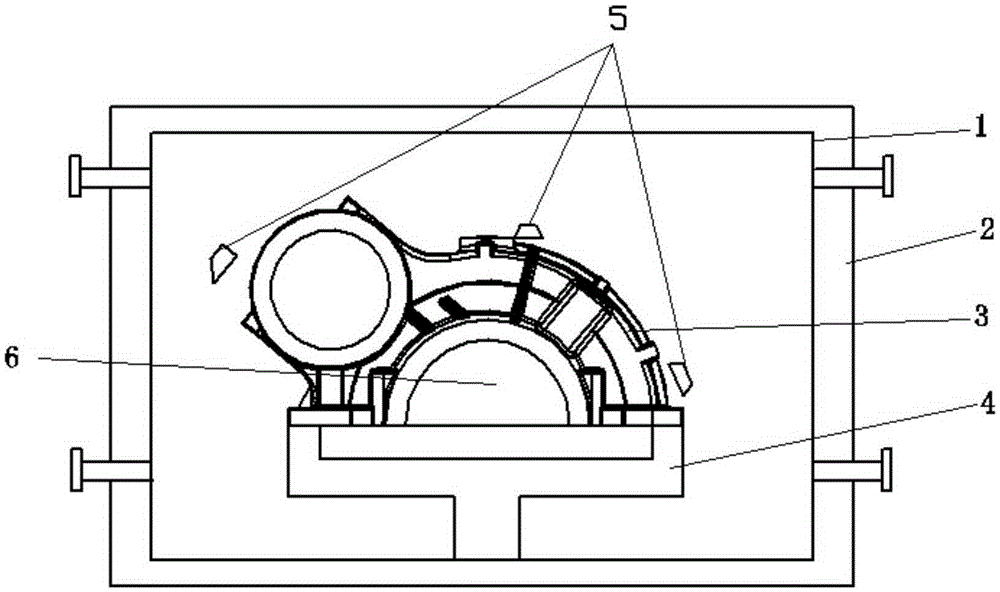

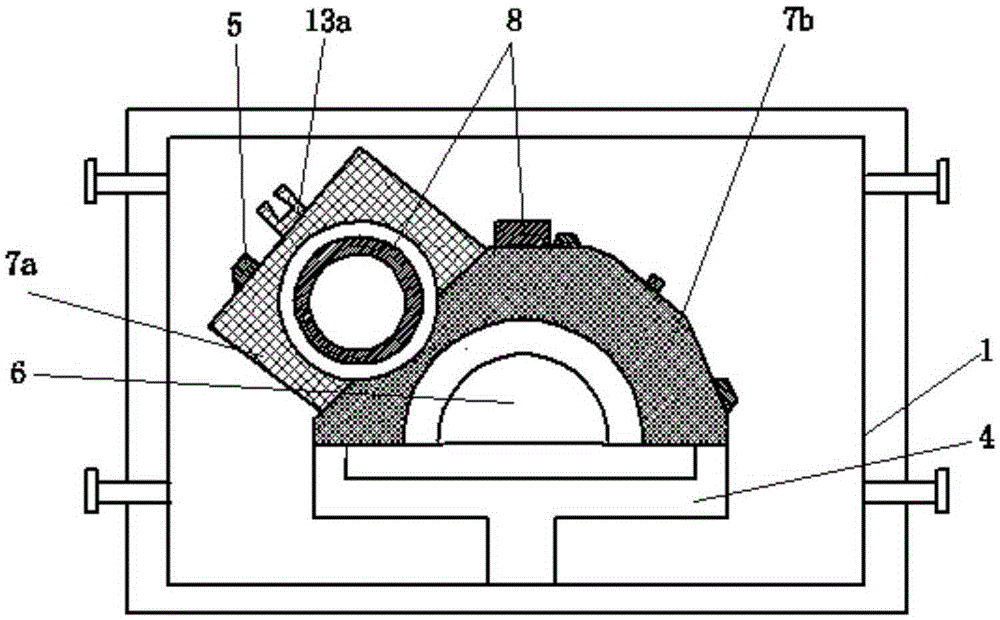

[0072] 1) Design and manufacture of molds: design and manufacture molds such as coated sand shooting core sand block 7, cold iron 8, and sand core 11;

[0073] 2) Production of chilled iron 8 and sand core 11: cast chilled iron 8 using chilled iron moulds; place the chilled iron 8 successfully cast above in the sand core mould to make sand core 11, and the sand core 11 of the present embodiment is coated with a film sand molding;

[0074] 3) Manufacture the coated sand block for assembling and forming the gear box case by the coated sand shooting core , 0.1kg of urotropine and 0.1kg of calcium stearate are evenly mixed to form coated sand;

[0075] The above-mentioned successfully poured cold iron 8 is placed in the mold of the coated sand shooting core sand block 7, and the sand is shot when the mold temperature is heated to 200 ° C. The coated sand is sintered and hardened under the action of the resin and the curing agent to form The coated sand block 7, the thickness of ...

Embodiment 2

[0084] 1) Design and manufacture of molds: design and manufacture molds such as coated sand shooting core sand block 7, cold iron 8, and sand core 11;

[0085] 2) the making of chilled iron 8 and sand core 11: respectively adopt chilled iron mould and sand core mould to pour chilled iron 8 and make sand core 11, and the sand core 11 of the present embodiment adopts resin sand 9 to form;

[0086] 3) Coated sand core shooting to make coated sand blocks Coated sand is uniformly formed. The above-mentioned successfully poured cold iron 8 is placed in the mold of the coated sand shooting core sand block 7, and the sand is shot when the temperature of the mold is heated to 250 ° C. The coated sand is sintered and hardened under the action of the resin and the curing agent to form The coated sand block 7, the thickness of the coated sand block 7 is 25mm, and the convex structure 13 is provided on the coated sand block 7 to present a chamfered shape 13b (such as Figure 7 (b)), it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com