Surface airbrushing method and airbrushing head for stereoscopic object

A technology of three-dimensional objects and nozzles, used in power transmission devices, printing, transfer materials, etc., can solve the problems of inability to further improve the transmission efficiency, consuming a lot of manpower, affecting the efficiency of mass production, etc., and achieving outstanding substantive characteristics. , easy to control, clear outline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

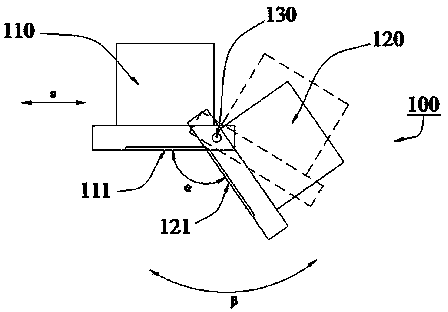

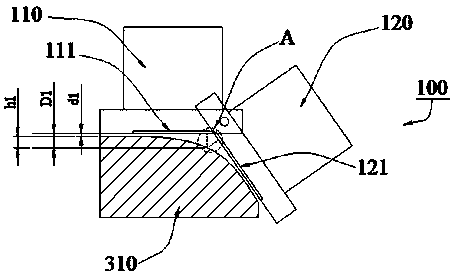

[0031] Embodiment 1: as figure 1 A three-dimensional surface inkjet nozzle 100 shown includes two groups of nozzle modules 110, 120 and an inkjet control system (not shown in the figure). The inkjet control system described above controls the change of the angle α between the nozzle modules 110 and 120 . This embodiment also includes a rotation mechanism (not shown) that controls the rotation of the entire inkjet nozzle 100 and a translation mechanism (not shown) that controls the translation of the entire inkjet nozzle 100. The inkjet control system controls the rotation mechanism and The translation mechanism drives the change of the overall position s and the change of the angle β of the inkjet nozzle 100, as shown in the figure.

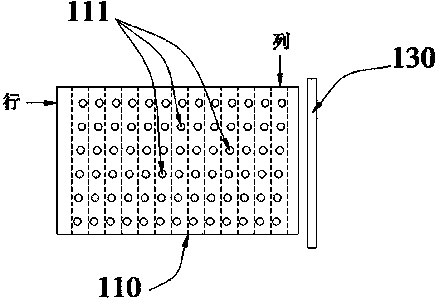

[0032] combine figure 1 and figure 2 As shown, nozzle holes 111 and 121 are distributed in matrix on the nozzle modules 110 and 120 . Taking the nozzle module 110 as an example, such as figure 2 As shown, each row of nozzle holes 111 is a ...

Embodiment 2

[0036] Embodiment 2: as Figure 6 and 8 A three-dimensional object surface inkjet nozzle 200 is shown, including three groups of nozzle modules 210, 220, 230 and an inkjet control system (not shown in the figure), and the three groups of nozzle modules 210, 220, 230 also pass Hinged together, the inkjet control system controls the angle change between the nozzle modules 210 , 220 and between the nozzle modules 210 , 230 .

[0037] Such as Figure 6 As shown, in the case that the cross section of the printing medium 330 is isosceles trapezoidal, the inkjet control system controls the nozzle modules 210, 220, and the angle between the nozzle modules 210, 230 changes, so that the inkjet nozzle 200 adapts to The surface profile of the printing medium 330, so that the distance between the three groups of nozzle modules 210, 220, 230 and the surface of the printing medium 330 is between 1 mm and 4 mm, and the distance difference between any nozzle hole in operation and the printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com