Lamp crimping and assembling mechanism

A technology of assembly mechanism and lamps, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inaccurate positioning, long upward stroke of the upper pressing component, damage of two parts, etc., so as to avoid inconvenient operation and improve production The effect of improving safety and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

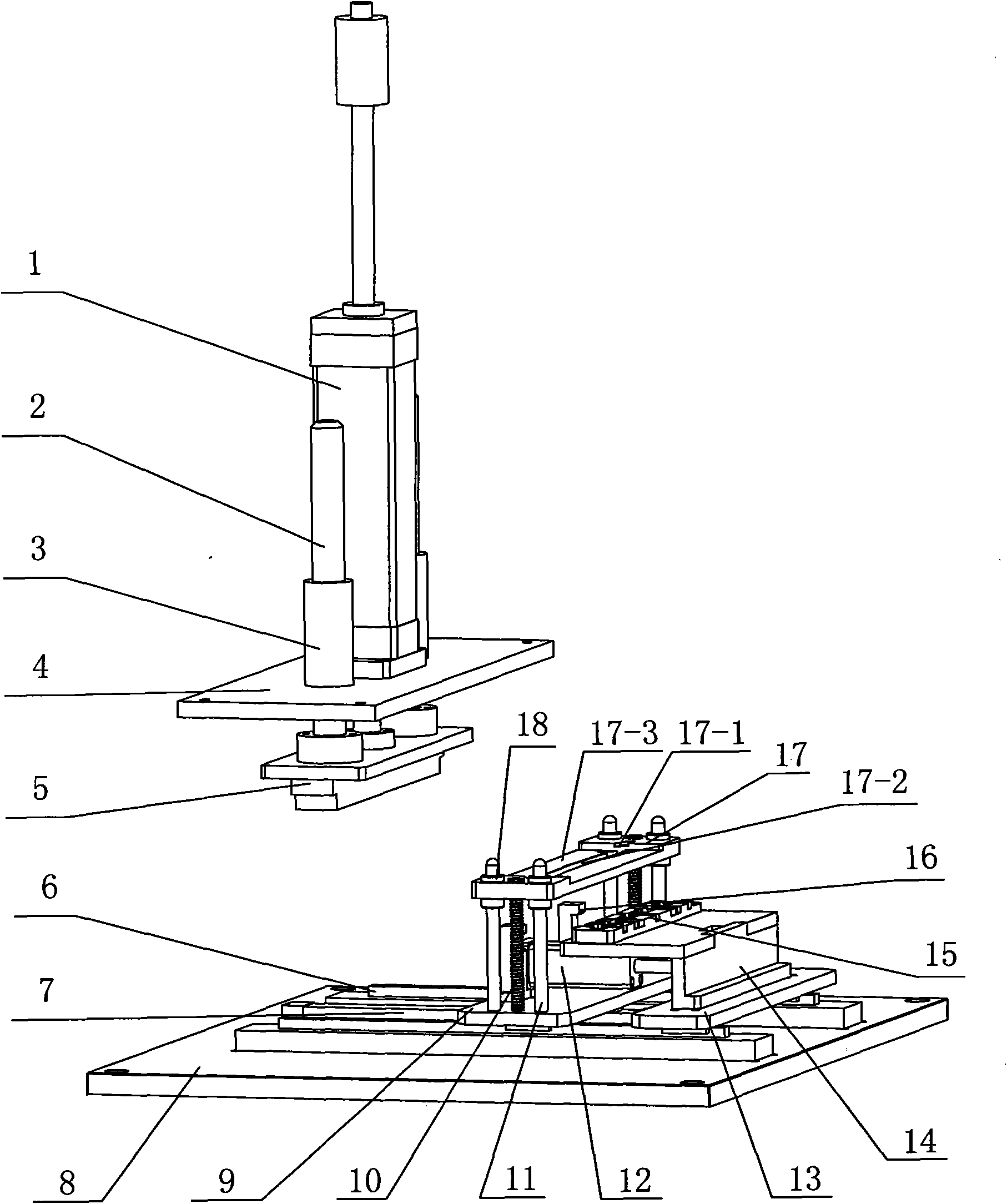

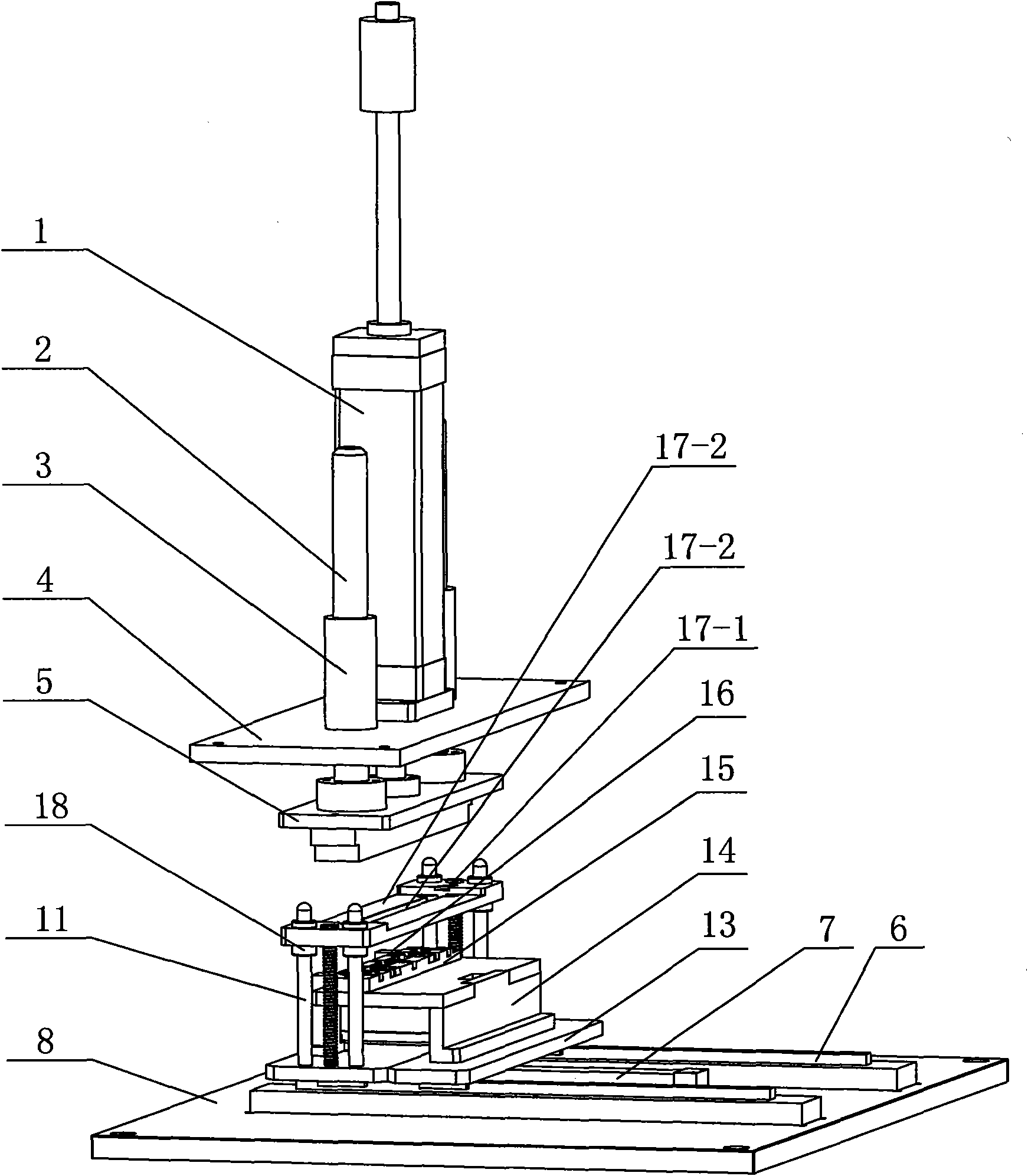

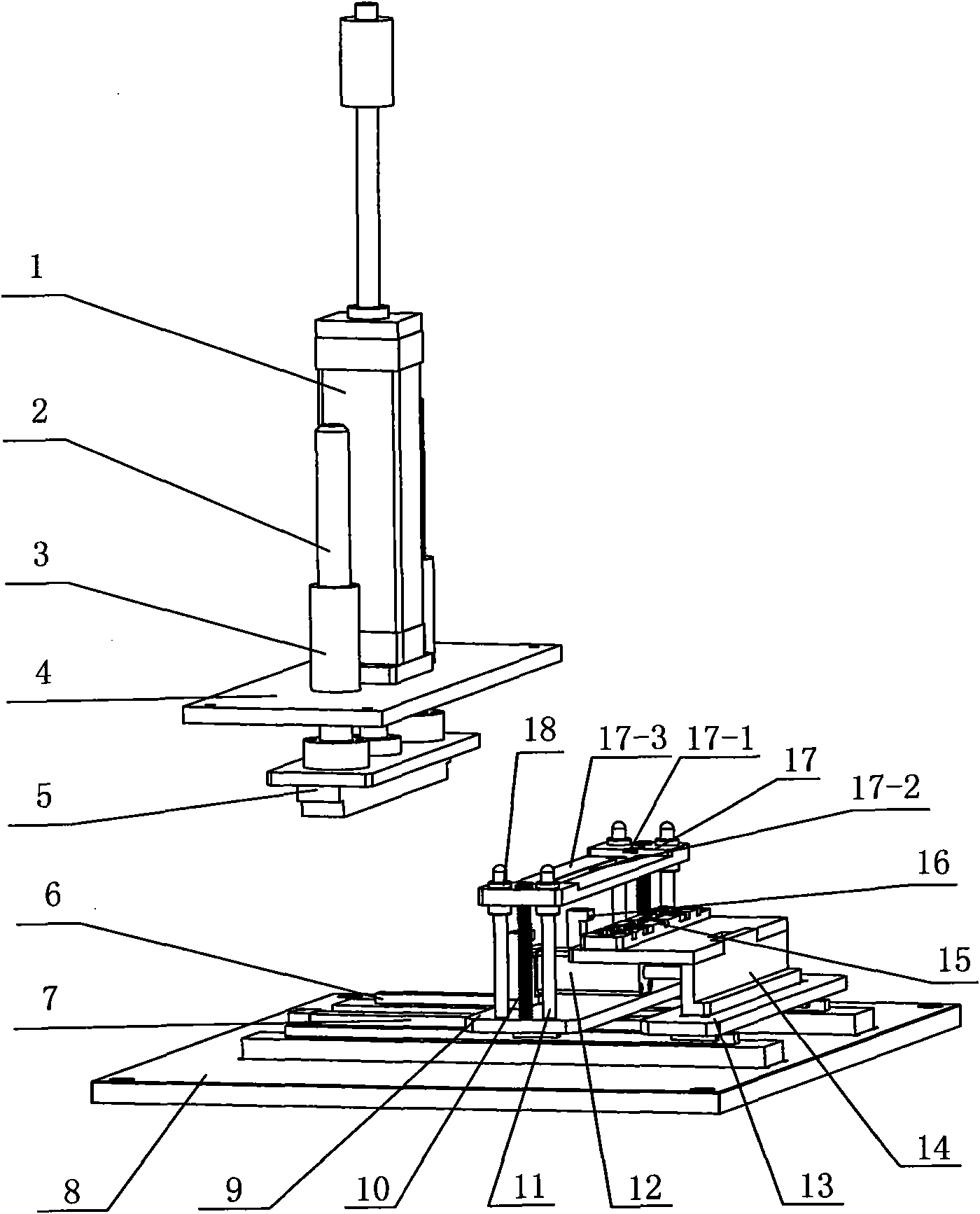

[0011] See figure 1 , 2 As shown, the lamp crimping assembly mechanism of the present invention includes an upper pressing assembly and a lower pressing assembly, and the upper pressing assembly includes an upper connecting seat 4, an upper cylinder 1 installed on the upper connecting seat 4, an upper guide sleeve 3 and an upper pressing assembly. block 5, the piston of the upper cylinder 1 is connected to the upper pressure block 5, and more than two upper guide posts 2 connected to the upper pressure block 5 are respectively arranged in the two upper guide sleeves 3, and pass through under the action of the upper cylinder 1 The piston drives the upper pressing block 5 to move up and down, and the upper guide sleeve 3 moves up and down along the upper guide post 2, so as to reduce the displacement of the upper pressing block 5 and ensure the accuracy of crimping assembly. See figure 1 , 2 As shown, the pressing assembly of the present invention includes a lower connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com