Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

496results about How to "Solve the inconvenience of operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

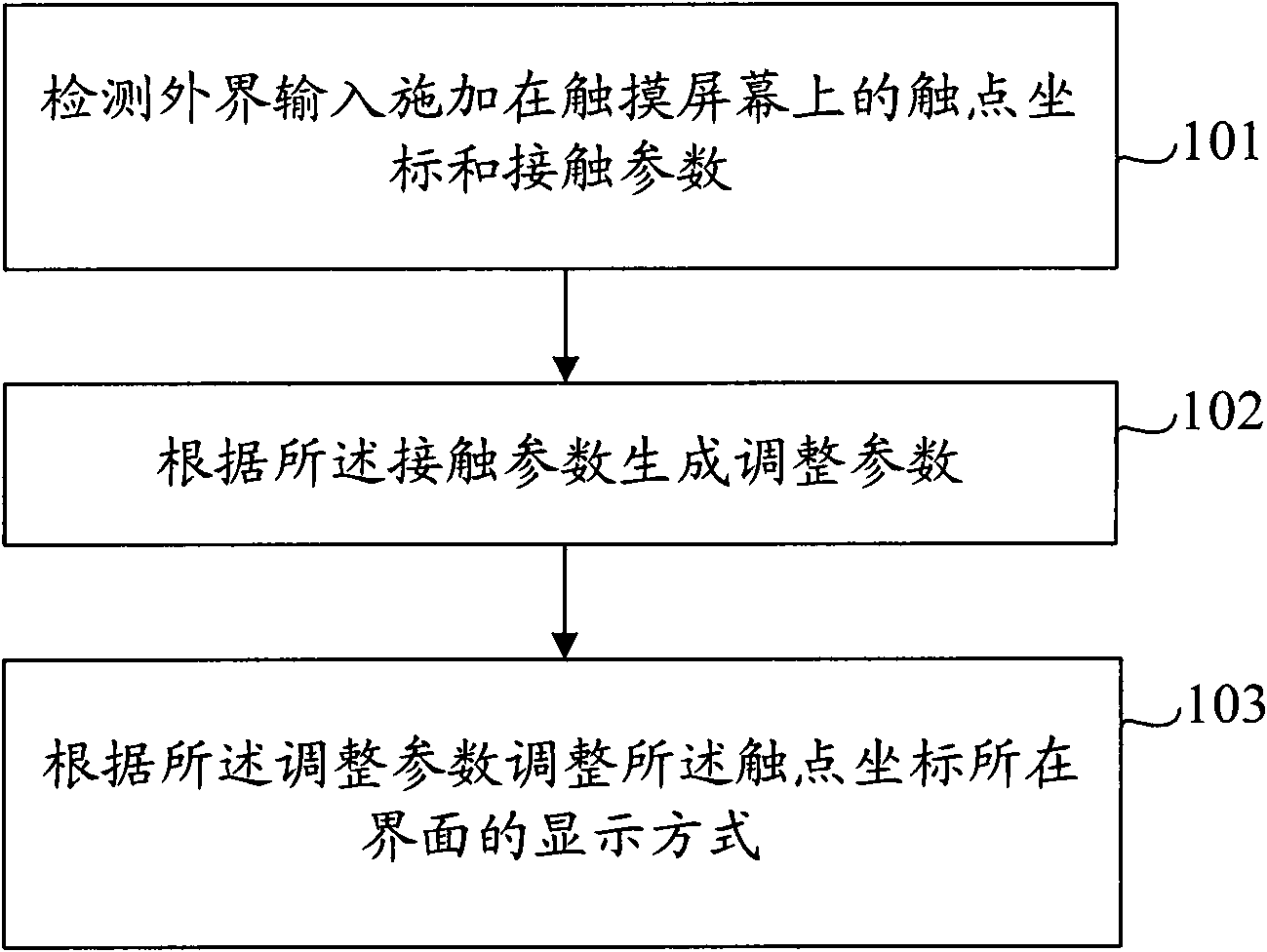

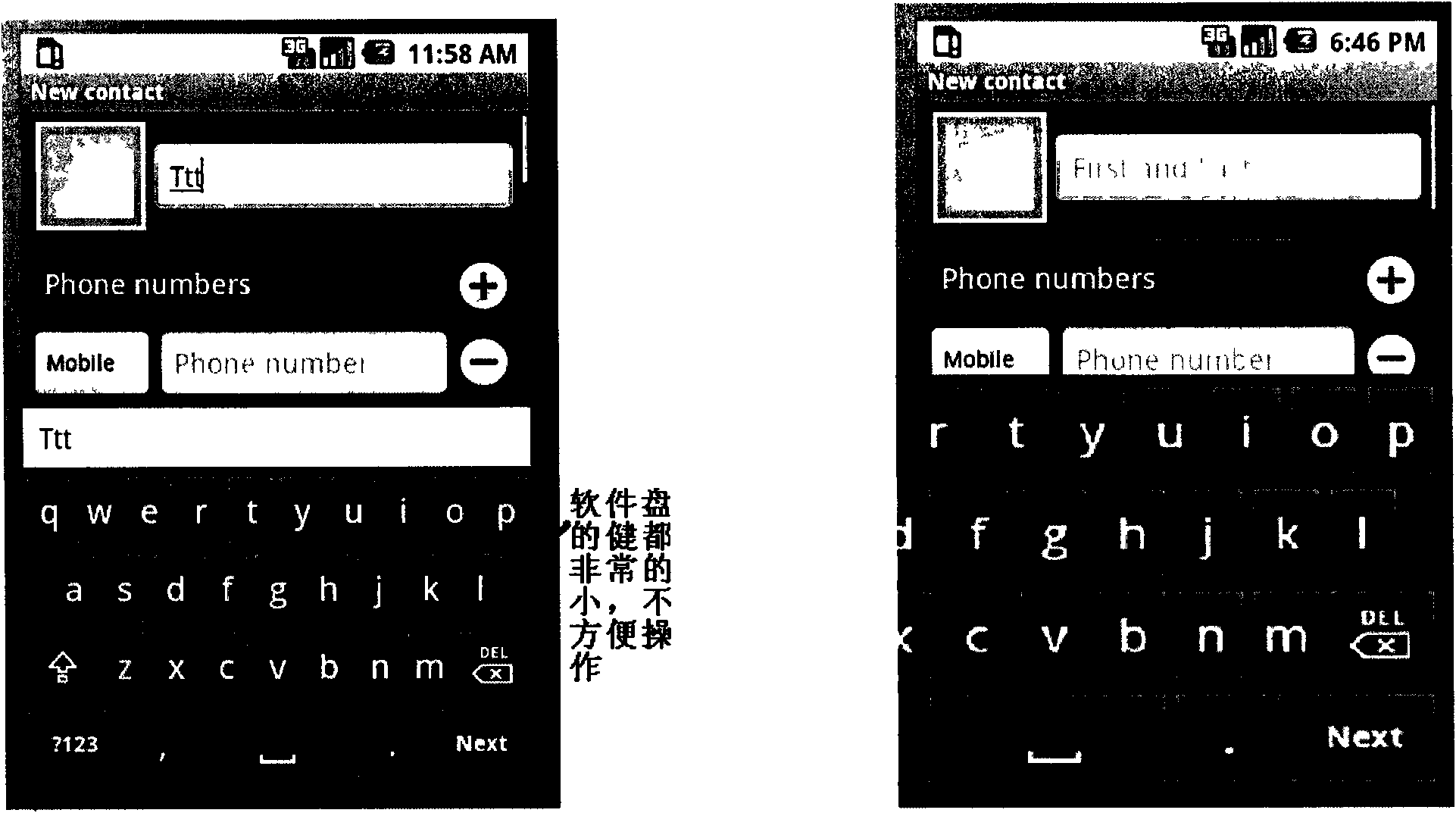

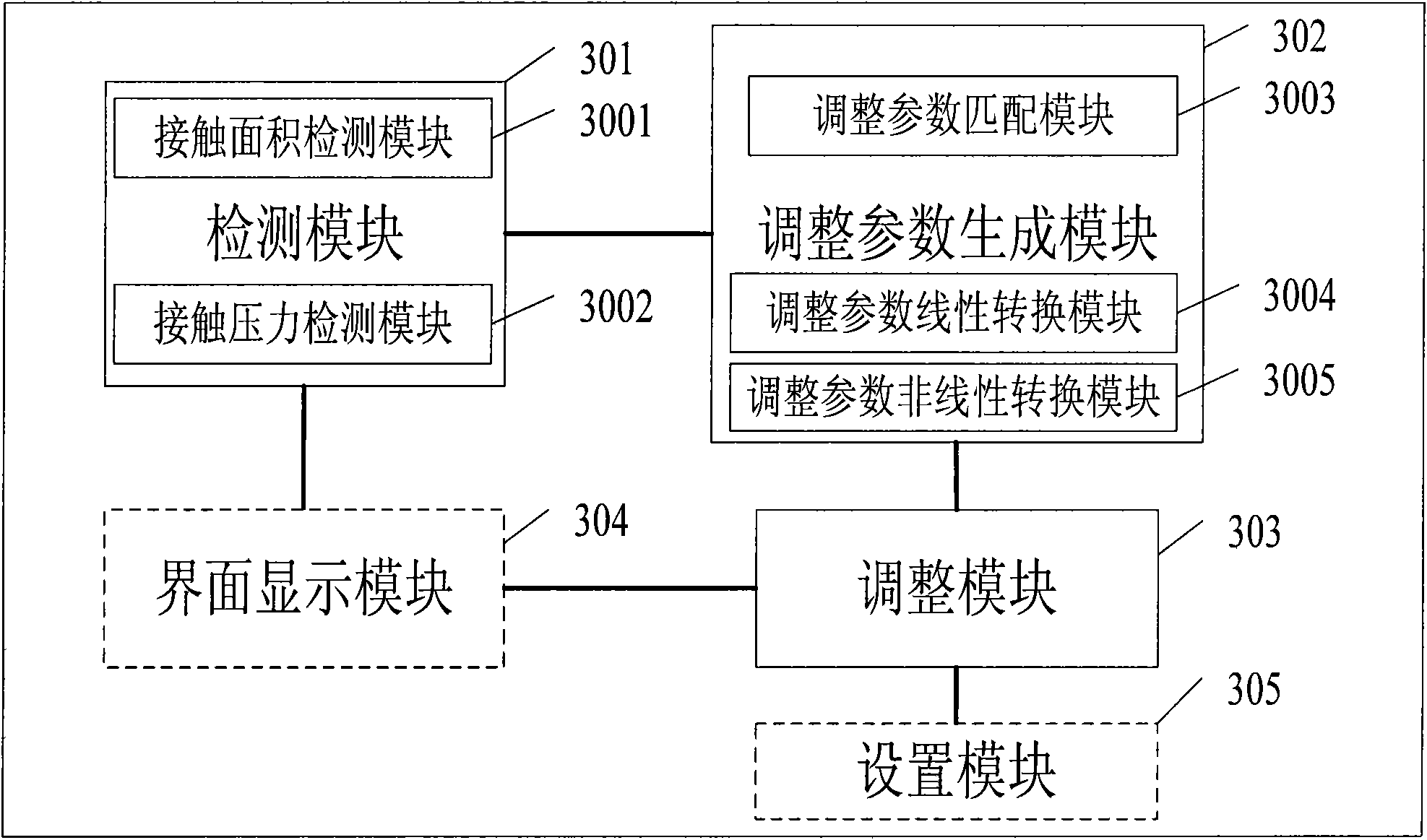

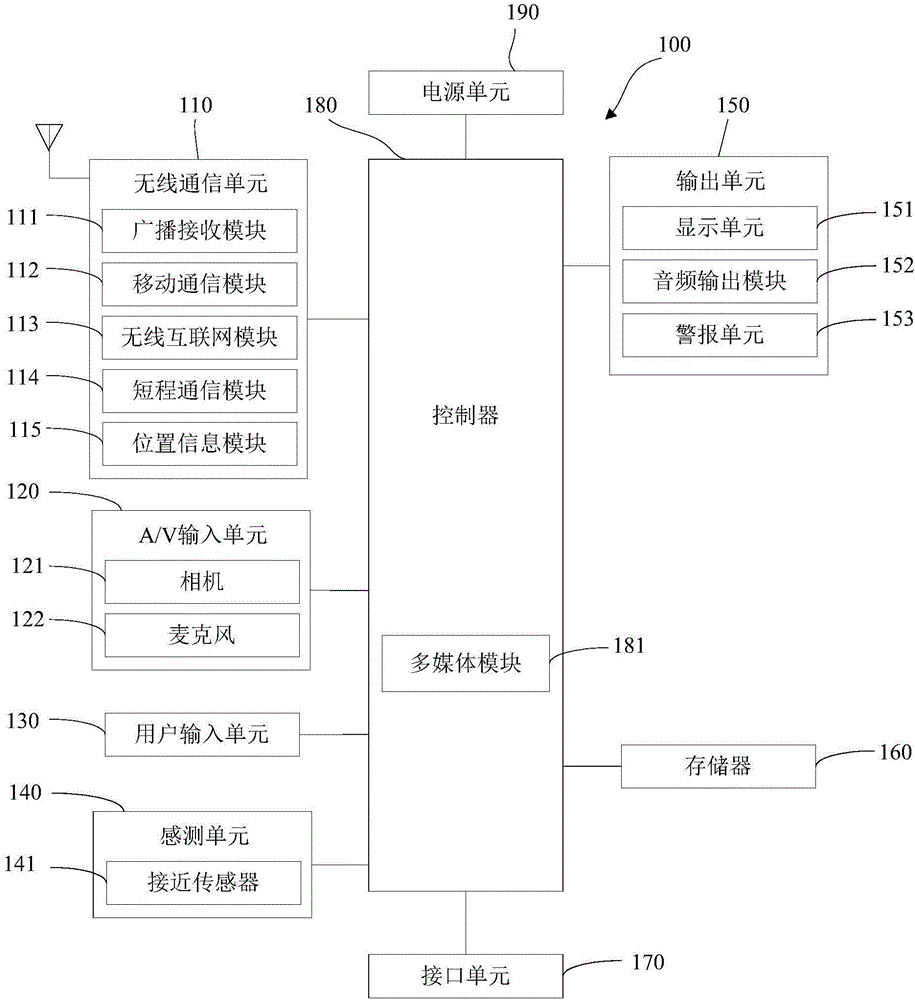

Method and terminal for adjusting interface

InactiveCN101630223ASolve the inconvenience of operationSubstation equipmentInput/output processes for data processingComputer terminalTouchscreen

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

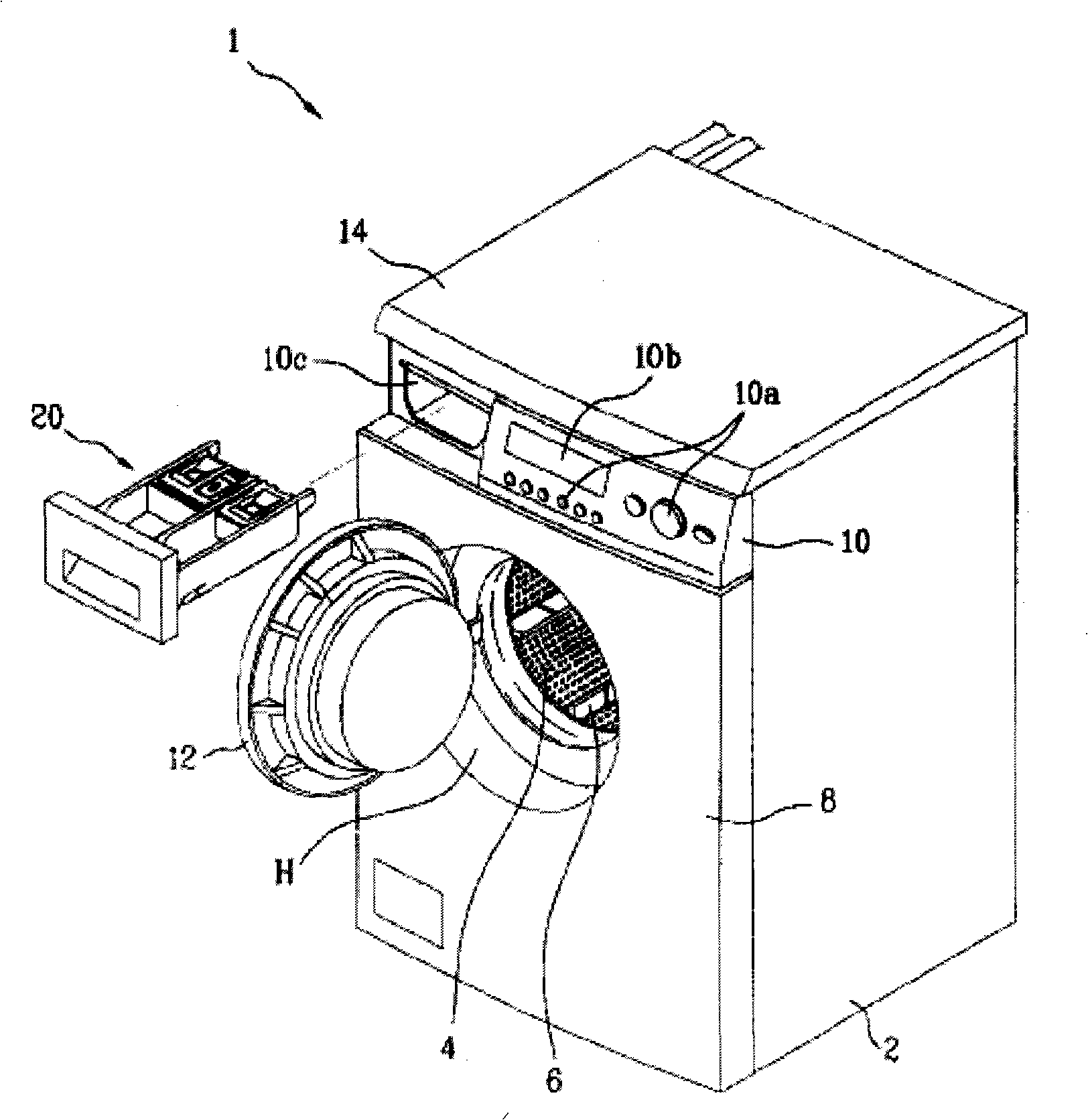

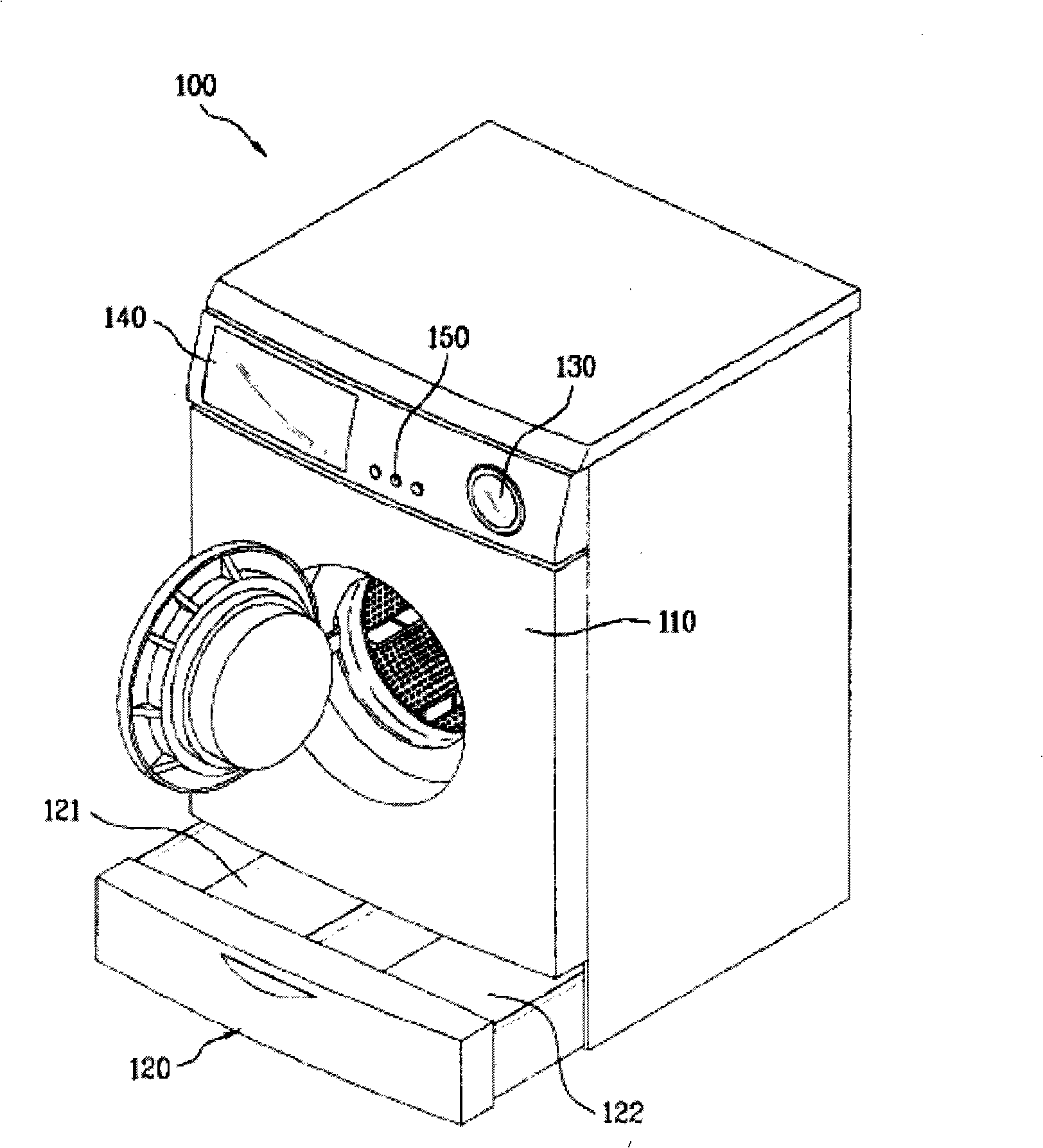

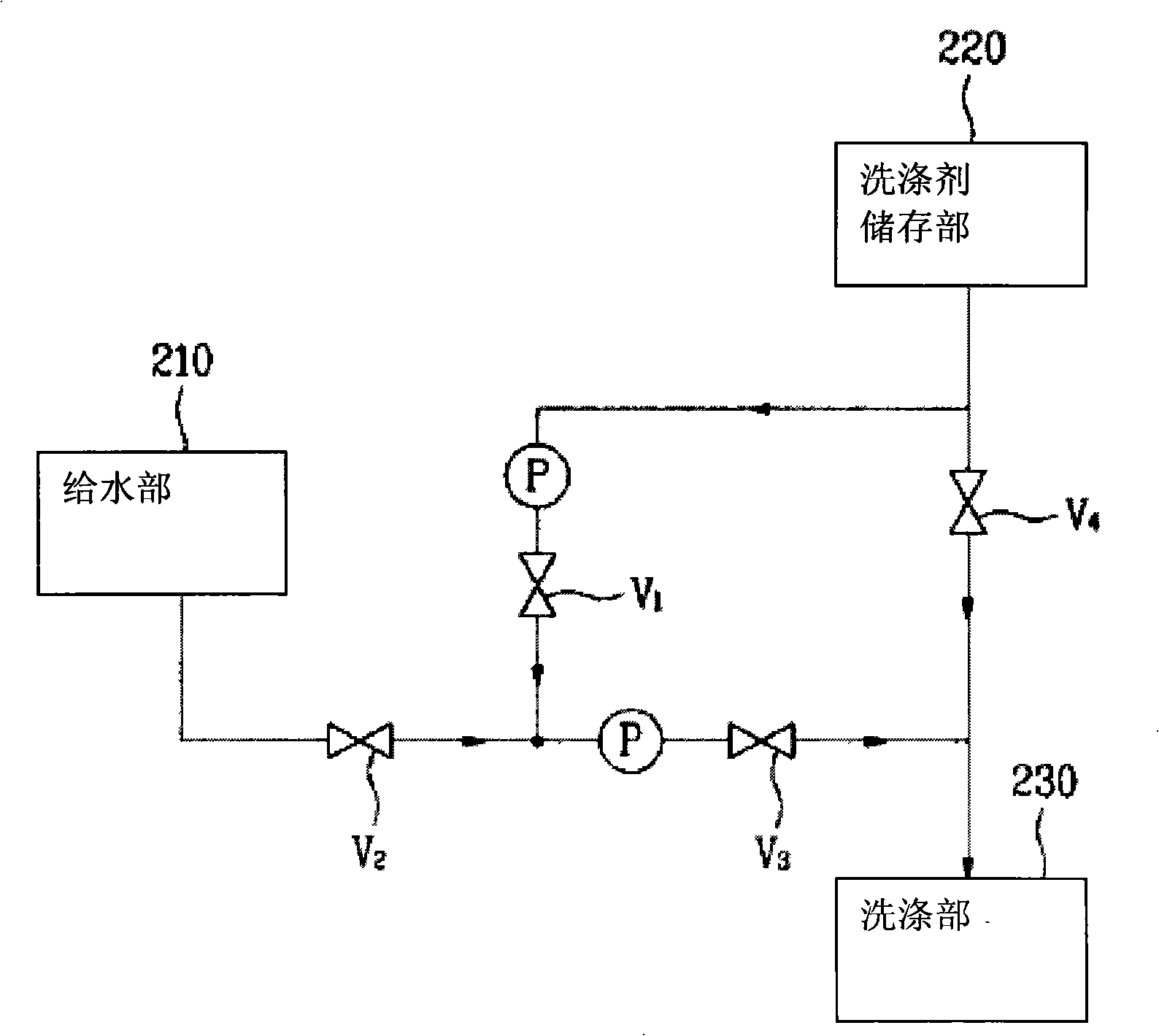

Laundry apparatus and its control method

InactiveCN101298733ASolve the inconvenience of operationOther washing machinesControl devices for washing apparatusEngineeringLaundry

The invention discloses a washing device which can automatically set washing process for washing according to washing information and a control method thereof. The washing device comprises a body of a washing part used for containing clothes for washing; a weight detecting part used for detecting the weight of the clothes contained in the washing part; a washing-agent storing part which is arranged on one side of the body and is used for storing liquid washing-agent and providing proper quantity of liquid washing-agent for the washing part; an information reading part used for receiving signals from an information label and obtaining the record in the information label; a control part used for controlling the washing-agent use-quantity to the washing body according to the information obtained by the information reading part. The control method includes the steps: information obtaining step; washing-agent use-quantity deciding step and washing-agent use-quantity executing step. The washing device and the method of the invention can identify the washing-agent use-quantity according to the variety of washing-agent and weight of clothes and can automatically release washing-agent.

Owner:NANJING LG PANDA APPLIANCES

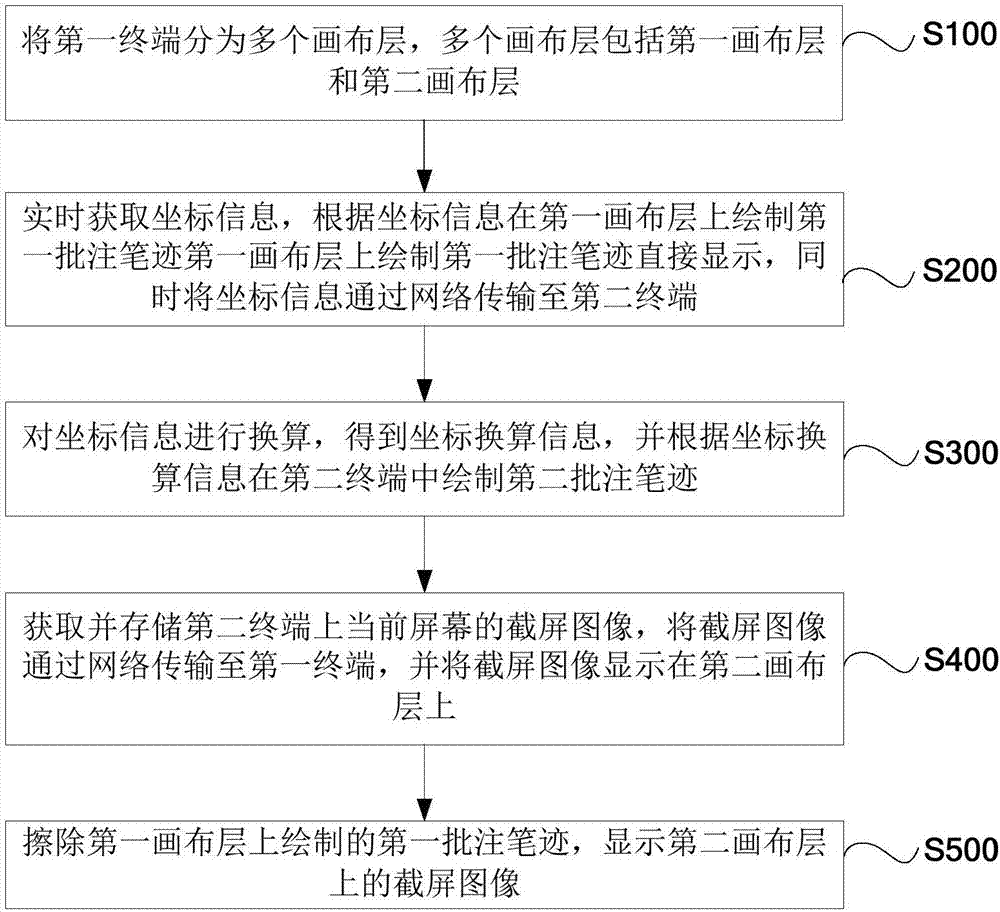

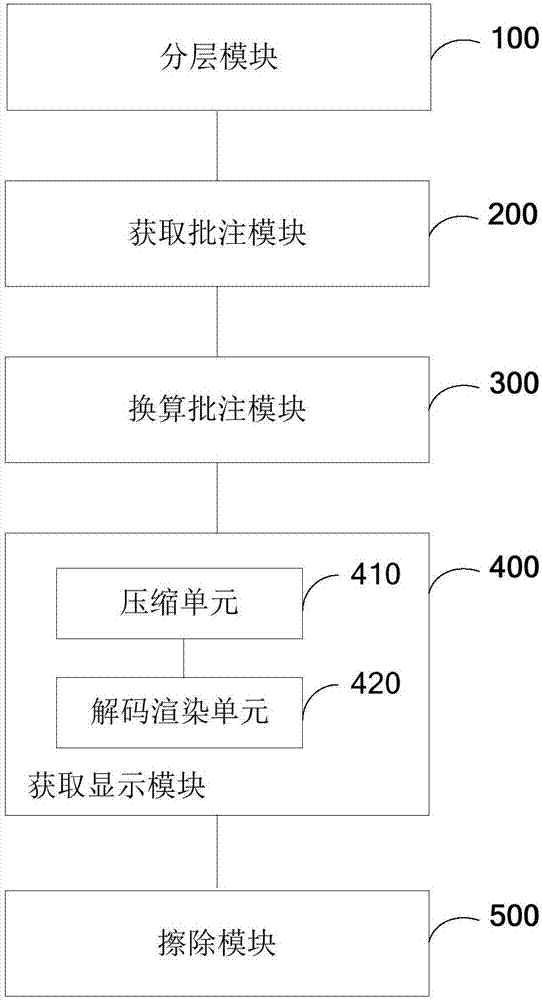

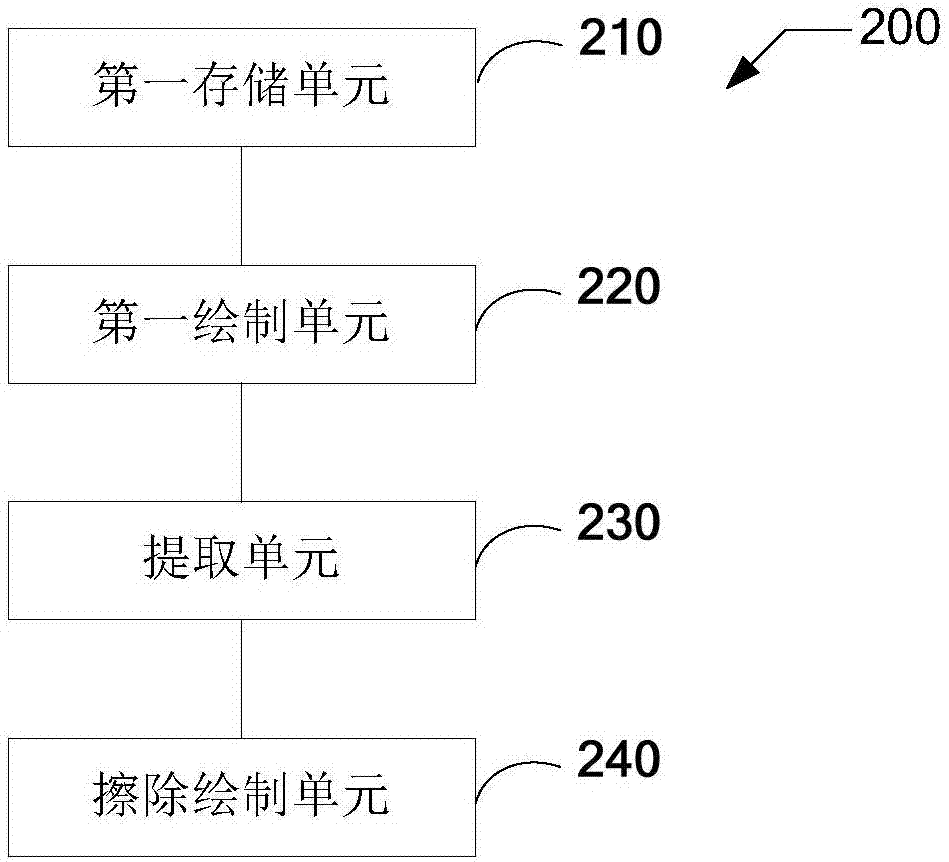

Projection screen annotation method and system

ActiveCN107168674AImprove experienceSolve the inconvenience of operationNatural language data processingSpecial data processing applicationsHandwritingDisplay lag

The invention discloses a projection screen annotation method and system. The method comprises the following steps of: dividing a first terminal into a plurality of canvas layers which comprise a first canvas layer and a second canvas layer; obtaining coordinate information in real time, drawing a first annotation handwriting on the first canvas layer according to the coordinate information, directly displaying the first annotation handwriting, and simultaneously transmitting the coordinate information to a second terminal through a network; converting the coordinate information to obtain coordinate conversion information, and drawing a second annotation handwriting in the second terminal according to the coordinate conversion information; obtaining and storing a screenshot image of the current screen on the second terminal, transmitting the screenshot image to the first terminal by the network, and displaying the screenshot image on the second canvas layer; and erasing the first annotation handwriting drawn on the first canvas layer, and displaying the screenshot image of the first terminal. According to the method and system disclosed by the invention, the problem of inconvenient operation caused by annotation handwriting display lag due to the influences of wireless environment and hardware resource is solved, so that the users cannot feel the bluntness of the writing and then the user experience is enhanced.

Owner:杭州信雅达三佳系统工程股份有限公司

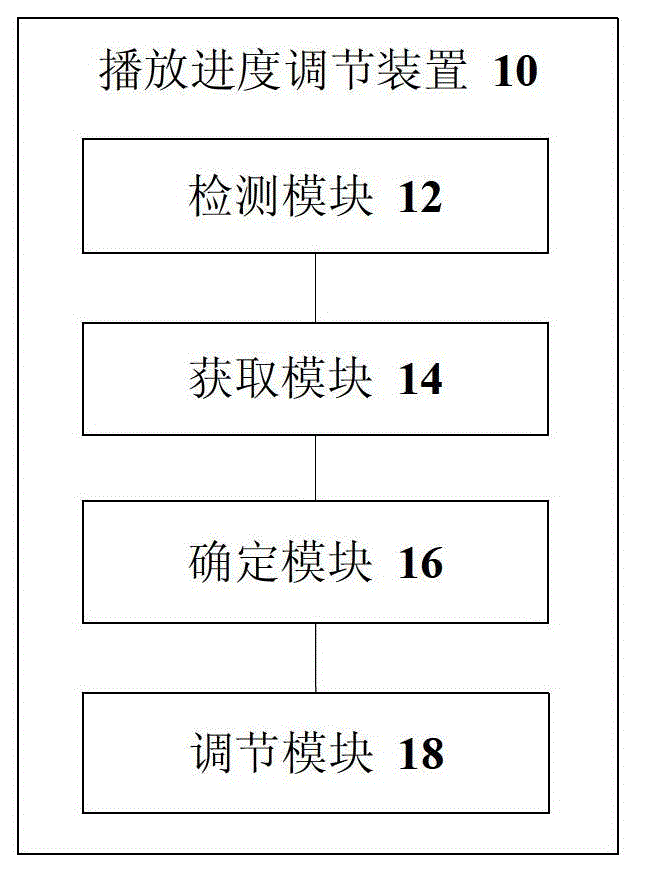

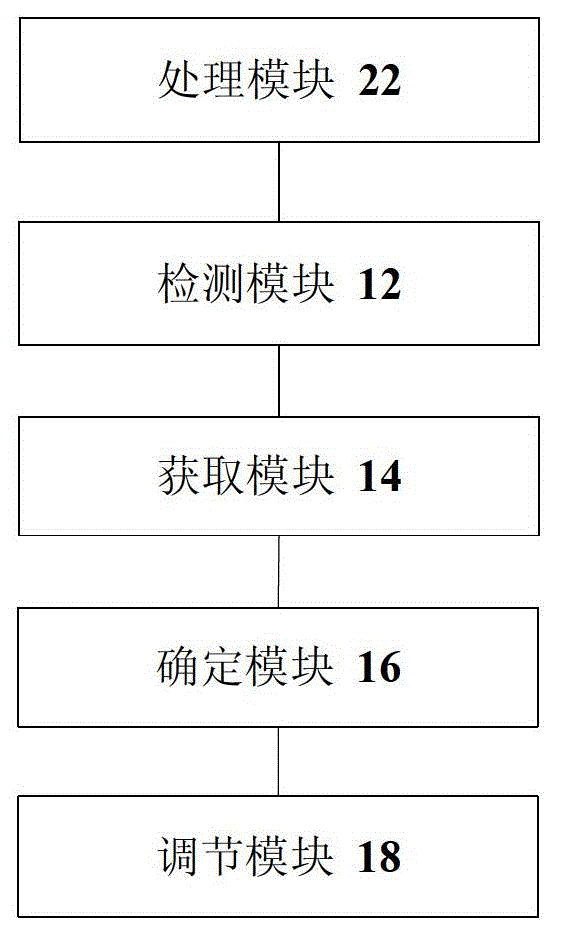

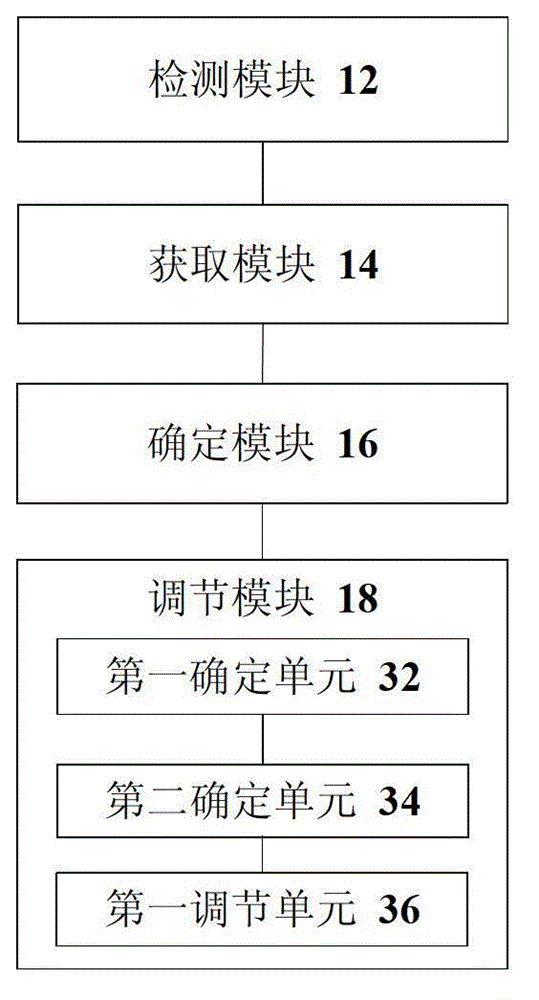

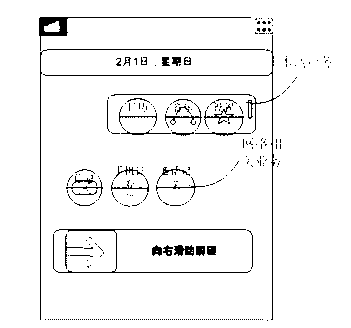

Broadcast progress adjusting method, device and terminal

InactiveCN104156162ASolve the inconvenience of operationEasy to operateCarrier indicating arrangementsInput/output processes for data processingComputer terminalHuman–computer interaction

A method, apparatus, and terminal for a user of a touch screen electronic device to readily and conveniently adjust or control multimedia playback progress using the touch screen are disclosed. In some embodiments, a playback progress adjustment method includes: detecting a contact with a touch screen at a multimedia playback window by a device having a processor and a touch screen; acquiring by the device a touch parameter of the contact; determining that the contact is a single contact with the touch screen based on the touch parameter, wherein the single contact is a continuous contact, the touch parameters corresponding to the continuous contact comprises a start position parameter and an end position parameter; adjusting playback progress of the multimedia based on the touch parameters.

Owner:TENCENT TECH (SHENZHEN) CO LTD

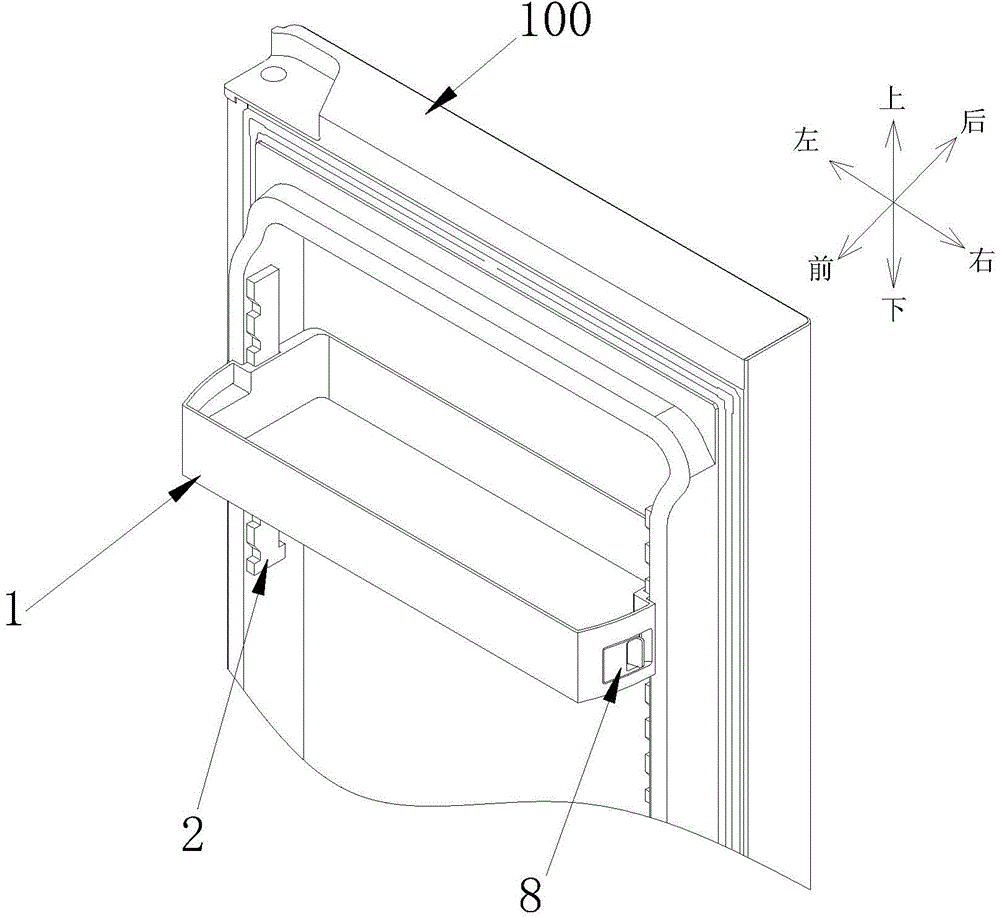

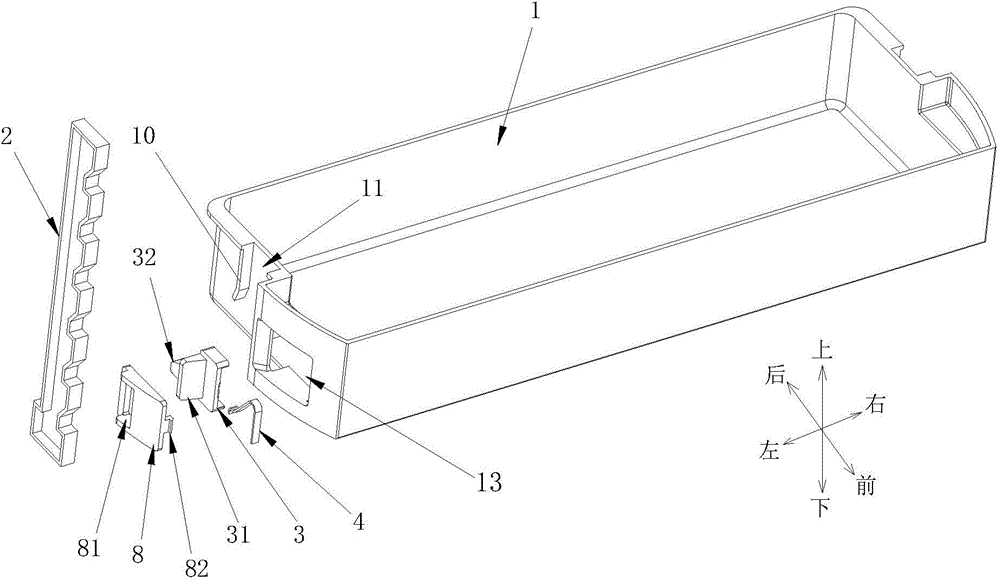

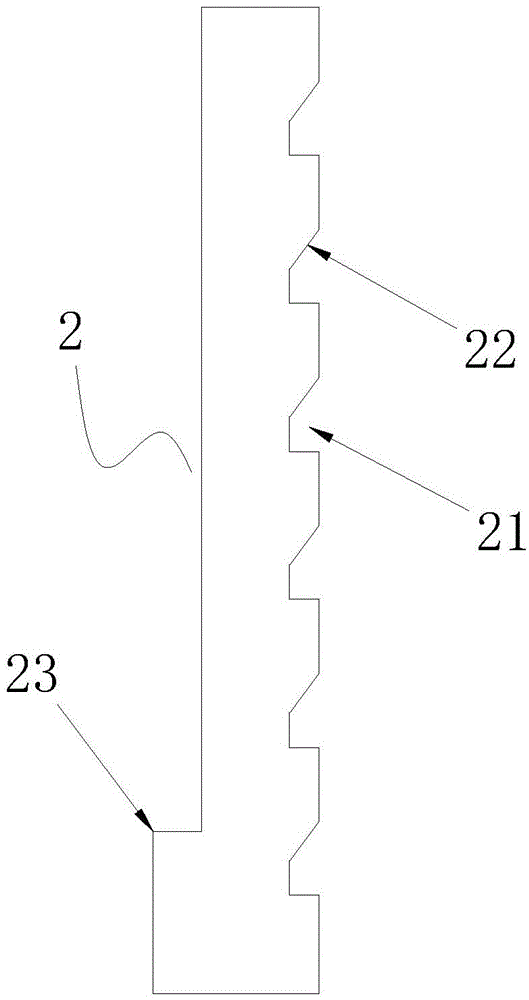

Refrigerator

ActiveCN104006619AIncrease profitSolve the inconvenience of operationLighting and heating apparatusSupportRefrigerated temperatureLinkage concept

Owner:HISENSE RONGSHENG YANGZHOU REFRIGERATOR CO LTD

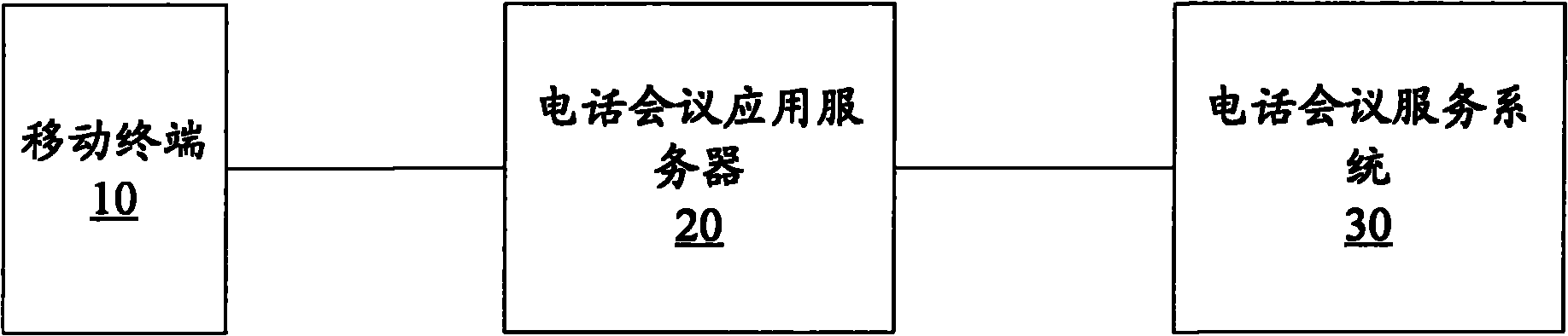

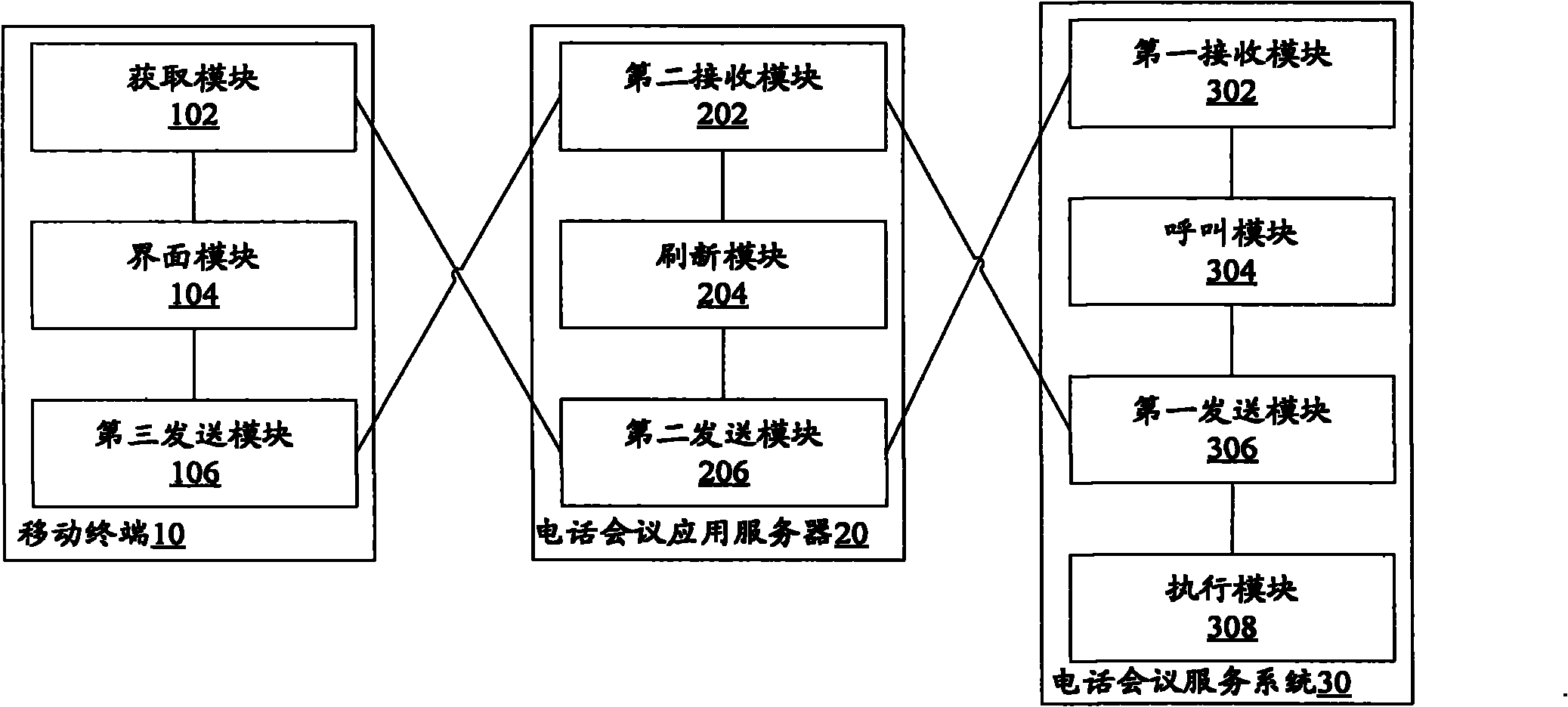

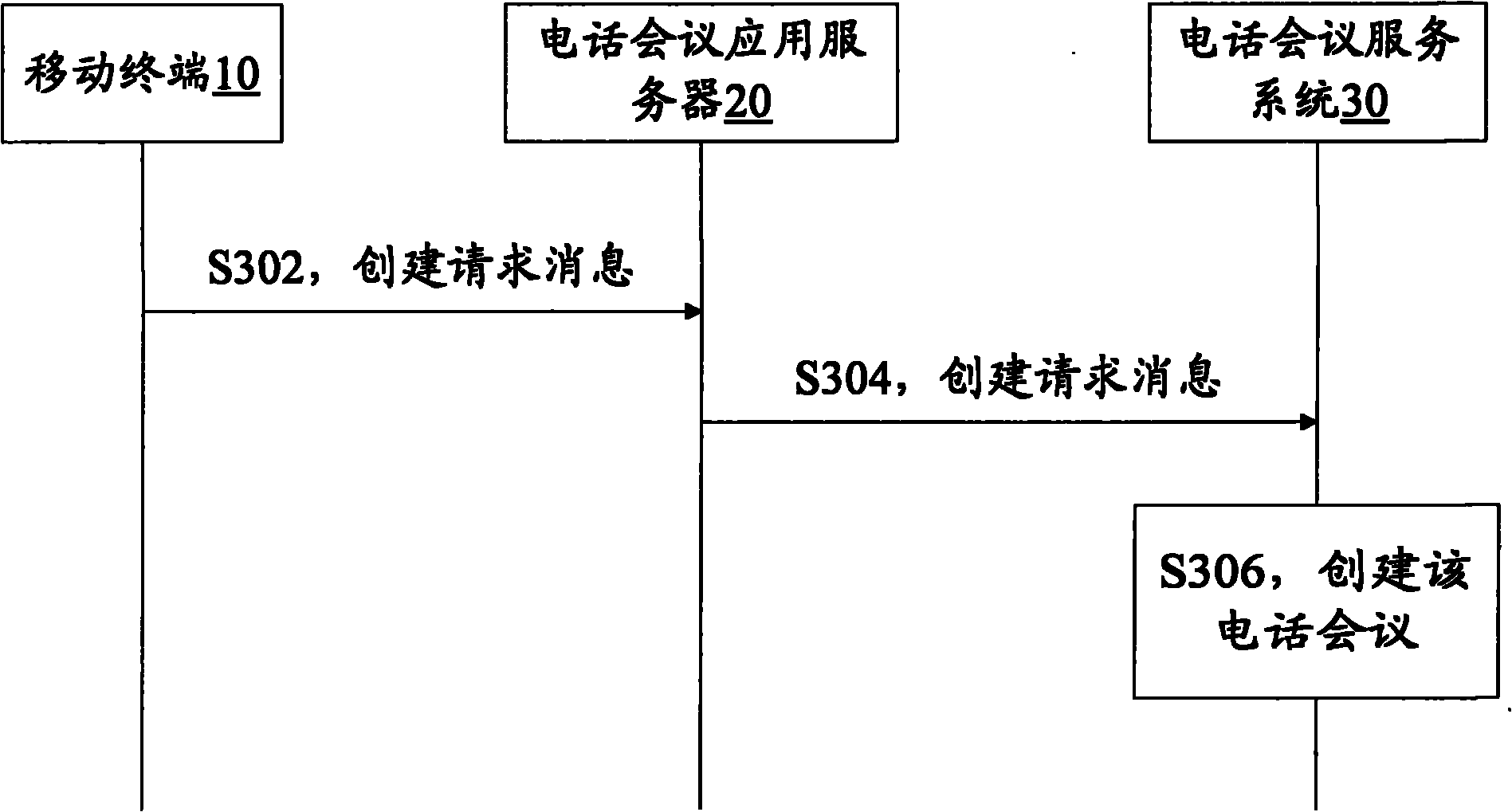

Implementation method and system of teleconference

InactiveCN101969513AEasy to operateSolve the inconvenience of operationSpecial service for subscribersWireless networksApplication serverMassage

The invention discloses an implementation method and system of a teleconference, wherein the implementation method comprises the following of: responding a massage on a teleconference to be established, which is input by a conference initiator through a teleconference interface, and sending an establishment request massage carrying the teleconference message to a teleconference application server by a mobile terminal; requesting a teleconference service system to establish the teleconference, by the teleconference application server according to the establishment request massage; and establishing the teleconference, by the teleconference service system according to the request from the teleconference application server. The invention provides great convenience for the operation of users, and solves the problem of inconvenient operation in relevant technologies.

Owner:ZTE CORP

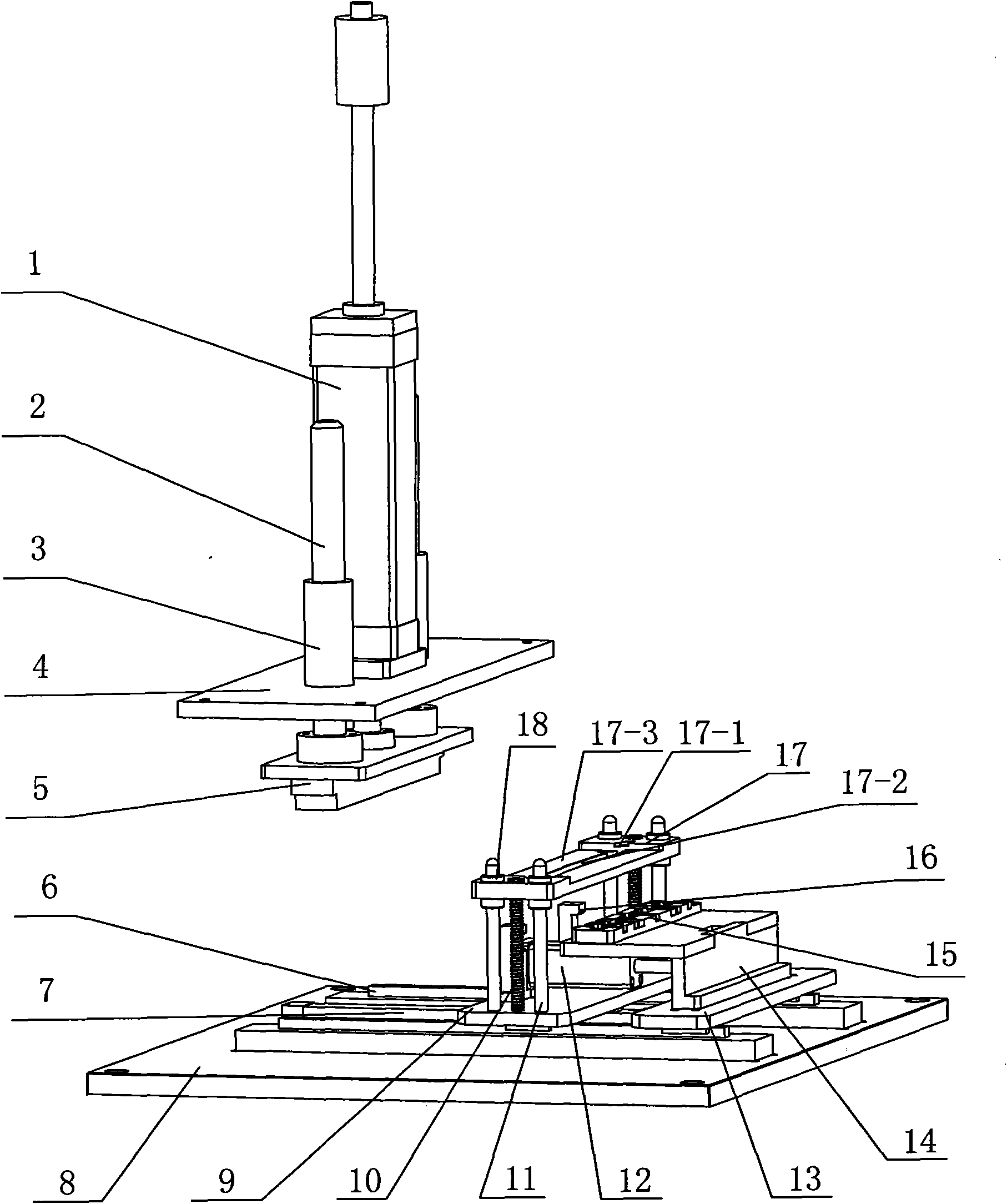

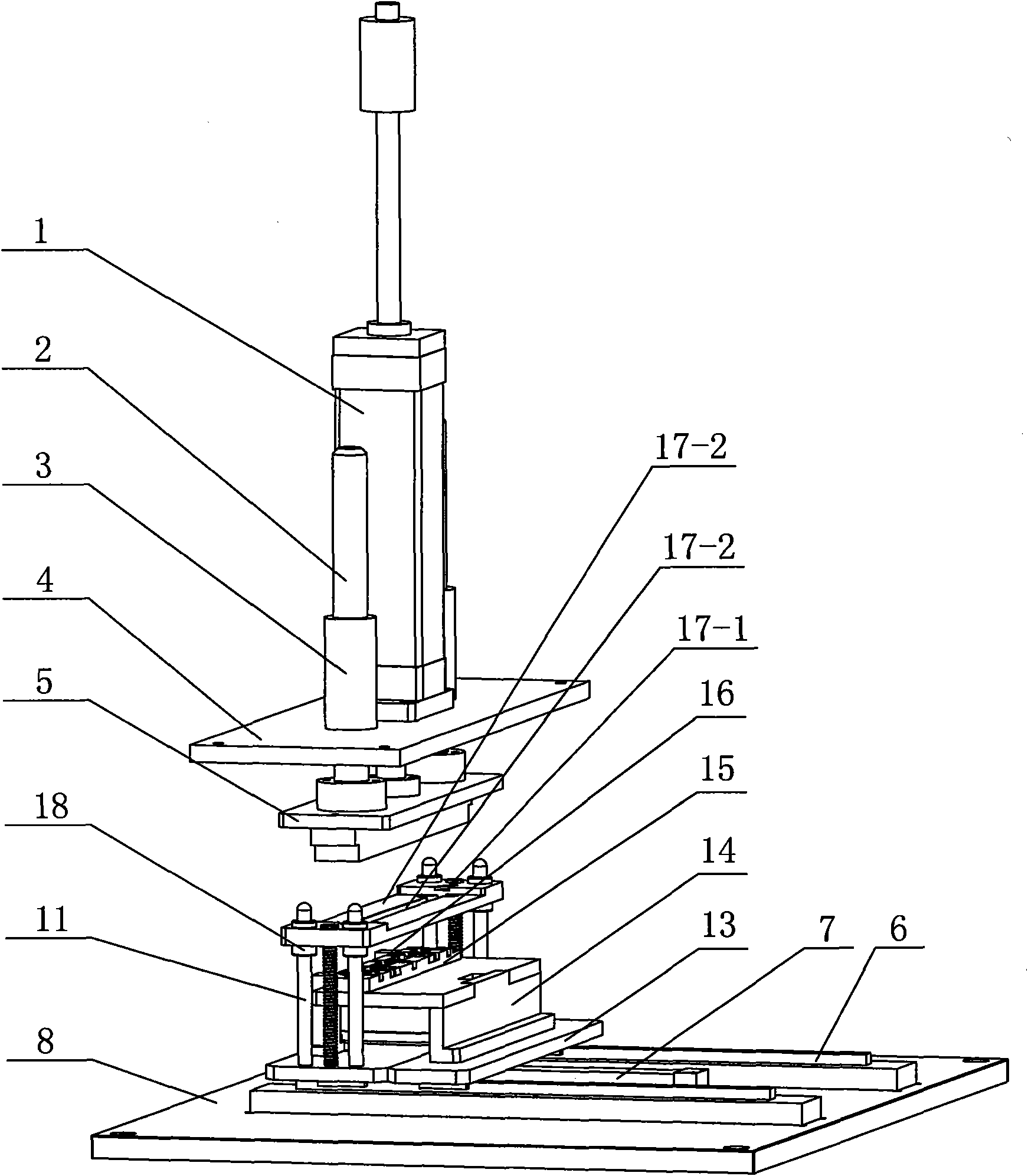

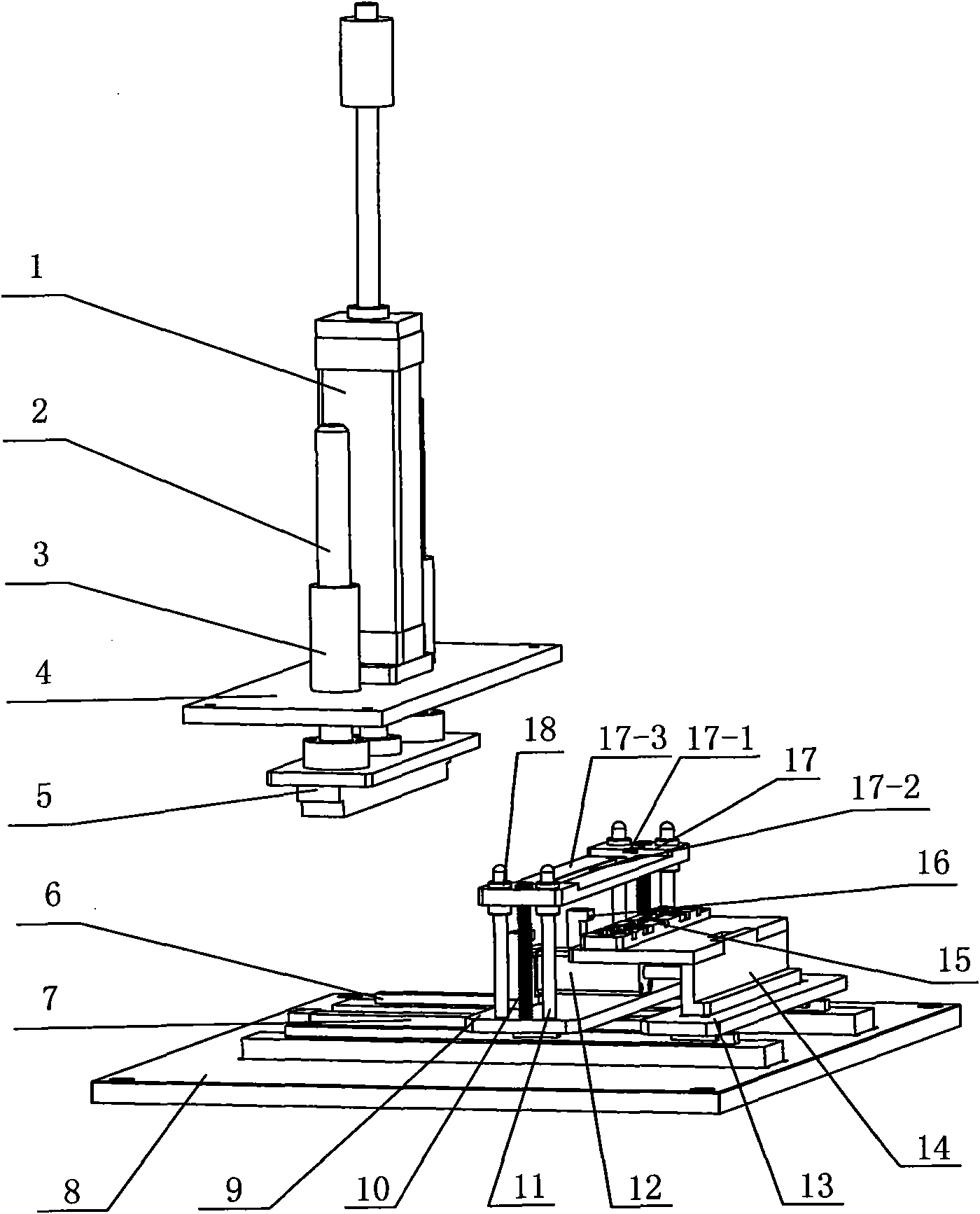

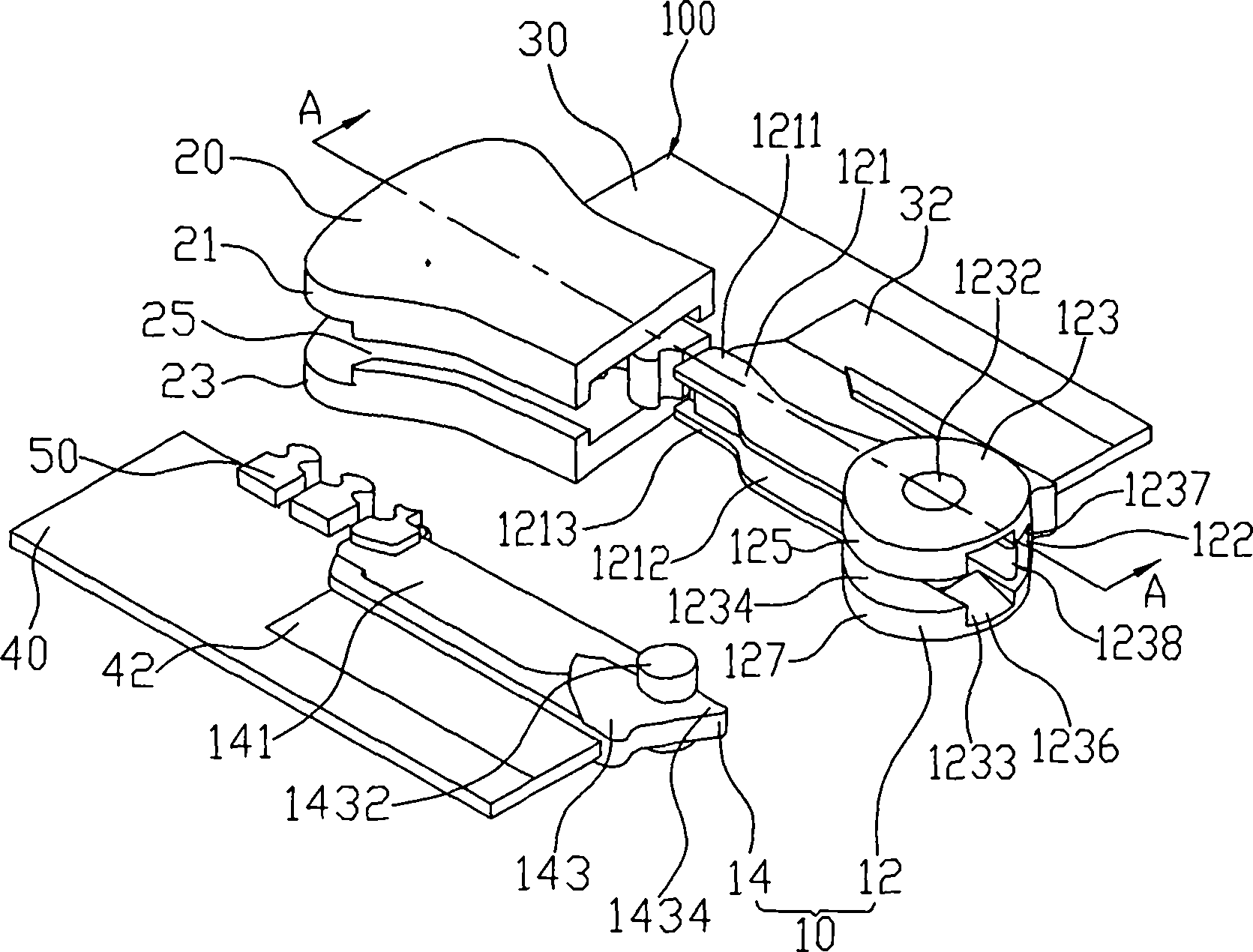

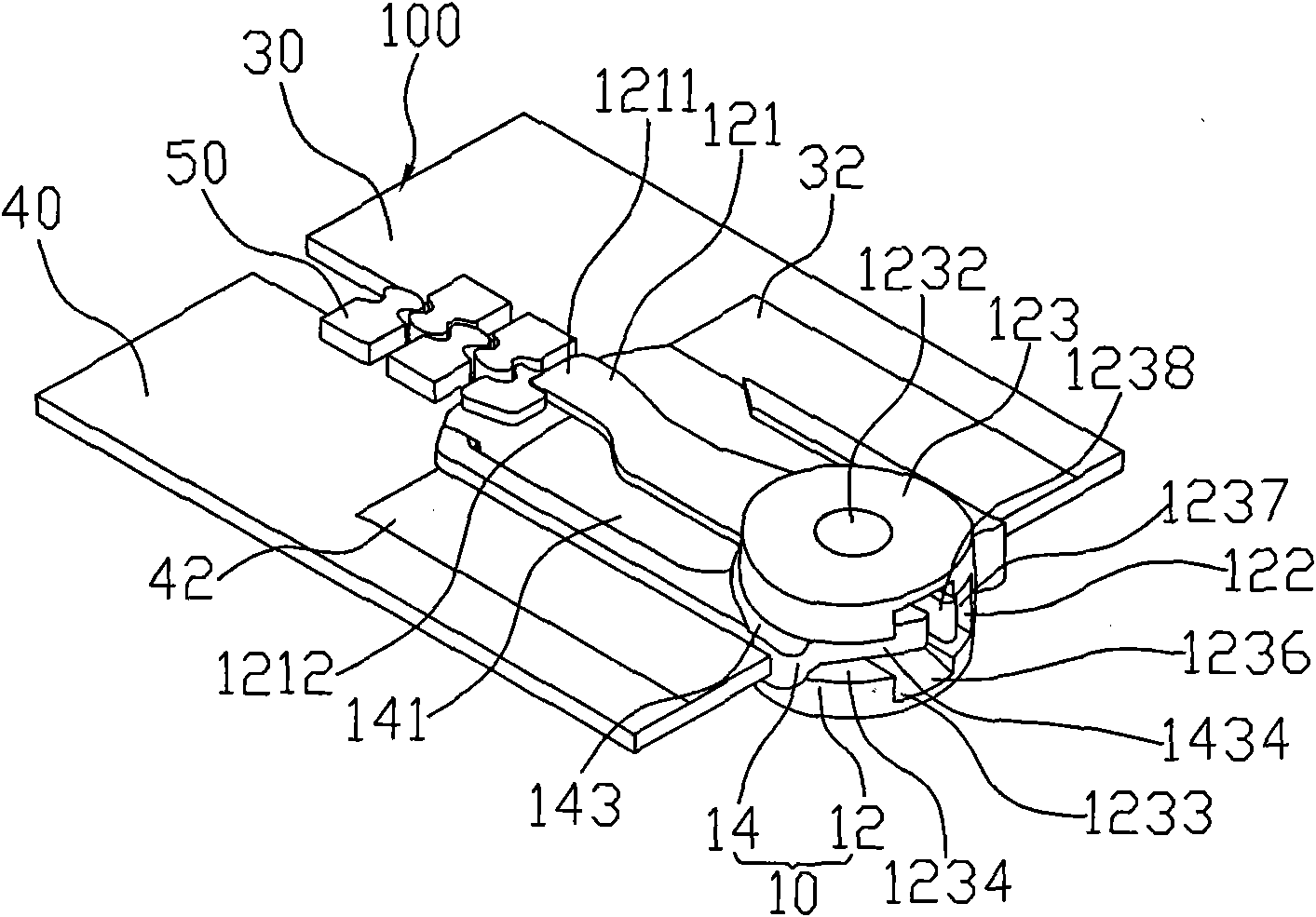

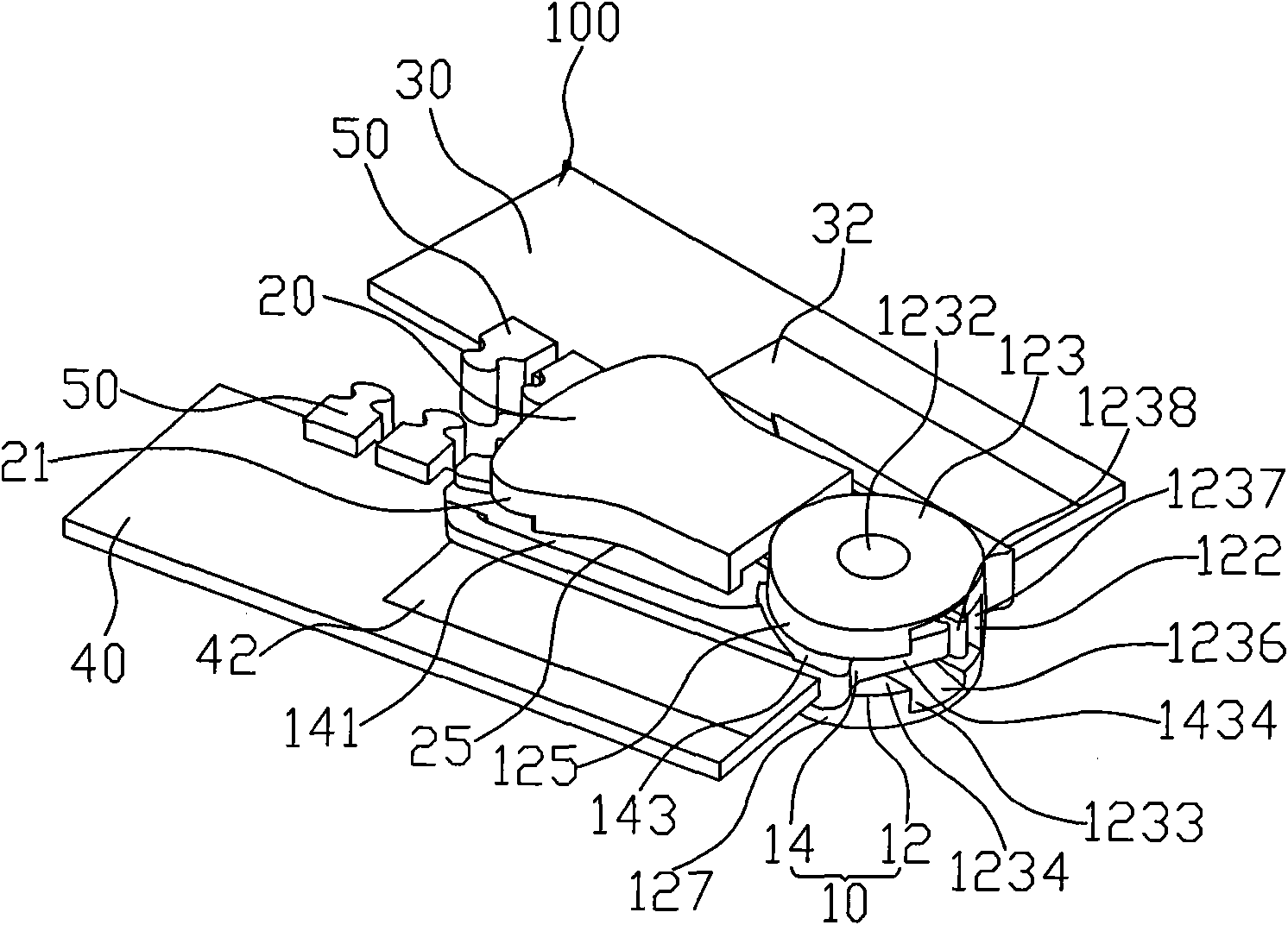

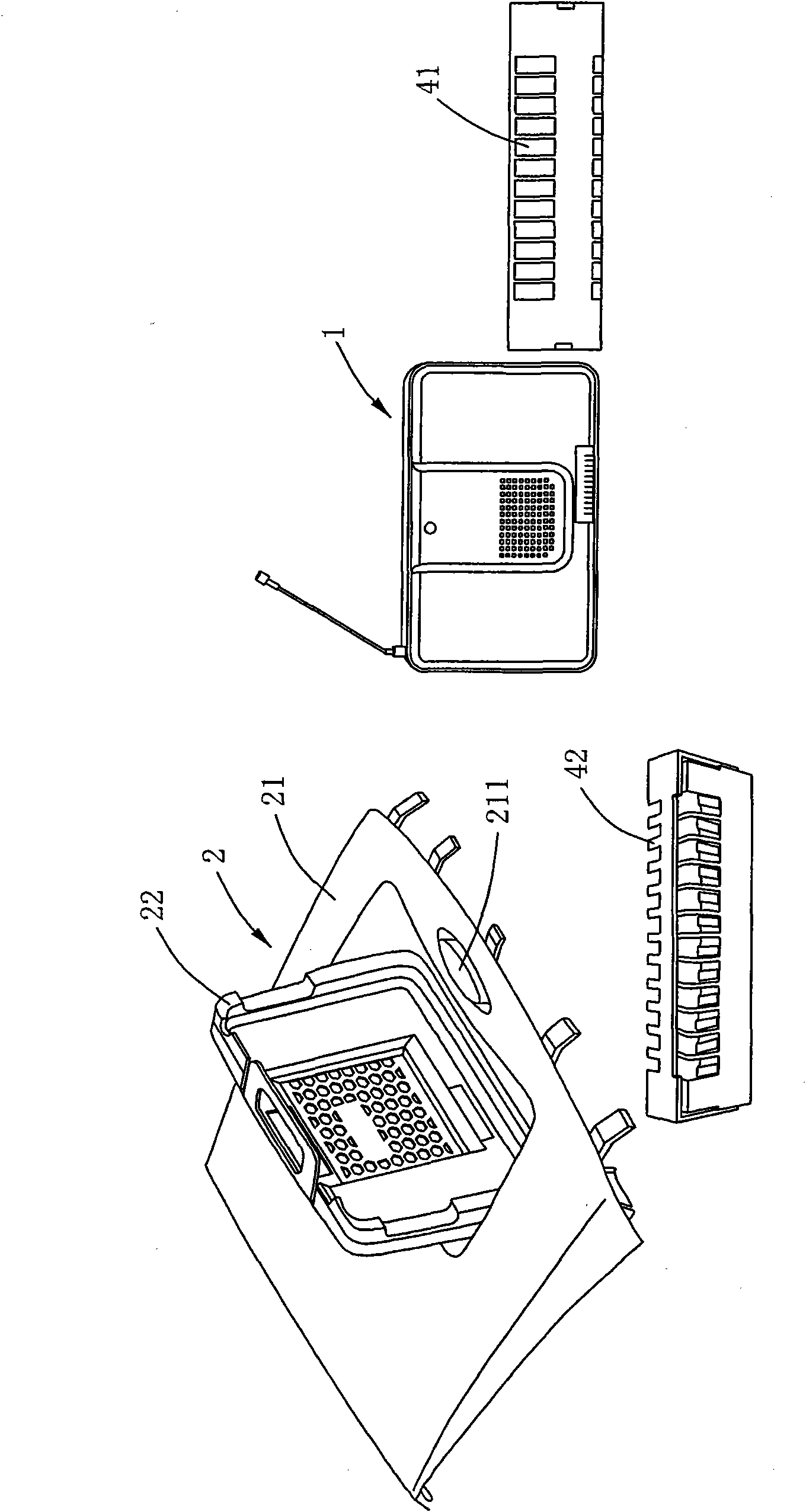

Lamp crimping and assembling mechanism

The invention relates to a lamp crimping and assembling mechanism, which comprises an upper crimping assembly and a lower crimping assembly, wherein a lower connecting base of the lower crimping assembly is provided with two linear guide tracks and a first cylinder in the transverse direction; a first sliding plate and a second sliding plate are arranged on the two linear guide tracks and are movable; the piston of the first cylinder is connected with the first sliding plate; at least two springs arranged on the first sliding plate are supported to a first limiting plate; the first limiting plate is provided with a mounting surface for mounting parts, a positioning groove and an H-shaped discharge notch arranged on the mounting surface; a second cylinder arranged on the first sliding plate is connected with a supporting plate arranged on the second sliding plate; a second limiting plate is arranged on the supporting plate; the second limiting plate is provided with a mounting surface for mounting parts and more than two spacing grooves; and the first sliding plate is provided with a positioning block for height positioning of the second limiting plate, and the positioning block is provided with a side positioning notch. The lamp crimping and assembling mechanism ensures that two parts can be placed in a staggered mode, can improve the assembly efficiency, and has accurate positioning, and safe and convenient operation.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

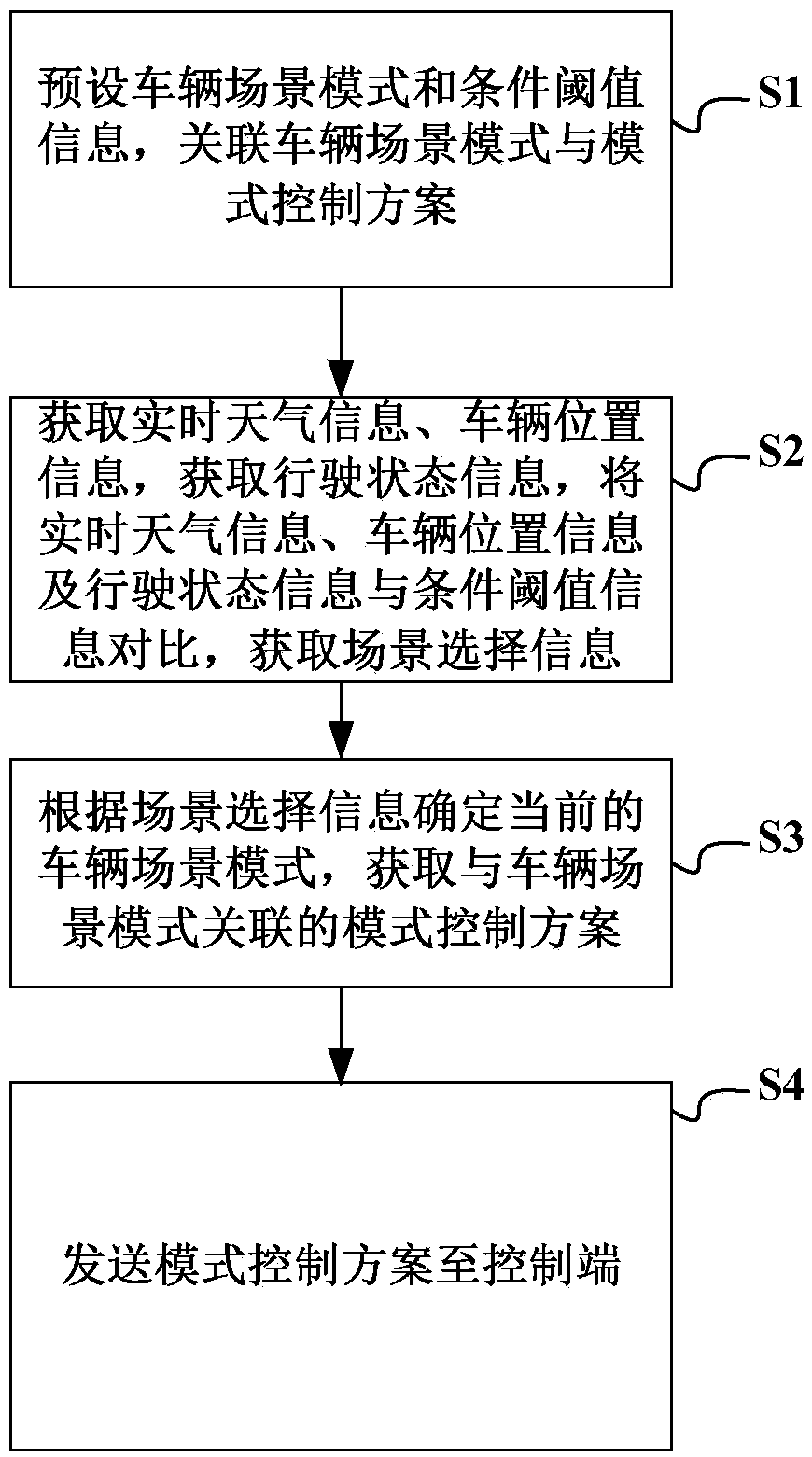

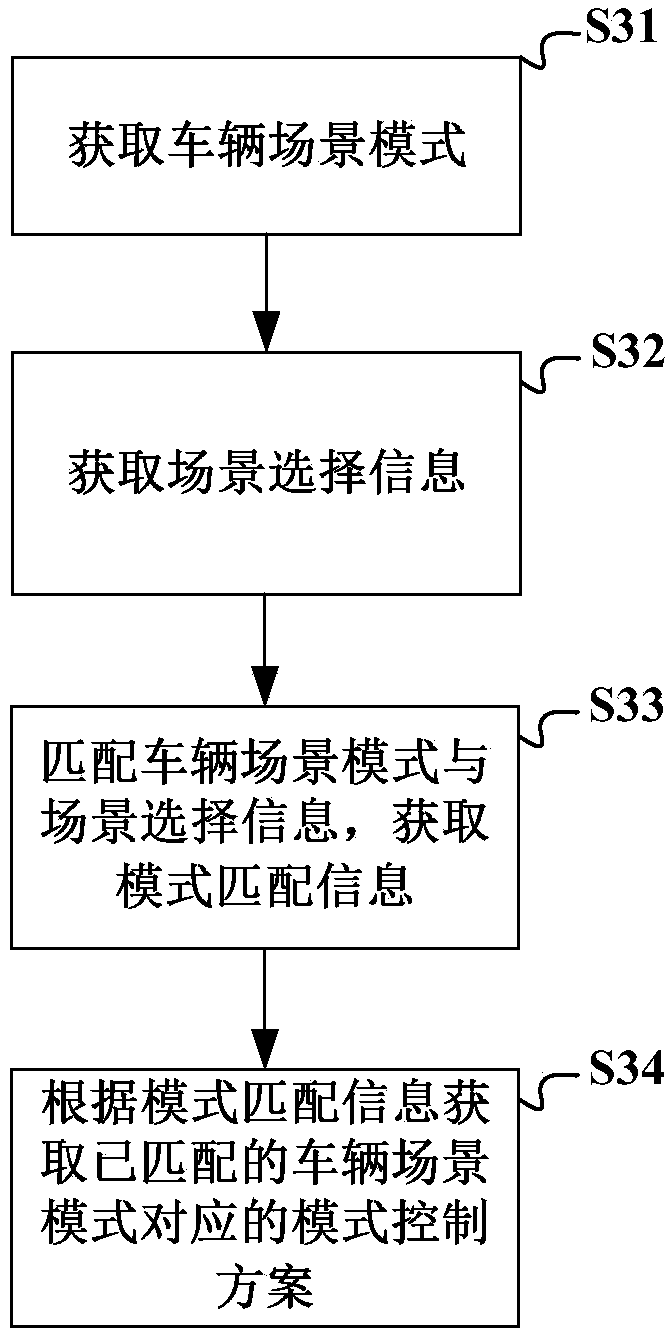

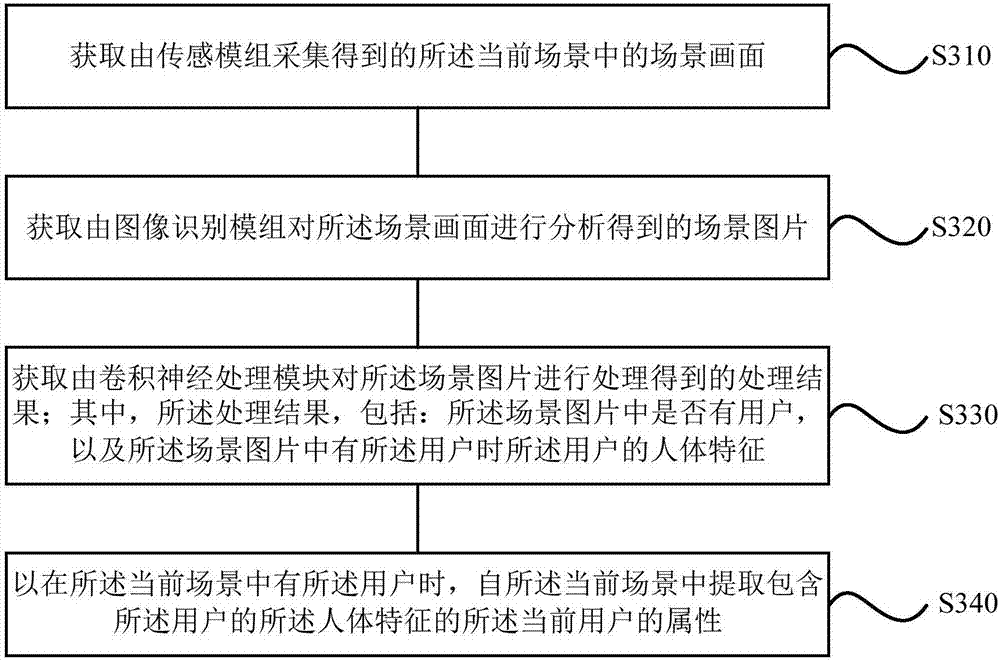

Intelligent scenario vehicle control method, server and client

InactiveCN109094575AImprove accuracyImprove securityElectric/fluid circuitMode controlVehicle control

The invention relates to an intelligent scene vehicle control method, comprising a server end and a control end. The intelligent scene vehicle control method comprises the following steps: presettingvehicle scene mode and condition threshold information, and associating the vehicle scene mode and the mode control scheme; Acquiring real-time weather information, vehicle position information, acquiring driving state information, comparing real-time weather information, vehicle position information and driving state information with condition threshold information, and acquiring scene selectioninformation; Determining a current vehicle scene mode according to the scene selection information, and obtaining a mode control scheme associated with the vehicle scene mode; Sends a mode control scheme to the control terminal. In the prior art, there are technical problems of low applicability of vehicle control operation method and single function of vehicle subsystem control and human-vehicleinteraction.

Owner:SHANGHAI QINGGAN INTELLIGENT TECH CO LTD

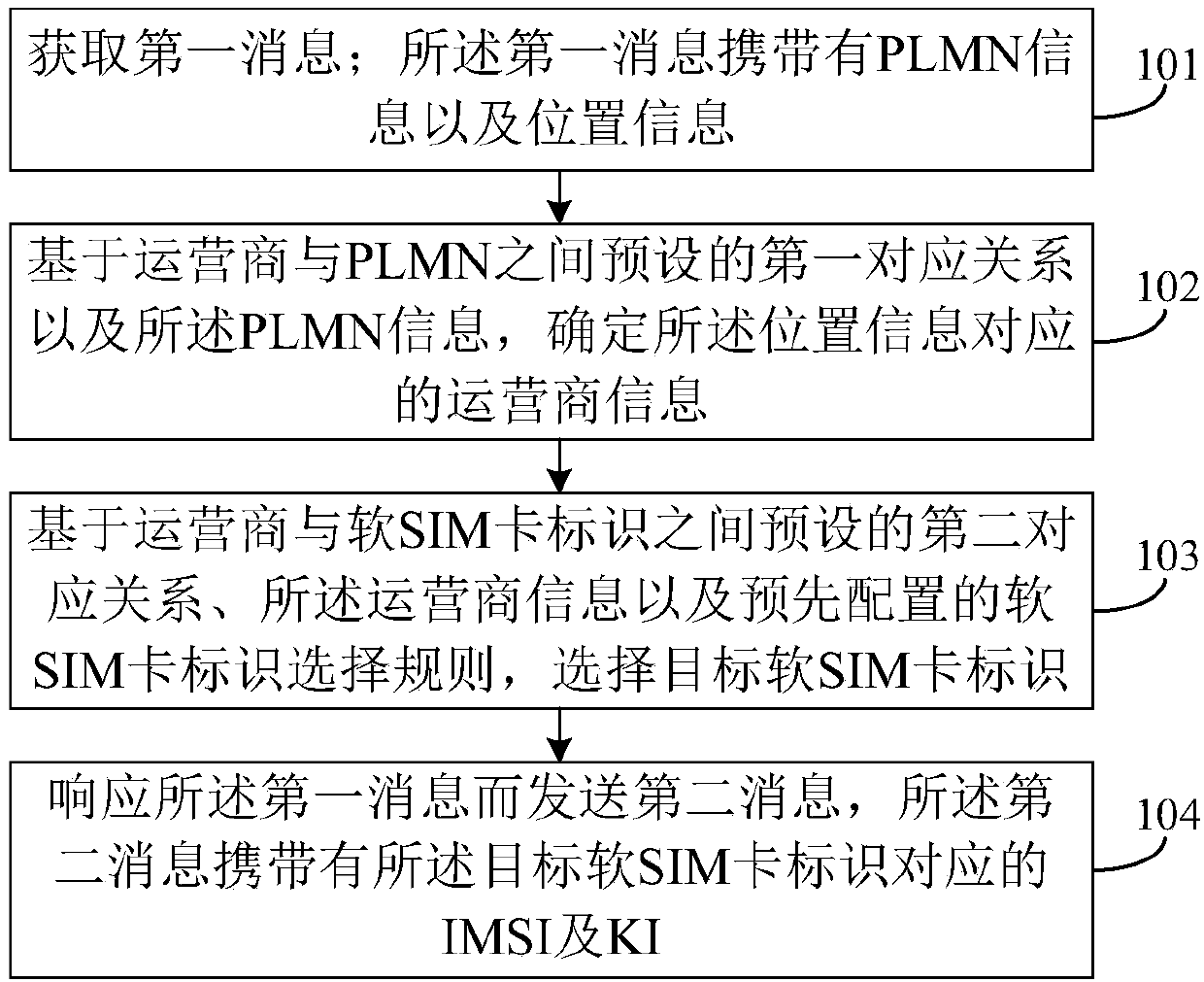

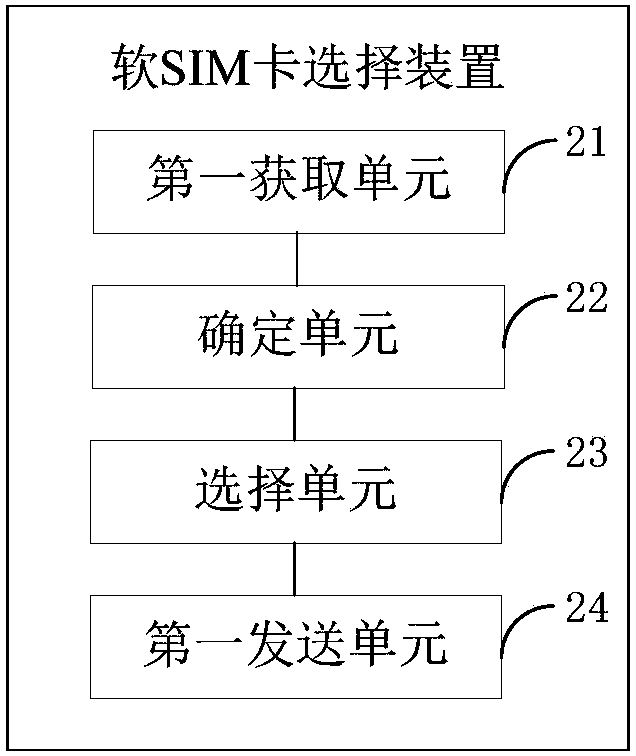

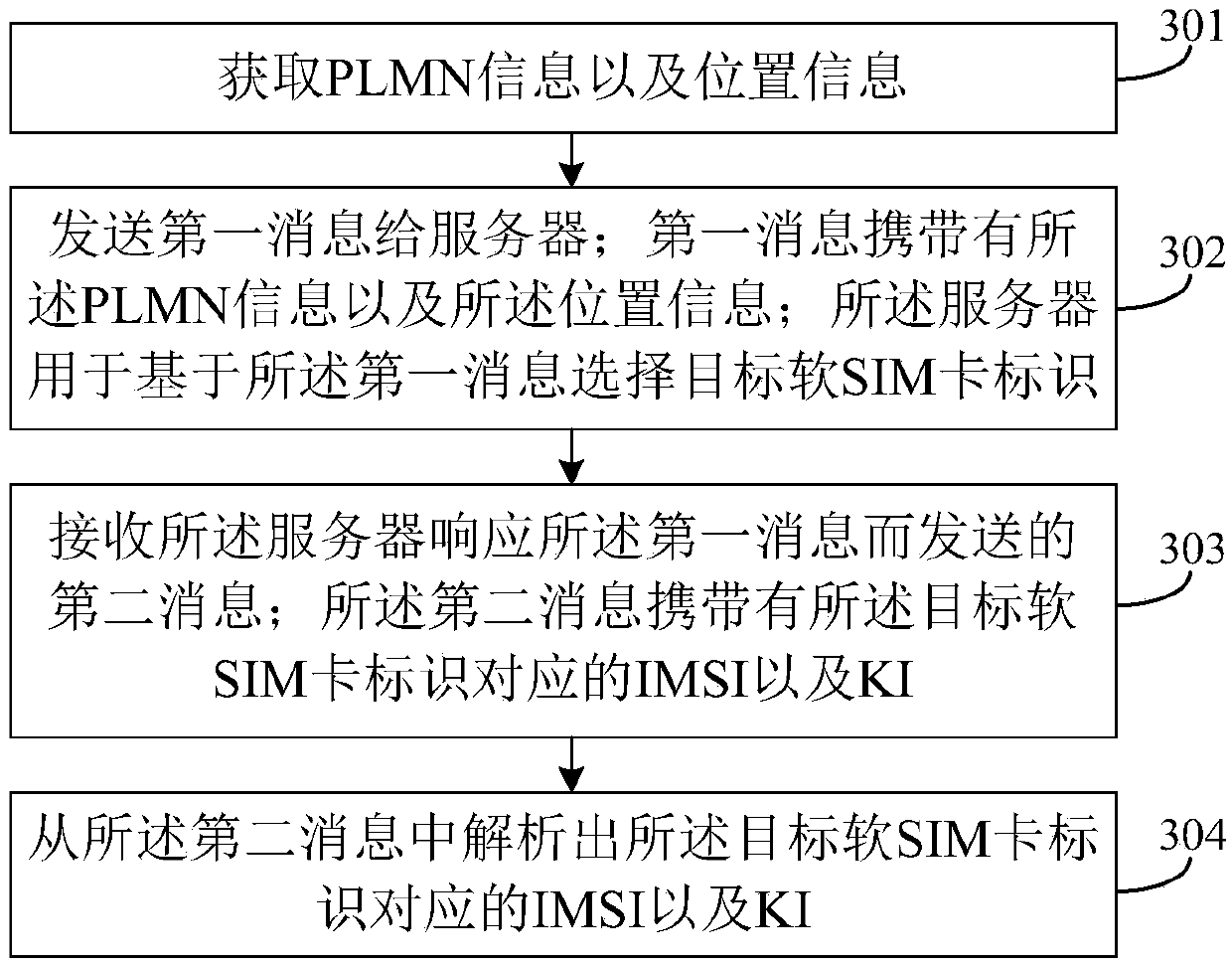

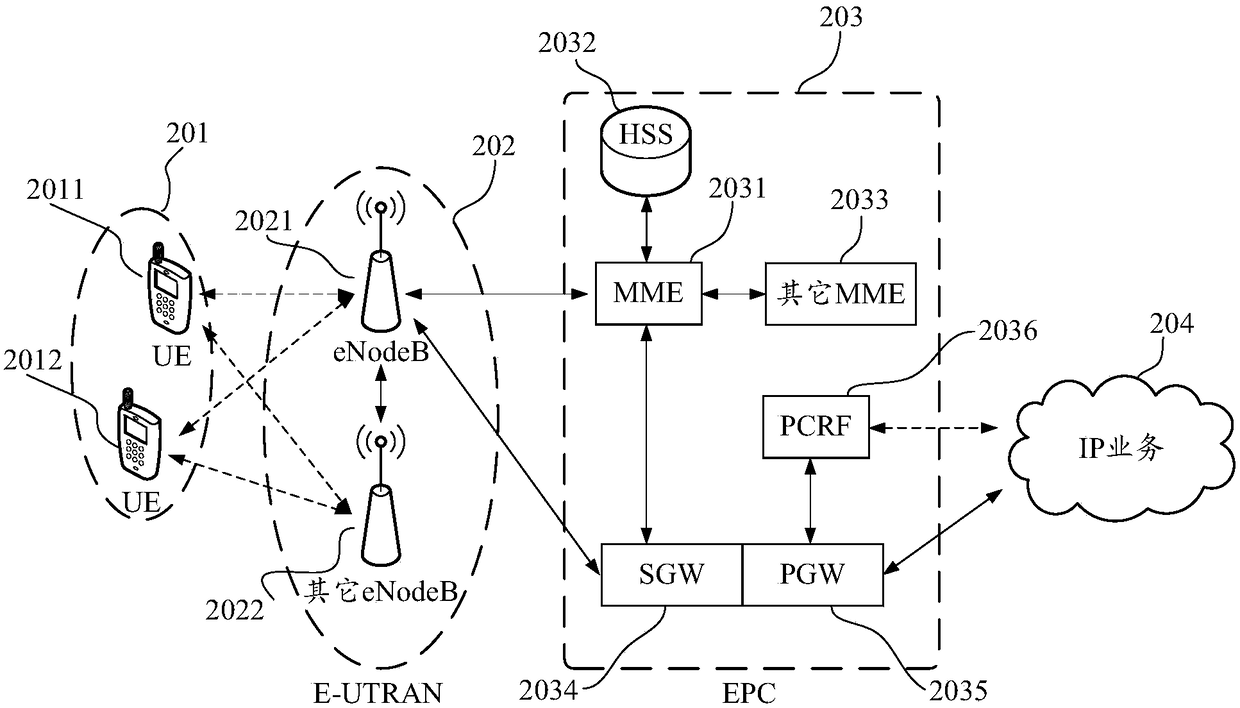

Soft SIM card selection and acquisition methods and devices

InactiveCN107682850ASolve the inconvenience of operationAccounting/billing servicesAssess restrictionComputer hardwareSelection method

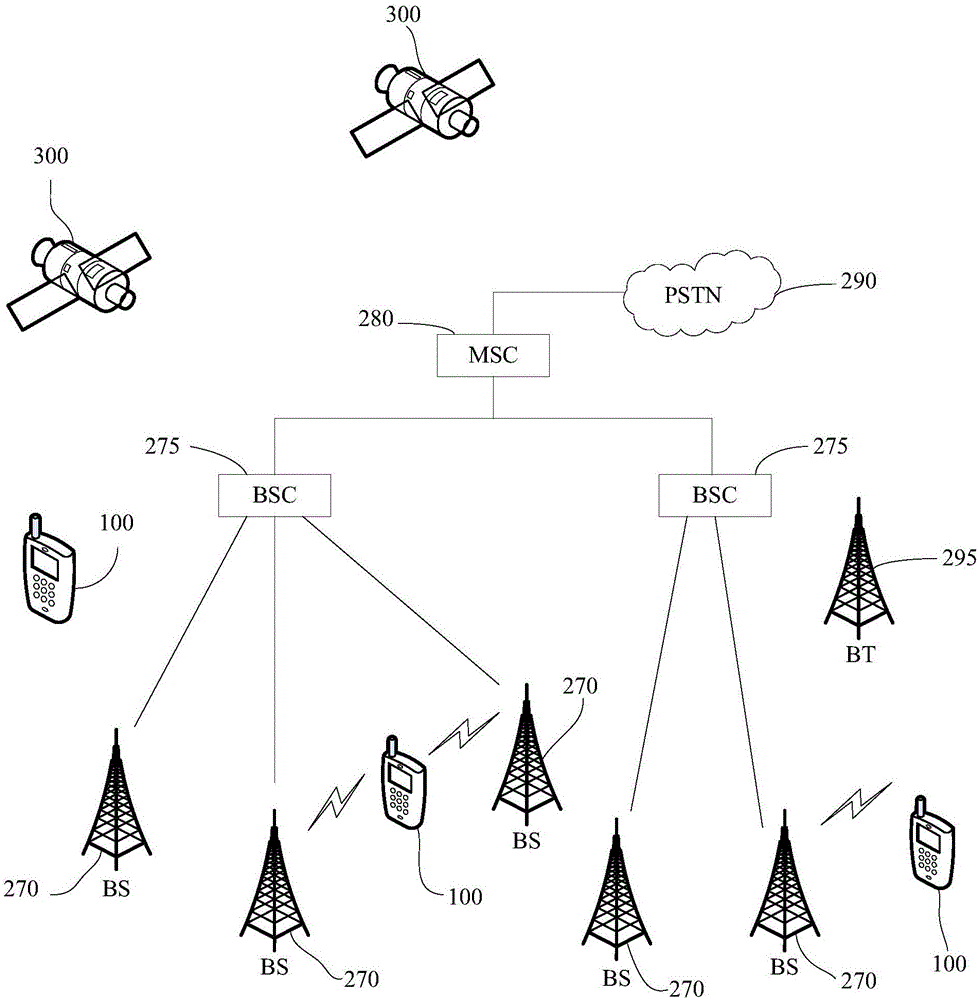

The embodiment of the invention relates to soft SIM card selection and acquisition methods and devices. The soft SIM card selection method comprises the steps of acquiring a first message carrying PLMN information and position information; determining operator information corresponding to the position information based on a first preset corresponding relation between an operator and a PLMN, and the PLMN information; selecting a target soft SIM card identifier based on a second preset corresponding relation between the operator and the soft SIM card identifier, the operator information and a preconfigured soft SIM card identifier selection rule; sending a second message in response to the first message, wherein the second message carries an IMSI and a KI corresponding to the target soft SIMcard identifier. According to the methods and devices provided by the embodiment of the invention, the operator information of a position where a terminal is located is determined via the corresponding relation between the operator and the PLMN, the target soft SIM card identifier accordant with the soft SIM card identifier selection rule is selected via the corresponding relation between the operator and the soft SIM card identifier, and thus the problem that a user using an entity SIM card is inconvenient to switch the operator or switch the SIM card is solved.

Owner:INFLUENTIAL TECH CO LTD

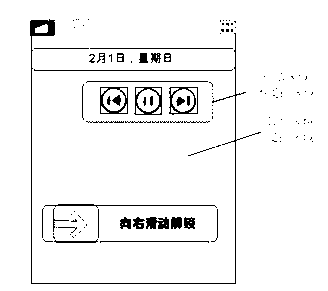

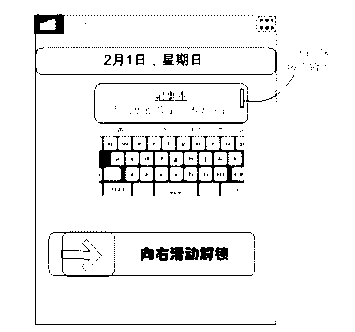

Terminal control method and terminal

ActiveCN102707888ASolve the inconvenience of operationImprove experienceInput/output processes for data processingMan machineLock screen

The invention provides a terminal control method and a terminal. The terminal comprises a man-machine interface module and a screen control module, wherein the man-machine interface module is used for receiving and recognizing an input operation of a user and transmitting the input operation of the user and coordinate position of the input operation to the screen control module, the screen control module is used for placing a corresponding business in a local area on a terminal interface according to a lock screen strategy when a screen is locked, the local area refers to an area which can continue performing the business operation when the screen is locked, and the local area is set on the terminal interface in advance or is randomly distributed on the terminal interface. According to the terminal control method and the terminal, a local lock screen method is utilized, inconveniences of operation brought by existing lock screen modes for the user are eliminated, and the user experience degree is improved.

Owner:ZTE CORP

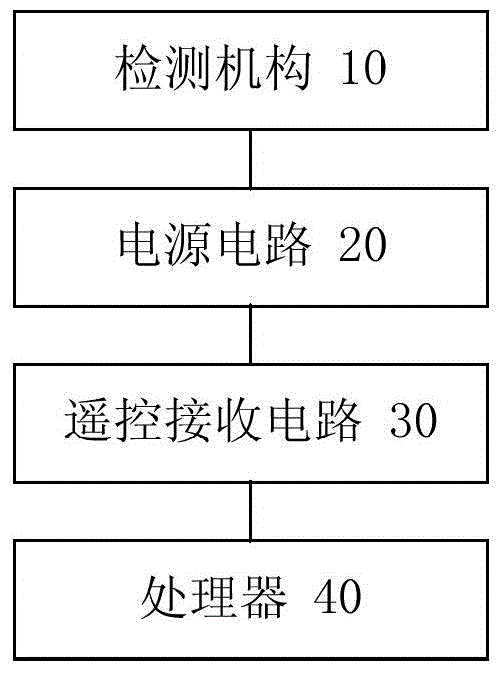

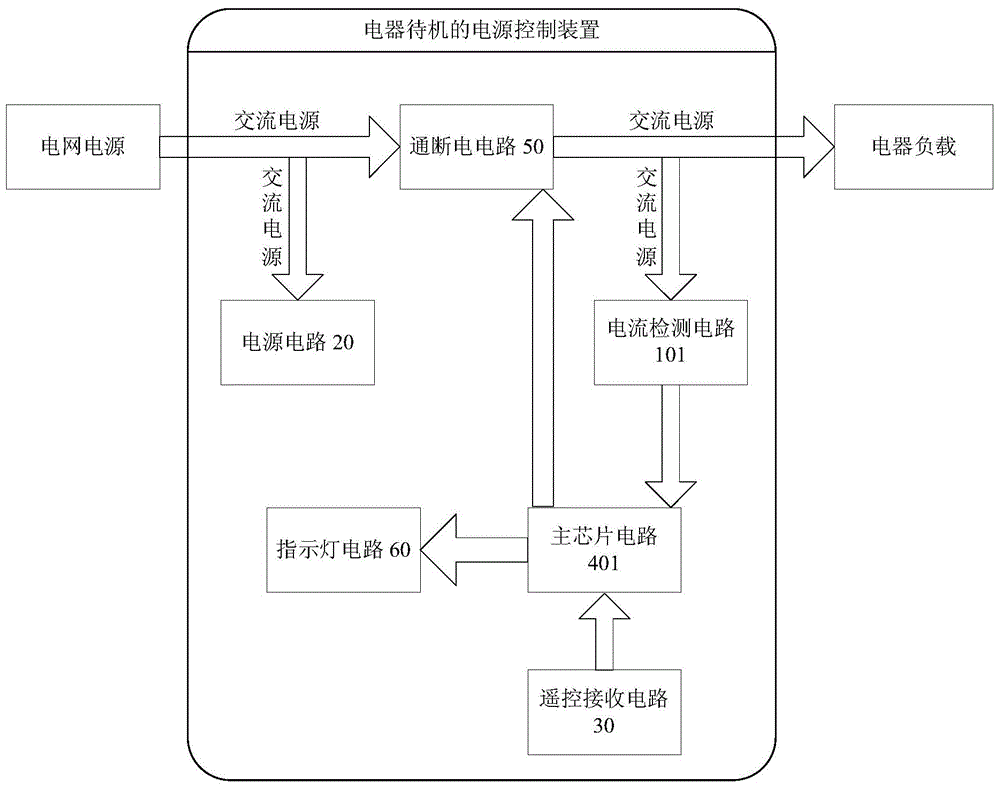

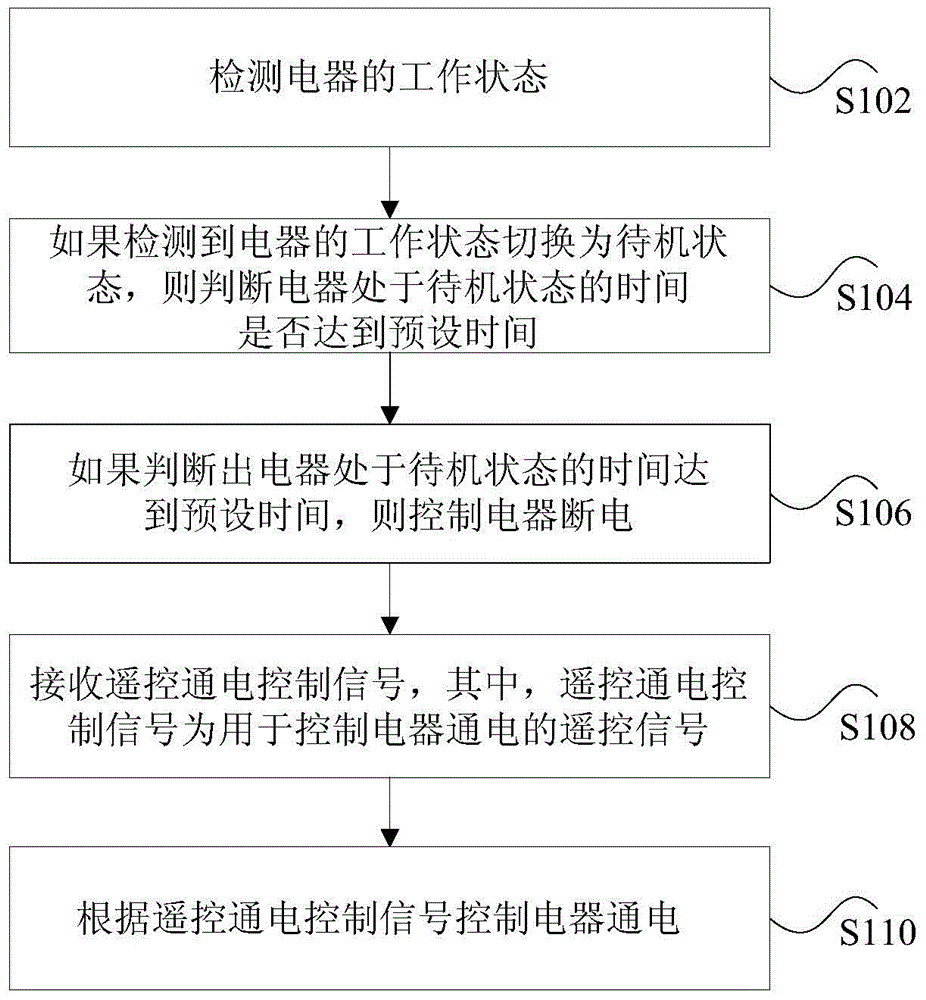

Electric appliance and standby power supply control method and device thereof

InactiveCN105022301ASolve the inconvenience of operationImprove convenienceProgramme control in sequence/logic controllersControl powerRemote control

The invention discloses an electric appliance and a standby power supply control method and device thereof. The standby power supply control method of the electric appliance comprises the steps that the working state of the electric appliance is detected; if the working state of the electric appliance is switched to a standby state through detection, whether time during which the electric appliance is in the standby state reaches preset time is judged; if time during which the electric appliance is in the standby state reaches the preset time through judgment, the electric appliance is powered off through control; a remote control power-on control signal is received, and the remote control power-on control signal is a remote control signal used for controlling power on of the electric appliance. With application of the standby power supply control method of the electric appliance, convenience of power-on operation after automatic power off of the electric appliance can be enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

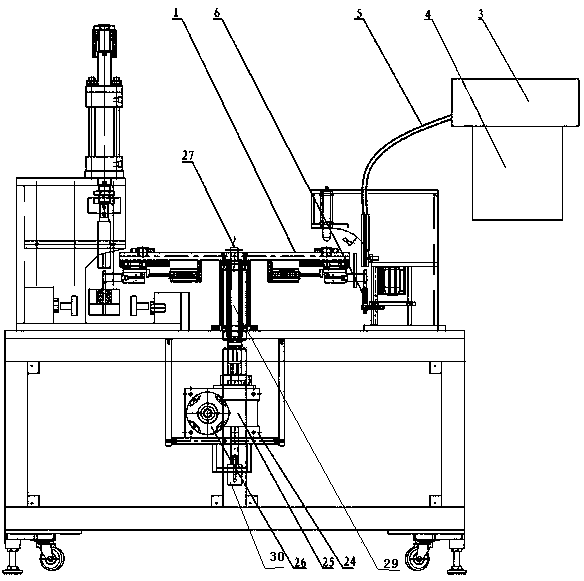

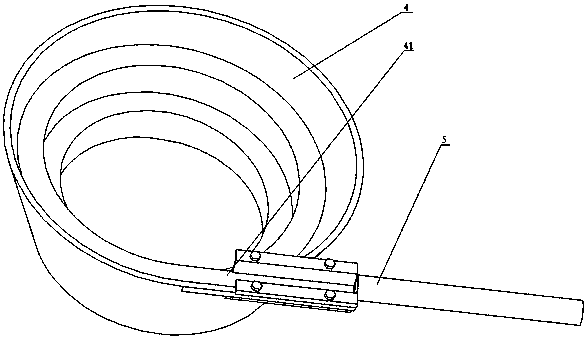

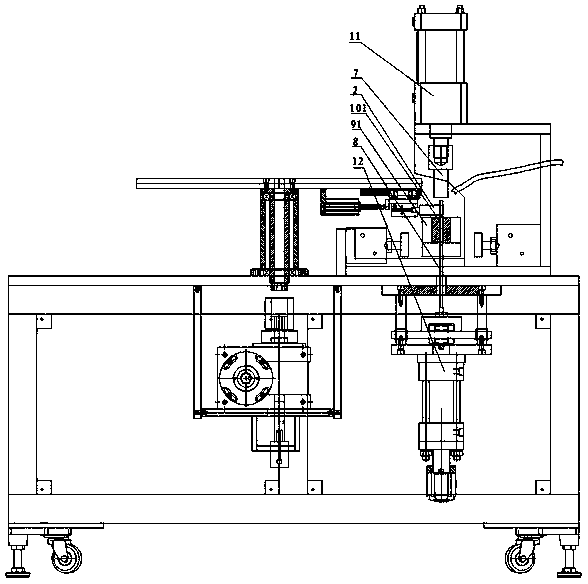

Full-automatic production equipment for compressor copper pipes

ActiveCN103801937AReduce processing timeFully automaticOther manufacturing equipments/toolsMetal working apparatusPipe fittingEngineering

The invention relates to full-automatic production equipment for compressor copper pipes, and belongs to the technical field of machining devices for compressor parts. The full-automatic production equipment for the compressor copper pipes comprises a feeding station, a flaring station, a connector binding station, a discharging station and a turntable, wherein the feeding station, the flaring station, the connector binding station and the discharging station are arranged on the side edge of the turntable in sequence, and a mechanical arm is arranged on the bottom of the turntable and is used for moving a pipe fitting to be machined from a previous station to a next station. After the pipe fitting enters through the feeding station, the pipe fitting is moved to the flaring station by the mechanical arm, flaring machining is carried out on the pipe fitting to be machined at the flaring station, the mechanical arm moves the flared pipe fitting to the connector binding station to carry out connector binding machining, then the mechanical arm moves the flared and connector bound pipe fitting to the discharging station, and thus a finished product is obtained. Through the adoption of the production equipment, full-automatic consecutive production of the feeding, the flaring, the connector binding and the discharging of the compressor copper pipes can be achieved.

Owner:绍兴汉立工业自动化科技有限公司

Display processing method and device and terminal

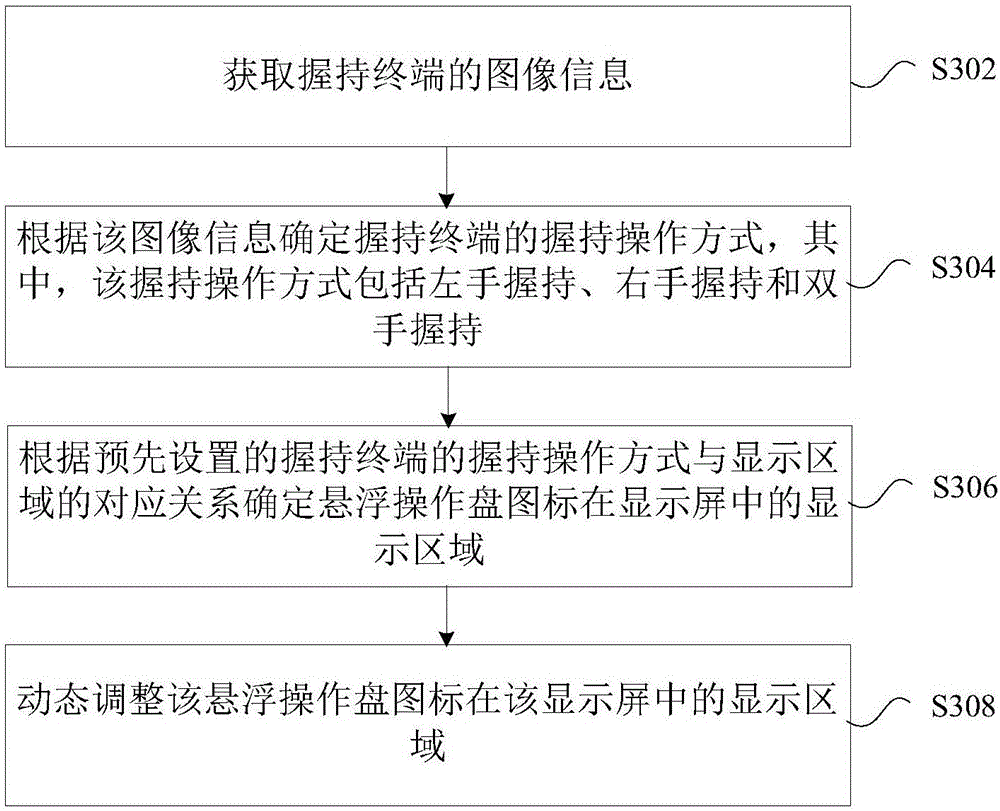

InactiveCN106648419ASolve the inconvenience of operationImprove experienceInput/output processes for data processingOperation modeComputer terminal

The invention discloses a display processing method. The display processing method includes the steps that image information of a holding terminal is obtained; the holding operation mode of the holding terminal is determined according to the image information, wherein the holding operation mode includes left hand holding, right hand holding and double-hand holding; a display area of a floating operating disc icon in a display screen is determined according to the preset corresponding relationship between the holding operation mode of the holding terminal and the display area, and the display area of the floating operating disc icon in the display screen is dynamically adjusted. The invention further discloses a display processing device and the terminal. The problem that in related technologies, displaying of the floating operation disc is not intelligent enough, so that user operation is inconvenient is solved; the display area of a floating operation disc is determined according to the holding mode of a user, so that the floating operating disc is displayed in the range the user can reach, and user experiences are improved.

Owner:NUBIA TECHNOLOGY CO LTD

Method and device for controlling play of multimedia data

ActiveCN103226960ARealize precision adjustmentRealize precise adjustmentRecord information storageRecording signal processingProgress barMultimedia

The invention discloses a method and device for controlling the play of multimedia data, and belongs to the field of communication technology. The method comprises the following steps: intercepting a playing interface of multimedia data when a terminal plays the multimedia data; obtaining a preset adjustment amount of the playing progress of the multimedia data according to a first preset gesture operation when the first preset gesture operation on an optional position of the playing interface of the multimedia data is intercepted; and adjusting the current playing progress of the multimedia data according to the preset adjustment amount. According to the invention, the preset adjustment amount of the playing progress of the multimedia data can be obtained through intercepting the gesture operation preset on the playing interface of multimedia data; the control of the playing progress of the multimedia data is not needed to be performed through dragging a playing progress bar of the multimedia data; the problem that the operation of controlling the playing progress of the multimedia data through the playing progress bar is inconvenient can be solved; and the precise adjustment of the playing progress can be realized.

Owner:XIAOMI INC

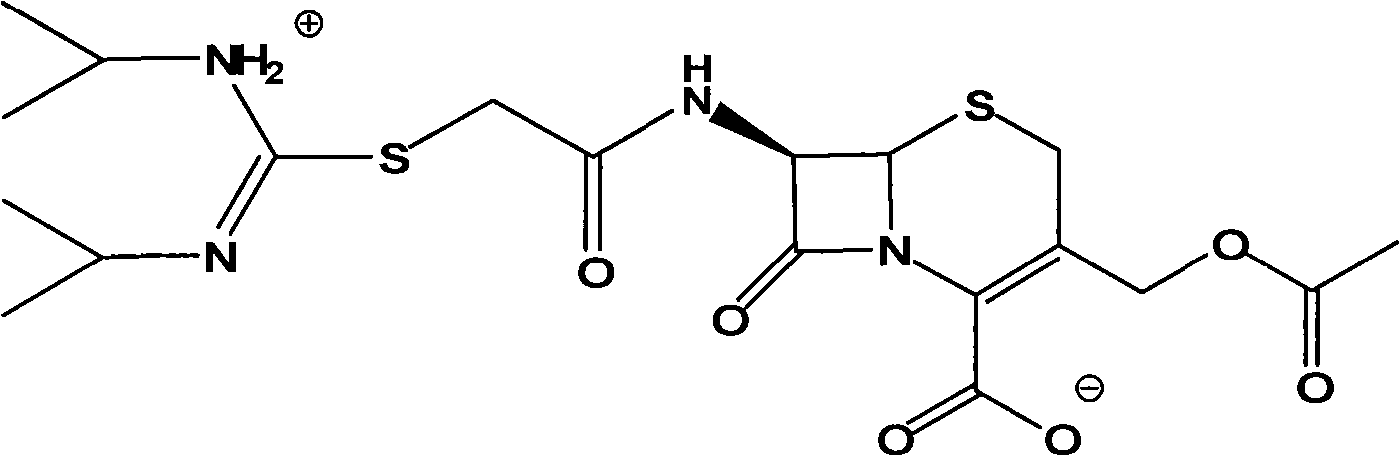

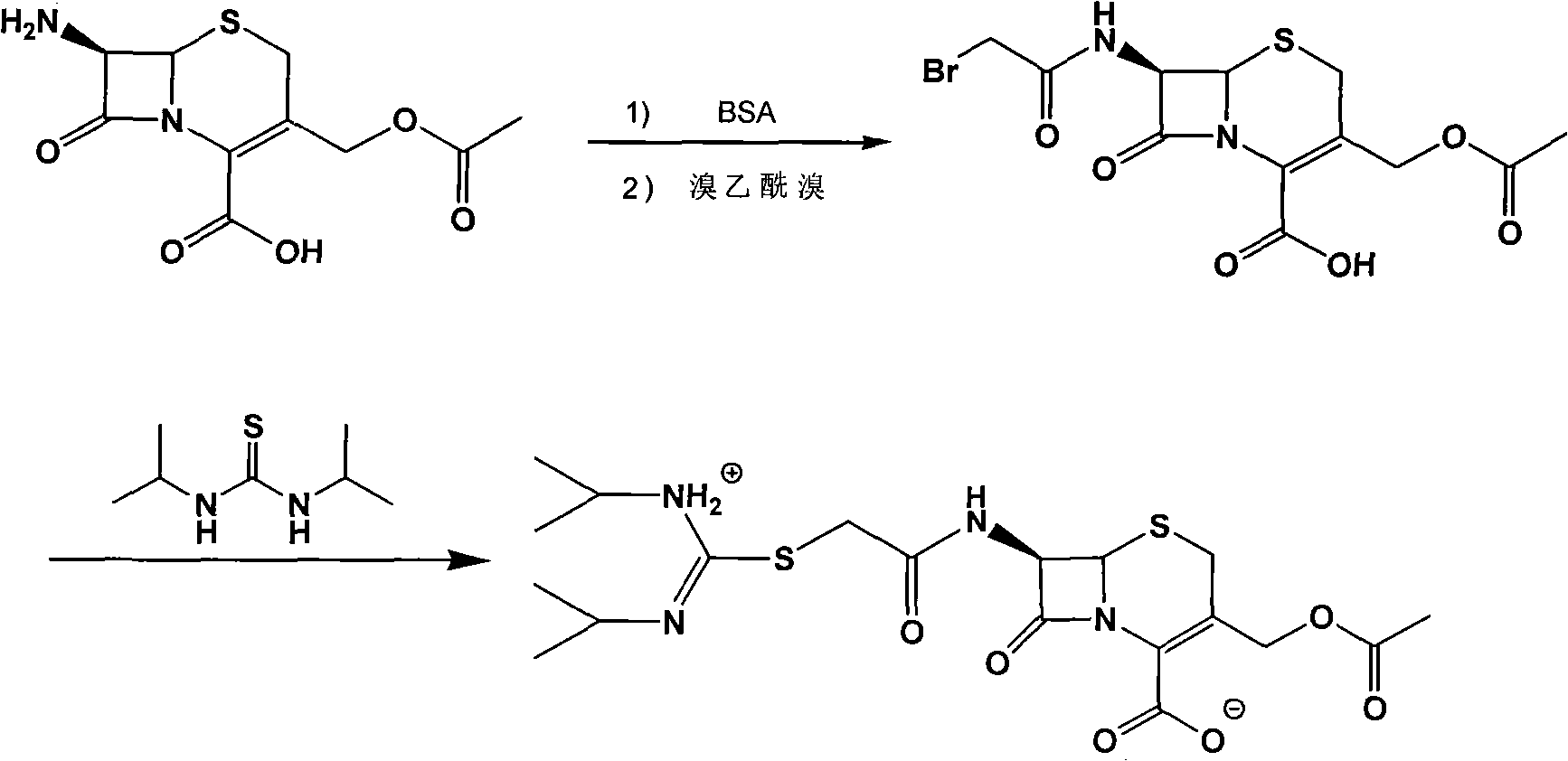

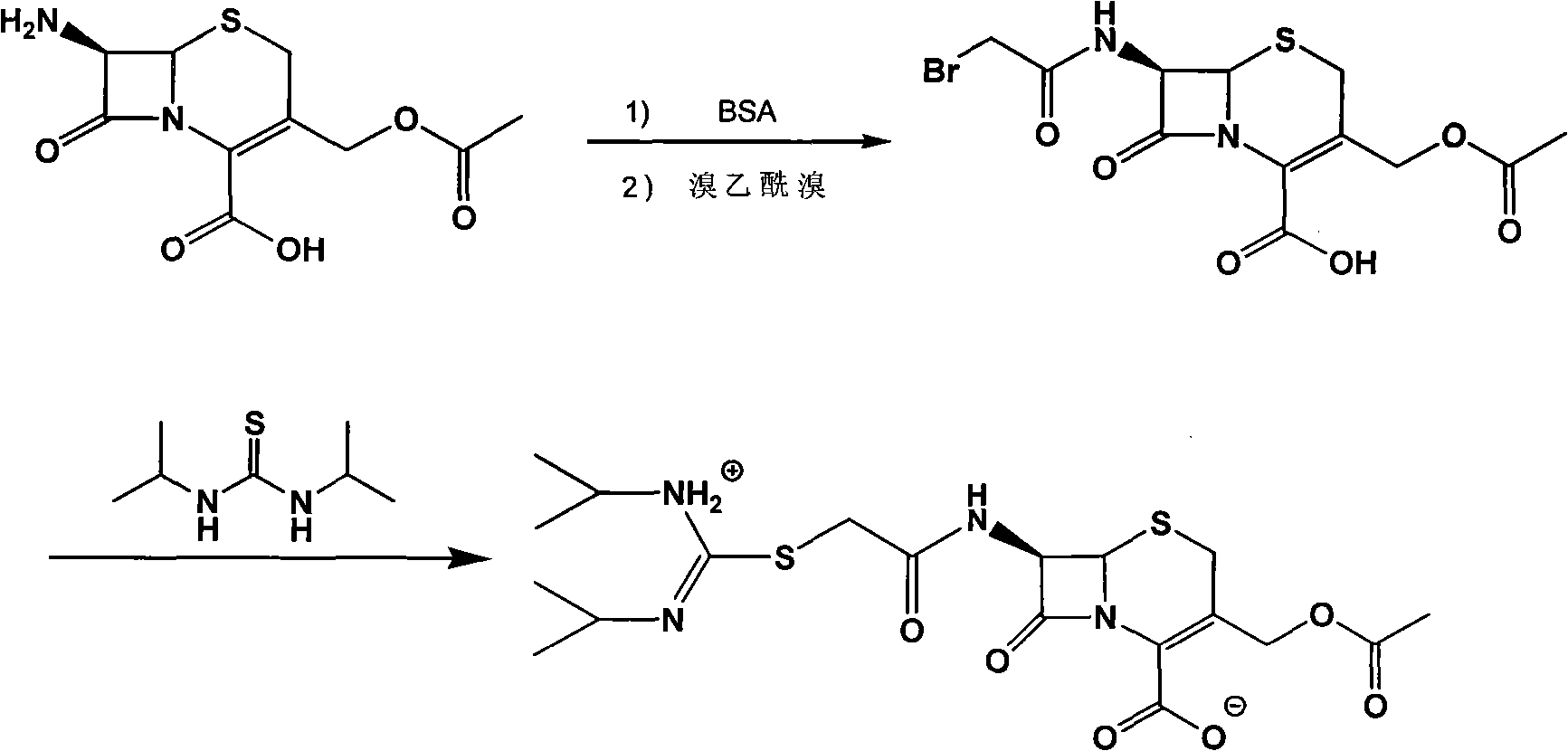

Preparation method of cefathiamidine

The invention relates to a preparation method of cefathiamidine, which comprises the following steps: (1) preparing cefathiamidine acid, performing silanization of 7-AC by BSA at room temperature, reacting with bromoacetyl bromide at zero DEG C, processing and separating out solid, filtering and drying to obtain high-purity cefathiamidine acid; (2) adding alkaline reagent to the cefathiamidine acid, reacting with N, N'-diisopropyl thiourea, adding slightly soluble solvent and separating out coarse cefathiamidine; and (3) dissolving the coarse cefathiamidine in a proper solvent, regulating the pH value of the solution to be between 4 and 5.5, adding the lightly soluble solvent until the solution is turbid, controlling the stirring speed, continuing slowly dripping the slightly soluble solvent, separating out the product, separating and drying to obtain the cefathiamidine. The method has the advantages of few steps, simple process, high purity and easy implementation.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

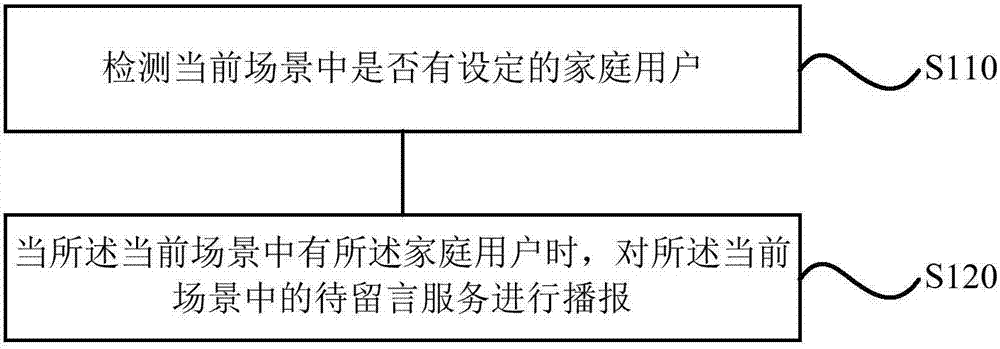

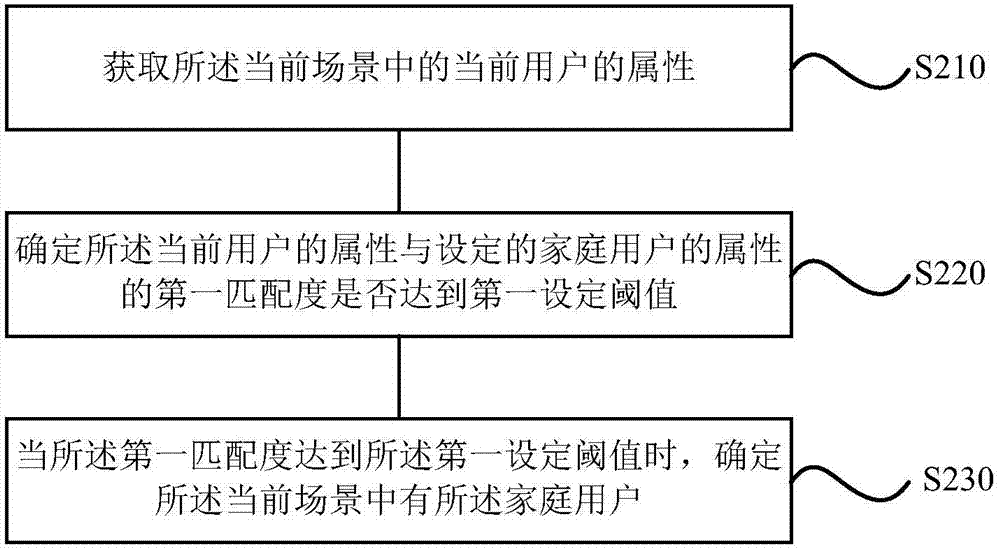

Message leaving method, message leaving device, storage equipment, mobile terminal and electric appliance

InactiveCN107131610AImprove experienceEasy to operateSpace heating and ventilation safety systemsLighting and heating apparatusInformation transmissionElectrical equipment

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Lower stop for closed-end zipper and closed-end zipper using same

ActiveCN102106630AEasy to operateSolve the inconvenience of operationSlide fastenersEngineeringMechanical engineering

The invention provides a lower stop for closed-end zipper and a closed-end zipper using the lower stop, wherein the lower stop comprises a socket and a plug; the plug comprises an insertion part and a pivot part; the socket comprises a clamping part and a socket body; the pivot part is pivotally connected to the socket body; an elastic element is further provided; the elastic element is used for applying an elastic force to the plug in a direction along which the lower stop can be closed. The lower stop and the closed-end zipper using the lower stop are rotatable and convenient for zipping.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

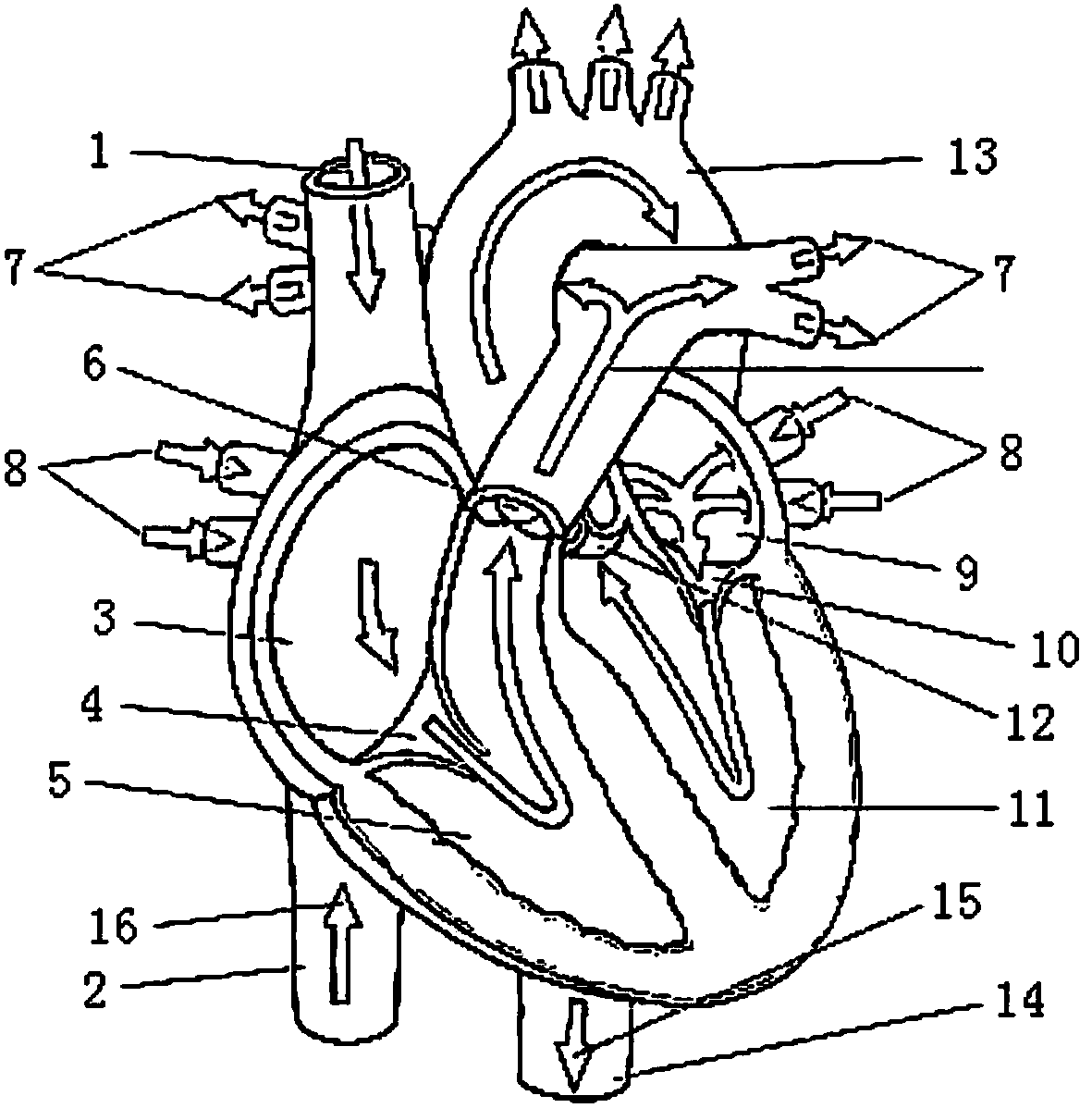

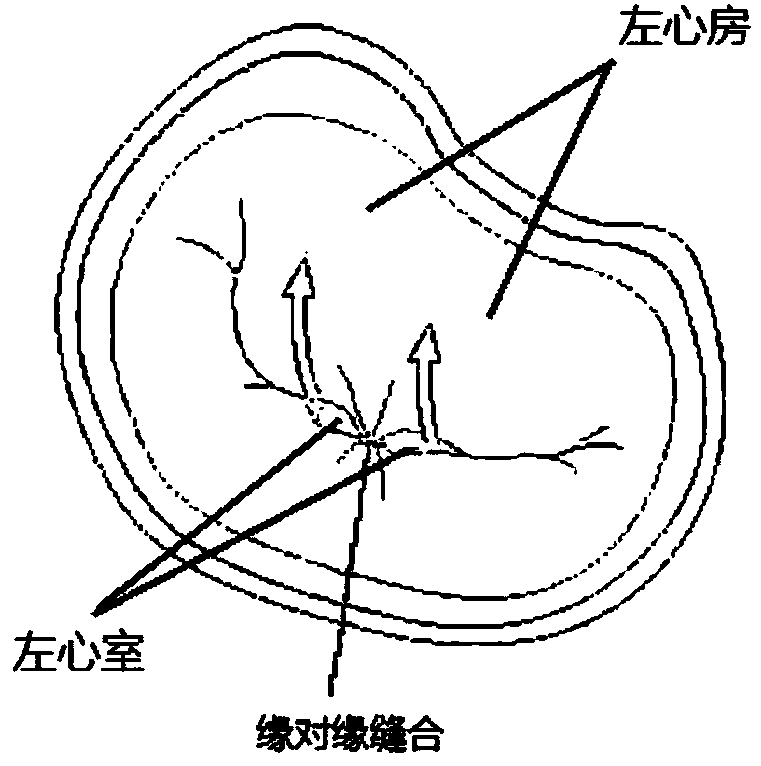

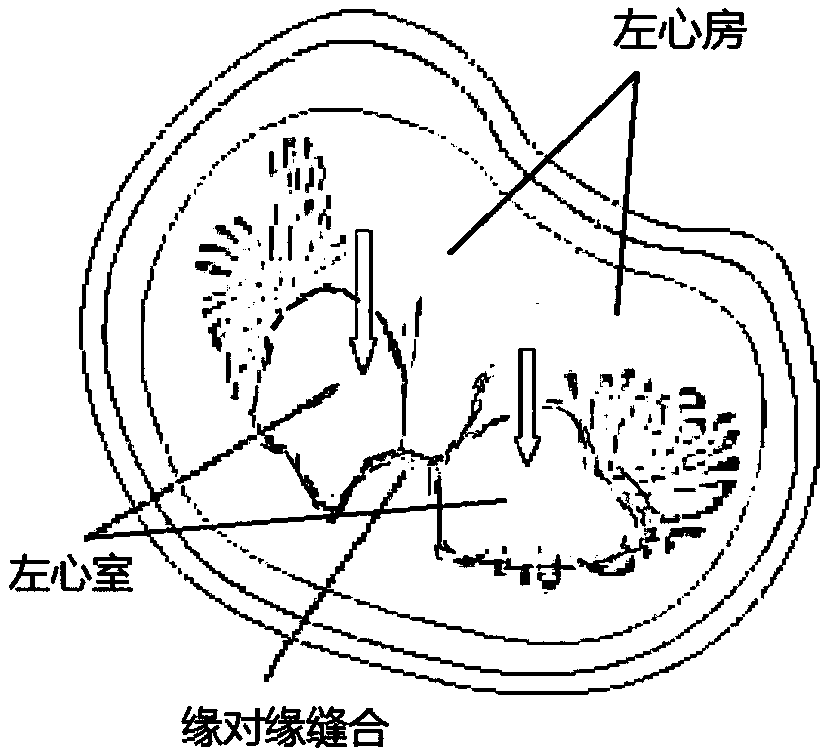

Valve clamping device

The invention discloses a valve clamping device. The valve clamping device comprises a first clamping component, a second clamping component and a fixing component. The fixing component is used for fixing the first clamping component and the second clamping component. The first clamping component comprises at least two first clamping arms. The second clamping component comprises a corresponding number of second clamping arms. A pair of clamps can be formed by each first clamping arm and the corresponding second clamping arm. The valve clamping device has the advantages that the valve clampingdevice can employ the smooth-transition top design, the high-clamping-stability clamping tooth design and the 'one-stripe-for-dualpurpose' fixing ring deign, so that damage to valves during movement of the clamping device is reduced, users capture the valves conveniently, and clamping performance is improved while damage to the valves is reduced; the overall structure of the clamping device has high machinability, and production and manufacture of factories are facilitated.

Owner:SHANGHAI HANYU MEDICAL TECH CO LTD

Authentication method and authentication device for user request

InactiveCN104980925ASolve the inconvenience of operationEasy to operateTransmissionSecurity arrangementAuthentication serverApplication software

The invention discloses an authentication method and an authentication device for a user request. The authentication method for the user request comprises the following steps of receiving the user request; authenticating the user request according to authentication information stored in a target application program; when the user request passes the authentication, sending the user request to a server to obtain a response message which responds to the user request; when the user request does not pass the authentication, sending a first refresh request to the server to obtain a second access token; and when the second access token sent by the server is received, sending the first access token included in the user request to the server after replacing to a second access token in order to obtain a response message which responds to the user request. According to the authentication method and the authentication device, the problem of inconvenience for user operation due to a more complicated way for authenticating the user request in the prior art is solved, so that the effects of simplifying an authentication process for the user request and improving the authentication efficiency are achieved.

Owner:走遍世界(北京)信息技术有限公司

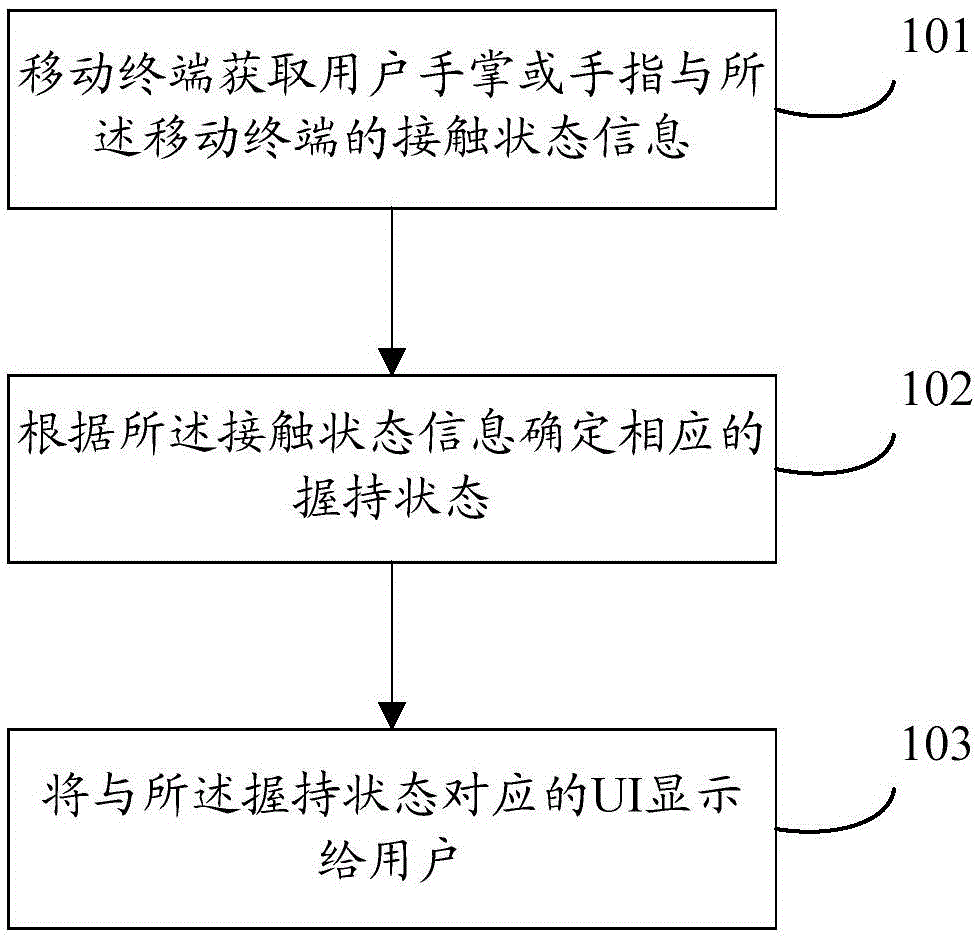

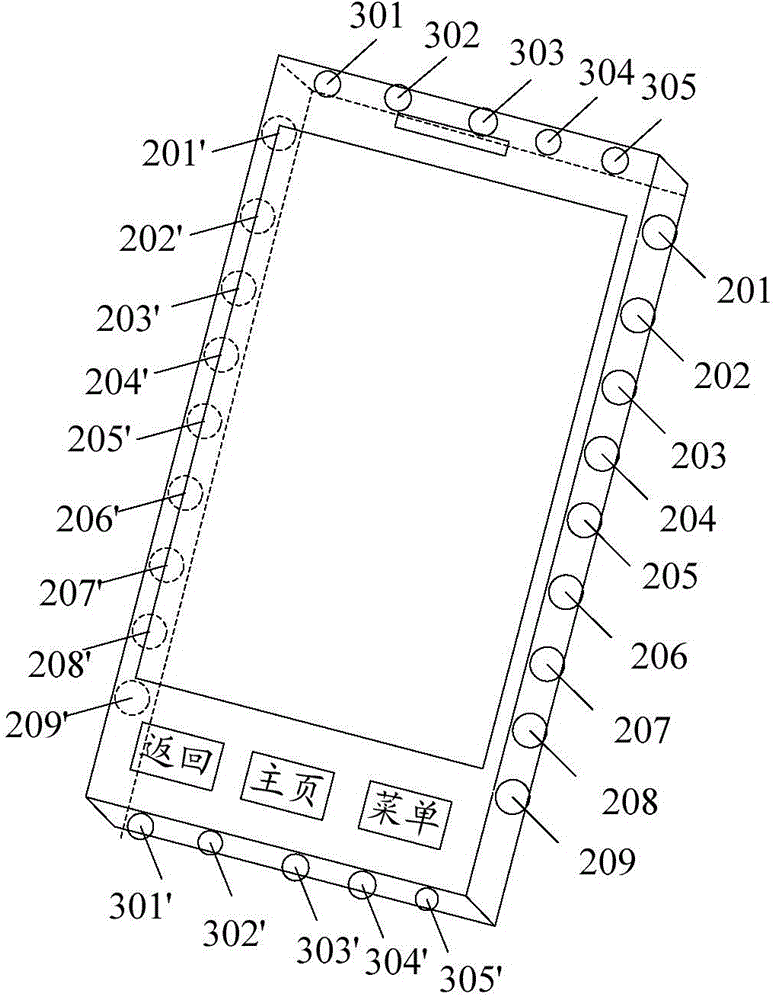

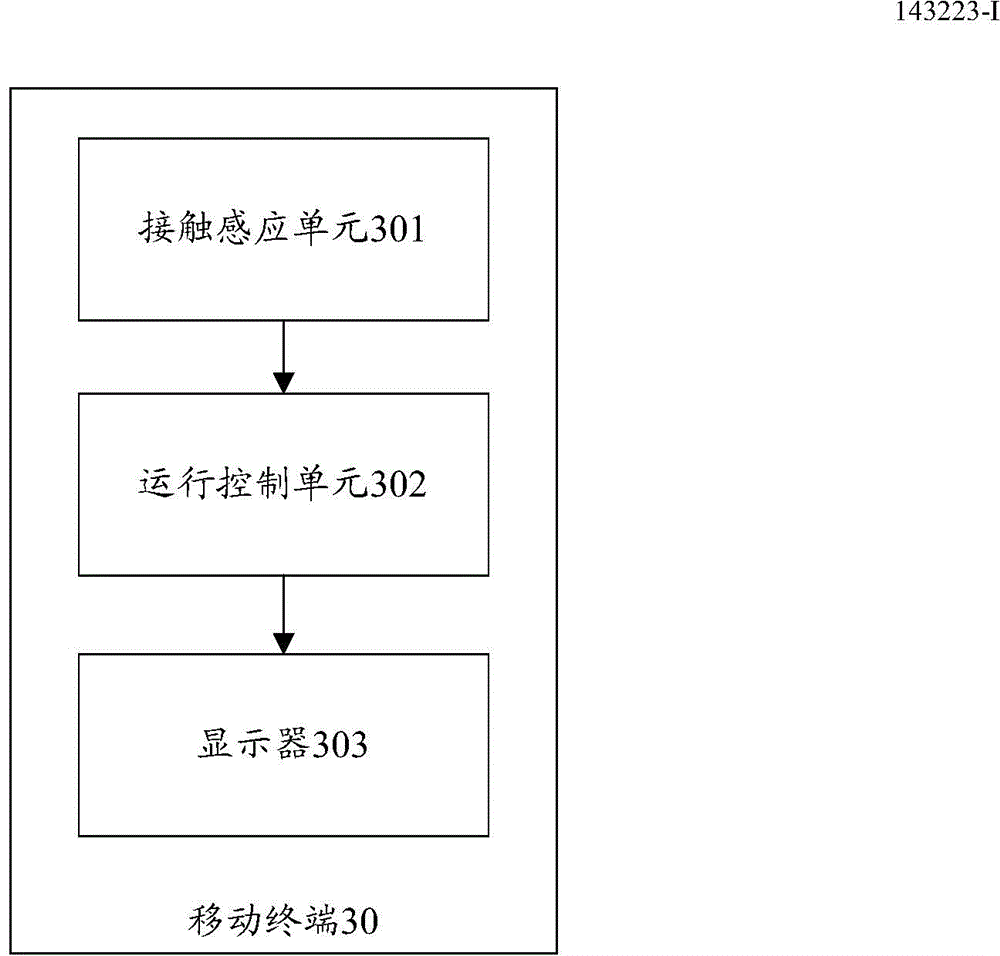

Mobile terminal capable of automatically identifying holding by left hand or right hand, and implementation method thereof

InactiveCN105468269AQuick judgmentImprove experienceInput/output processes for data processingUser interfaceEmbedded system

The invention discloses an implementation method of a mobile terminal capable of automatically identifying holding by a left hand or a right hand. The method comprises the following steps: a mobile terminal acquires contact state information between a user's palm or user's fingers and the mobile terminal; determining a corresponding holding state according to the contact state information; and displaying a user interface (UI) corresponding to the holding state to a user. The invention further discloses the mobile terminal capable of automatically identifying holding by the left hand or the right hand.

Owner:SANECHIPS TECH CO LTD

Production technology of 7-series aluminum alloy tubular products

ActiveCN109554561AReduce air cooling speedLower the deoxidation temperatureManufacturing technologyDeoxygenation

The invention belongs to the technical field of aluminum alloy production and manufacture, and relates to a production technology of 7-series aluminum alloy tubular products. Aluminum alloy ingot casting is prepared from the following components in percentage by mass: 4.0-7.0% of Zn, 0.6-1.5% of Mg, 0.1-0.5% of Cu, less than or equal to 0.1-0.5% of Cr, less than or equal to 0.15-0.25% of Zr, lessthan or equal to 0.1% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurities and the balance of Al. Sulfate and graphite are adopted to be added into molten aluminum liquid according to the mass fraction ratio of 1 to 9-3 to7 in the process of aluminum liquid refining, magnesium oxide and aluminum oxide in the aluminum liquid are removed, the deoxygenation temperature is 720+ / -5 DEG C, therefore, the air cooling speed of aluminum alloy profiles after extruded forming is 100 DEG C / min, and the problems that in the prior art, the production technology of 7-series aluminum alloy with no Mn element added has excessive cooling speed and is not easy to control are solved.

Owner:CHINA ZHONGWANG

Vehicle-mounted navigation system, support used on same and control method of same

InactiveCN102114811ASolve the problem of exposed and unsightly wiring harnessEasy to useInstruments for road network navigationVehicle componentsEngineeringNavigation system

The invention relates to a vehicle-mounted navigation system and a control method of the system. A vehicle-mounted navigator comprises an external portable navigator, a support and a whole vehicle entertainment system, wherein the portable navigator can be detachably fixed on the support, and the support is directly and fixedly integrated on a center control platform in a vehicle, so that the portable navigator can transmit data with the whole vehicle entertainment system by the support; and the control method includes the steps of entering a navigation mode, outputting sound and video, sending out an command, receiving the command and quitting from the navigation mode. The vehicle-mounted navigation system reduces the allocation threshold, increases the selection range of users to the portable navigator, and accelerates the popularization of the application of the vehicle-mounted navigation system.

Owner:SAIC GENERAL MOTORS +1

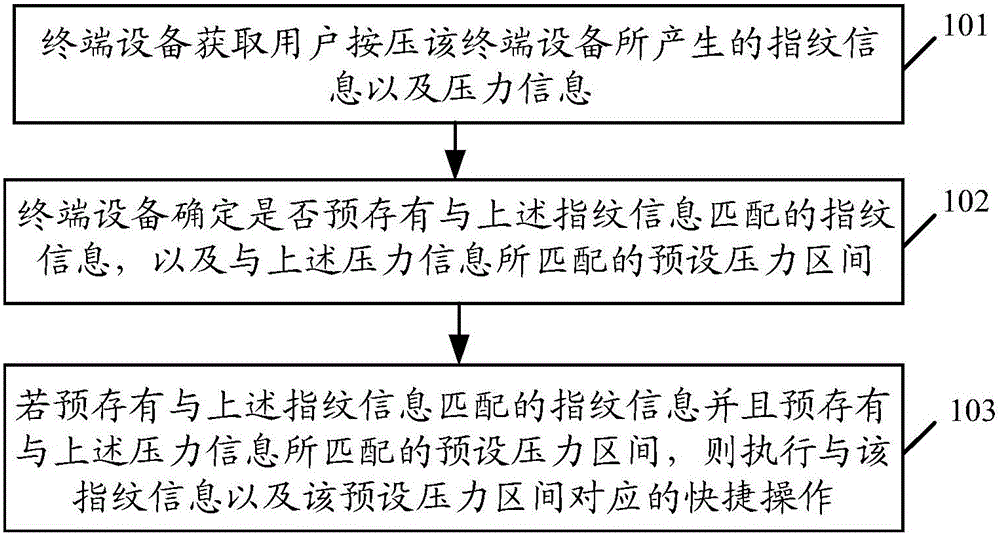

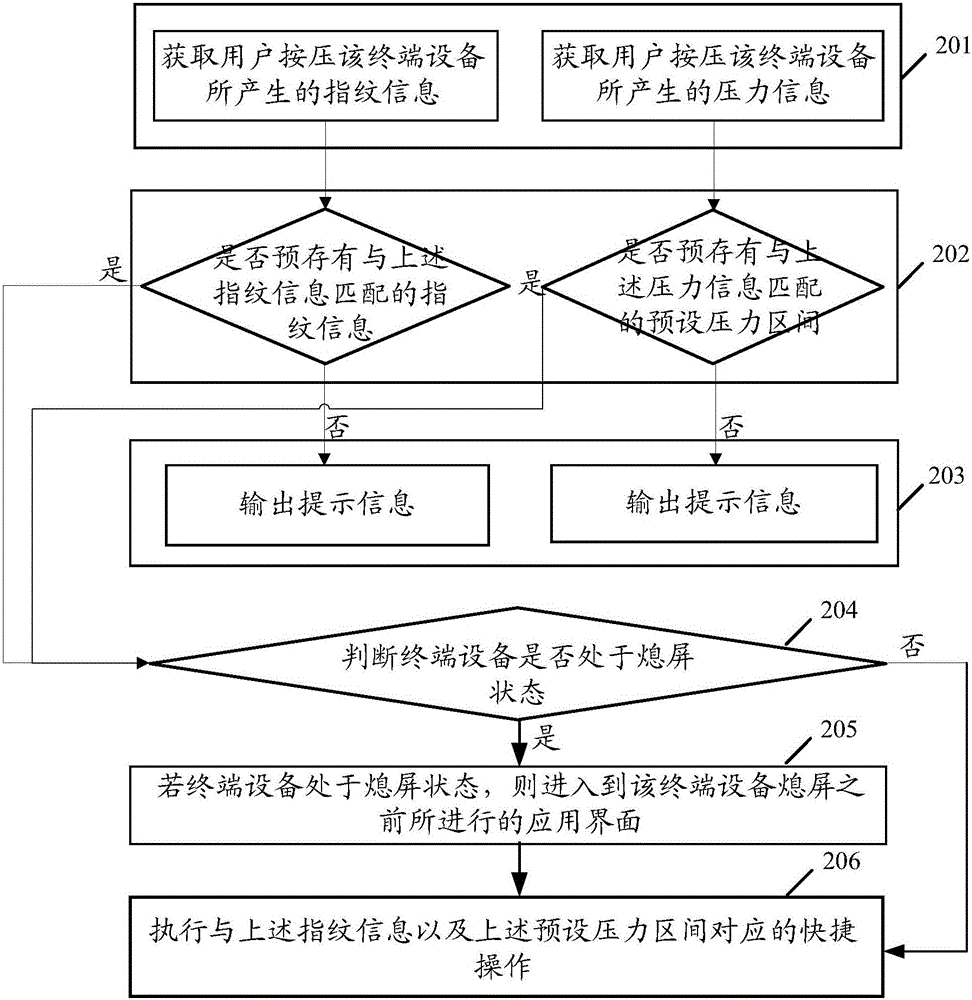

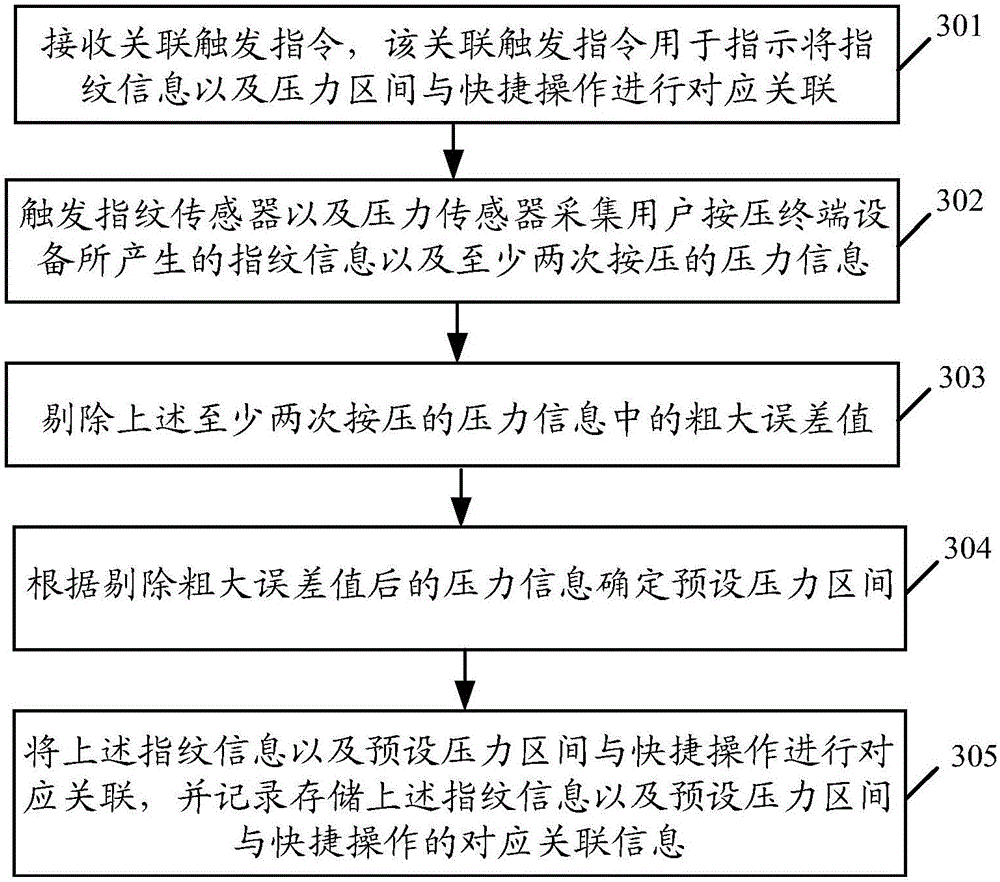

Shortcut operation implementation method and terminal equipment

InactiveCN105843540AImprove interaction efficiencySolve the inconvenience of operationCharacter and pattern recognitionInput/output processes for data processingDirect touchKey pressing

Embodiments of the invention disclose a shortcut operation implementation method, and terminal equipment, and are applied to the technical field of mobile communications. The method disclosed by the embodiments of the invention comprises that the terminal equipment obtains fingerprint information and pressure information generated by pressing the terminal equipment by a user; the terminal equipment determines whether there is pre-stored fingerprint information matching with the fingerprint information, and whether there is a pre-stored preset pressure range matching with the pressure information; and if there is the pre-stored fingerprint information matching with the fingerprint information, and there is the pre-stored preset pressure range matching with the pressure information, a shortcut operation corresponding to the fingerprint information and the preset pressure range is executed. According to the method and terminal equipment disclosed by the embodiments of the invention, operating inconvenience caused by a direct touch on a shortcut key by a user can be avoided, thereby improving information interaction efficiency.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

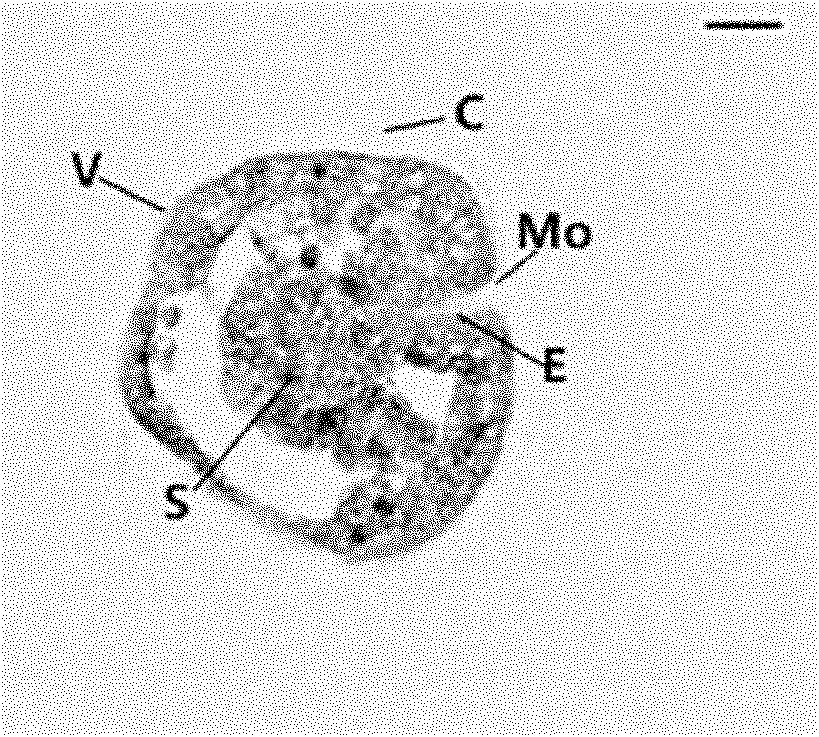

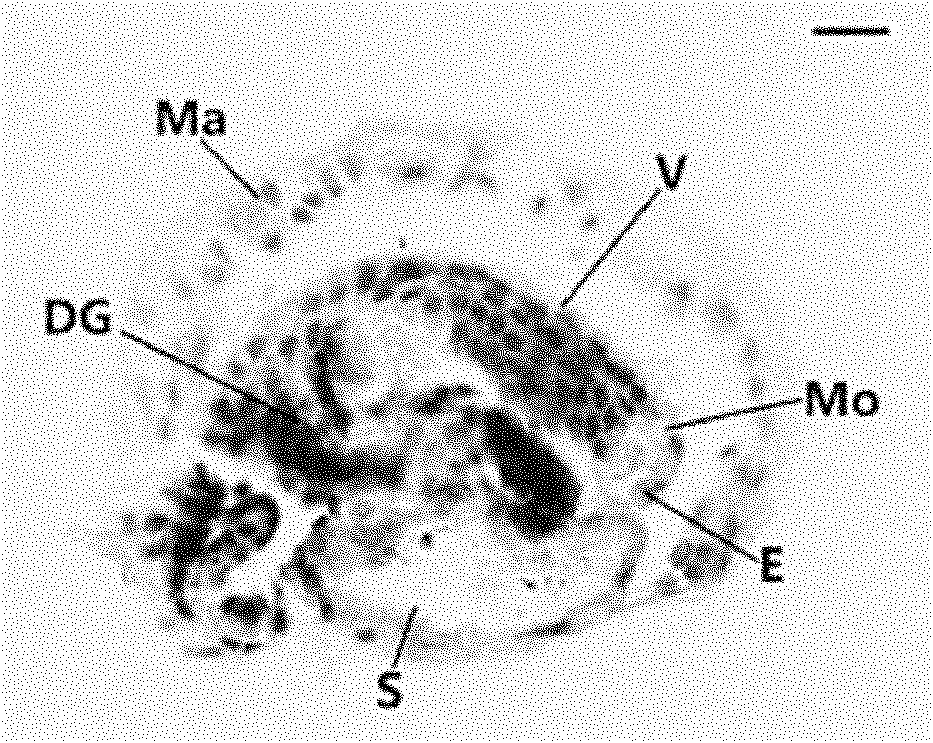

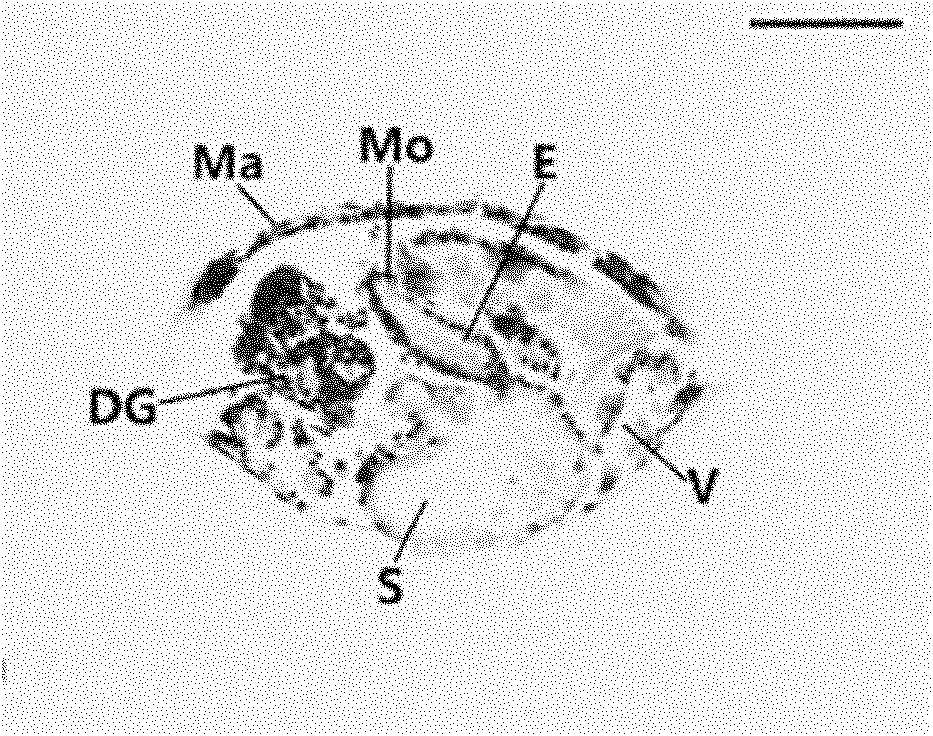

Paraffin sectioning method for ocean shellfish D-shaped larva

InactiveCN102147337ASimple methodOptimize operating timeWithdrawing sample devicesPreparing sample for investigationWaxAlcohol

The invention relates to a paraffin sectioning method for an ocean shellfish D-shaped larva, which comprises the following steps: (1) Boulin solution is added to a container having an ocean shellfish D-shaped larva sample, and then alcohol with mass percentage concentration of 70% is added so as to obtain a fixed ocean shellfish D-shaped larva; (2) the fixed ocean shellfish D-shaped larva is wrapped up and is placed in a sample embedding box, and the sample embedding box is placed in a dehydrator or a staining jar; and then the steps of dehydration, transparency and wax impregnation are carried out; (3) embedding and sample location are carried out; (4) slicing and drying are carried out; and (5) a hematoxylin-eosin counterstaining method is adopted for dying. The paraffin sectioning method is simple and practical, has short processing time and transitional steps, leads all tissues of the larva to be gradually and completely immersed by reagent, well keeps the original state and structure of the tissues of the larva and provides a practical and effective technical means for research on early stage embryos and larva development of shellfishes.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

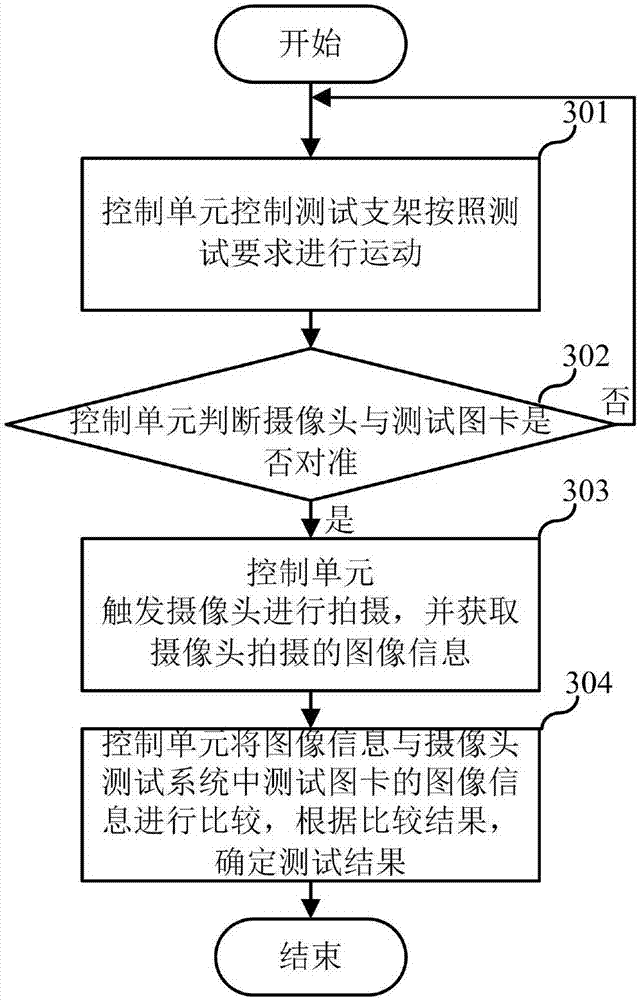

Camera testing system and method, terminal and computer-readable storage medium

InactiveCN108012142ASimple structureEasy to adjustTelevision system detailsColor television detailsComputer hardwareImage resolution

The embodiment of the invention, which relates to the technical field of camera testing, discloses a camera testing system and method, a terminal and a computer-readable storage medium. The testing system is composed of a control unit, a test light box, a test stand arranged in the test light box, and a test picture card arranged in the test light box. The test stand is used for fixing a to-be-tested terminal and being connected to a camera of the to-be-tested terminal. The control unit in communication connection with the test stand and the camera is used for controlling the test stand to move freely in the test light box, triggering the camera to carry out shooting after the test stand reaches a designated position, and acquiring image information shot by the camera. With the camera testing system and method, the terminal and the computer-readable storage medium, while the need of testing the camera of the terminal is met, the testing requirements of the resolution, ambient light source types, and picture quality and the like are guaranteed and the testing costs are lowered and the economic and practical effects are good.

Owner:SHANGHAI YUDE TECH CO LTD

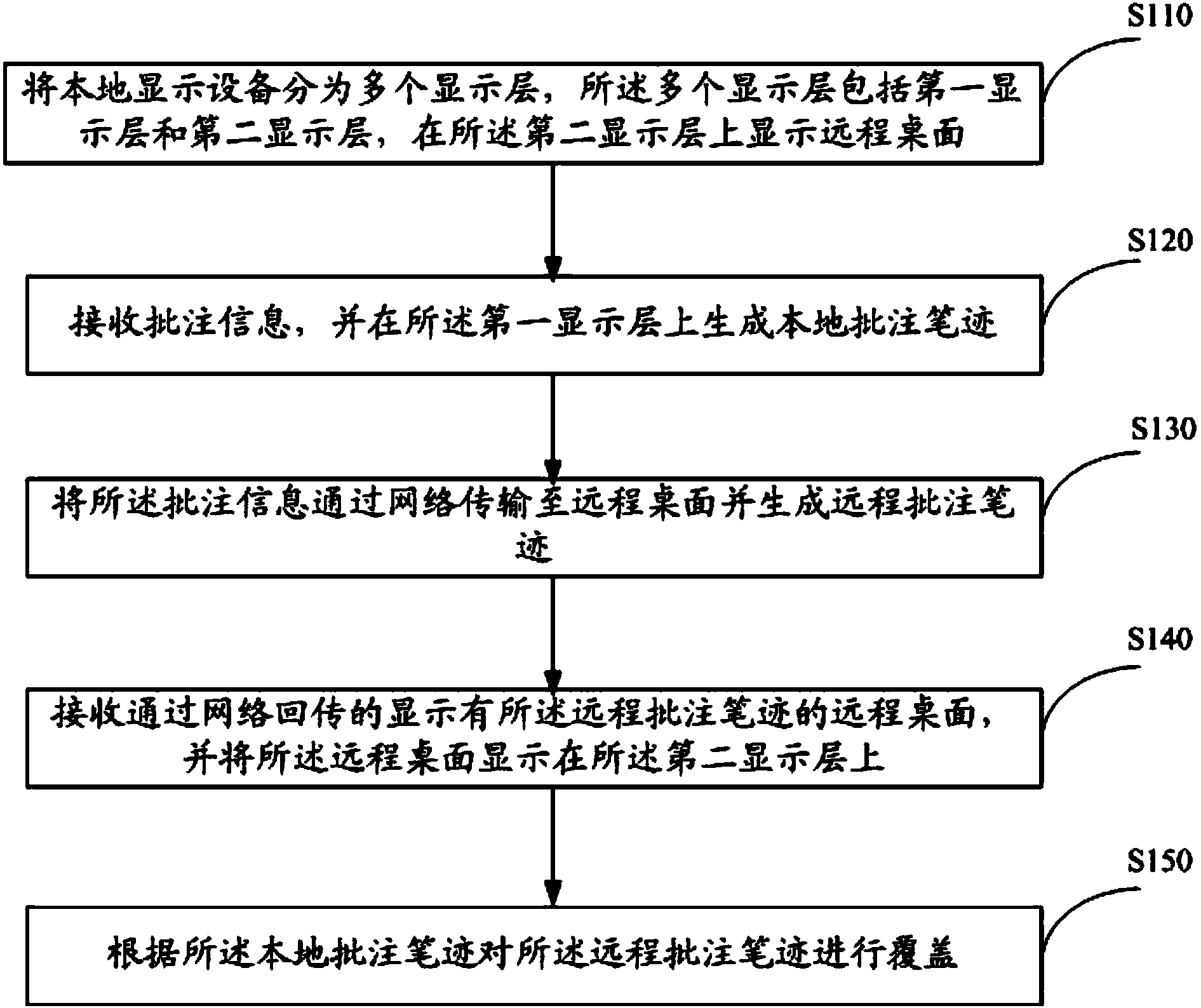

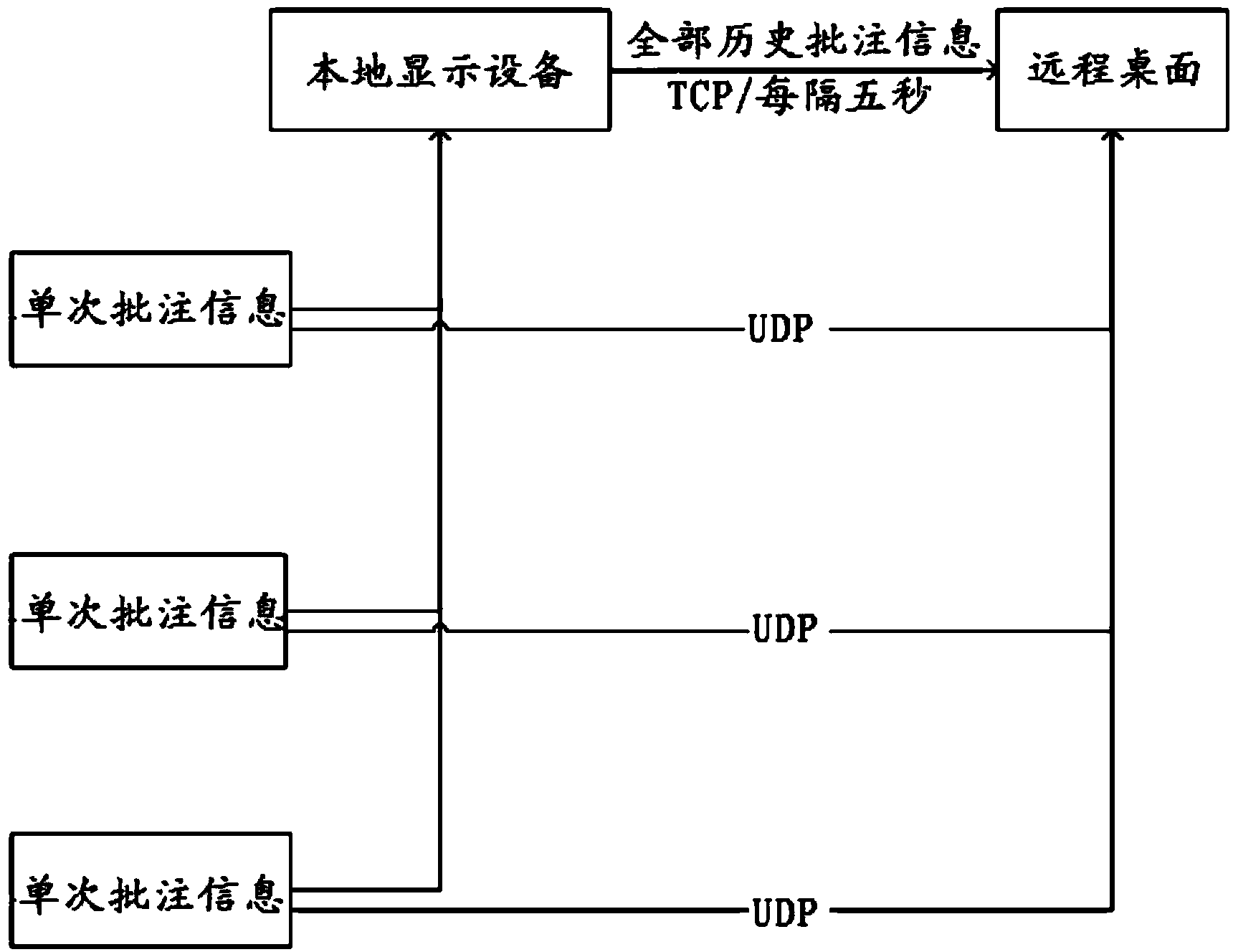

Long-distance annotating method and system

ActiveCN103984512ASolve the inconvenience of operationDoes not affect renderingTransmissionDigital output to display deviceRemote desktopHandwriting

The invention provides a long-distance annotating method and system. The method comprises the steps that local displaying equipment is divided into a plurality of displaying layers which comprise a first displaying layer and a second displaying layer, a long-distance desktop is displayed on the second displaying layer, annotating information is received, local annotating handwriting is generated on the first displaying layer, the annotating information is transmitted to the long-distance desktop through network, long-distance annotating handwriting is generated, the long-distance desktop which is transmitted back by the network and displays the long-distance annotating handwriting is received, the long-distance desktop is displayed on the second displaying layer, and the long-distance annotating handwriting is covered according to the local annotating handwriting. The local annotating handwriting is drawn on the local displaying equipment when a local end sends the annotating handwriting to the long-distance desktop and is instantly presented to a local user, and the problem of operating inconvenience caused by the transmitting back delaying of the long-distance annotating handwriting is solved.

Owner:GUANGZHOU SHIRUI ELECTRONICS

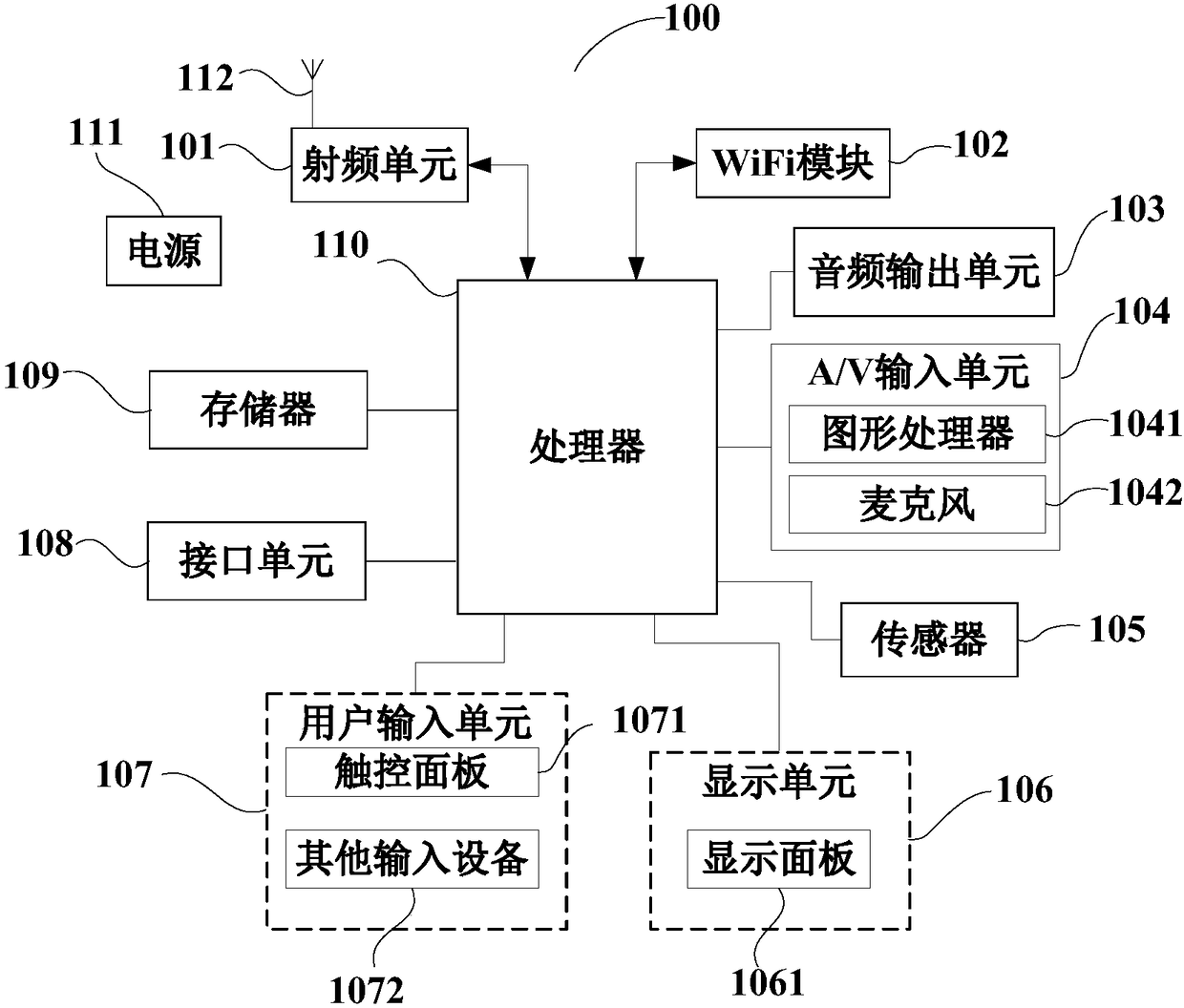

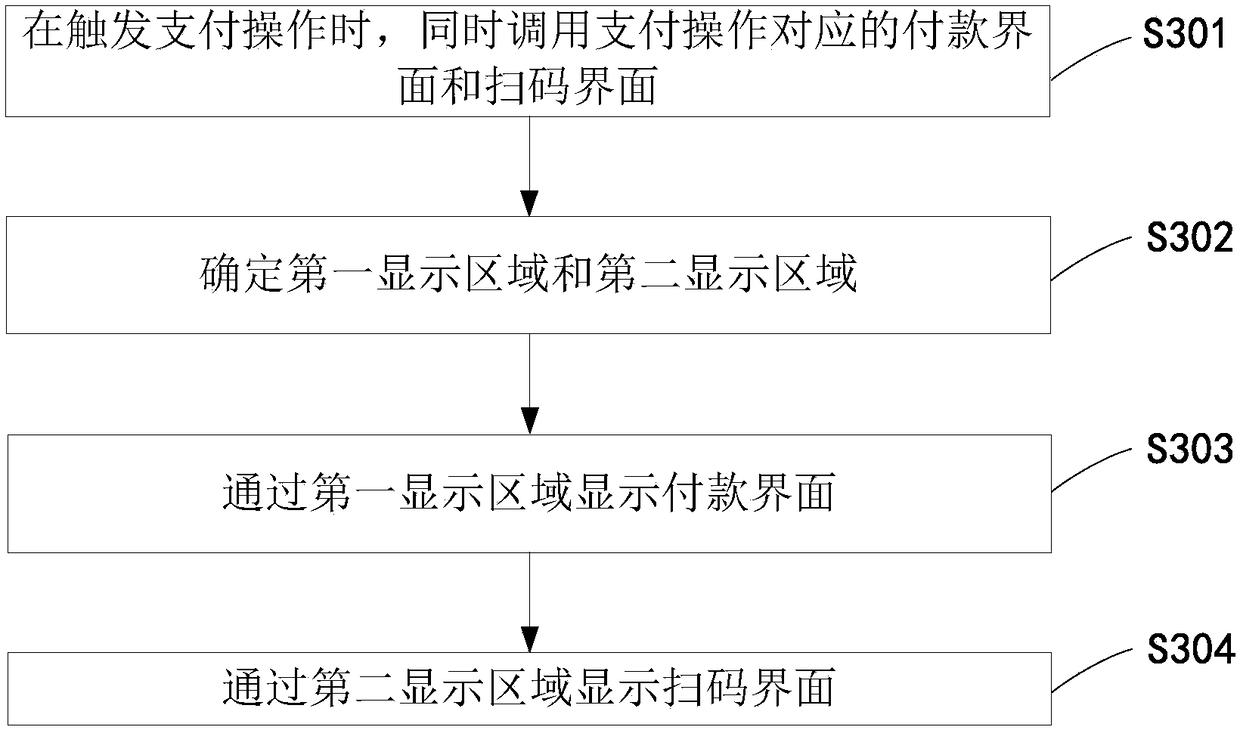

Payment display method, terminal and computer readable storage medium

InactiveCN108491240AImprove user experienceSolve the inconvenience of operationPayment architectureExecution for user interfacesMobile paymentEnd user

The invention provides a payment display method, a terminal and a computer readable storage medium. When the terminal triggers a payment operation, a payment interface and a code scanning interface corresponding to the payment operation are called and displayed at the same time, so that no matter which mobile payment manner is supported by merchants, terminal users can complete payment by directlyusing corresponding interfaces without inquiring or guessing payment manners, so that the problem of inconvenient operation caused by selecting payment manners by the terminal users in existing mobile payment technologies is solved. The invention furthermore provides the terminal and the computer readable storage medium. According to the payment display method, the terminal and the computer readable storage medium, the using experience of the users is strengthened.

Owner:NUBIA TECHNOLOGY CO LTD

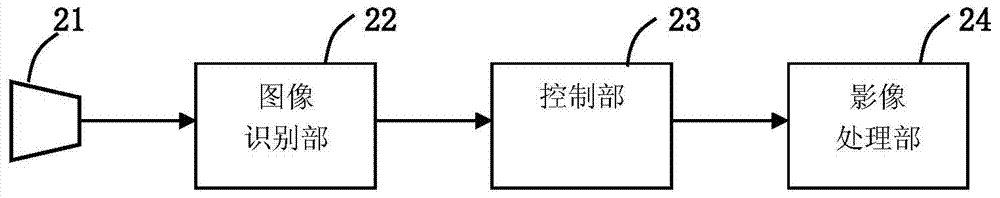

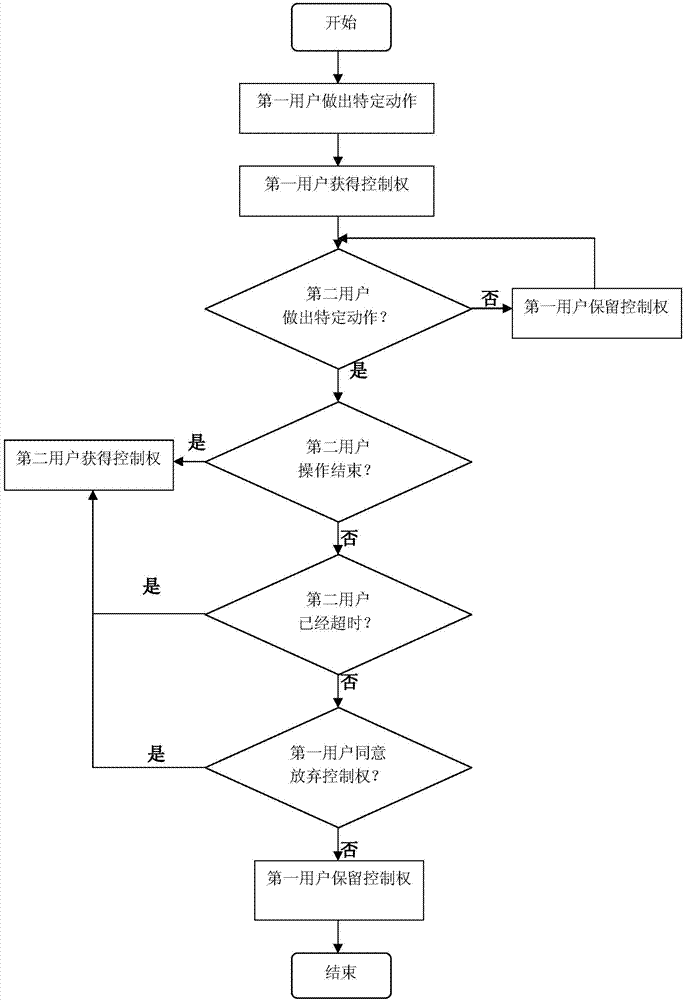

Gesture remote control system

InactiveCN104333793AImprove user experienceSolve the inconvenience of operationSelective content distributionInput/output processes for data processingImaging processingRemote control

The invention discloses a gesture remote control system, which can be applied to an electronic device. The gesture remote control system comprises a shooting part (21), an image recognition part (22), a control part (23) and an image processing part (24). When the image recognition part (22) detects a first user (2) to make a specific action, after the gesture remote control system starts a gesture remote control function, when a second user (5) is detected to make the specific action, the control part (23) judges whether remote control operation of the first user (2) is finished already, the first user (2) is queried according to the judging result whether to agree to abandon control right on the electronic equipment, and corresponding control right is transferred. Thus, transfer of control rights among different users can be realized in the process of remote control operation, the user waiting time and operation steps can be saved, and the use experience degree of the user is improved.

Owner:BAOJI UNIV OF ARTS & SCI

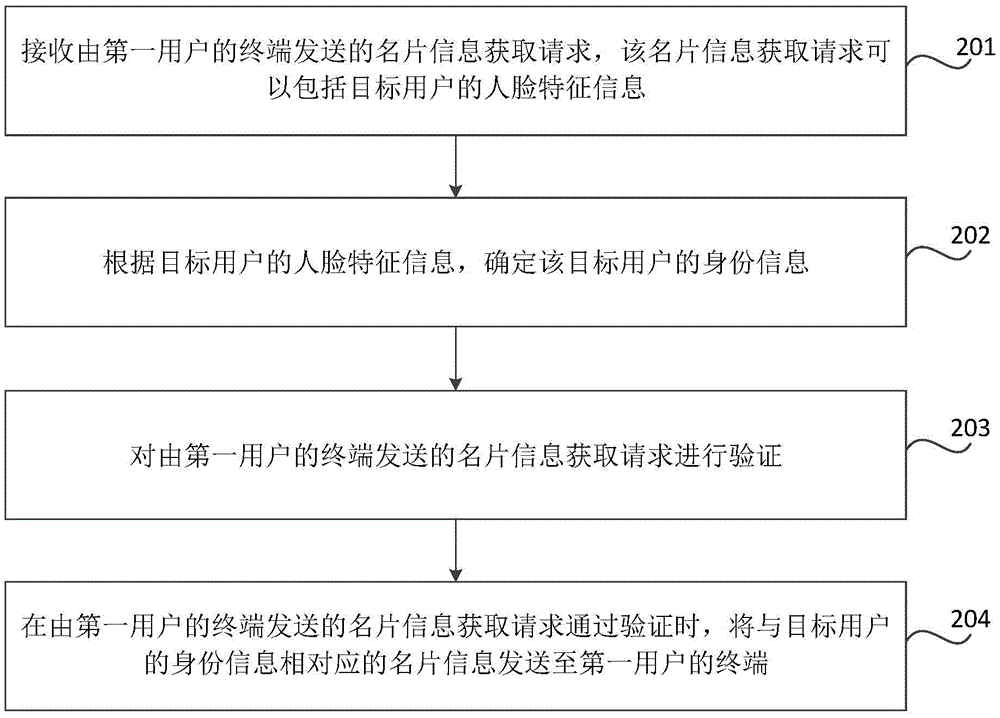

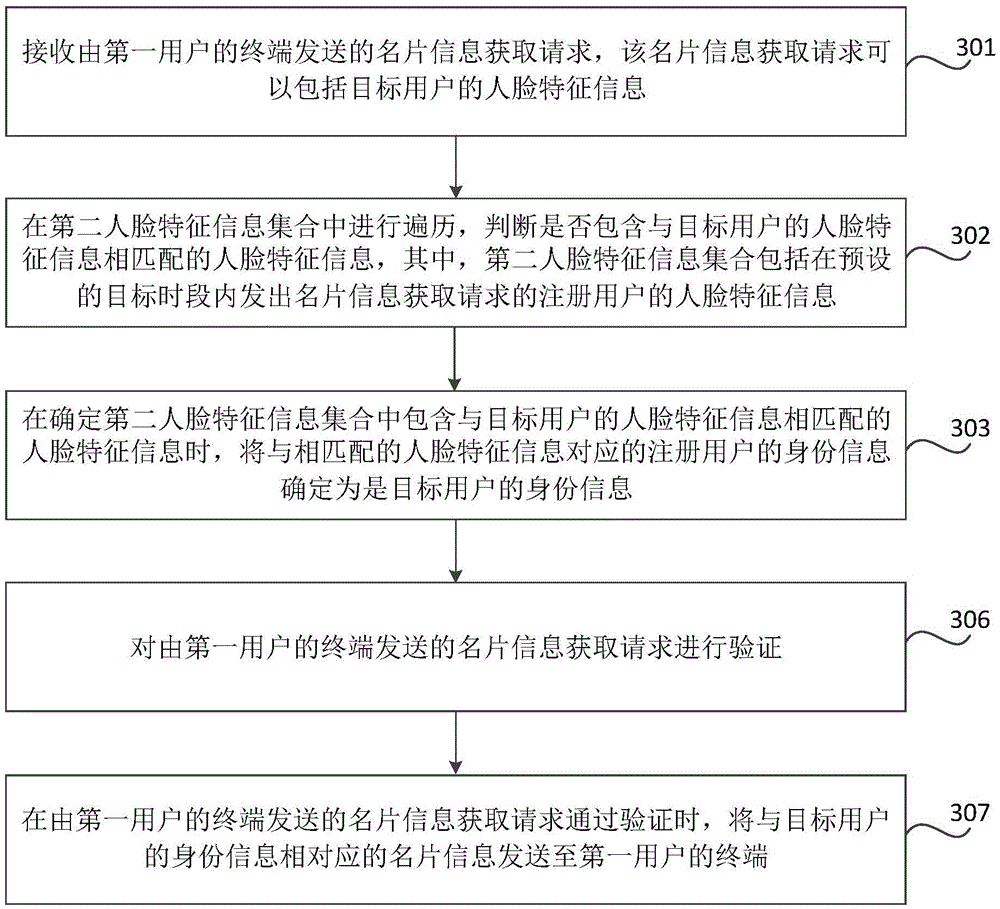

Method and device for acquiring calling card information

ActiveCN105468767ASolve the inconvenience of operationPromote exchangeWeb data indexingCharacter and pattern recognitionComputer hardwareServer-side

The invention relates to a method and a device for acquiring calling card information. The method applied to a server side comprises the steps of receiving a calling card information acquiring request sent by a terminal of a first user, wherein the calling card information acquiring request comprises facial feature information of a target user; determining the identity information of the target user according to the facial feature information of the target user; authenticating the calling card information acquiring request sent by the terminal of the first user; and sending the calling card information corresponding to the identity information of the target user to the terminal of the first user, when the calling card information acquiring request sent by the terminal of the first user is authenticated. Therefore, the problem of inconvenient operation due to the fact that the calling card information is obtained through manually inputting the calling card information by the user or scanning a two-dimension code can be solved, the effect of automatically obtaining the calling card information of the opposite side through the facial image of the same is achieved, regional restriction is avoided, and the users can conveniently exchange the calling card information even the two calling card exchange parties are far away from each other.

Owner:XIAOMI INC

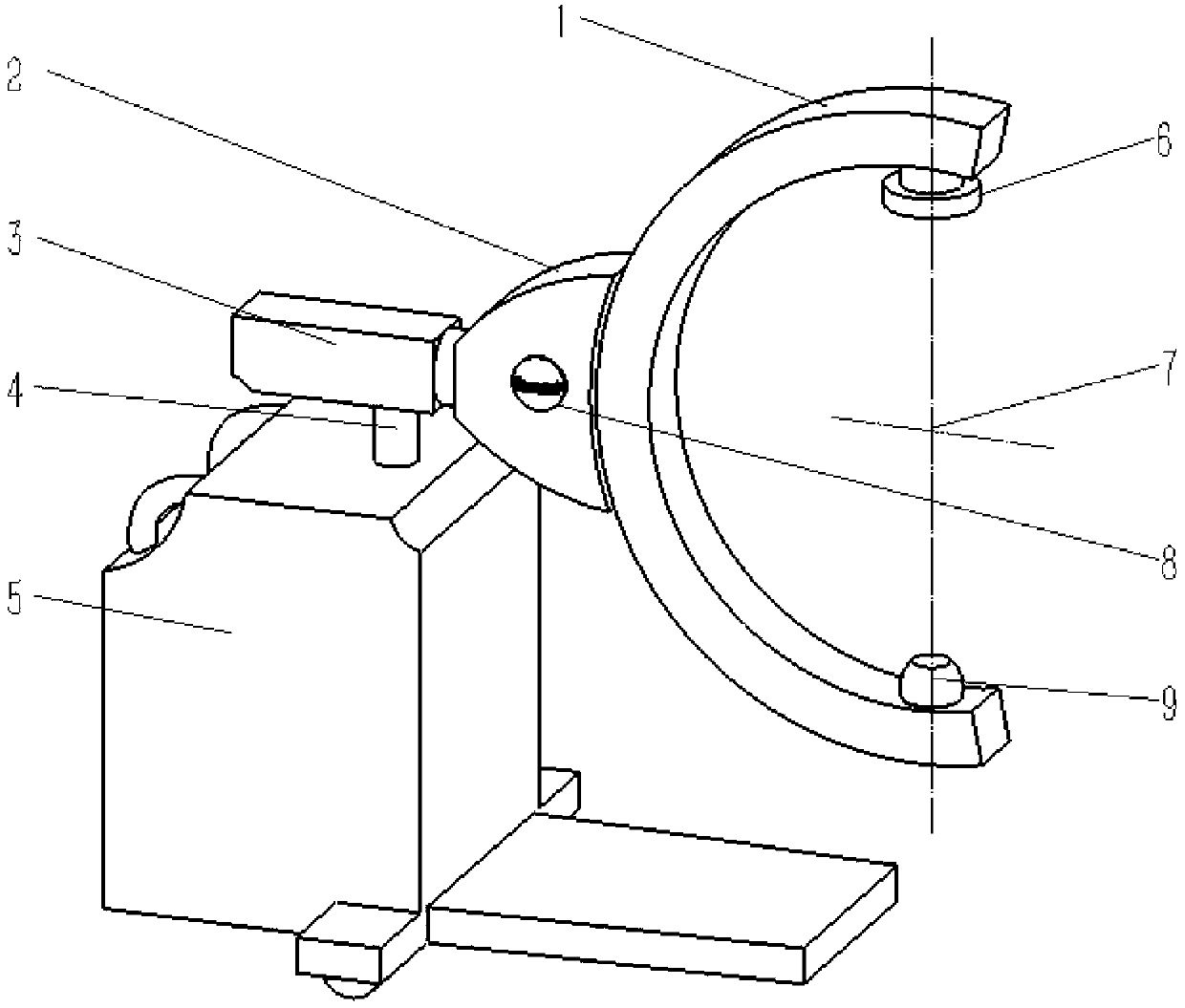

Control device and control method for achieving C arm system follow-up motion

ActiveCN103340640AFlexible operationHas a boosting effectRadiation diagnosticsEngineeringDriven element

The invention discloses a control device for achieving C arm system follow-up motion. The control device comprises active driving elements, an auxiliary control handle, an infrared switch and a force sensor. All joints of a C arm system are provided with the active driving elements, the auxiliary control handle is connected with the C arm system through the force sensor, and the infrared switch is arranged on the auxiliary control handle. In the starting state, the force sensor obtains operating intentions and transmits commands to the active driving elements of all the joints, and the active driving elements drive the joints of the C arm system to move. According to the control device for achieving C arm system follow-up motion, an operator only needs to apply a little force to flexibly and naturally operate a C arm so as to accurately complete expected motion and positioning according to the will of the operator, and therefore intuitive, simple, accurate and efficient operation is achieved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com