Caulking machine

A technology of caulking machine and caulking agent, which is applied in the direction of construction, building structure, and building material processing. It can solve problems such as low work efficiency, low strength, and pan-alkali, so as to prevent water penetration and improve work efficiency. , filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

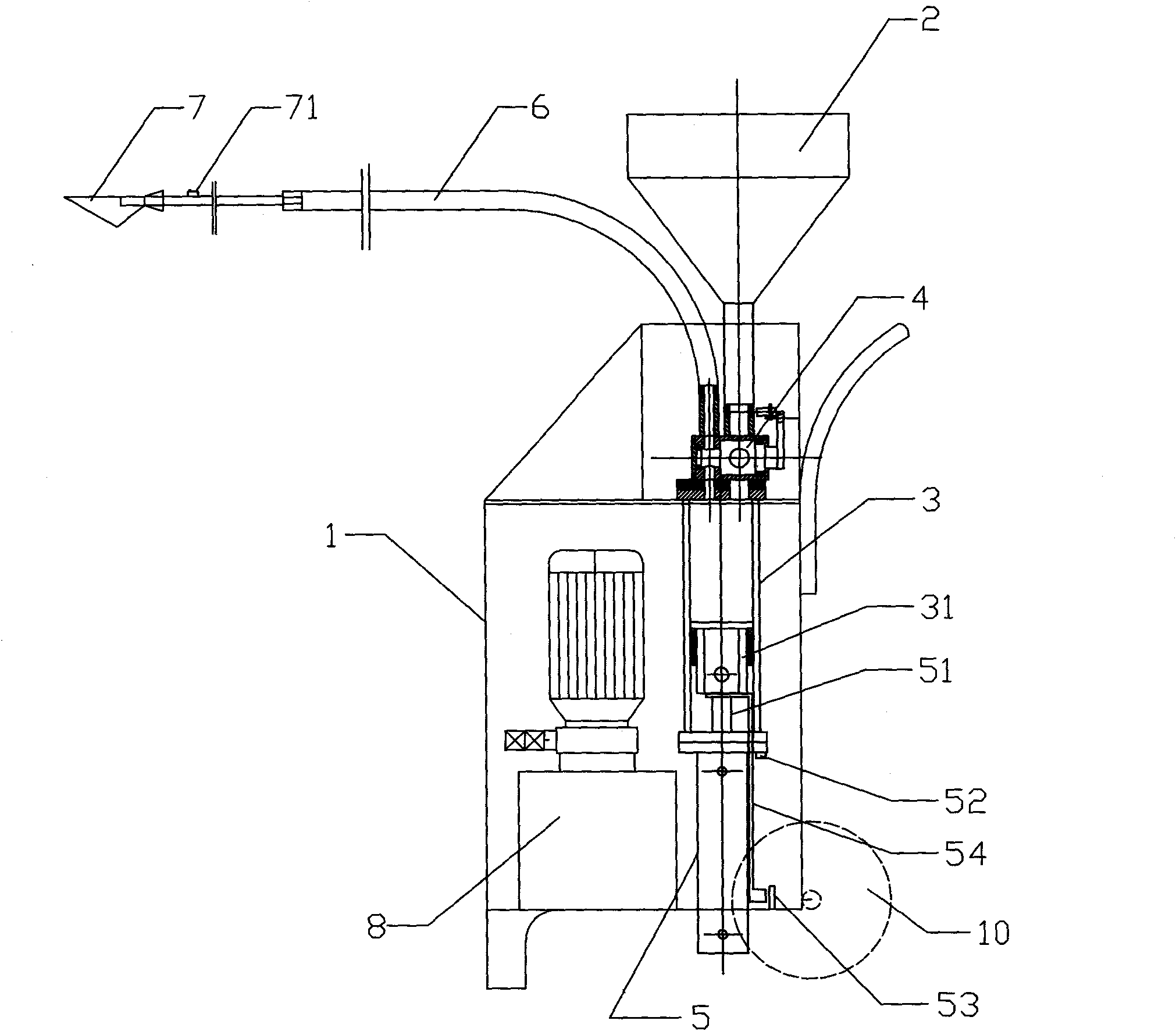

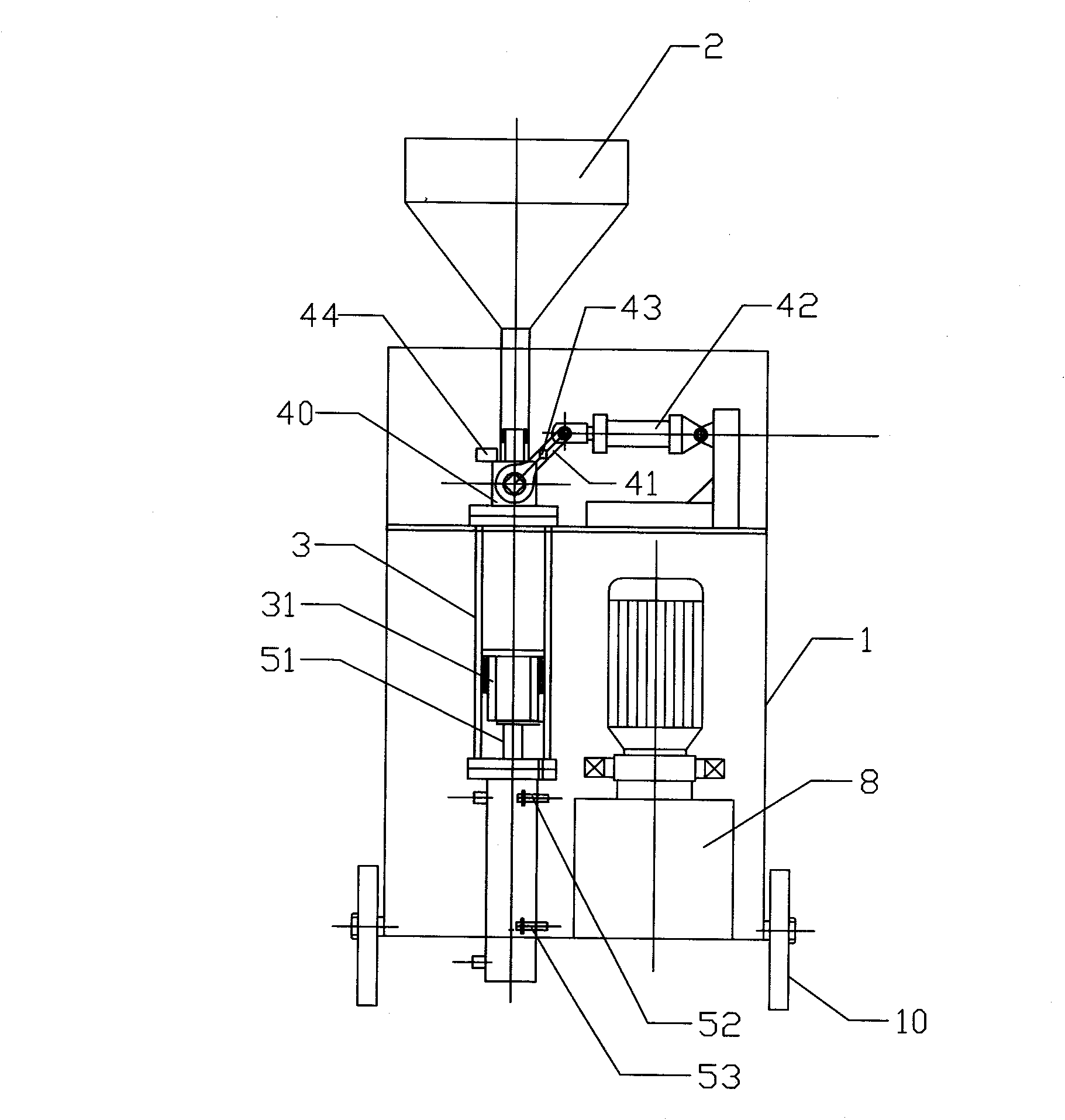

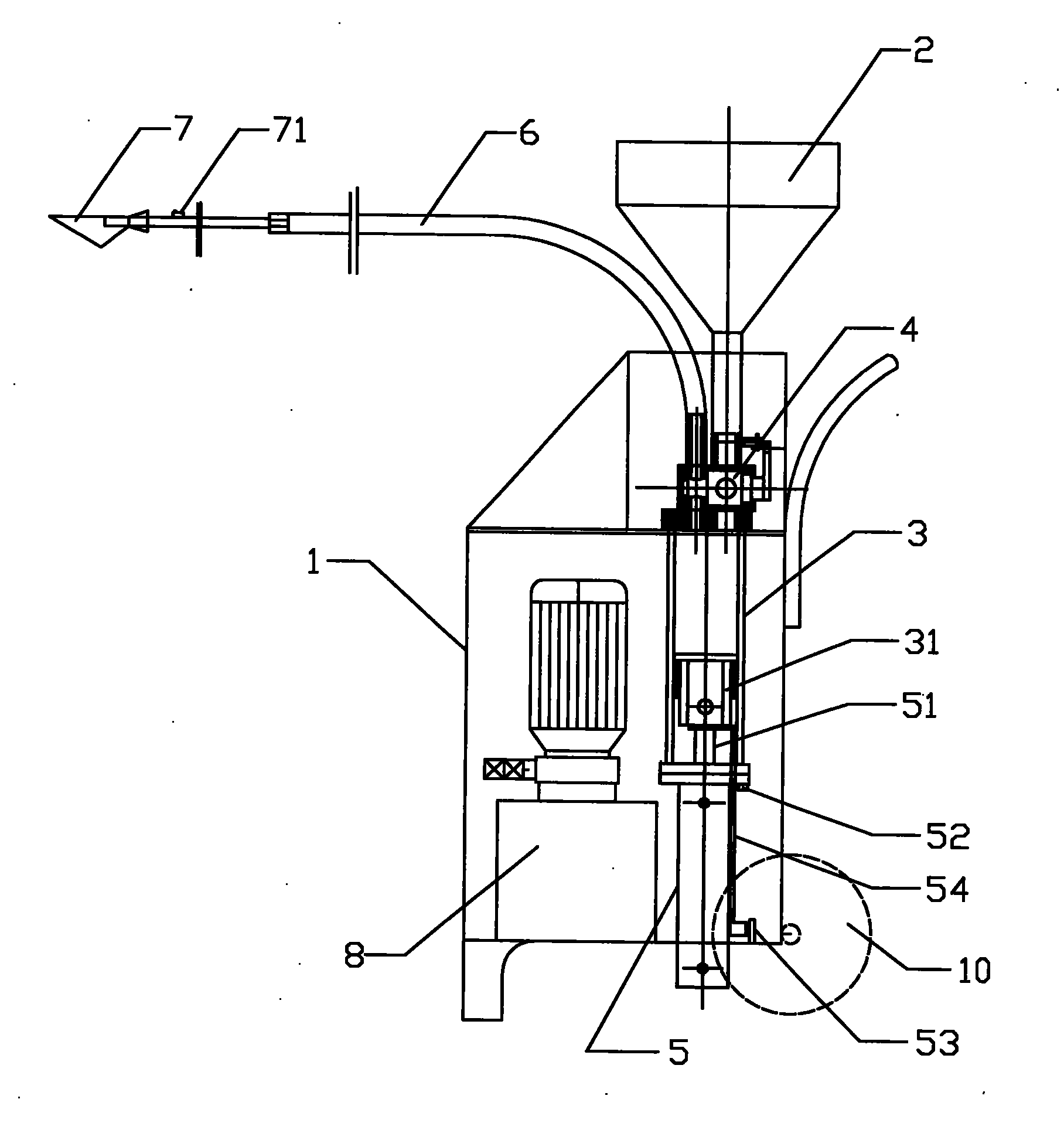

[0015] Specific implementation methods: such as Figure 1-2 As shown, the caulking machine of the present invention mainly consists of a frame 1, a feed hopper 2 positioned above the frame 1, a caulking agent cylinder 3, an inlet and outlet valve converter 4, a pusher 5, and a feeding pipe 6 and a caulking gun 7 with a control switch. The caulking agent cylinder 3 is installed in the frame 1 and connected to the inlet and outlet valve converter 4. The upper end of the inlet and outlet valve converter 4 has a feed port and a discharge port. The feed port is connected to the lower end of the feed hopper 2, one end of the feed pipe 6 is connected to the discharge port, and the other end is connected to the caulking gun 7, and the inlet and outlet valve converter 4 is installed with the caulking agent cylinder 3, the hopper 2, and the caulking gun 7, the inlet and outlet valve converter 4 can be switched to connect the hopper 2 with the caulking agent cylinder 3 or the caulking gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com