Grooving-free masonry construction method based on BIM technology and prefabricated building blocks and grooved building blocks

A construction method, block technology, applied in the direction of construction, building components, building structures, etc., can solve the problems of low construction efficiency, large construction waste, cumbersome construction, etc., to ensure accuracy and efficiency, improve work efficiency, and guarantee The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further limited below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the descriptions made. Related technical means not described in detail in the present invention can be understood and implemented with reference to the prior art or the common knowledge of those skilled in the art. The relevant technical terms used in the present invention are meanings and definitions that can be understood by those skilled in the art according to conventional technical knowledge.

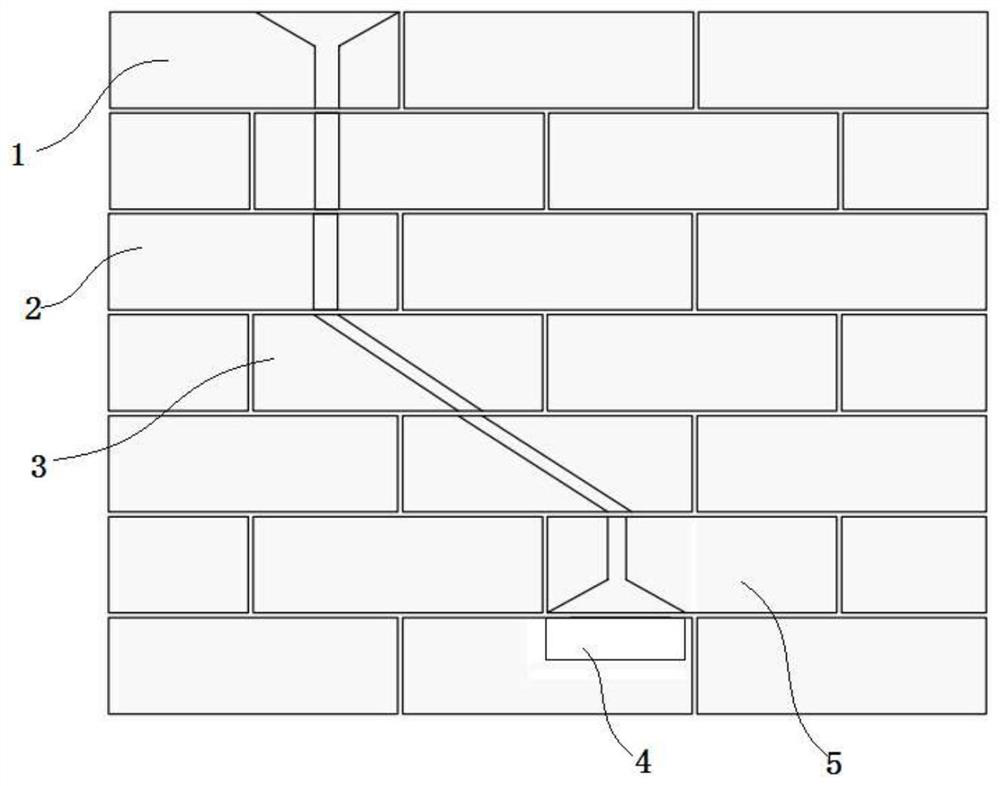

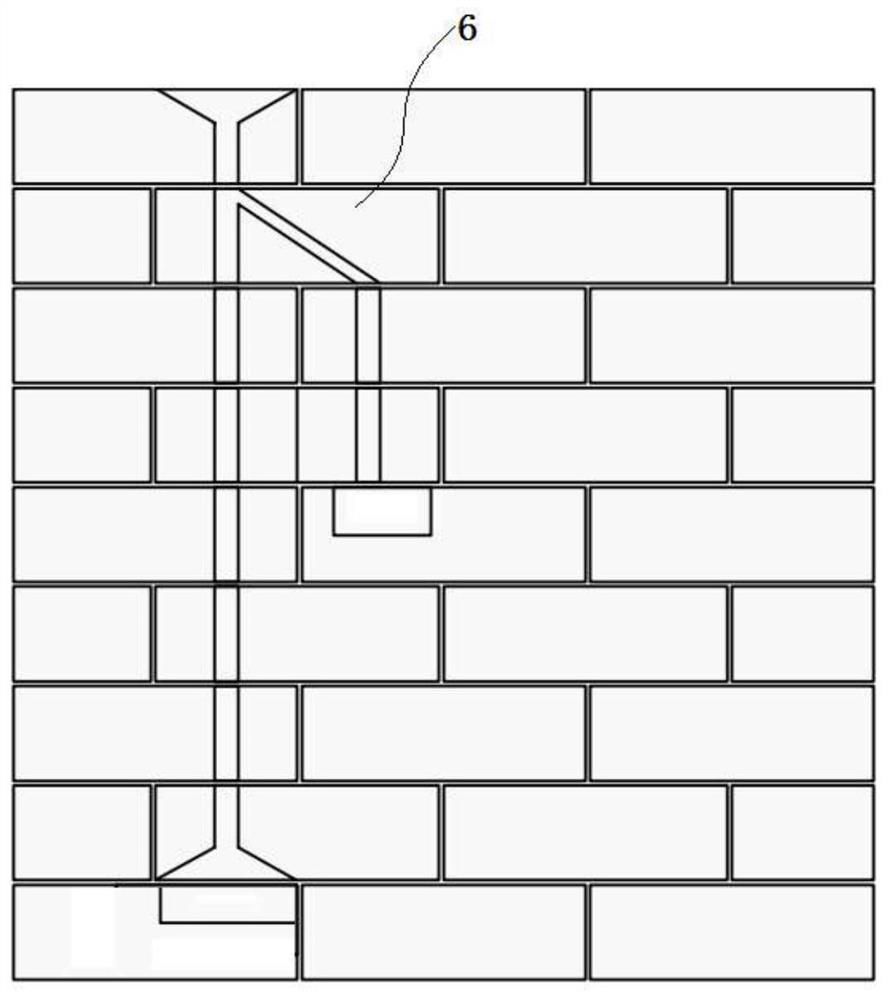

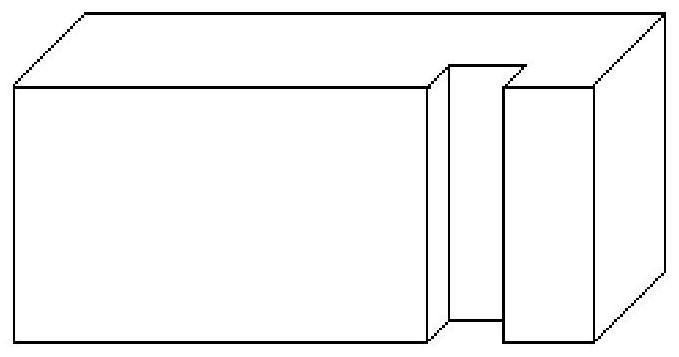

[0043] like figure 1 As shown, in one embodiment, it can form a similar wall structure after being built by masonry. Specifically, the masonry method is formed based on BIM technology and the slot-free structure design of prefabricated blocks, specifically including the following step:

[0044] Step 1: Construct the BIM model of the project to be built: check and optimize the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com