Production method of tunnel cement mortar

A technology of cement mortar and production method, applied in the field of building materials, can solve problems such as ecological environment damage, and achieve the effects of improving comprehensive performance, improving flexural strength level, and improving defoaming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

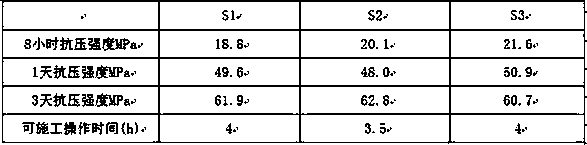

Examples

Embodiment 1

[0061] A production method for tunnel cement mortar, which comprises the following raw materials in parts by weight: 65 parts of sand aggregate, 35 parts of rapid hardening sulfoaluminate cement, 2 parts of composite coupling agent, 0.3 part of dispersible latex powder, polysiloxane 0.5 part of defoamer, 0.5 part of retarder, 0.1 part of methyl cellulose ether, 0.02 part of potato starch ether, 0.01 part of polypropylene anti-cracking fiber, and 0.05 part of polycarboxylate superplasticizer.

[0062] The production method of tunnel cement mortar comprises the following steps:

[0063] First, the limestone machine-made sand is used as the aggregate, the cement is the cementitious material, the sand aggregate fineness modulus is between 1.5 and 1.8, the cement is the cementitious material, and compound coupling agent, water-resistant dispersible latex powder, Defoamer, retarder, cellulose ether, starch ether, anti-crack fiber, water reducing agent are mixed evenly.

Embodiment 2

[0065] A production method for tunnel cement mortar, which comprises the following raw materials in parts by weight: 70 parts of sand aggregate, 40 parts of rapid hardening sulfoaluminate cement, 3 parts of composite coupling agent, 0.4 part of dispersible latex powder, polysiloxane 0.6 part of defoamer, 0.7 part of retarder, 0.2 part of hydroxypropyl methylcellulose ether, 0.03 part of corn starch ether, 0.02 part of polyester anti-cracking fiber, and 0.1 part of polycarboxylate superplasticizer.

[0066] The production method of tunnel cement mortar comprises the following steps:

[0067] First, the limestone machine-made sand is used as the aggregate, the cement is the cementitious material, the sand aggregate fineness modulus is between 1.5 and 1.8, the cement is the cementitious material, and compound coupling agent, water-resistant dispersible latex powder, Defoamer, retarder, cellulose ether, starch ether, anti-crack fiber, water reducing agent are mixed evenly.

Embodiment 3

[0069] A production method for tunnel cement mortar, which comprises the following raw materials in parts by weight: 75 parts of sand aggregate, 45 parts of rapid hardening sulfoaluminate cement, 4 parts of composite coupling agent, 0.5 part of dispersible latex powder, polysiloxane 0.7 part of defoamer, 0.9 part of retarder, 0.3 part of hydroxyethyl cellulose ether, 0.04 part of tapioca starch ether, 0.03 part of polypropylene anti-cracking fiber, and 0.15 part of polycarboxylate superplasticizer.

[0070] The production method of tunnel cement mortar comprises the following steps:

[0071] First, the limestone machine-made sand is used as the aggregate, the cement is the cementitious material, the sand aggregate fineness modulus is between 1.5 and 1.8, the cement is the cementitious material, and compound coupling agent, water-resistant dispersible latex powder, Defoamer, retarder, cellulose ether, starch ether, anti-crack fiber, water reducing agent are mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com