Production method of low-cost vitrified brick paste mortar

A production method and technology of vitrified bricks, applied in the field of building materials, can solve problems such as low water absorption and falling off of vitrified bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

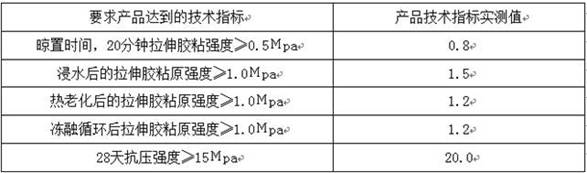

Examples

Embodiment 1

[0051] A method for producing low-cost vitrified brick paste mortar, which includes the following raw materials in parts by weight: 20 parts of dust collection waste; 30 parts of pure portland cement; 35 parts of quartz powder; 2 parts of composite coupling agent; acrylic rubber powder 0.3 parts; 0.1 parts of methyl cellulose ether; 0.02 parts of potato starch ether; 0.05 parts of melamine-based water reducer.

[0052] A method for producing low-cost vitrified brick paste mortar, comprising the following steps:

[0053] The dust collection waste below 0.3 mm in the limestone sand making process, 0.3 mm quartz powder, and cement are used as the main materials, put into the mill for mixed grinding, and use a 0.08mm water sieve to control the fineness of the mill at 20±2 %;

[0054] The ground powder is mixed with composite coupling agent, acrylic rubber powder, cellulose ether, starch ether, and melamine-based water reducer, and mixed evenly by a high-speed mixer.

Embodiment 2

[0056] The production method of low-cost vitrified brick pasting mortar comprises the following raw materials in parts by weight: 22 parts of dust collection waste; 32 parts of pure portland cement; 36 parts of quartz powder; 3 parts of composite coupling agent; acrylic rubber powder 0.4 parts; 0.3 parts of hydroxyethyl cellulose ether; 0.03 parts of corn starch ether; 0.1 parts of melamine-based water reducer.

[0057] A method for producing low-cost vitrified brick paste mortar, comprising the following steps:

[0058] The dust collection waste below 0.3 mm in the limestone sand making process, 0.3 mm quartz powder, and cement are used as the main materials, put into the mill for mixed grinding, and use a 0.08mm water sieve to control the fineness of the mill at 20±2 %;

[0059] The ground powder is mixed with composite coupling agent, acrylic rubber powder, cellulose ether, starch ether, and melamine-based water reducer, and mixed evenly by a high-speed mixer.

Embodiment 3

[0061] A method for producing low-cost vitrified brick paste mortar, which includes the following raw materials in parts by weight: 23 parts of dust collection waste; 35 parts of pure portland cement; 40 parts of quartz powder; 4 parts of composite coupling agent; acrylic rubber powder 0.5 parts; 0.4 parts of hydroxypropyl methylcellulose ether; 0.04 parts of tapioca starch ether; 0.15 parts of melamine-based water reducer.

[0062] A method for producing low-cost vitrified brick paste mortar, comprising the following steps:

[0063] The dust collection waste below 0.3 mm in the limestone sand making process, 0.3 mm quartz powder, and cement are used as the main materials, put into the mill for mixed grinding, and use a 0.08mm water sieve to control the fineness of the mill at 20±2 %;

[0064] The ground powder is mixed with composite coupling agent, acrylic rubber powder, cellulose ether, starch ether, and melamine-based water reducer, and mixed evenly by a high-speed mixer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com