Connecting method and structure of masonry wall and shear wall

A connection method and shear wall technology, which can be applied to walls, building components, building structures, etc., can solve the problems of affecting the appearance and prone to cracks, so as to reduce the cost of plastering, reduce hollowing or cracking, and speed up the construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

[0023] A method for connecting a masonry wall and a shear wall, the method is constructed according to the following steps:

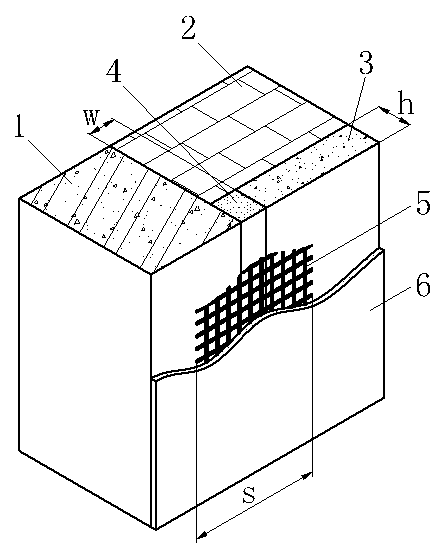

[0024] A. Masonry wall construction is carried out on the end face of the shear wall, and steps are provided between the masonry wall and the shear wall; the height h of the steps is 10mm.

[0025] B. Apply a plaster layer on the masonry wall, leaving a gap between the end face of the shear wall and the end face of the plaster layer; the thickness of the plaster layer is equal to the shear wall, and the width of the gap between the shear wall and the masonry wall is 8mm.

[0026] C. After the plastering layer on the masonry wall is dried to 70-90%, the plastering layer is preferably dried to 80%, and the gap between the end face of the shear wall and the end face of the pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com