External building wall thermal insulation board and production method thereof

A technology for thermal insulation formwork and building exterior wall, applied in thermal insulation, building components, manufacturing tools, etc., can solve problems such as easy peeling of XPS thermal insulation layer and bonding mortar, hidden dangers of human and material safety, and hollowing, and achieve obvious thermal insulation effect. , good performance stability, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Provide a kind of preparation method of building exterior wall insulation formwork in the embodiment of the present invention, comprise the following steps:

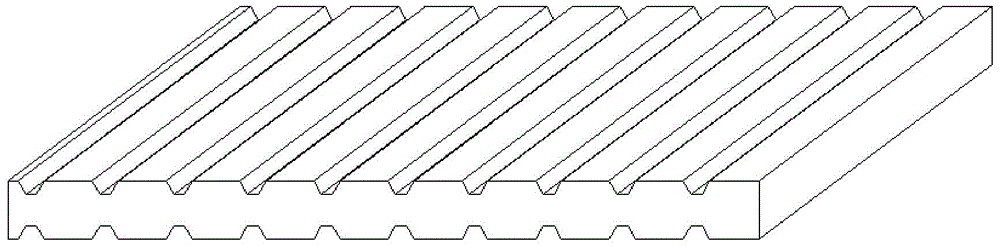

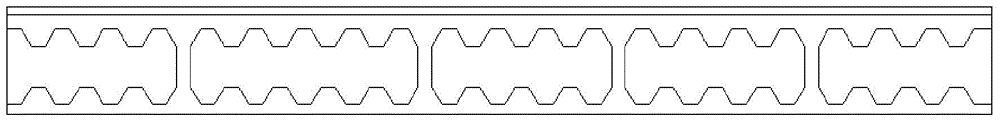

[0029] (a) Saw-tooth grooves are made on both sides of the extruded board, such as figure 1 shown;

[0030] (b), one side of the extruded board after sawtooth grooving is carried out with adhesive mortar laying;

[0031] (c) Carry out maintenance on the extruded boards laid with bonded mortar until they are completely hardened;

[0032] (d) Laying thermal insulation mortar and adhesive mortar on the other side of the cured extruded board in sequence, curing until it is completely hardened, and obtaining a finished thermal insulation formwork for building exterior walls.

[0033] The preparation method of the building exterior wall thermal insulation template provided by the embodiment of the present invention is to carry out sawtooth grooves on both sides of the extruded plastic board, and then lay adhesive mort...

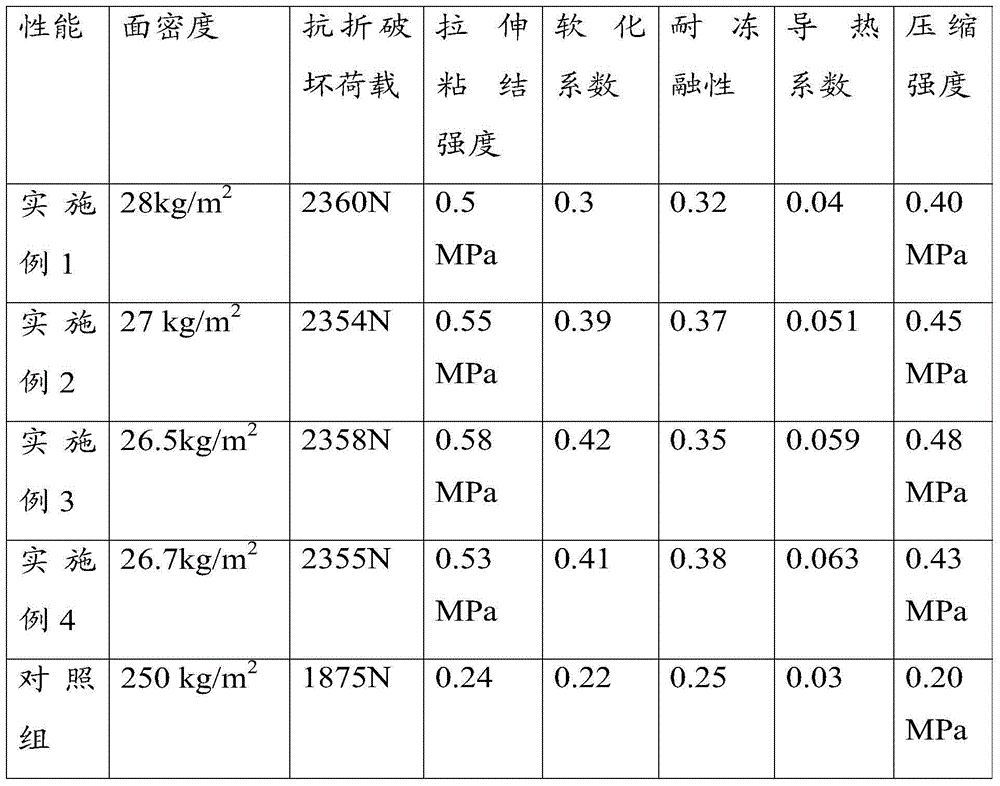

Embodiment 1

[0055] Saw-tooth grooves are made on both sides of the extruded board;

[0056] Prepare the bonding mortar, the bonding mortar is prepared as follows:

[0057] Get the following main ingredients, auxiliary materials and water respectively:

[0058] The main ingredients include the following ingredients: by weight percentage, 25% of 425 cement, 70% of quartz sand, and 5% of heavy calcium; the auxiliary materials include the following ingredients: cellulose ether is 1% of the total weight of the main ingredient, and wood fiber is the main ingredient. 0.2% of the total weight of the main material, rubber powder is 1.5% of the total weight of the main material; water is 20% of the total weight of the main material and auxiliary materials, and the particle size of the quartz sand is 0.1-0.3mm. Mix all the ingredients together and stir evenly , get bonded mortar;

[0059] Lay one side of the extruded board after sawtooth grooving with adhesive mortar, lay it into a flat rough surf...

Embodiment 2

[0066] Make sawtooth grooves on both sides of the extruded board, and then punch multiple through holes on the extruded board, the diameter of the through holes is 30mm;

[0067] Prepare the bonding mortar, the bonding mortar is prepared as follows:

[0068] Get the following main ingredients, auxiliary materials and water respectively:

[0069] The main ingredients include the following ingredients: by weight percentage, 425 cement 32%, quartz sand 65%, and heavy calcium 3%; auxiliary materials include the following ingredients: cellulose ether is 2% of the total weight of the main ingredient, and wood fiber is the main ingredient. 0.6% of the total weight of the main material, rubber powder is 2% of the total weight of the main material; water is 21% of the total weight of the main material and auxiliary materials, and the particle size of the quartz sand is 0.3-0.5mm. Mix all the ingredients together and stir evenly , get bonded mortar;

[0070] Lay one side of the extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com