Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Reduce the probability of air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

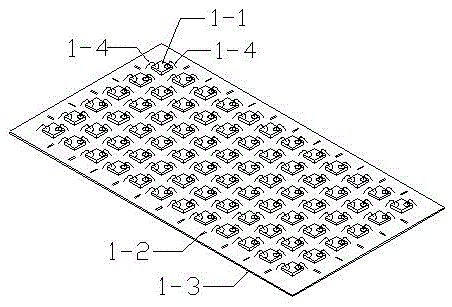

Construction method for paving ground tile floor

InactiveCN104120855AReduce hollowingReduce the probability of air bubblesFlooringArchitectural engineeringStructural engineering

The invention discloses a construction method for paving a ground tile floor. The construction method includes the following steps of (1) pasting cement blocks and marking elevation lines, (2) laying bonding layer mortar, (3) snapping the lines, (4) tiling, (5) flattening and poking joints; (6) caulking and (7) curing. The construction method for paving the ground tile floor is easy to operate, low in price, and capable of effectively reducing the probability of empty drums and bubbles generated on the ground tile floor and prolonging the service life of ground tiles.

Owner:杨哲

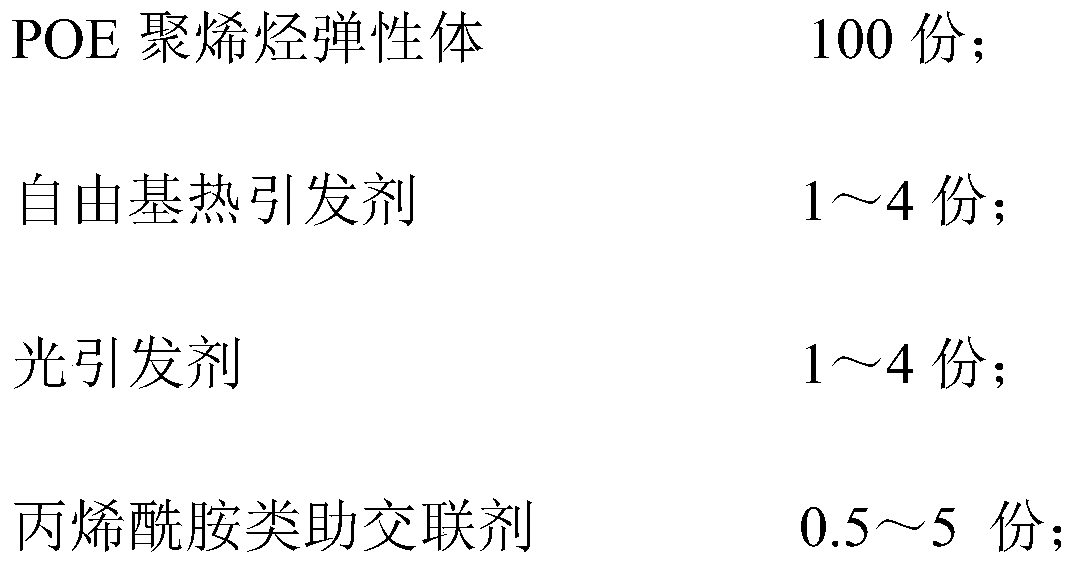

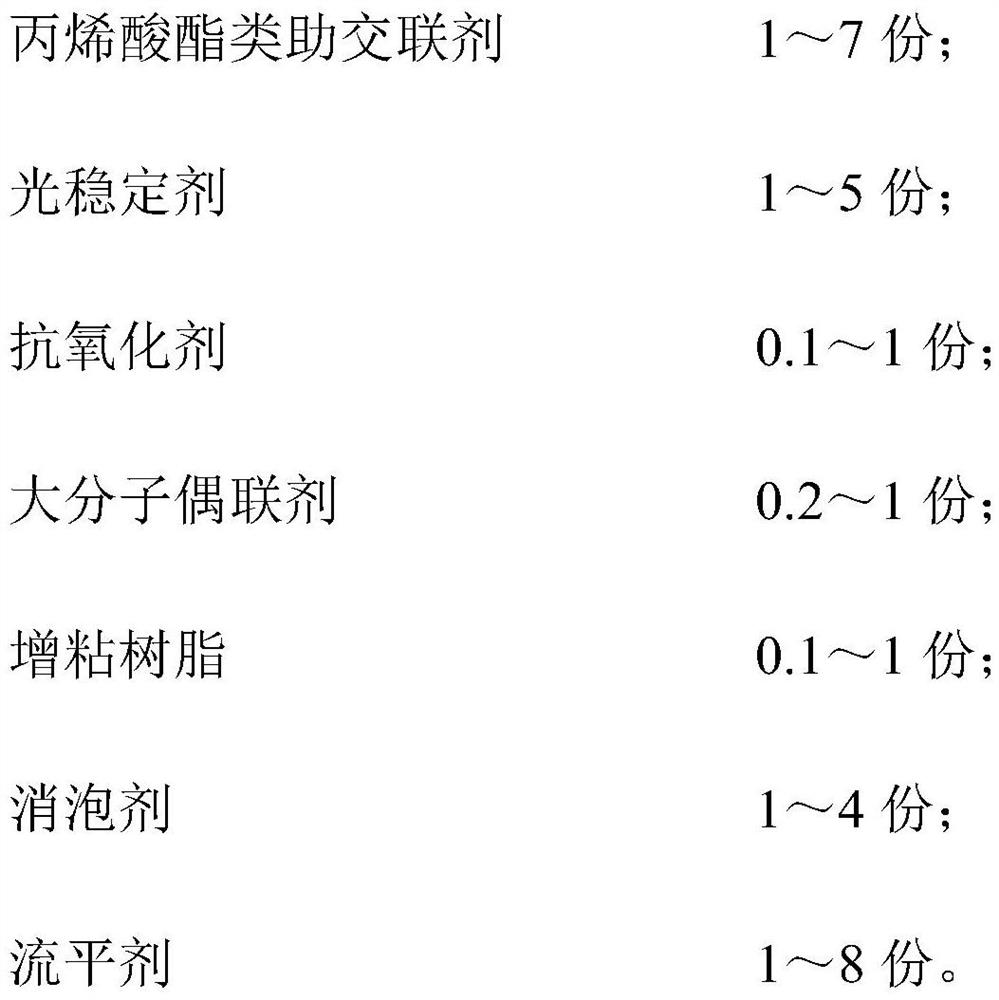

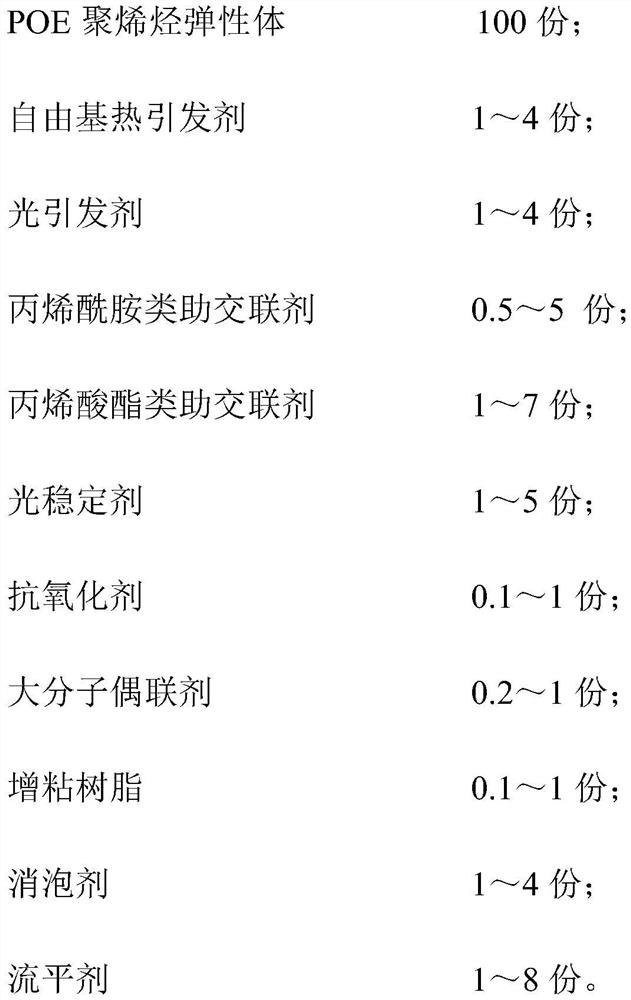

Photovoltaic photo-thermal dual-curing POE packaging adhesive film and preparation method thereof

ActiveCN111117498AImprove lamination efficiencyReduce energy consumptionFilm/foil adhesives without carriersPhotovoltaic energy generationBattery bankPolymer science

The invention discloses a photovoltaic photo-thermal dual-curing POE packaging adhesive film and a preparation method thereof. The packaging adhesive film comprises a POE polyolefin elastomer, a freeradical thermal initiator, a photoinitiator, an acrylamide assistant cross-linking agent, an acrylate assistant cross-linking agent, a light stabilizer, an antioxidant, a macromolecular coupling agent, tackifying resin, an antifoaming agent and a leveling agent. The packaging adhesive film can realize rapid low-temperature curing, has the advantages of high light transmittance, high adhesive strength, low shrinkage rate, low water permeability, no bubbles, high efficiency, low cost, easiness in reworking and the like after being laminated, and is suitable for an efficient battery assembly which is sensitive to temperature or has a high requirement for the packaging rate; compounding of POE with different melt indexes improves the fluidity, reduces the bubble rate and guarantees that glue overflowing and battery string spacing deviation do not occur; and the macromolecular coupling agent is added through a chemical grafting method, so that the long-term bonding reliability is improved.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

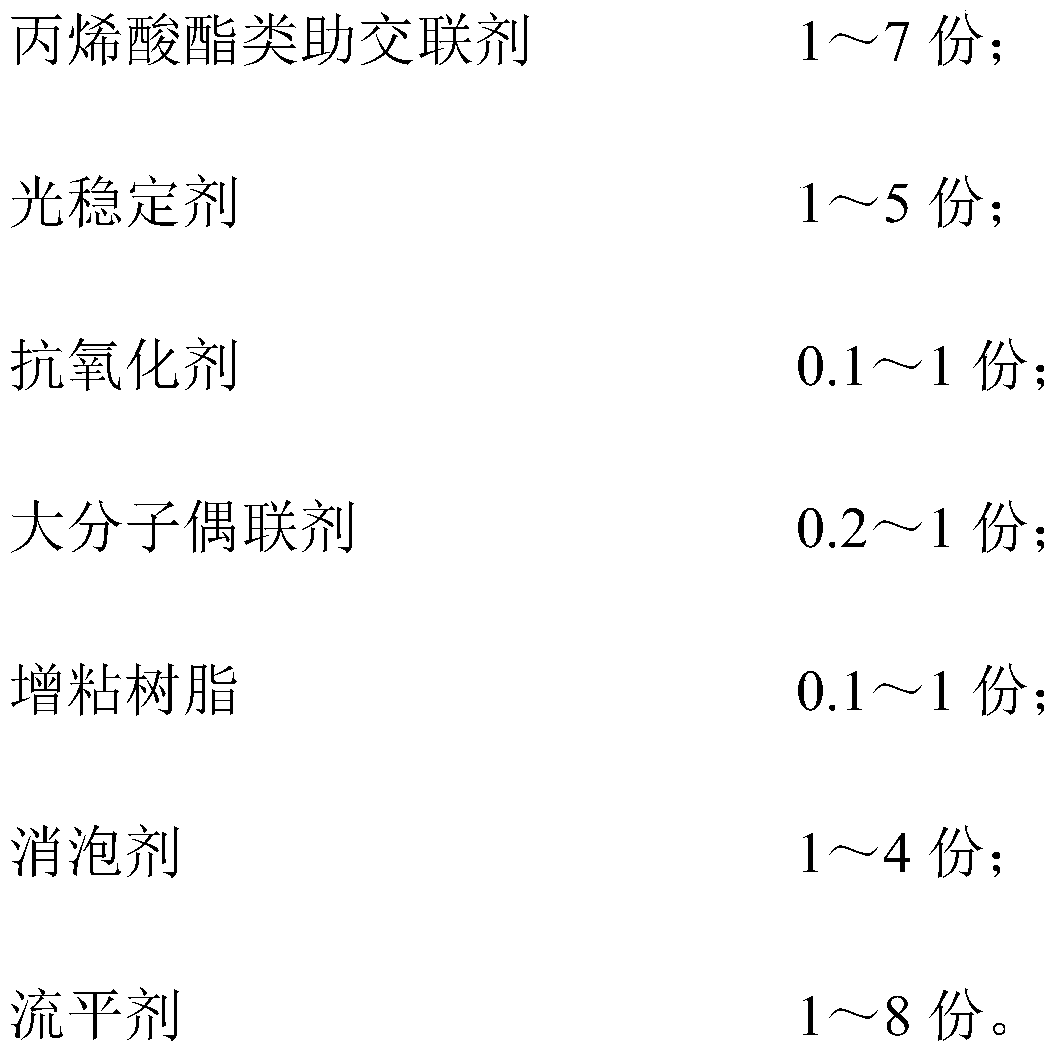

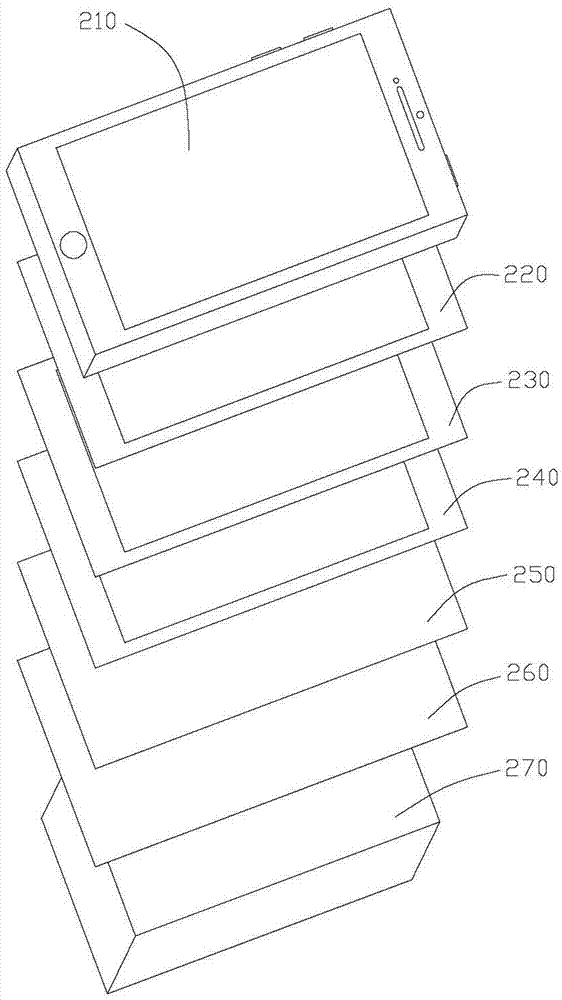

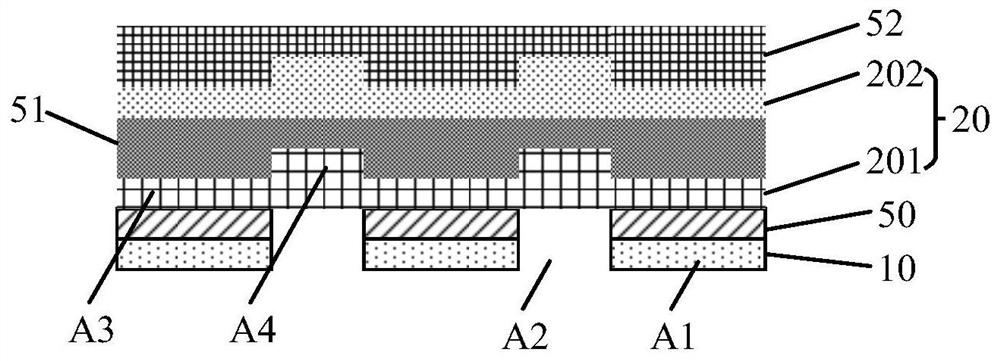

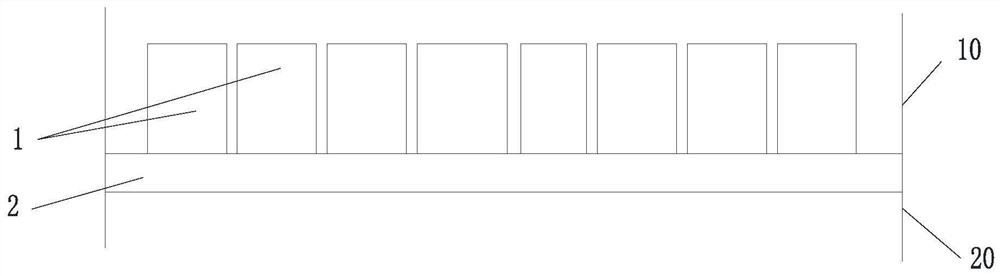

Touch display apparatus

ActiveCN105446527AReduce the differenceReduce the probability of air bubblesInput/output processes for data processingLight absorbanceOxide

The present invention relates to a touch display apparatus. The touch display apparatus is defined to comprise a touch area for displaying an image and receiving a touch operation and a non-touch area surrounding the touch area. The touch display apparatus comprises a cover plate, a display panel, and a decorative layer and a shielding layer that are located between the cover plate and the display panel and are arranged corresponding to the non-touch area. The decorative layer is used for providing a required border color for the touch display apparatus, and the shielding layer is used for shielding electrical signal transmission cabling surrounding the touch display apparatus. The decorative layer is between the cover plate and the shielding layer. The shielding layer is made of metal or metal oxide. According to the touch display apparatus, metal or metal oxide is used as the shielding layer of the touch display apparatus, so that a probability of bubble generation in the touch display apparatus is reduced. In addition, light absorbance of a decorative border can be improved, thereby having a good shielding effect.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

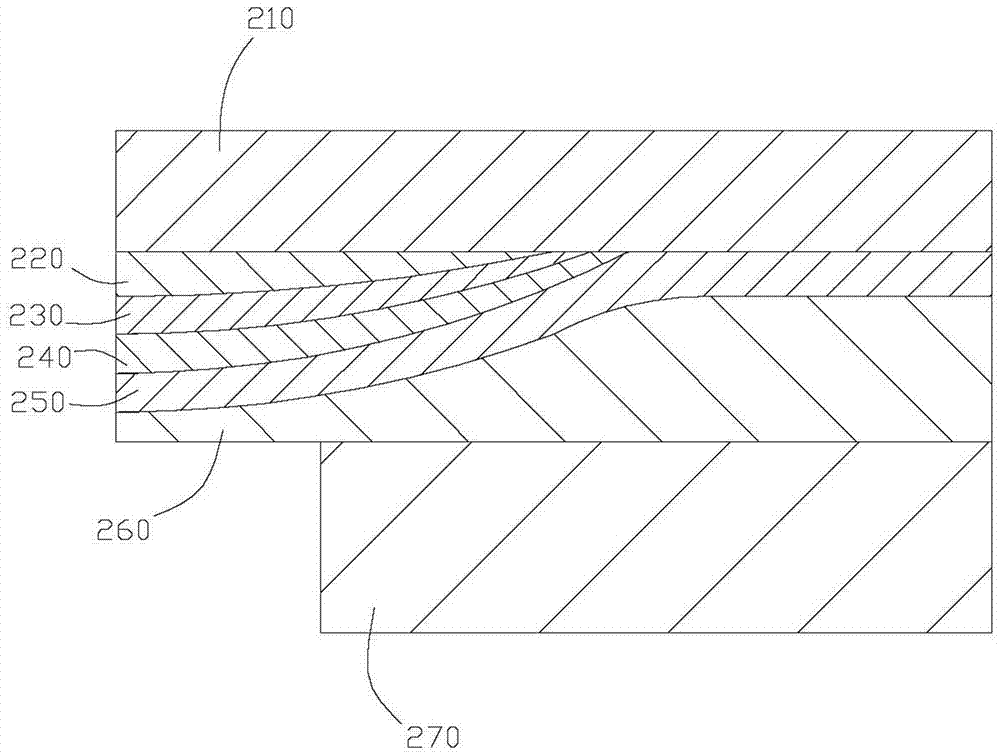

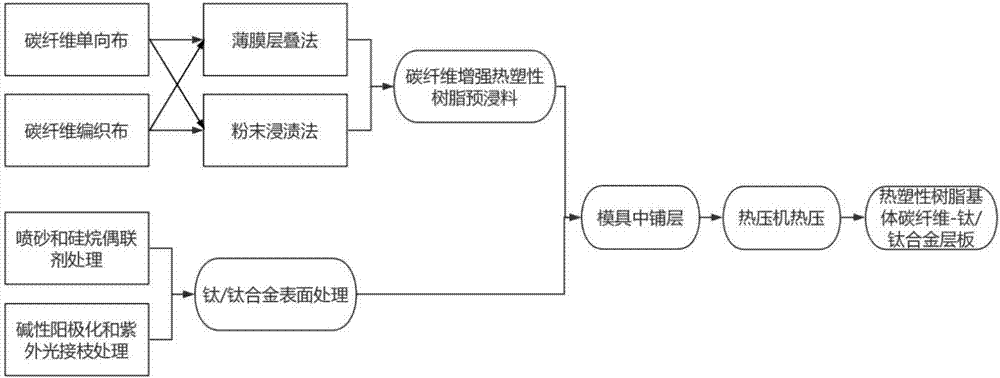

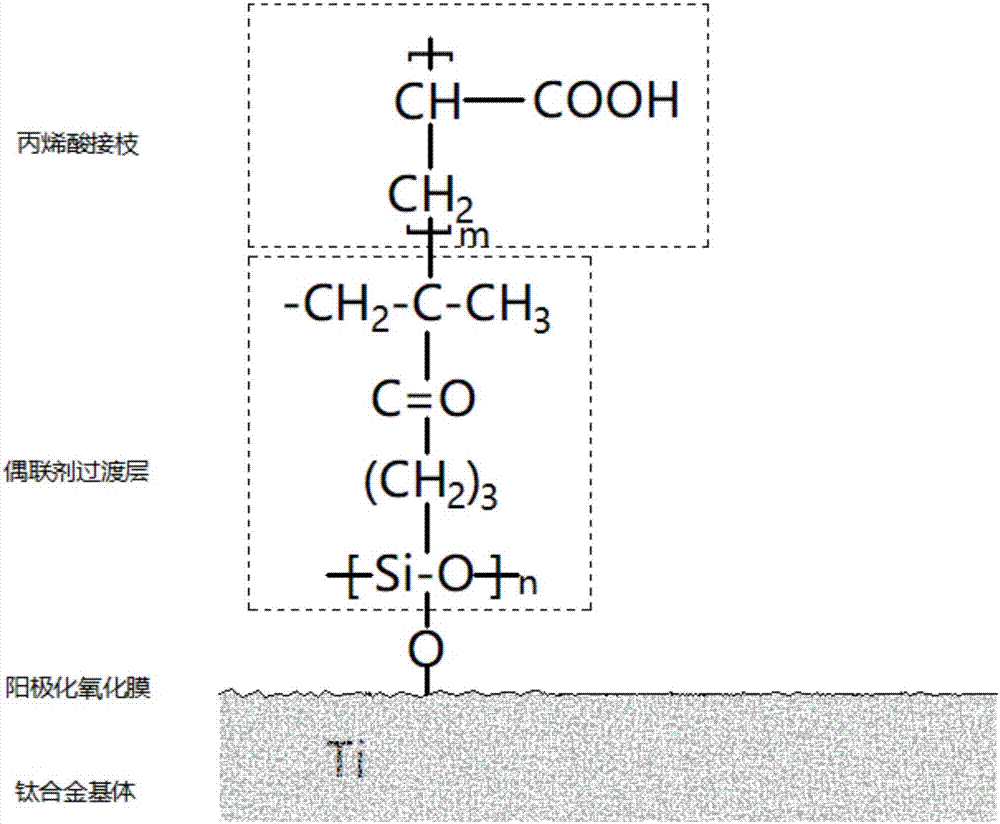

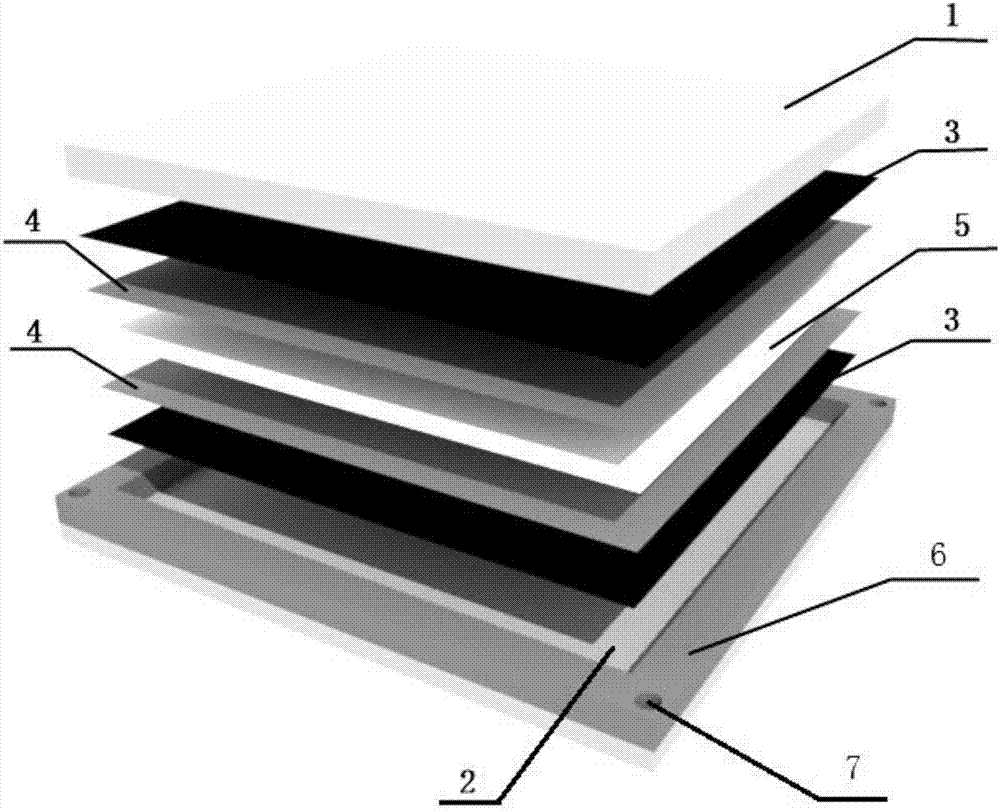

Preparing method of thermoplastic resin matrix carbon fiber-titanium/titanium alloy laminate plate

ActiveCN107283871AImprove impregnation effectHigh mechanical strengthCoatingsThermoplasticCarbon fibers

The invention discloses a preparing method of a thermoplastic resin matrix carbon fiber-titanium / titanium alloy laminate plate, and belongs to the field of light composite materials. The technical purpose is to solve the problem that currently the interface glue joint effect of titanium alloy of carbon fiber reinforcement titanium alloy laminate plate TiGr and a prepreg is poor. The thermoplastic resin comprises three kinds of high-performance thermoplastic resin including polyether-ether-ketone (PEEK), polyphenylene sulfide (PPS) and polyetherimid (PEI), with the coordination of a film laminating method and a powder impregnation method, the problem that the impregnation effect of the thermoplastic resin on carbon fiber is poor is solved.

Owner:HARBIN INST OF TECH

A kind of LED molding sealing device and sealing method thereof

InactiveCN104210064BEasy to implementReduce manufacturing costCoatingsSemiconductor devicesThermodynamicsAdhesive glue

The invention discloses an LED molding sealing device and a sealing method thereof. The device comprises an upper mold, a lower mold and a glue channel partition structure. The upper part of the upper mold is provided with a glue injection port, the upper part of the lower mold is provided with a cavity, and the glue injection port The cavity is connected to the mold cavity through the glue channel set on the lower part of the upper mold and the upper part of the lower mold. The upper mold and the lower mold are locked by the locking parts. It also includes the glue channel partition structure set in the glue channel. The glue channel partition structure is shifted to connect the rubber channel. When the glue injection is completed, the glue thrust disappears, and the glue channel partition structure is reset to automatically isolate the glue channel. The present invention is applicable to the LED sealing field. The present invention not only has a simple structure and is convenient to use, but also can well maintain the pressure of the glue in the mold cavity when the sealing is completed, avoiding volume shrinkage during the heat curing process of the sealing glue, and ensuring the sealing effect. The colloid of the finished product is complete, increasing the yield of the molded product.

Owner:GUANGDONG VTRON TECH CO LTD

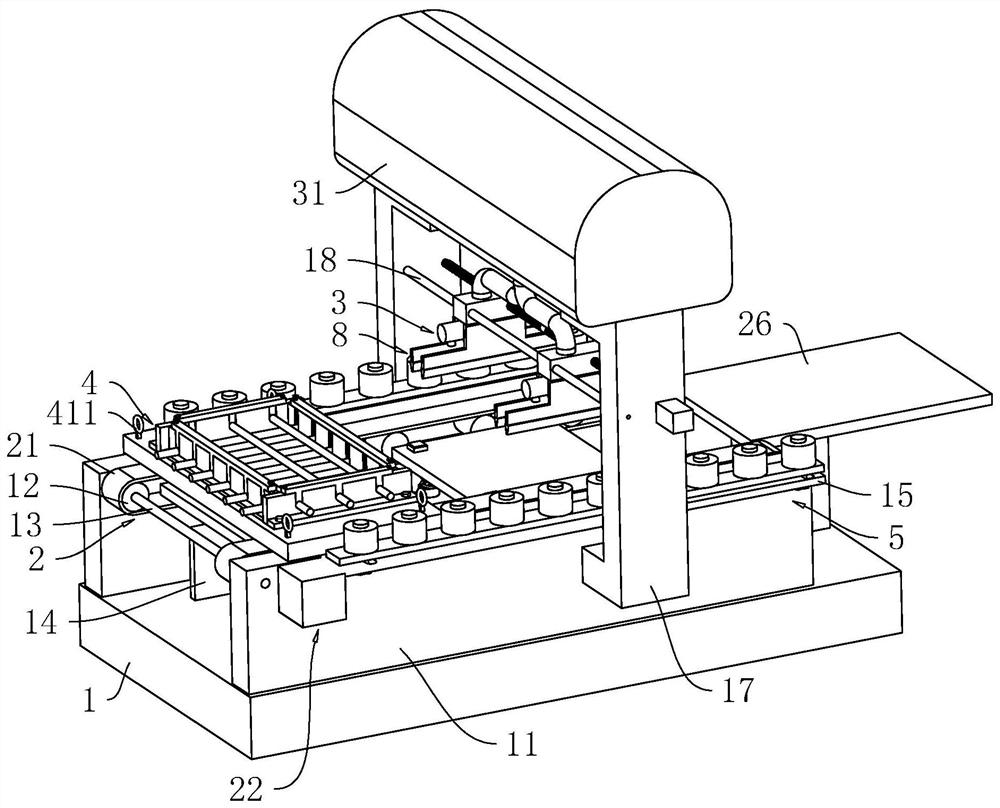

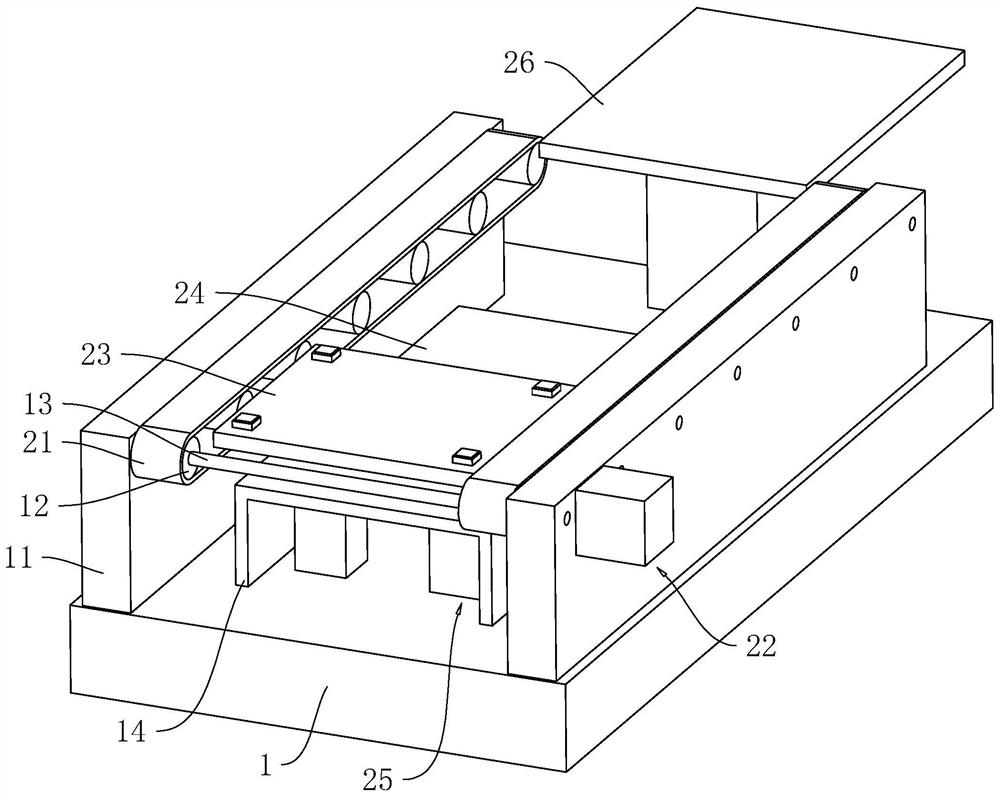

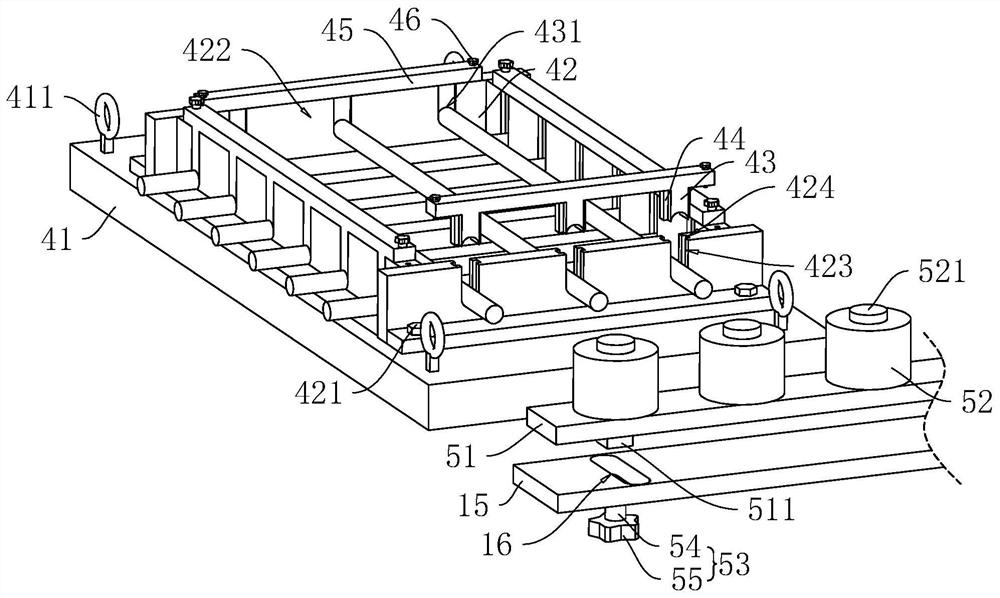

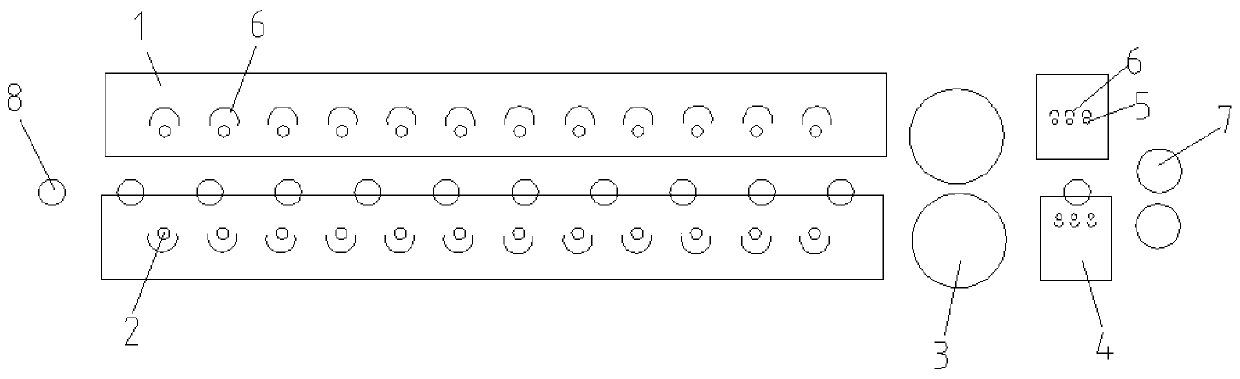

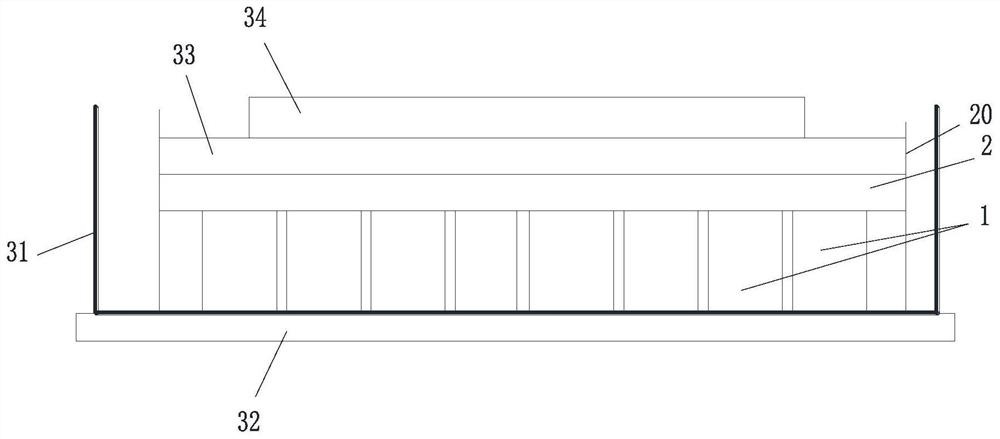

Production device and process for prefabricated part

ActiveCN112045821AImprove production efficiency is lowShorten the timeCeramic shaping plantsRebarMechanical engineering

The invention relates to a production device and process for a prefabricated part. The production device comprises a rack; a conveying mechanism is arranged on the rack, and the conveying mechanism comprises a conveying belt, a driving piece, a first lifting table, a second lifting table, a lifting assembly and a receiving table; the conveying belt is arranged on the rack; the driving piece is arranged on the rack; and the first lifting table and the second lifting table are both slidably arranged on the rack, the lifting assembly is arranged on the rack, the receiving table is arranged on therack, and a mold can move to the receiving table. A reinforcing steel bar is mounted on the mold, after mounting is completed, the lifting assembly is started to place the mold on the conveying belt,the mold is moved to the second lifting table, the lifting assembly is started to drive the mold to get away from the conveying belt, then a filling mechanism is started to pour concrete into the mold, thus the mold does not need to be manually placed on the filling mechanism, the time is saved, and the problem of low production efficiency of the prefabricated part is solved.

Owner:浙江三杰建筑产业化有限公司

Lamination technology of film photovoltaic assembly

ActiveCN104900756AReduce the probability of air bubblesReduced risk of splinteringFinal product manufactureLaminationVacuum pumpingAtmospheric pressure

The invention relates to a lamination technology of a film photovoltaic assembly. The lamination technology comprises the flows of 1) preparing a battery chip; 2) leading a transmission structure; 3) laying a connection film layer; 4) laying a backboard package; 5) laminating a battery assembly; and 6) completing the battery assembly. In the flow 5), the lamination temperature is controlled between 160 and 165 DEG C, the lamination time is kept within 6-8 min, the vacuum-pumping time is controlled within 3 to 5 min, the laminating vacuum degree is kept between 0 and 50 Pa, and the laminating pressure is controlled between 0.4 and 0.6 that of the atmospheric pressure. The qualified rate and production efficiency of products are effectively improved, and the film photovoltaic assembly of higher reliability, longer service life and high stability and consistency can be obtained in the lamination process via optimization.

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

Glass batch and production process of glass batch

The invention relates to the field of glass manufacture, in particular to a glass batch with the advantages of high product quality, low production cost and capability of effectively improving production efficiency, and a production process of the glass batch. The glass batch is characterized in that the glass batch contains sodium metasilicate pentahydrate and comprises the following ingredients according to the following proportions: 672kg of quartz sand, 85kg of feldspar, 163kg of sodium carbonate, 184kg of calcite, 20kg of lepidolite, 14kg of fluorite, 100kg of sodium metasilicate pentahydrate, 10kg of clarifying agents and 24kg of selenium powder. Compared with the prior art, the glass batch and the production process can realize the target that the energy consumption is not increased or even is reduced while the melting rate of a kiln is improved, and have the obvious advantages that the production cost is low, the energy consumption is small, the air bubble rate of products is low, and the like.

Owner:山东华鹏石岛玻璃制品有限公司

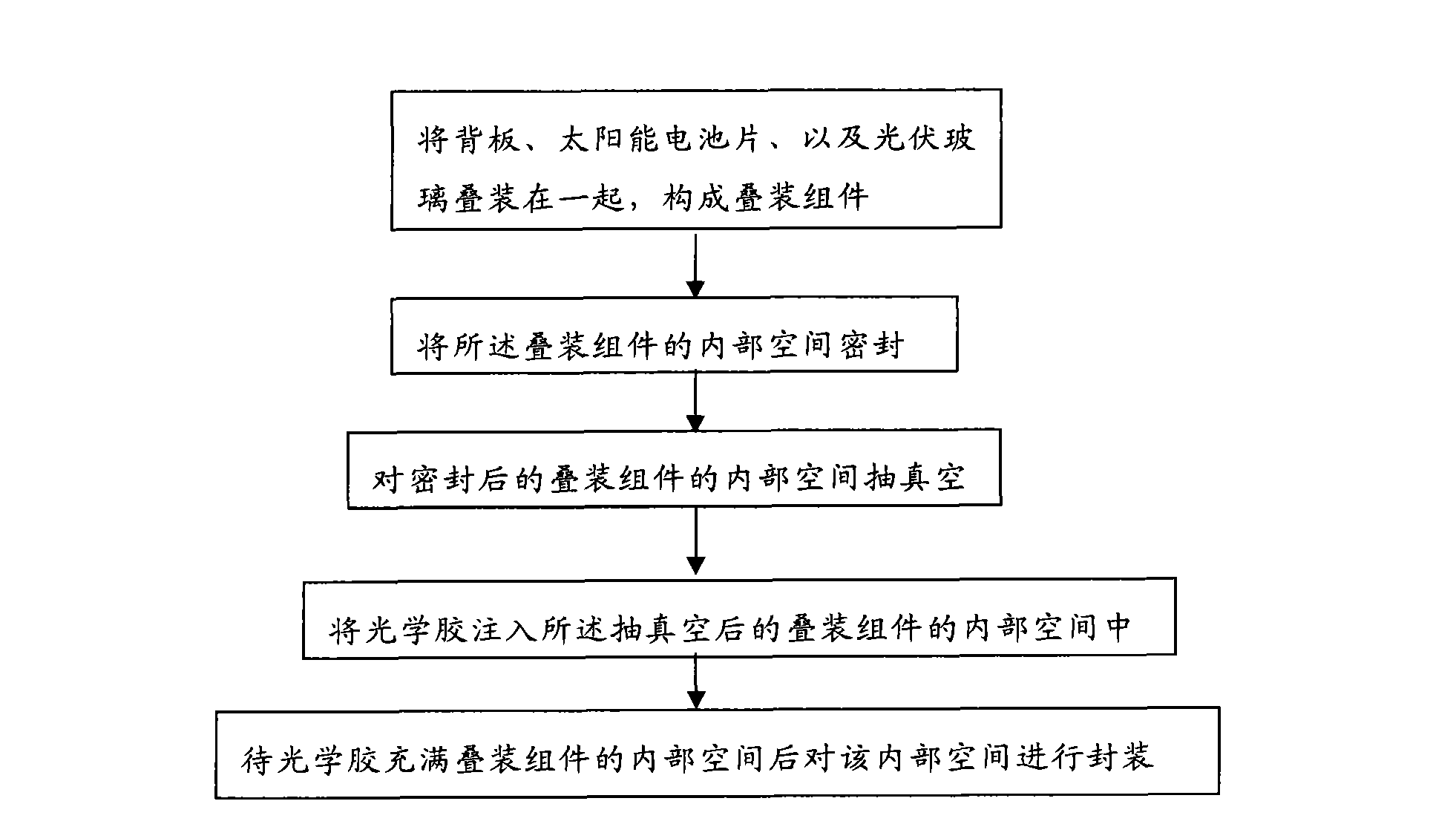

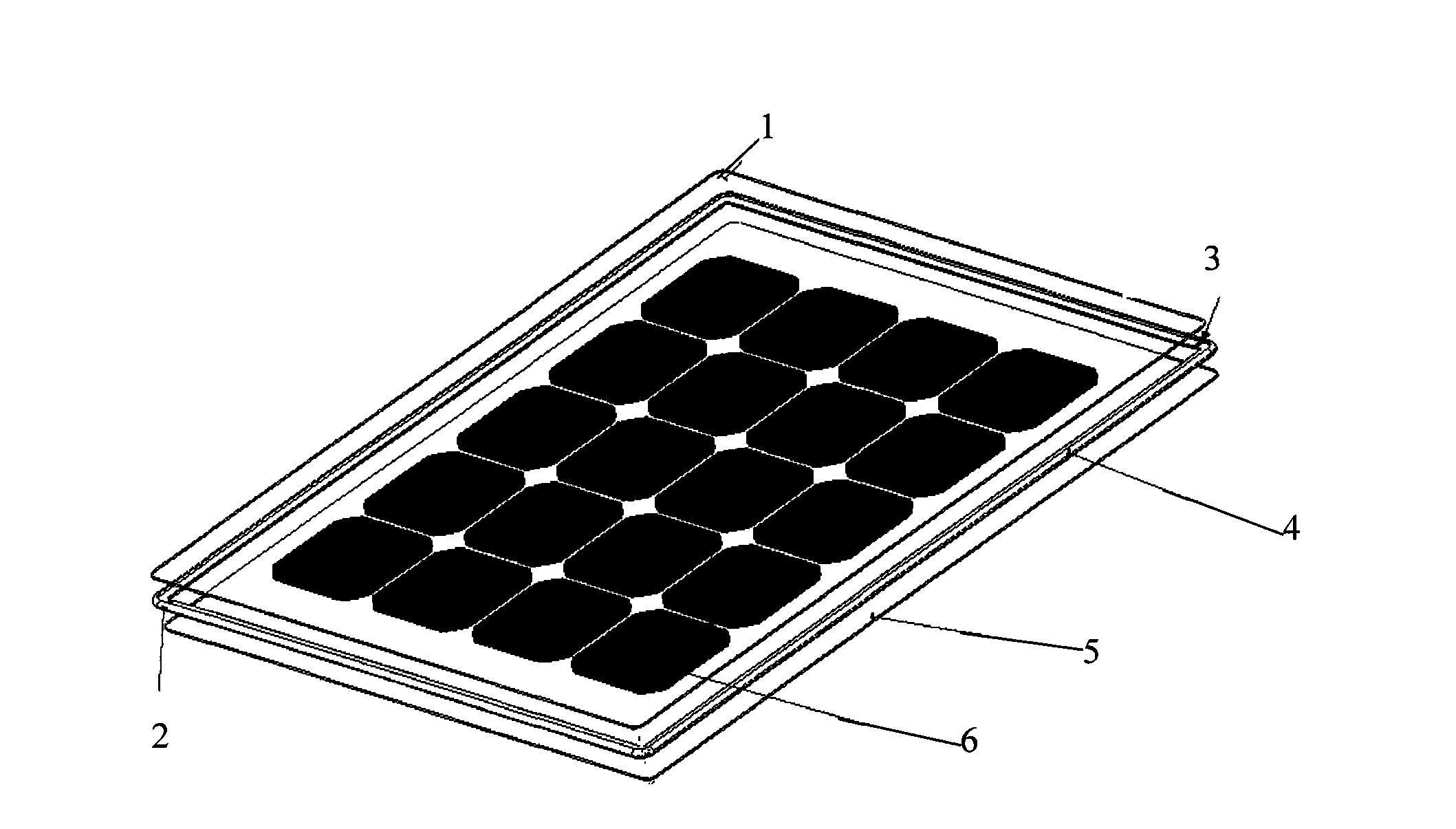

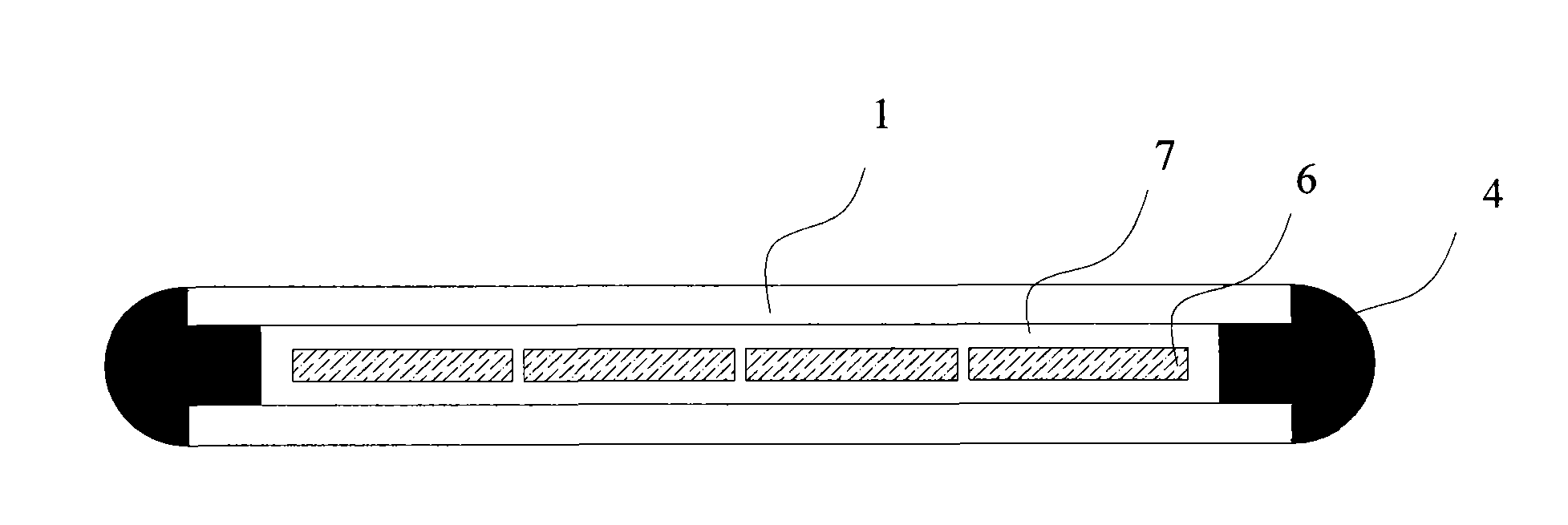

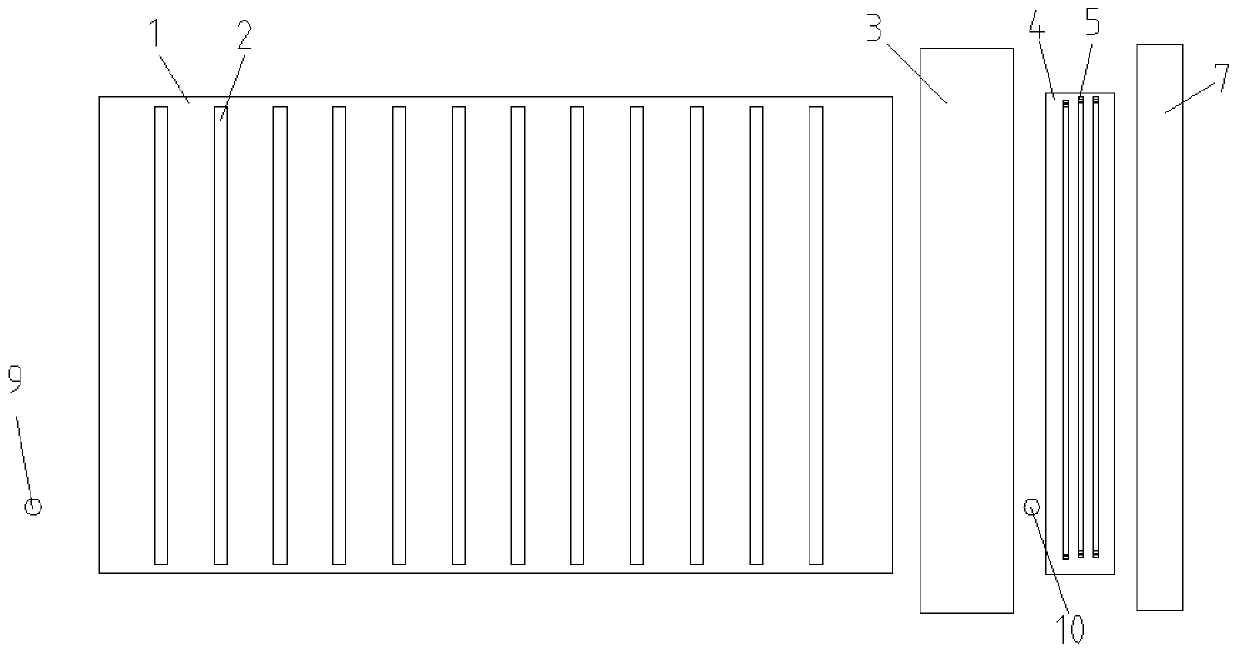

Manufacturing method of solar battery module and solar battery module

ActiveCN102496650AExpensive to solveSolve complexityFinal product manufactureLaminationVacuum pumpingElectrical battery

The invention provides a manufacturing method of a solar battery module. The method comprises the following steps: stacking a backboard, a solar battery sheet and photovoltaic glass together to form a stack assembly; (2) sealing internal space of the stack assembly; (3) carrying out vacuum-pumping on the sealed internal space of the stack assembly; (4) injecting optical cement into the internal space of the stack assembly after vacuum-pumping processing; and (5) after filling out the internal space of the stack assembly with the optical cement, sealing the internal space. Correspondingly, the invention provides a solar battery module prepared by employing the above method. The manufacturing method of the invention is simple in technology, operation time can be substantially shortened, and product yield is high.

Owner:CHERY AUTOMOBILE CO LTD

Dry laminated glass production equipment and method for producing laminated glass

The invention relates to dry laminated glass production equipment and a method for producing laminated glass. The production equipment comprises a roller furnace, an exhaust pressure roller, an edge sealing compensation furnace and an edge sealing roller which are sequentially arranged; the roller furnace includes a roller furnace body and a roller heating pipe, and the roller heating pipe is a medium wave radiation pipe; the edge sealing compensation furnace includes a compensation furnace body and compensation heating pipes located in the compensation furnace body; the compensation heating pipes are shortwave radiation pipes. By the technical scheme, the problem about film suffocation is solved, production of the laminated glass by the roller pressing process is realized and is not affected by glass thickness and glass type, and defects of the vacuum pumping production is avoided.

Owner:天津南玻节能玻璃有限公司 +1

Stacked encapsulation structure and manufacturing method thereof

ActiveCN103632988AImprove yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention provides a manufacturing method of a stacked encapsulation structure. The manufacturing method comprises the following steps that: a connection substrate is provide, wherein the connection substrate includes a substrate body and a plurality of conductive columns arranged in the substrate body; one side of a first surface of the connection substrate is provided a first encapsulation device; one side of a second surface of the connection substrate is provided with an encapsulation colloid, such that a semi-finished stacked encapsulation structure can be formed; and one side of the encapsulation colloid, which is far away from the encapsulation device, is provided with a second encapsulation device, such that the stacked encapsulation structure can be formed. The invention also relates to a stacked encapsulation structure formed through using the above method.

Owner:LEADING INTERCONNECT SEMICON TECH SHENZHEN CO LTD +2

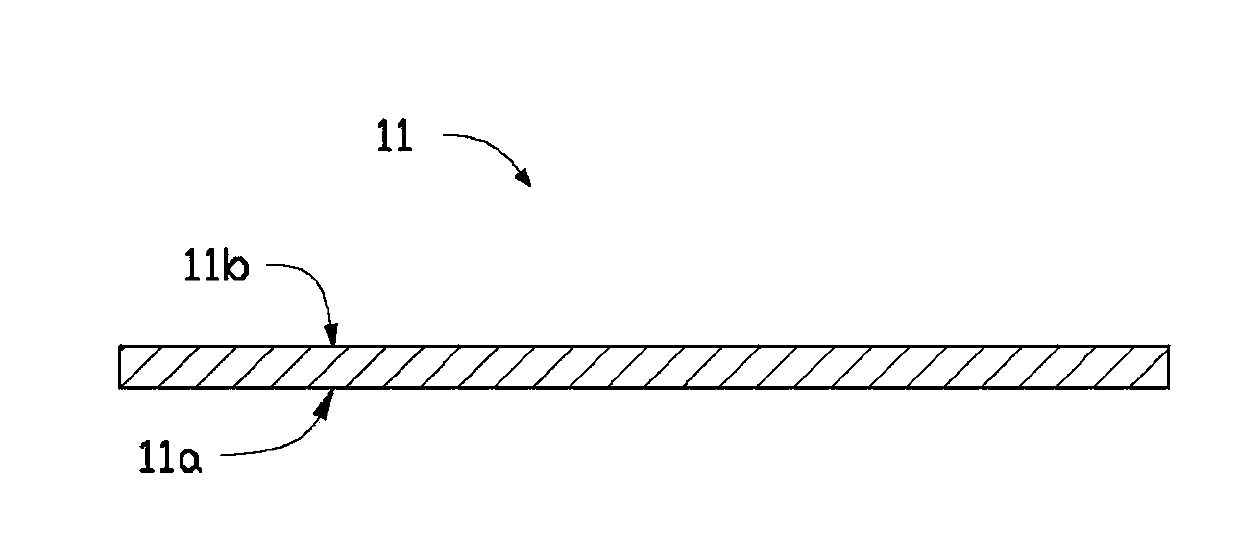

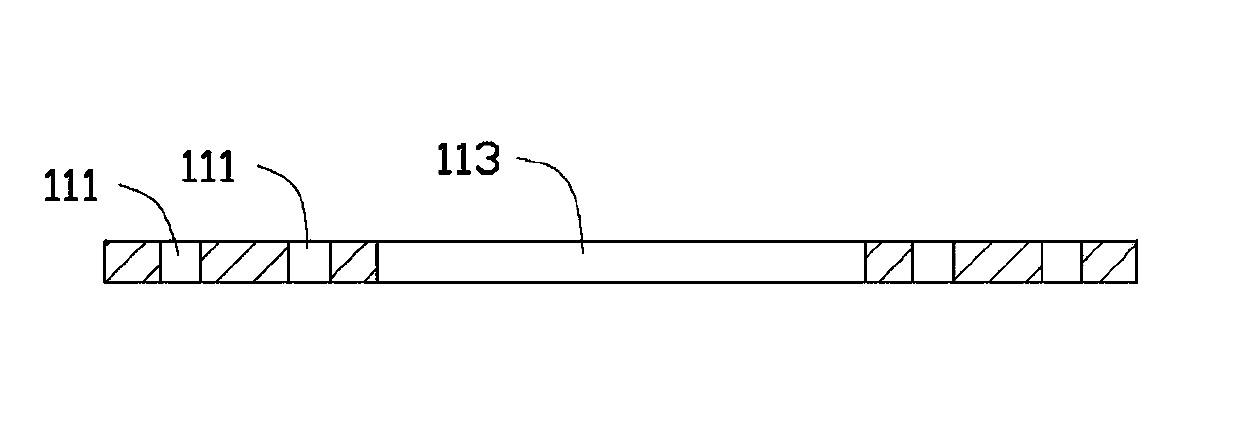

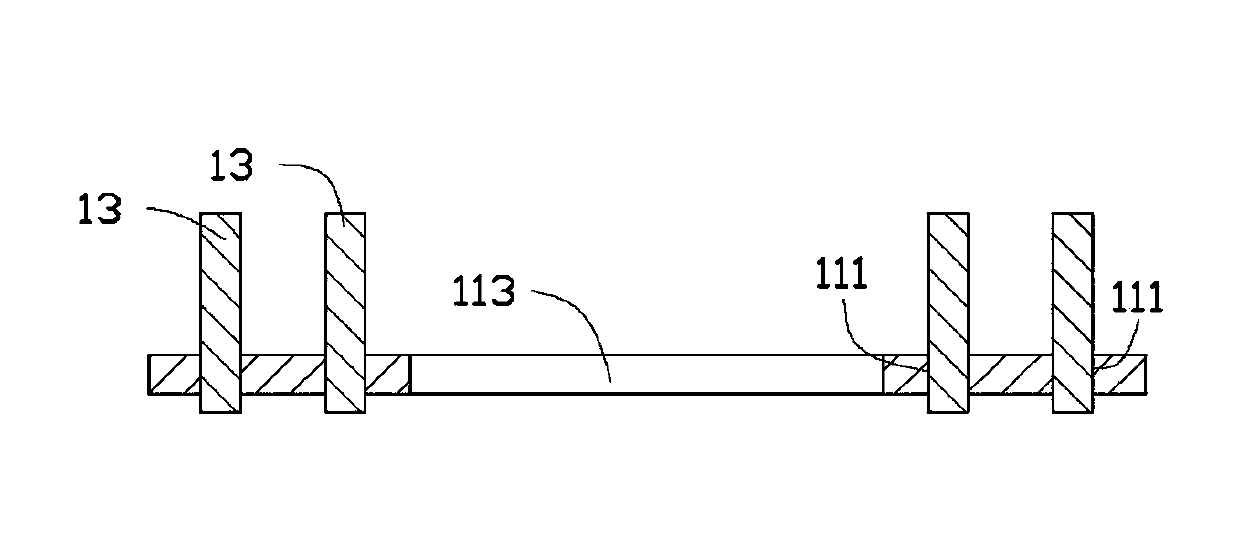

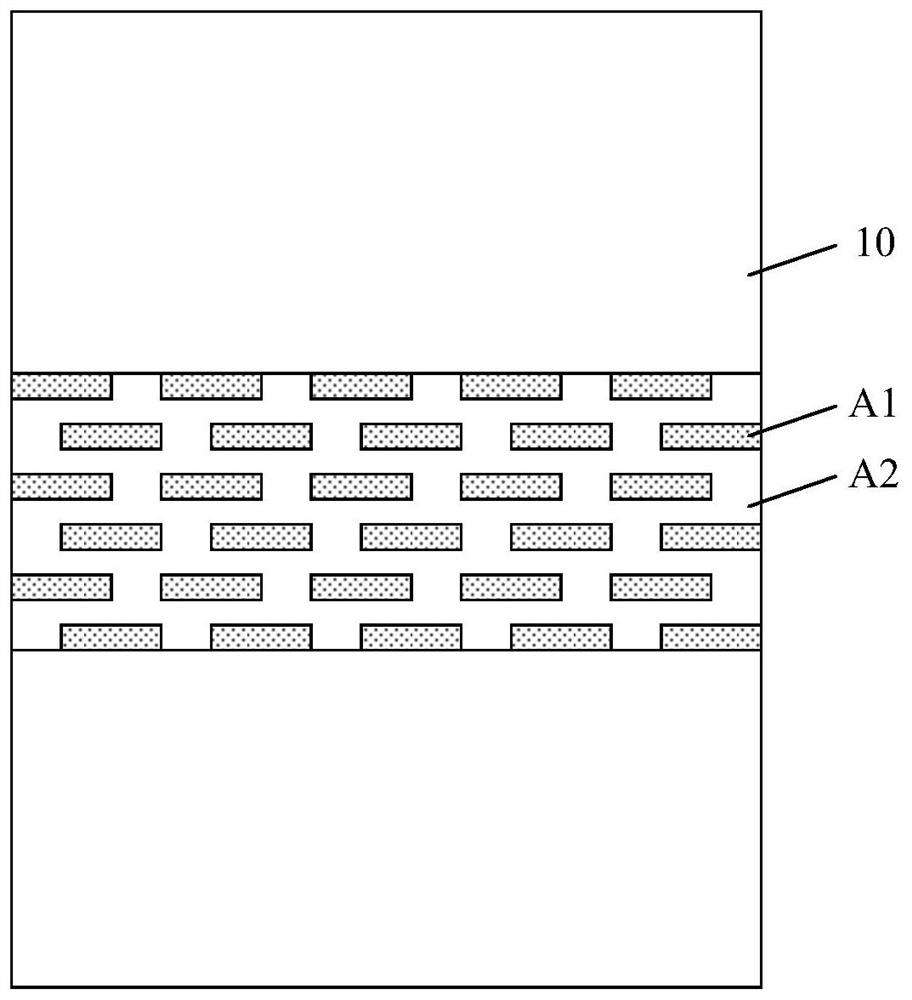

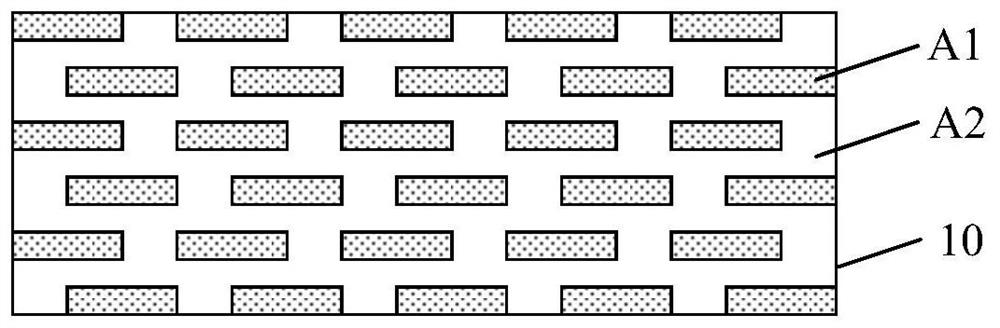

Flexible substrate and flexible display device

PendingCN111883573AReduce the probability of air bubblesImprove roll resistance to bending or slippingSolid-state devicesSemiconductor/solid-state device manufacturingComposite materialEngineering

The embodiment of the invention provides a flexible substrate and a flexible display device, and relates to the technical field of display. The flexible substrate comprises a flexible substrate and ametal support layer, wherein the metal support layer comprises a first region and a second region; the flexible substrate is stacked on the metal supporting layer, and the flexible substrate comprisesa third area corresponding to the first area and a fourth area corresponding to the second area; wherein the thickness of the first area is larger than that of the second area, and the thickness of the third area is smaller than that of the fourth area. According to the flexible substrate, the difference value of strain borne by different parts of the adhesive layer in the flexible display devicein the bending process can be reduced, so that the probability that bubbles are generated in the bending process of the adhesive layer is reduced, the anti-bending or anti-slip performance of the flexible display device is improved, and the service life of the flexible display device is prolonged.

Owner:BOE TECH GRP CO LTD

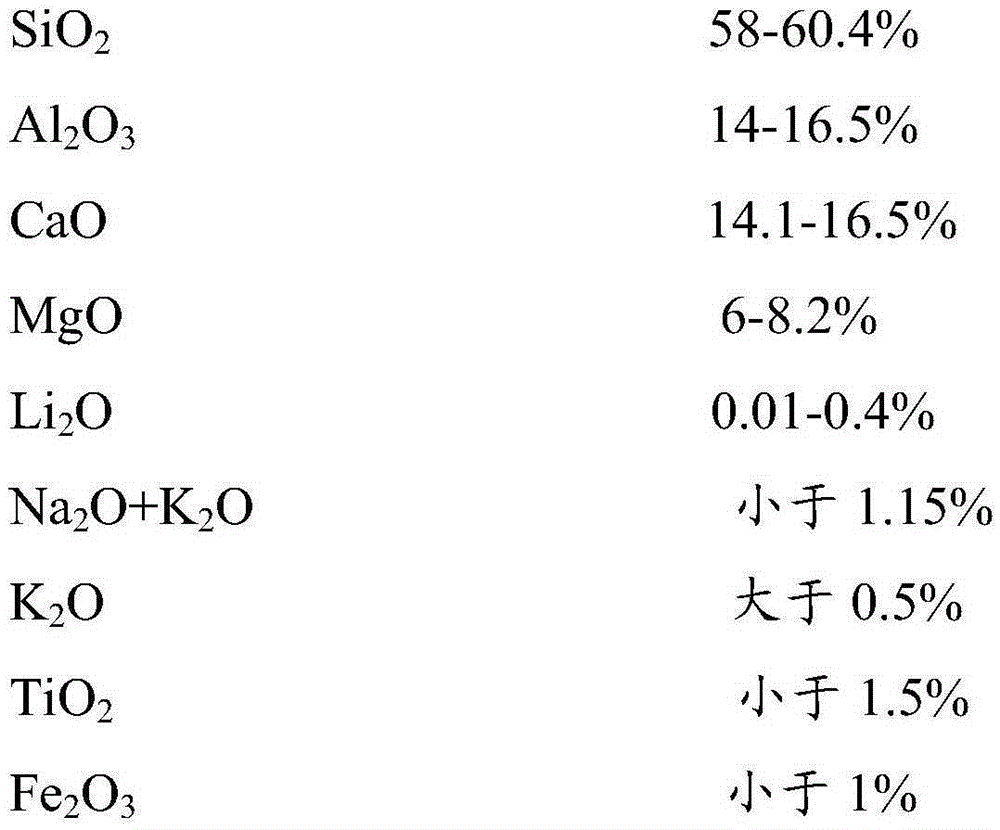

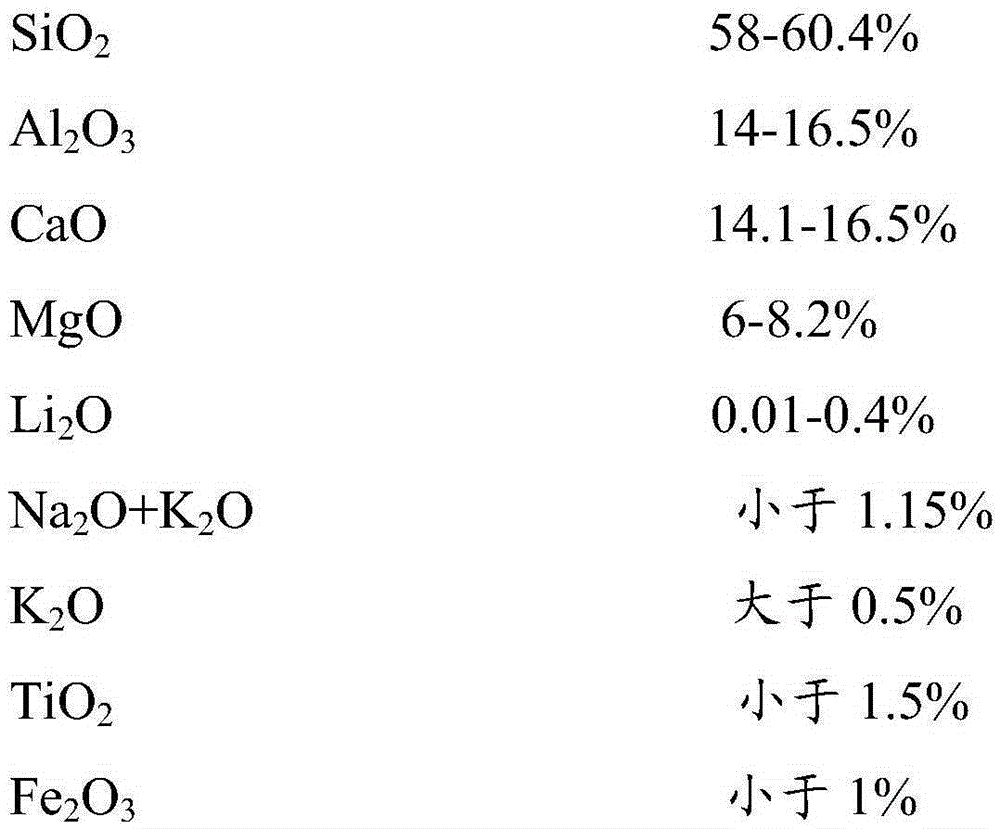

Boron-free glass fiber composition and glass fibers and composite material thereof

The invention provides a boron-free glass fiber composition and glass fibers and a composite material thereof, wherein the boron-free glass fiber composition comprises the following components in percentage by weight: 58-60.4% of SiO2, 14-16.5% of Al2O3, 14.1-16.5% of CaO, 6-8.2% of MgO, 0.01-0.5% of Li2O, less than 1.15% of Na2O + K2O, greater than 0.5% of K2O, less than 1.5% of TiO2 and less than 1% of Fe2O3; and the ratio C1=CaO / MgO of the weight percentage is greater than 2 and less than or equal to 2.4. The boron-free glass fiber composition can remarkably reduce the surface tension of glass, improves the mechanical strength and chemical resistant stability of the glass fibers, can effectively inhibit the crystallization tendency of the glass, reduces the liquidus temperature of the glass and is particularly suitable for production of high-performance glass fibers with low bubble rates.

Owner:JUSHI GRP CO

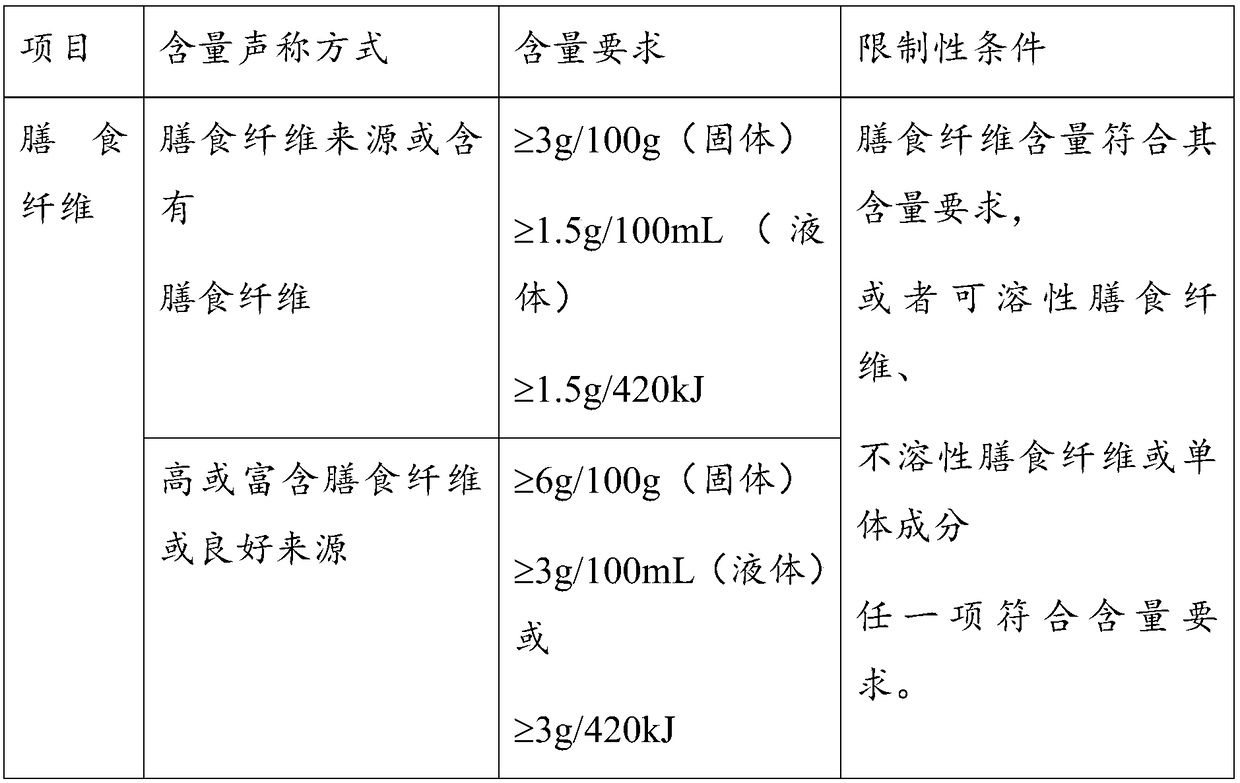

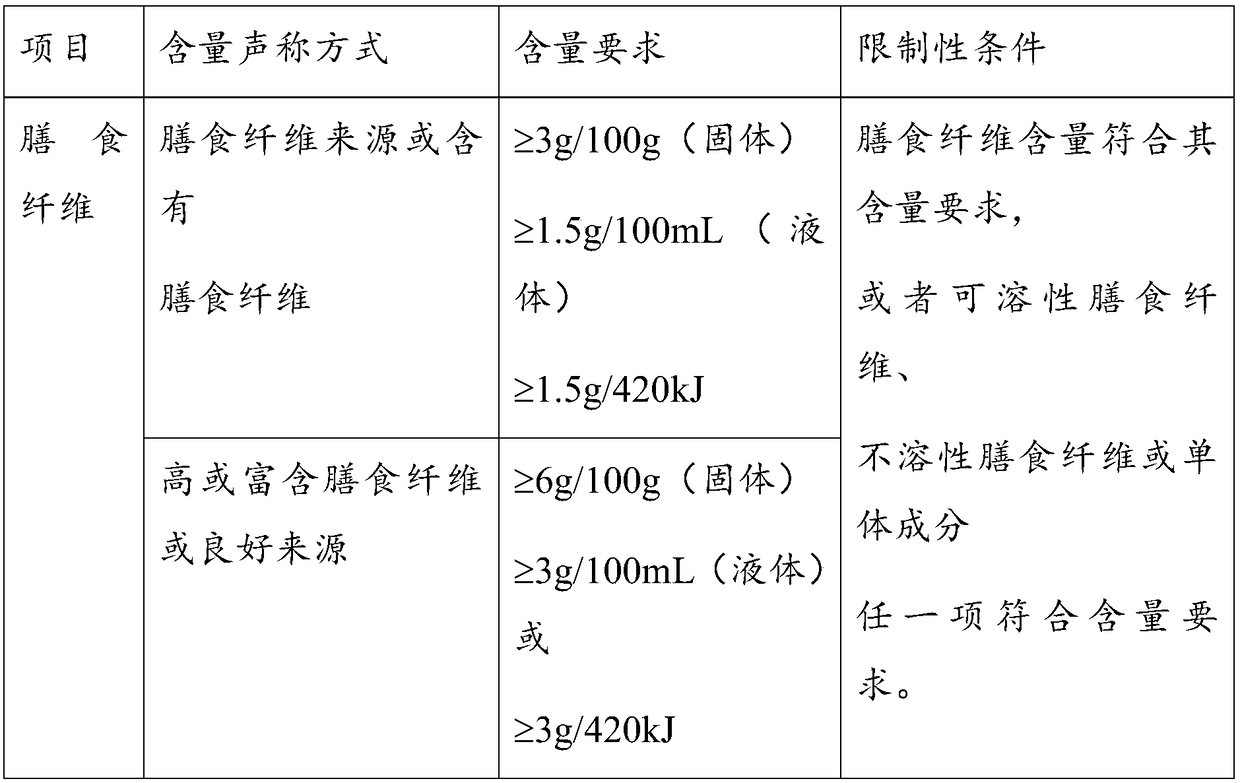

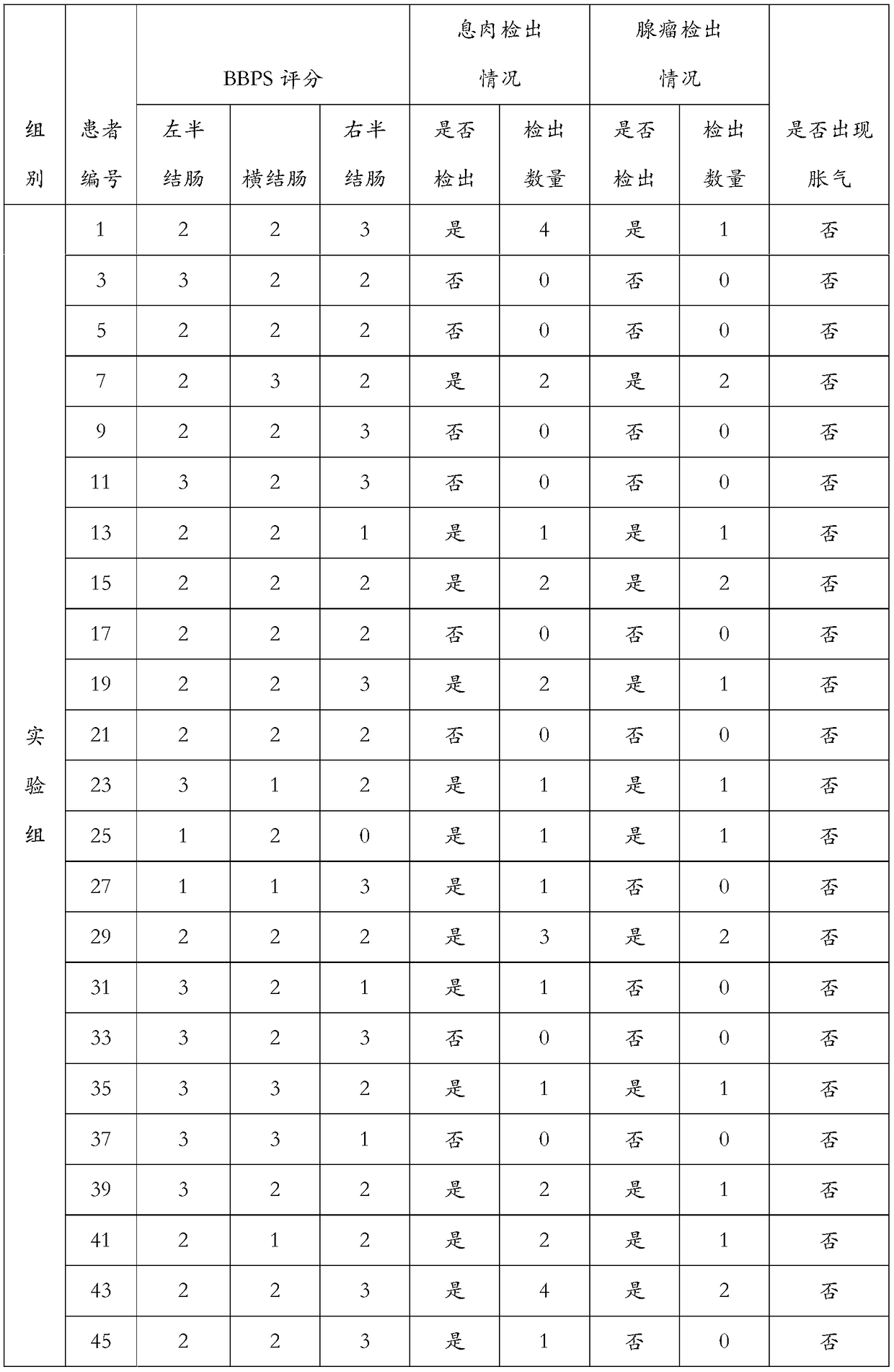

Pea protein low-residue nutritional formula product and preparation method and application thereof

ActiveCN108783459AEasy to cleanAvoid flatulenceVitamin food ingredientsFood ingredient functionsProduction rateDietary fiber

The invention provides a low-residue nutritional formula product and a preparation method and application thereof. The product does not contain dietary fibers and is applicable to patients who need toget intestinal tract cleaning preparation for performing intestinal tract inspection and intestinal tract operations. The product contains protein, carbohydrates, fat, minerals and vitamins, and theprotein selects pea protein with lower anti-nutritional factors. Compared with a conventional intestinal tract cleaning mode, the intestinal tracts treated by the product provided by the invention have high cleanliness, high detection rate of adenomas and polyp of the intestinal tracts, low gas production rate, good nutrient support and high patient suitability.

Owner:北京麦孚医学科技有限公司 +2

Chemical reaction kettle for solid-liquid reaction

InactiveCN112604639AEasy to recycleEasy to cleanProcess control/regulationChemical/physical/physico-chemical stationary reactorsChemical reactionElectric machinery

The invention discloses a chemical reaction kettle for solid-liquid reaction, and particularly relates to the technical field of chemical equipment, the chemical reaction kettle comprises a kettle body, support legs are fixedly connected to two sides of the bottom end of the kettle body, a liquid outlet pipe is fixedly connected to the middle of the bottom end of the kettle body, and a water tank is fixedly connected to one side of the kettle body. The spraying mechanisms are arranged on the two sides of the interior of the kettle body, and a connecting base is fixedly connected to the top end of the kettle body. By arranging a material homogenizing plate, a feeding port, a fixed seat, a driving motor and a first connecting rotating shaft, when the reaction kettle is used, materials are poured in from the feeding port and enter the kettle body through the fixed seat, the driving motor is started, the driving motor drives the material homogenizing plate to rotate through the first connecting rotating shaft, and the material homogenizing plate is in a windmill shape and has the effect of uniformly conveying the materials; and the multiple sets of material uniformizing plates are arranged at equal intervals, the situation that too many materials are poured at a time, and a discharging opening formed in the bottom of the fixing base is blocked is avoided, and the use efficiency of equipment is improved.

Owner:黄声宇

Marine fish oligopeptide low-residue nutritional formula product and preparation method and application thereof

ActiveCN109043505AGood cleaning prepReduce the incidence of infectionFood ingredient functionsPatient needDietary fiber

The invention provides a low-residue nutritional formula product and a preparation method and application thereof. The product is not added with dietary fibers and is suitable for patients needing toundergo intestinal cleaning preparation for intestinal examination and intestinal surgery. The product contains protein, carbohydrate, fat, minerals and vitamins, marine fish oligopeptide with smallermolecular weight is adopted to replace collagen, nutrient ingredients which can be more easily absorbed are provided while ultralow residue is kept, and thereby, while the intestines are cleaned andthe production of intestinal gas is reduced, sufficient nutrition is provided for patients. Compared with the conventional intestinal cleaning method, the preparation method provided by the inventionhas the following advantages that the cleanliness of the intestines treated by the produced disclosed by the invention is high, the intestinal adenoma and polypus detection rate is high, the amount ofproduced gas is small, nutritional support is good, and the applicability to patients is high.

Owner:麦孚营养科技(北京)有限公司 +1

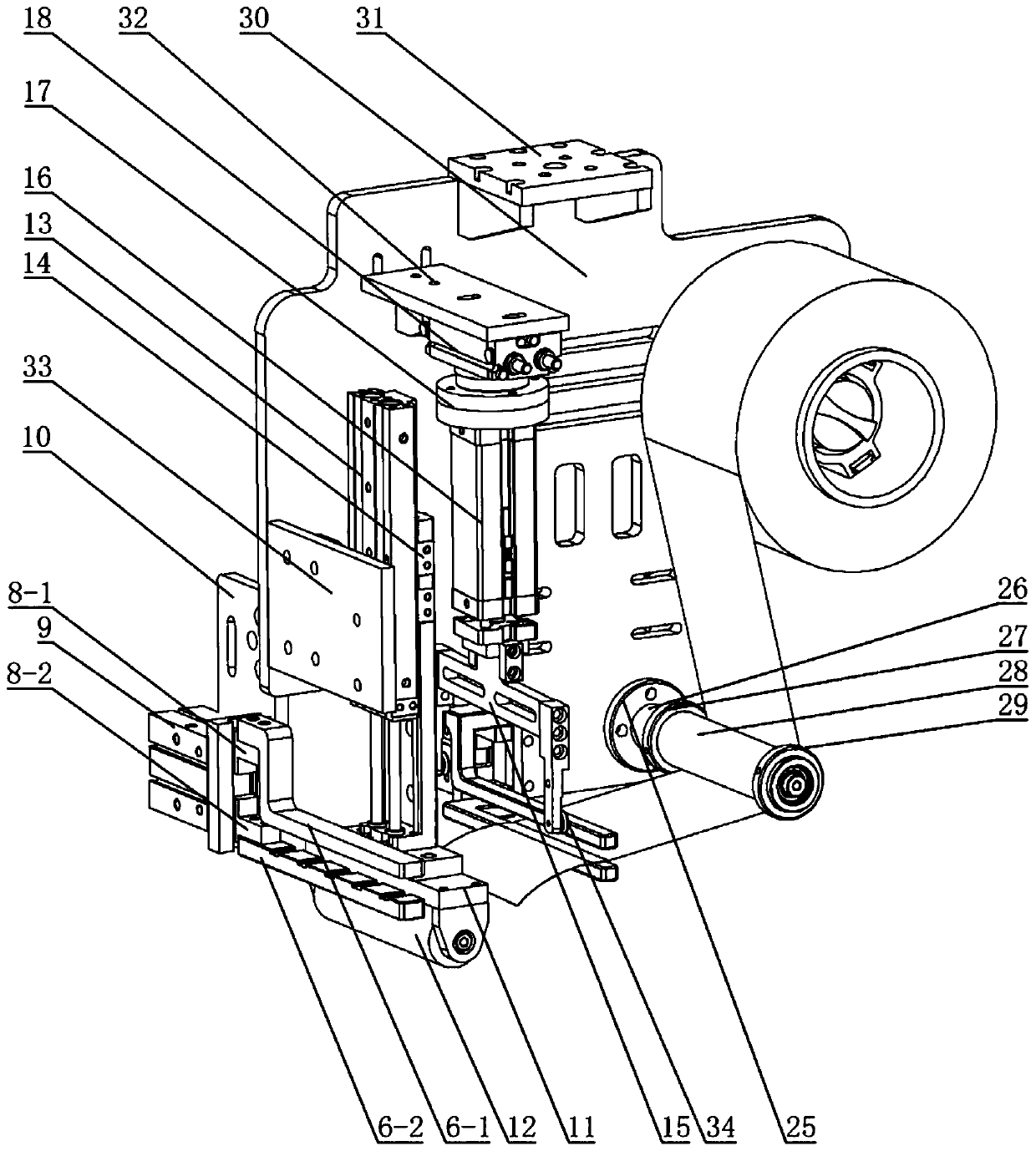

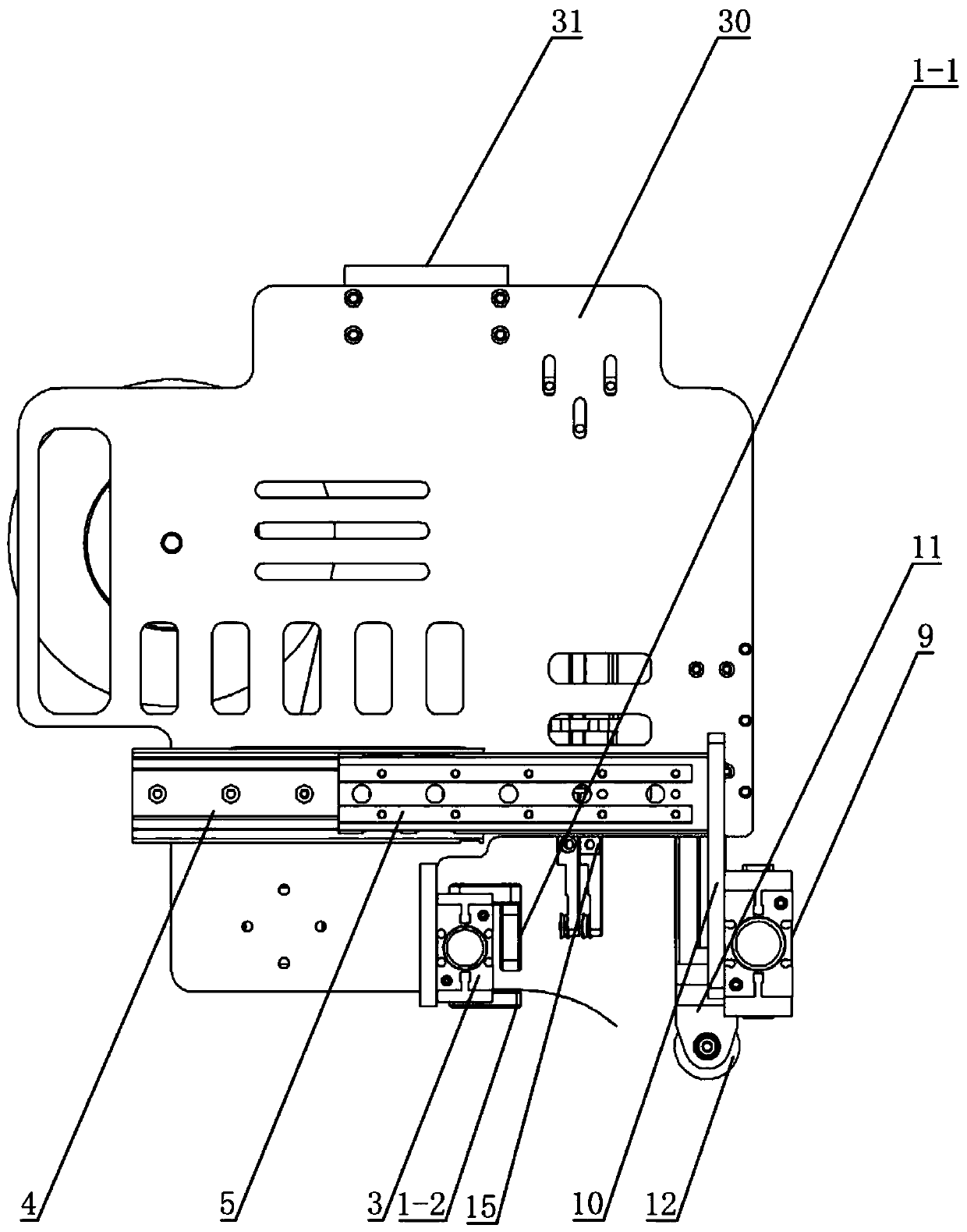

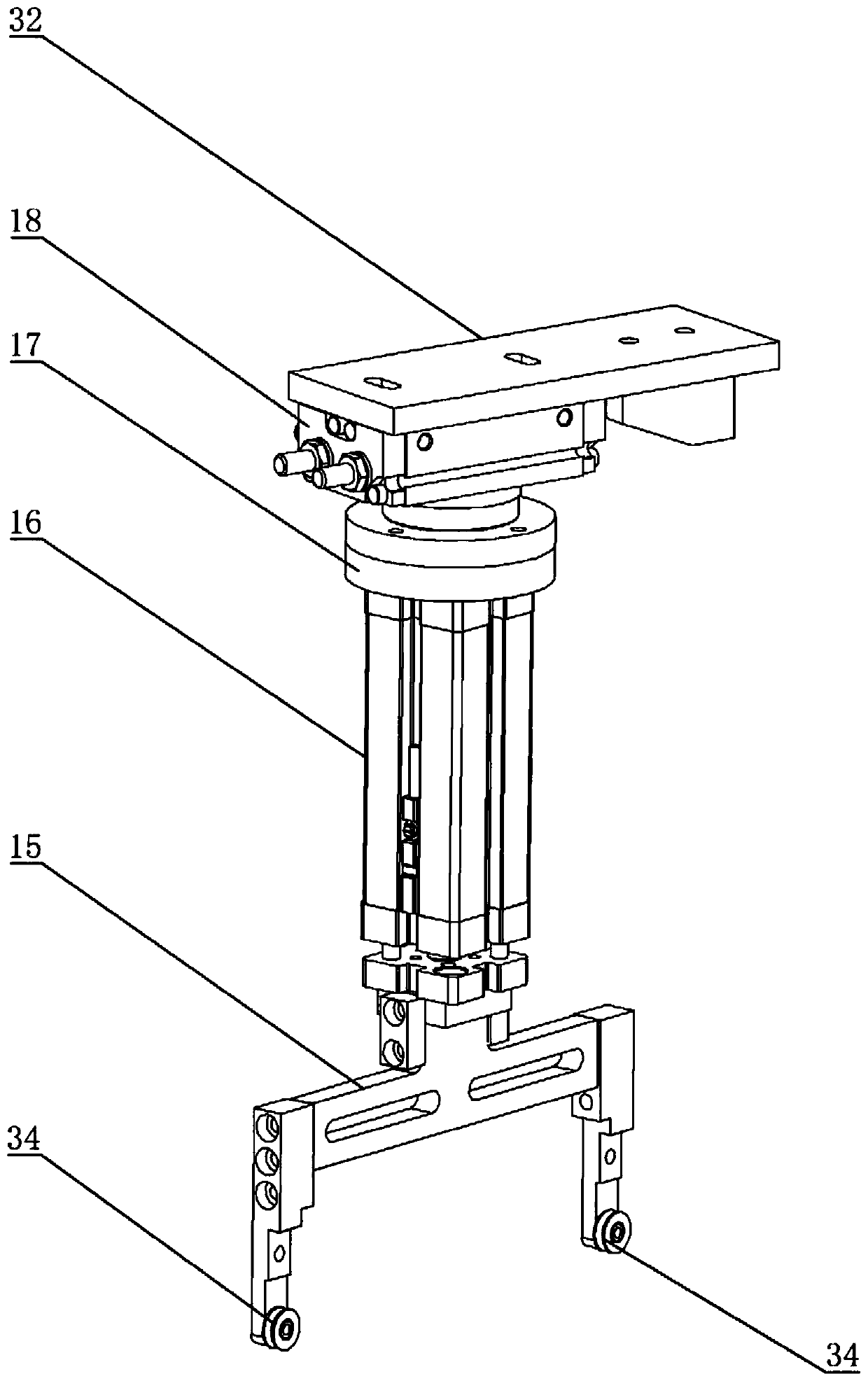

Film pasting combination device

InactiveCN109849321AReduce the probability of air bubblesLarge rotation angleEngineeringMechanical engineering

The invention discloses a film pasting combination device. The film pasting combination device comprises a clamping device, wherein the clamping device comprises a first clamping mechanism and a second clamping mechanism. The film pasting combination device is characterized in that a shaping device is arranged between the first clamping mechanism and the second clamping mechanism; the shaping device comprises a pressure applying mechanism and a cutting mechanism; and a material conveying device is arranged in the feeding direction of the clamping device. High automatic equipment is developed and designed for pasting films on high-gloss curved products, and a heat cutter mechanism is additionally arranged, so that the problems that broken surfaces are not balanced and the cutter is easily consumed are overcome; and secondly, materials of pressure-applying rollers for film pasting are changed, rotation angles of the pressure-applying rollers are increased, a film pasting effect is obviously promoted, a film-pasting finished product ratio is correspondingly improved, and a bubble ratio caused in a film pasting process is obviously reduced.

Owner:浙江君睿智能装备有限公司

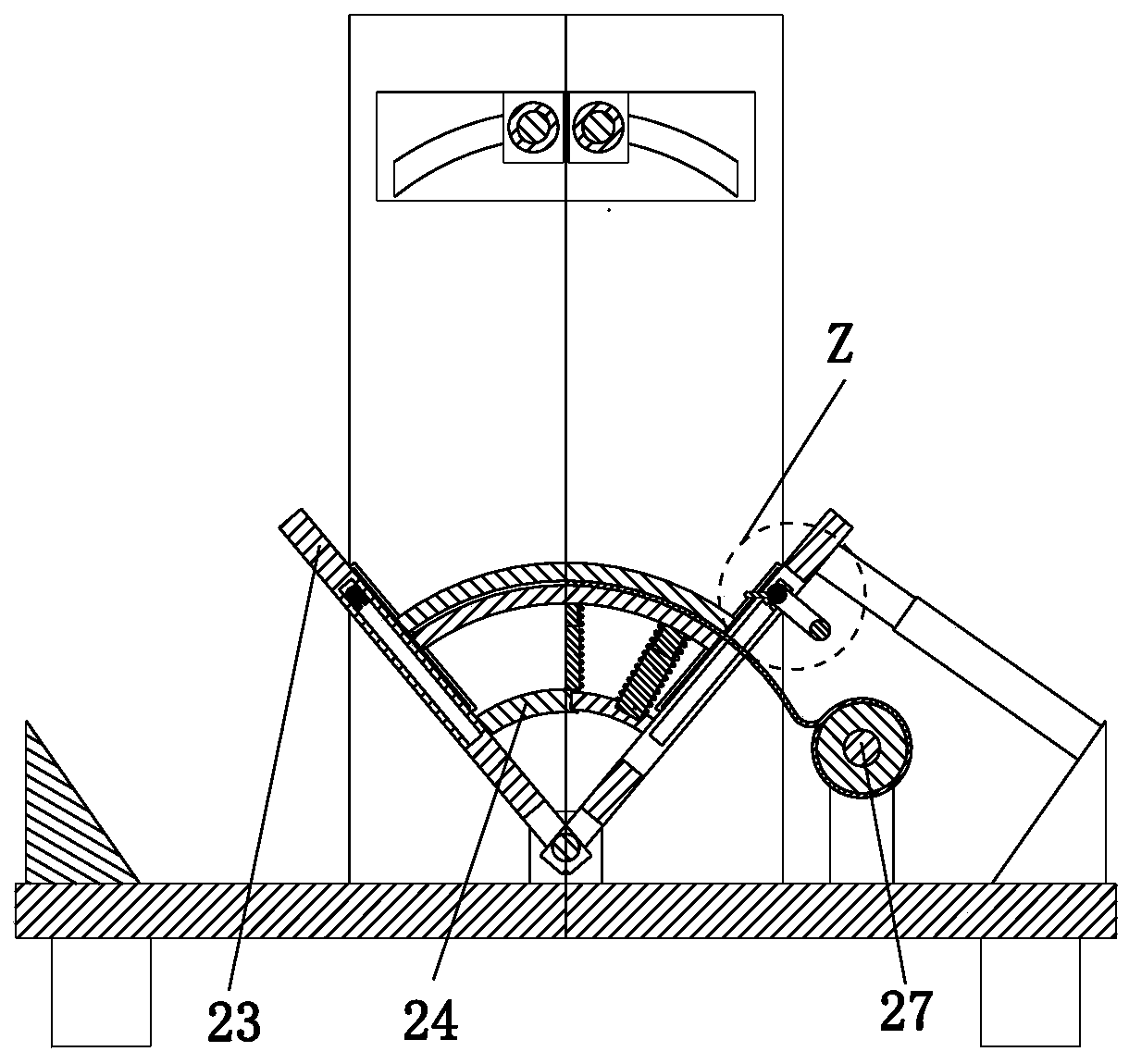

Auxiliary clamp tool for laminated glass production and processing

ActiveCN110978725AHigh forming precisionIncrease profitLaminationLamination apparatusWorkbenchIndustrial engineering

The invention relates to an auxiliary clamp tool for laminated glass production and processing. The tool comprises a workbench, a clamping and fixing device and a rolling device, the clamping and fixing device is installed on an upper end face of the workbench, the rolling device is arranged on a rear side of the clamping device, and the rolling device is installed on an upper end face of the workbench. According to the auxiliary clamp tool for laminated glass production and processing, a V-shaped adjustable design concept is adopted for processing laminated glass, a clamp is of a V-shaped structure and can adapt to clamping and fixing of curved laminated glass, meanwhile, the middle angle of the clamp can be accurately controlled, the clamp can adapt to clamping of laminated glass raw sheets of different thicknesses and sizes, the laminated glass forming precision is improved, and the equipment utilization rate is increased.

Owner:广西远大玻璃节能科技股份有限公司

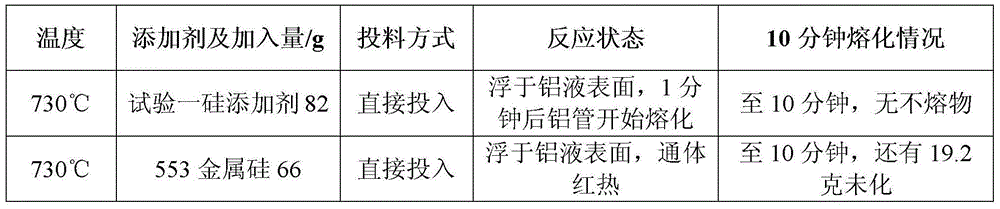

Silicon additive for melting and casting aluminum alloy and preparation method of silicon additive

The invention discloses a silicon additive for melting and casting an aluminum alloy and a preparation method of the silicon additive, and aims at solving the problems that the practical yield is low, components cannot be adjusted precisely and a great deal of energy is consumed as the ordinary silicon element is easy to oxidize when the aluminum alloy is molten and smelted. The silicon additive consists of silicon powder, a pure aluminum tube and a pure aluminum foil. The preparation method comprises the following steps: sealing one end of the pure aluminum tube by using the pure aluminum foil, filling the pure aluminum tube with the silicon powder from the other end of the pure aluminum tube, and further sealing by using the pure aluminum foil, thereby obtaining the silicon additive. The silicon additive disclosed by the invention is low in melting temperature, that is, the silicon additive can be completely molten at 730 DEG C; the melting speed is high, that is, the melting speed is 25-30% higher than that of a metal silicon block which is used at present; the practical yield of the silicon additive is high, that is, the practical yield of the prepared silicon additive is greater than 90%; an aluminum alloy which is uniform and precise in components is easy to prepare, and the silicon additive is environment-friendly and pollution-free when being used as no element such as potassium, sodium or fluorine is added.

Owner:哈尔滨东盛金材科技(集团)股份有限公司

Soybean protein isolate low-residue comprehensive nutritional formula product and preparation method and application thereof

ActiveCN108783438AGood cleaning prepReduce the incidence of infectionVitamin food ingredientsInorganic compound food ingredientsProduction rateFood borne

The invention provides a low-residue comprehensive nutritional formula product and a preparation method and application thereof. The product does not contain dietary fibers and is applicable to patients who need to get intestinal tract cleaning preparation for performing intestinal tract inspection and intestinal tract operations. The product contains protein, carbohydrates, fat, minerals and vitamins, does not contain food-borne gas-producing components, contains extremely low residue, contains rich and absorbable nutritional components, and can provide the patients with sufficient nutrientswhile cleaning and reducing gas production in intestinal tracts. Compared with a conventional intestinal tract cleaning mode, the intestinal tracts treated by the product provided by the invention have high cleanliness, high detection rate of adenomas and polyp of the intestinal tracts, low gas production rate, good nutrient support and high patient suitability.

Owner:北京麦孚医学科技有限公司 +2

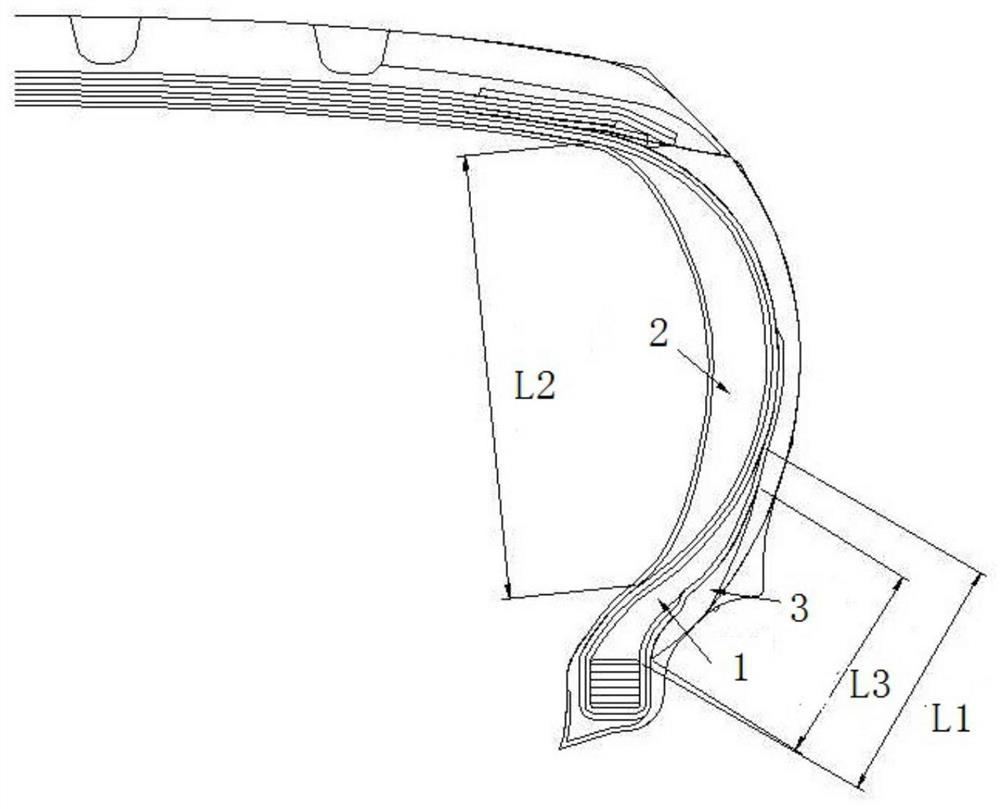

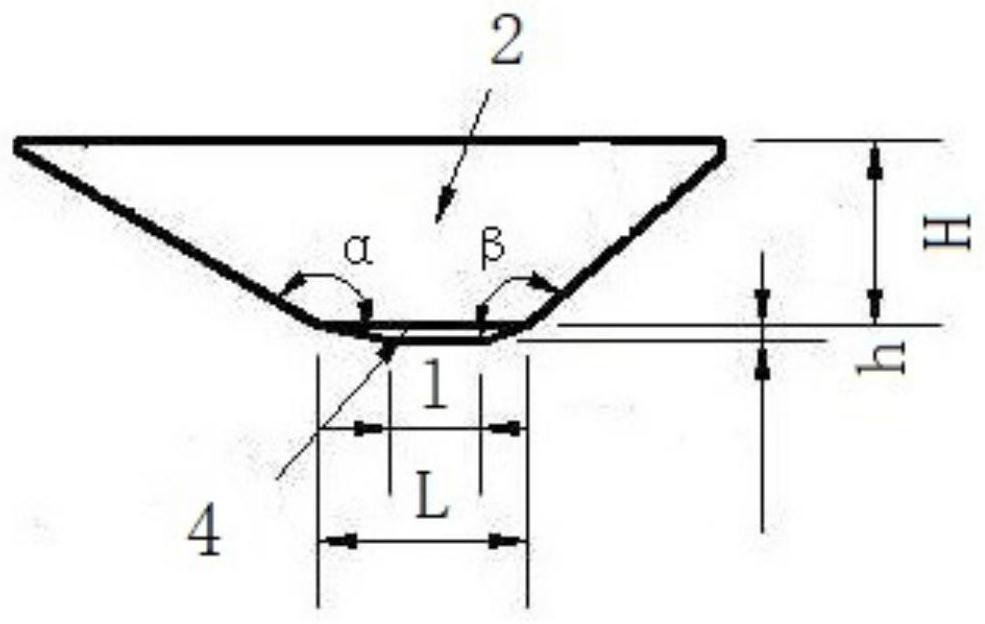

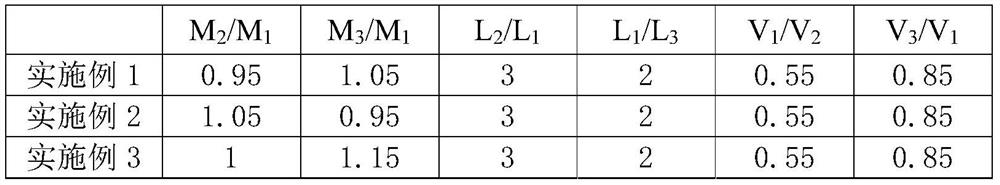

Run-flat tire with excellent performance

The invention discloses a run-flat tire with the excellent performance. The run-flat tire comprises a lining layer, a tire body, a tire sidewall and a tire bead. The tire bead comprises bead filler and a steel ring, the tire sidewall comprises tire sidewall wear-resistant rubber, and supporting rubber is arranged between the lining layer at the tire sidewall and the tire body; the elastic modulusM1 of the bead filler, the elastic modulus M2 of the supporting rubber and the elastic modulus M3 of the sidewall wear-resistant rubber are set to meet the following relations: 0.85 < = M2 / M1 < = 1.15and 0.85 < = M2 / M3 < = 1.15; the distance L1 from the upper end point to the lower end point of the bead filler, the distance L2 from the upper end point to the lower end point of the supporting rubber and the distance L3 from the upper end point to the lower end point of the sidewall wear-resistant rubber are set to meet the following relations: 2.5<= L2 / L1 <=3.5 and1.5<= L1 / L3 <=2.5. The durability of the tire is improved by limiting the supporting rubber, the bead filler and the wear-resistant rubber,.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

Straw-containing wood-plastic outdoor floor and production method thereof

The invention relates to a formula of a straw-containing wood-plastic outdoor floor and a production method of the straw-containing wood-plastic outdoor floor.The straw-containing wood-plastic outdoor floor comprises, by weight, 100 parts of recycled polypropylene plastics, 150-200 parts of wheat straw wood fiber, 1-3 parts of maleic anhydride grafted polypropylene, 2-5 parts of activated calcium carbonate, 1-3 parts of vinyl amine distearate, 2-8 parts of flake graphite, 1-8 parts of nano-zinc oxide, 10-15 parts of glass fiber, 2-10 parts of ultraviolet absorber UV-327, 5-8 parts of light stabilizer GW-944, 3-12 parts of antioxidant 2,6-tert-butyl-4-methylphenol and 3-6 parts of iron oxide red.The production method includes subjecting wheat straws to airing, impurity removing, pulverizing, screening and drying, subjecting the polypropylene plastics to washing, airing and cutting, drying the auxiliaries, and performing melting, hot pressing and cooling so as to obtain the outdoor floor.The straw-containing wood-plastic outdoor floor is high in durability and ageing resistance and free of natural defects of wood and can be recycled.

Owner:河南金土地科技服务有限公司

A kind of photothermal dual curing poe encapsulation adhesive film for photovoltaic and preparation method thereof

ActiveCN111117498BImprove lamination efficiencyReduce energy consumptionFilm/foil adhesives without carriersPhotovoltaic energy generationElastomerPolymer science

The invention discloses a photothermal dual curing POE encapsulation film for photovoltaics and a preparation method thereof. The encapsulation film comprises the following components: POE polyolefin elastomer, free radical thermal initiator, photoinitiator, acrylamide auxiliary Crosslinking agent, acrylate co-crosslinking agent, light stabilizer, antioxidant, macromolecular coupling agent, tackifying resin, defoaming agent and leveling agent. The encapsulating adhesive film of the invention can realize rapid low-temperature curing, and has the advantages of high light transmittance, high adhesive force, low shrinkage rate, low water permeability, no bubbles, high efficiency, low cost, easy rework and the like after lamination, and is suitable for For high-efficiency battery modules that are sensitive to temperature or have high requirements for packaging speed, due to the compounding of POEs with different melt indices, the fluidity is improved, the bubble rate is reduced, and at the same time, it ensures that no glue overflow and the offset of the battery string spacing occur; large The molecular coupling agent is added by chemical grafting, which improves the long-term bonding reliability.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

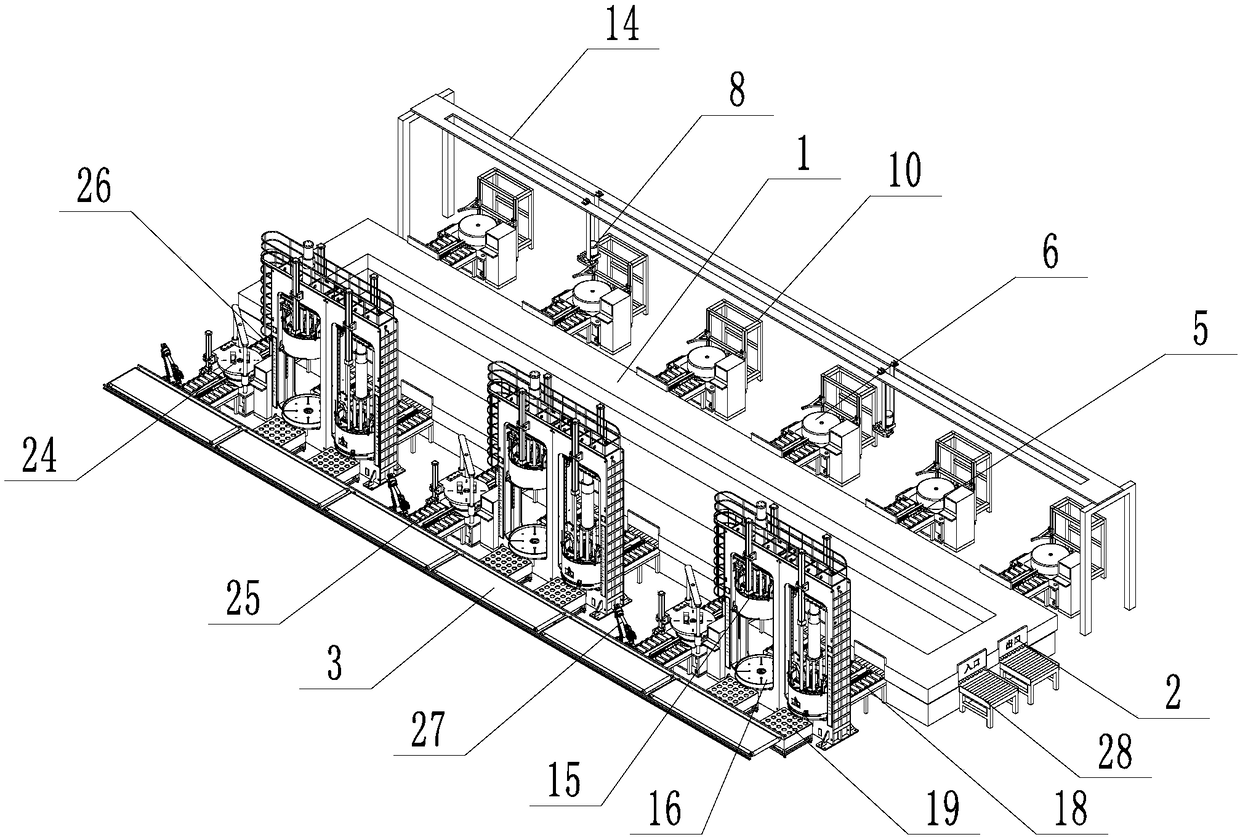

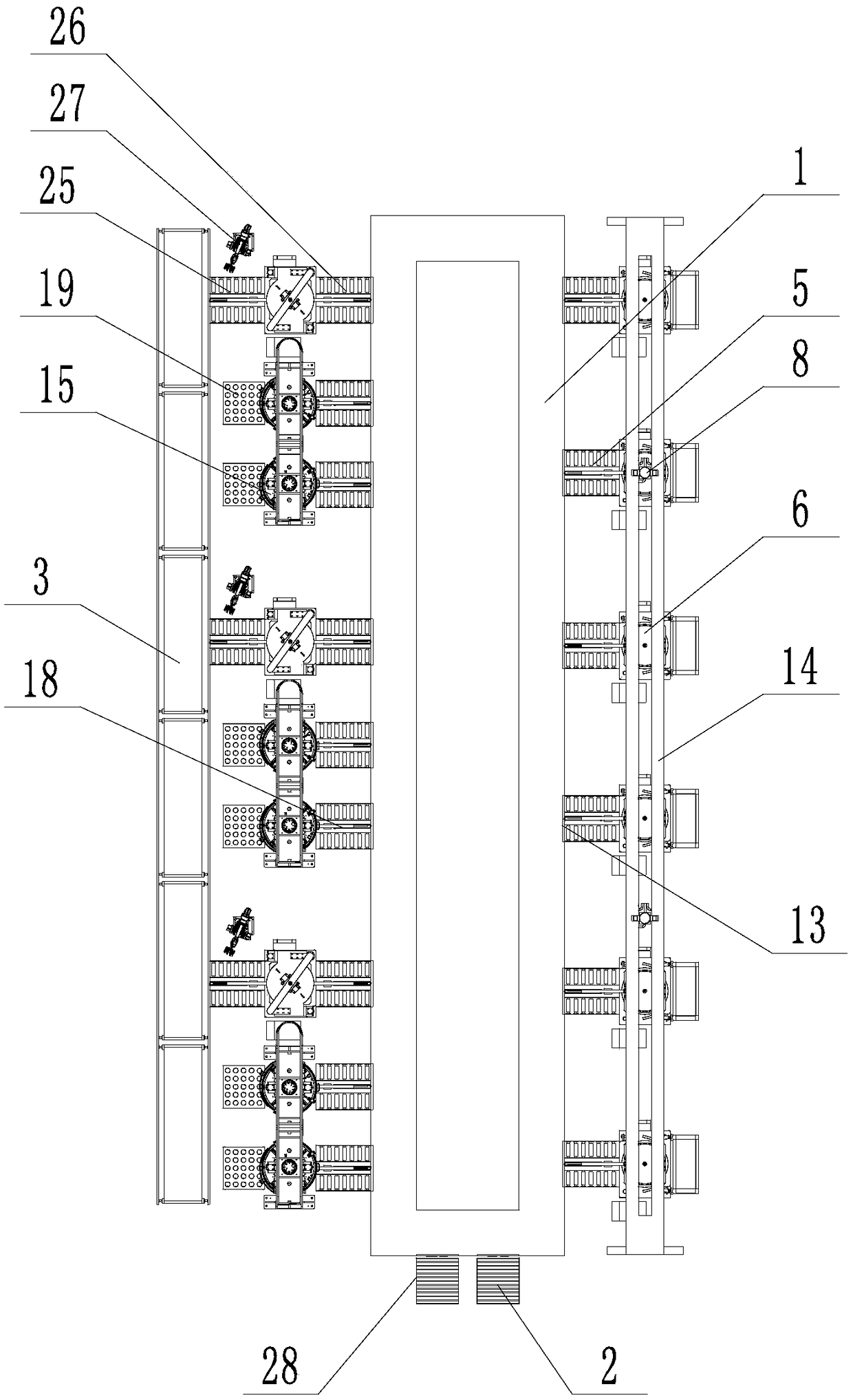

Rubber and plastic product continuous production system and production method

ActiveCN108908823AReduce the probability of air bubblesImprove product qualityProduction lineOperability

The invention provides a rubber and plastic product continuous production system and a production method. The production system comprises an insulation conveying ring line for conveying empty molds, an inlet mold conveying door arranged on the insulation conveying ring line and used for conveying the empty molds to the insulation conveying ring line, a vacuum pouring device arranged on one side ofthe insulation conveying ring line, and a mold opening and closing device and a vulcanizing device arranged on the other side of the insulation conveying ring line; and a product conveying line for conveying vulcanized rubber and plastic products is arranged on one sides of the mold opening and closing device and the vulcanizing device. The insulation conveying ring line, the vacuum pouring device, the mold opening and closing device and the vulcanizing device are reasonably arranged in sequence, and the connecting operation of all the devices is scientific and reasonable, so that the operability is high, and the efficiency is high; and the whole production line is controlled by a controller in an unified manner, and an unmanned factory is built, so that the intelligence degree is high, the labor cost is saved, the working efficiency is high, and the product quality is effectively guaranteed.

Owner:青岛海琅智能装备有限公司

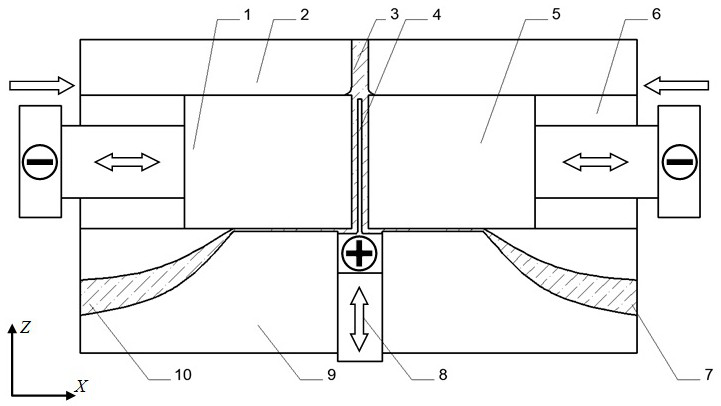

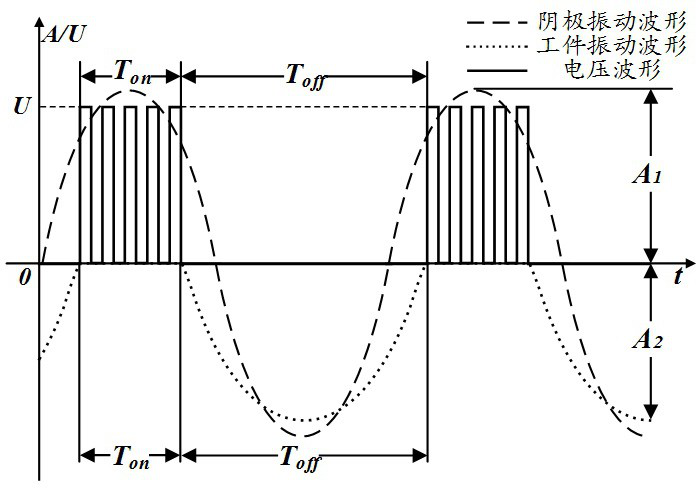

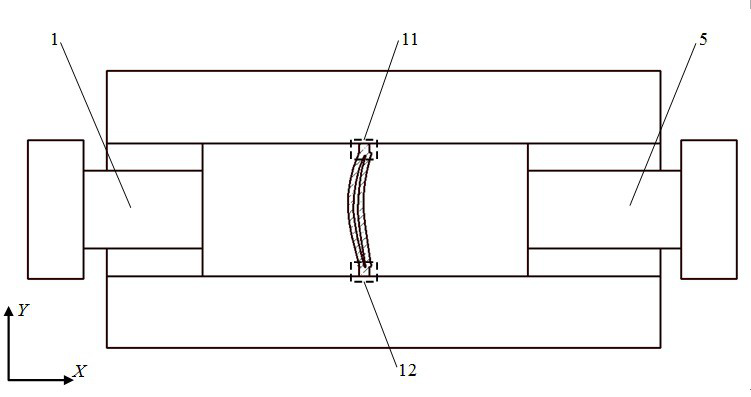

Cathode and workpiece cooperative pulse dynamic precise electrolytic machining method

PendingCN113245646AImprove uniformityVelocity increasesElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentMachining

The invention relates to a cathode and workpiece cooperative pulse dynamic precise electrolytic machining method, and belongs to the technical field of electrolytic machining. The device is mainly characterized in that a workpiece is vertically mounted in a clamp, a blade basin cathode and a blade back cathode perform reciprocating vibration while being fed oppositely, and the workpiece performs cooperative vibration in the vertical direction. The tool cathodes on the two sides are always fed oppositely, in a single dissolution period, a power source is applied when the tool cathodes vibrate to be close to the workpiece, the workpiece is located at the machining position, and the material is dissolved. When power is cut off, the cathodes on the two sides vibrate and return, the workpiece also vibrates and returns in the vertical direction, materials are not dissolved, and electrolysis products are discharged. Through vertical installation of the workpiece, the bubble discharging speed can be increased, the bubble rate at an outlet is reduced, and the influence of bubbles on machining gap distribution is reduced. The flushing effect of the electrolyte on products attached to the surface of the workpiece is enhanced through the cooperative vibration of the cathodes and the workpiece, and discharge of the electrolytes is promoted; and a disturbance effect is applied to a flow field through up-down movement of the workpiece in a flow field, so that the uniformity of bubbles and temperature is improved, and the allowance distribution uniformity of the workpiece is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

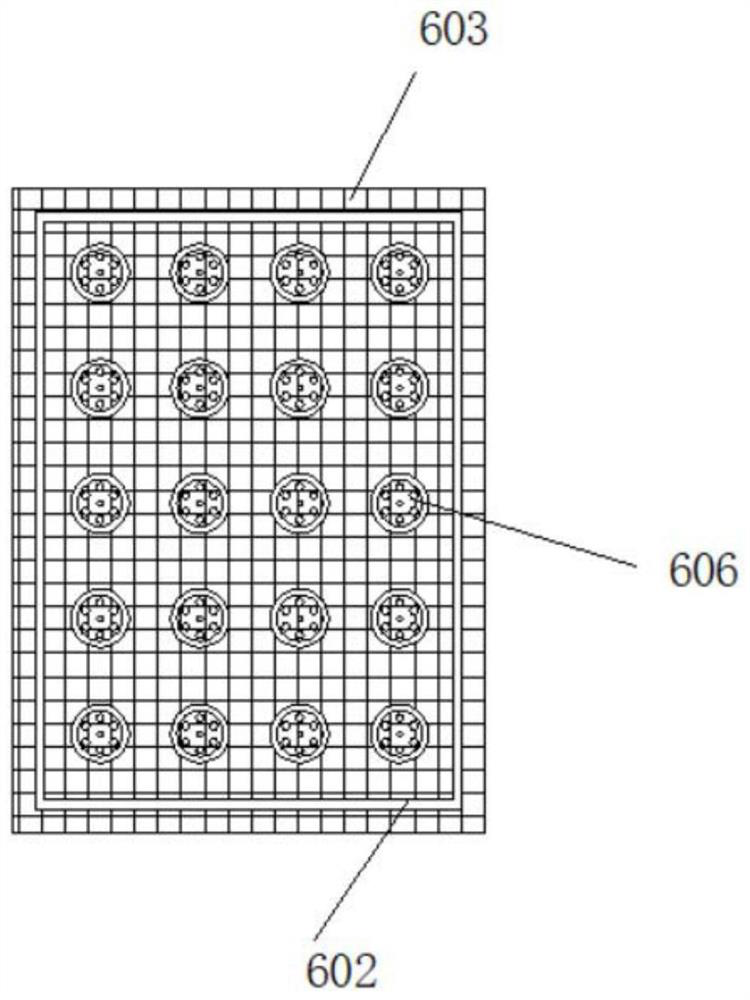

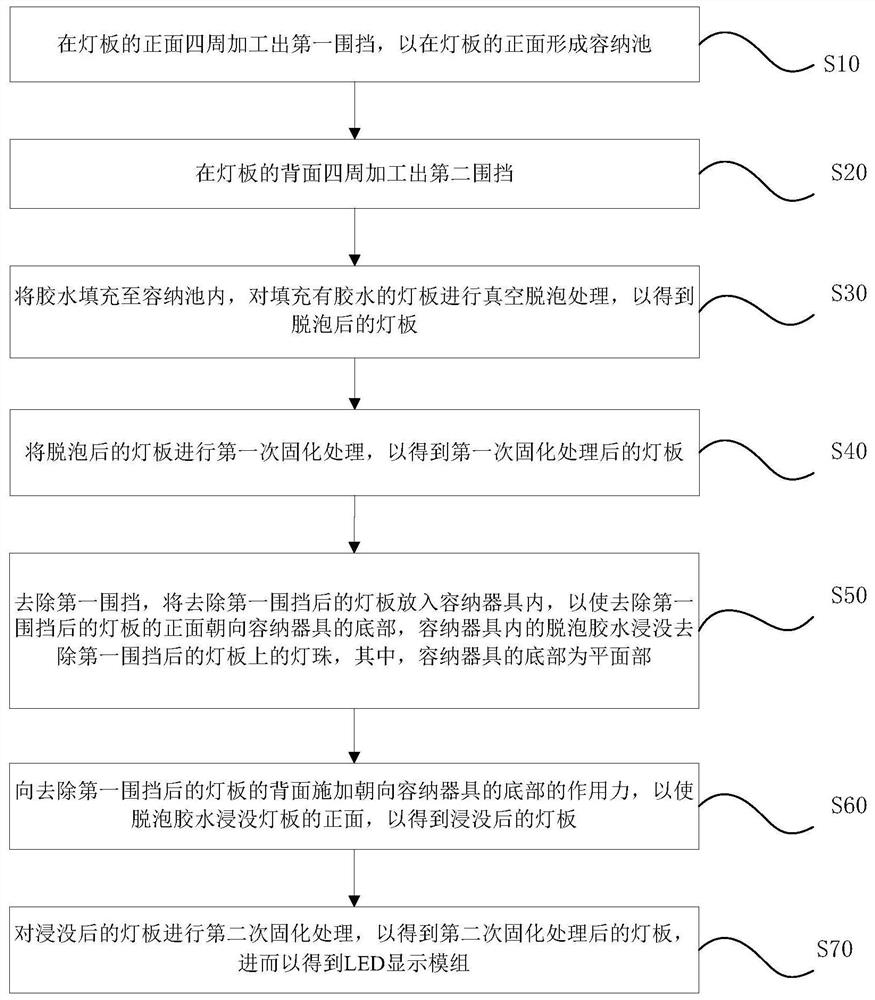

Preparation method of LED display module

PendingCN113763832AWon't happenReduce the probability of air bubblesSolid-state devicesIdentification meansLED displayEngineering

The invention provides a preparation method of an LED display module, which comprises the following steps: S10, a first enclosure is processed on the periphery of the front surface of a lamp panel so as to form an accommodating pool on the front surface of the lamp panel; S30, the containing pool is filled with glue, and the lamp panel filled with the glue is subjected to vacuum defoaming treatment; S40, the defoamed lamp panel is subjected to first-time curing treatment; S50, the first enclosure is removed, the lamp panel with the first enclosure removed is placed in a containing appliance, so that the front face of the lamp panel with the first enclosure removed faces the bottom of the containing appliance, and lamp beads on the lamp panel with the first enclosure removed are immersed in the defoaming glue in the containing appliance; and S60, acting force facing the bottom of the containing appliance is applied to the back face of the lamp panel with the first enclosure removed, so that the front face of the lamp panel is immersed in the defoaming glue. According to the technical scheme, the problem that the display effect is affected due to the fact that air existing in lamp seams of lamp beads cannot be exhausted in the prior art is effectively solved.

Owner:LEYARD

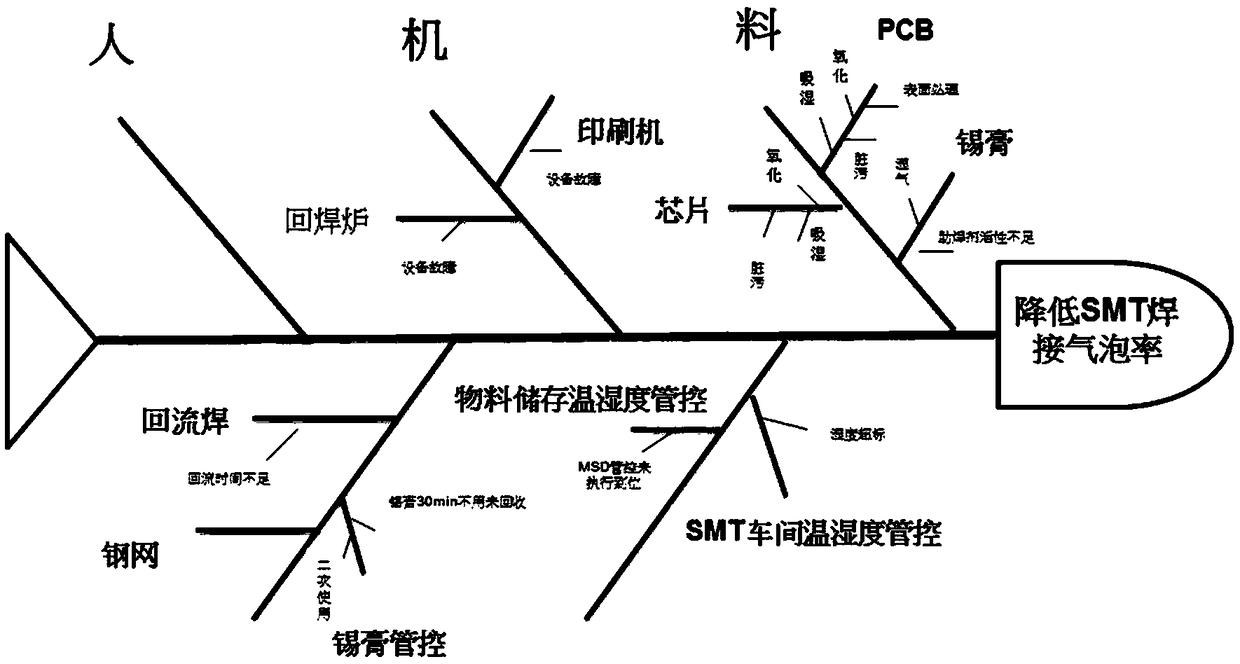

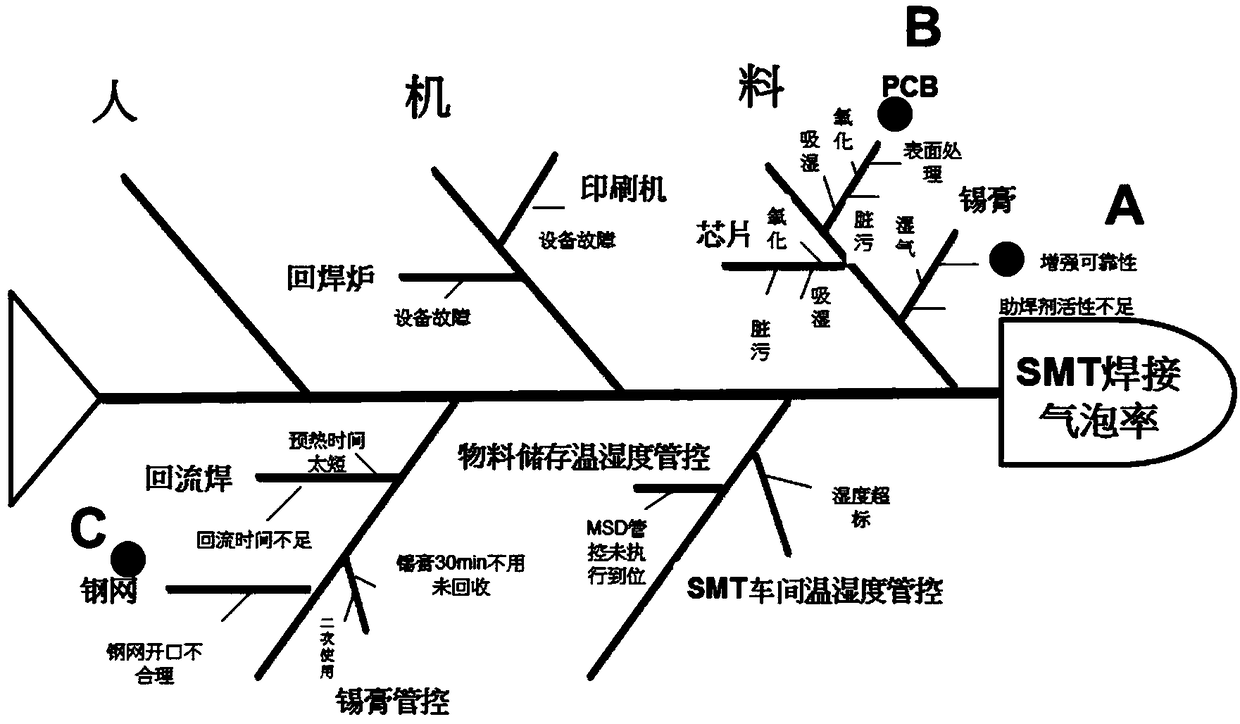

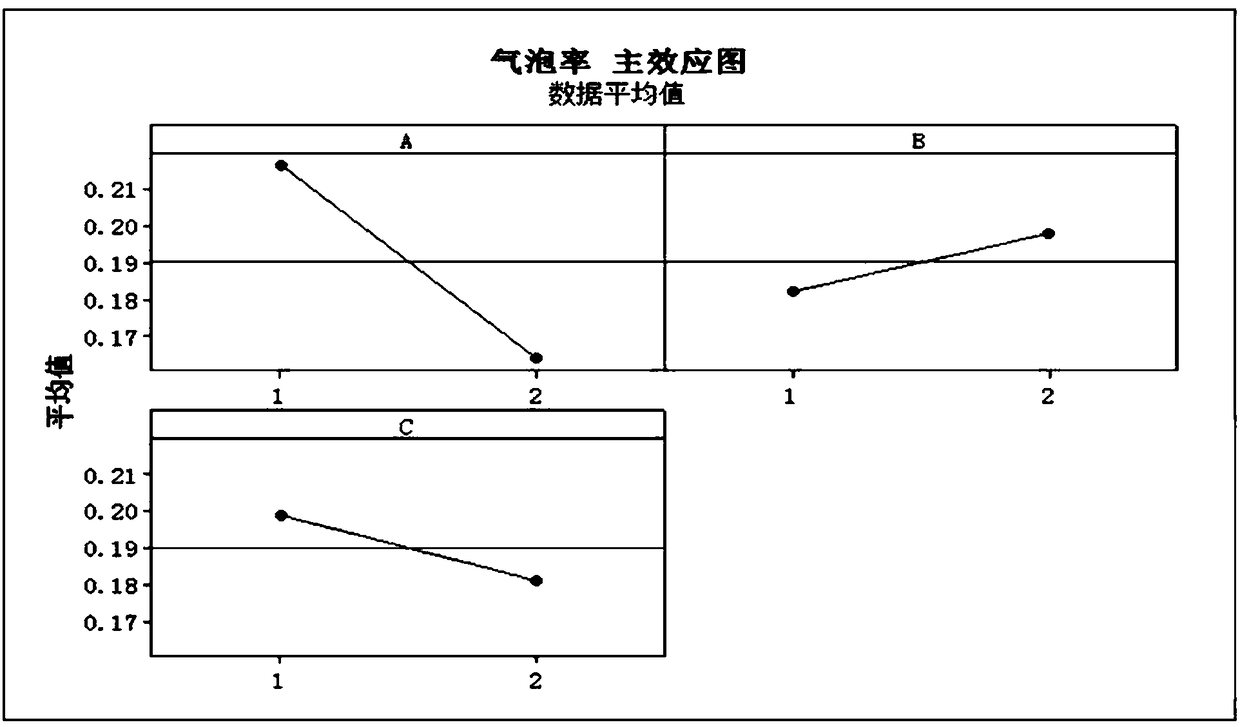

Method for reducing welding bubble rate of QFN chip and steel mesh structure obtained by applying method

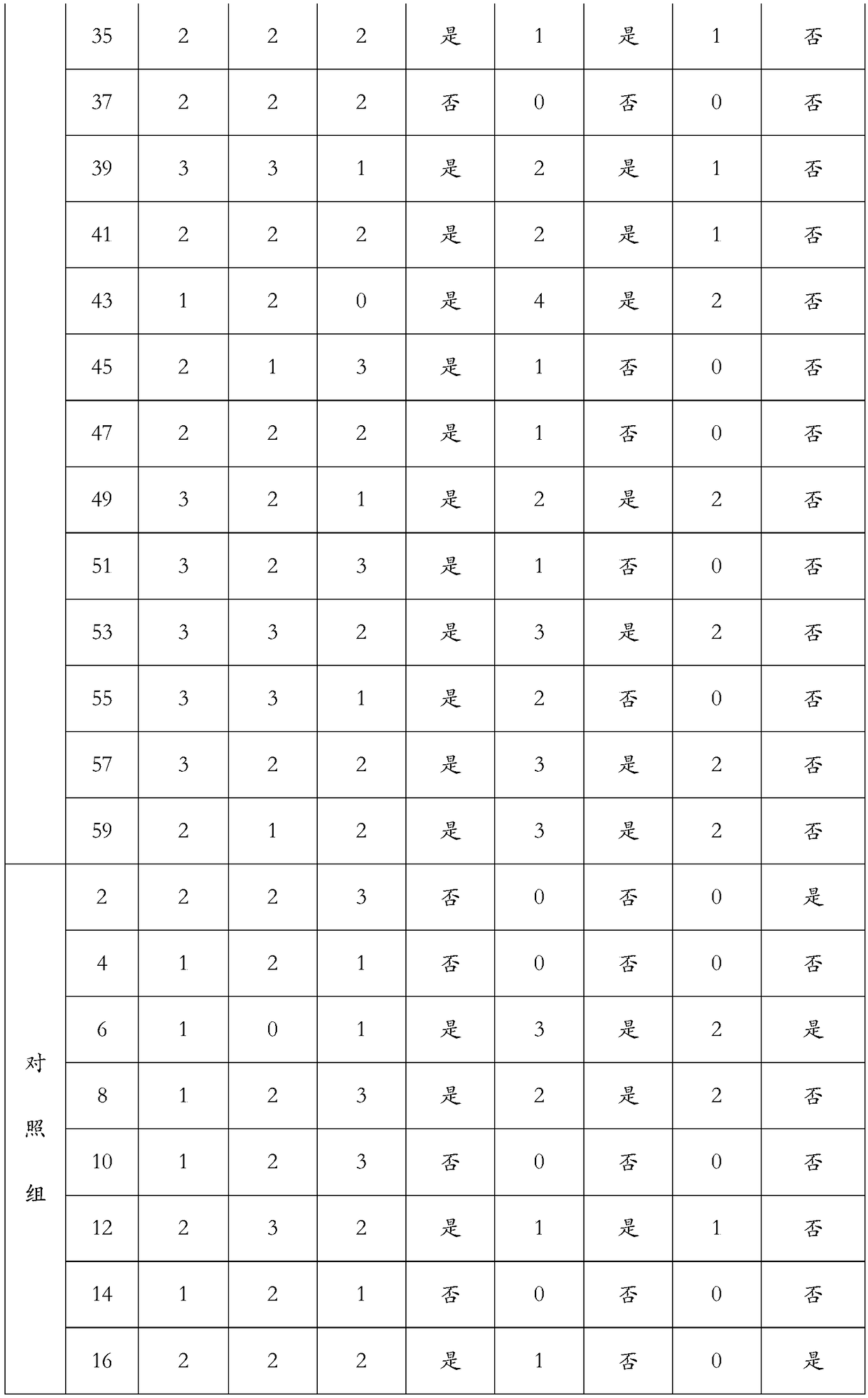

ActiveCN108637517AReduce welding bubble rateThe amount of tin increasedWelding apparatusSolder feeding devicesComputer scienceTest group

The invention relates to a method for reducing a welding bubble rate of a QFN chip and a steel mesh structure obtained by applying the method. The method comprises the following steps of: judging factors of generating a bubble rate to obtain several main factors; separately giving out two different first fixed data by each factor; separately selecting a first fixed datum by each factor in the several factors to define a first test group, thereby obtaining a bubble rate value of the corresponding first test group; obtaining important factors which affect the bubble rate according to the bubblerate value; separately giving out multiple different second fixed data by each important factor according to the important factors; separately selecting a second fixed datum by each important factor to form a second test group to obtain a final bubble rate value of the corresponding second test group; and obtaining final factors which affect the bubble rate value according to the final bubble ratevalue. On the basis of ensuring reliability of a welding spot by the method, the shape of the steel mesh is improved, so that tin amount is increased, and therefore, the bubble rate generated duringwelding is effectively reduced.

Owner:SHANGHAI VEI SHENG AUTO PARTS MFG CO LTD

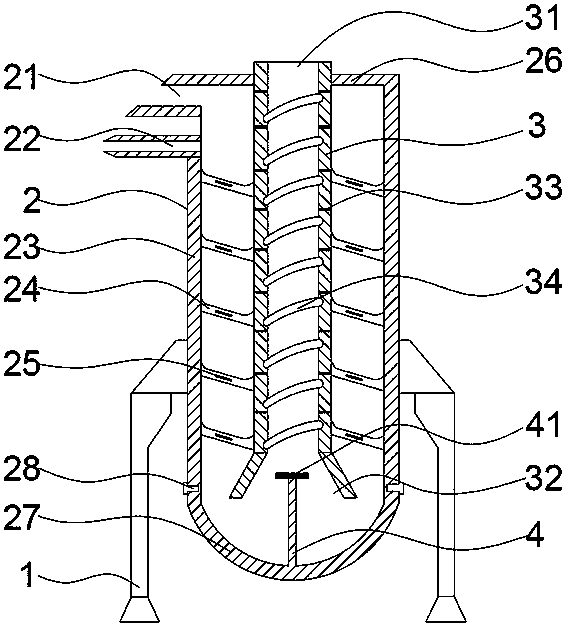

Spiral type heating dryer with materials being loaded separately

InactiveCN107560357AQuality improvementAvoid stickingDrying gas arrangementsDrying chambers/containersPulp and paper industryIndustrial dryer

The invention provides a spiral type heating dryer with materials being loaded separately, and belongs to the field of industrial dryers. The spiral type heating dryer comprises an outer drying cylinder, an inner drying cylinder and a supporting column, wherein the supporting column supports and is fixedly connected with the outer drying cylinder; the outer drying cylinder comprises an outer cylinder body, a top cover and a cylinder bottom, wherein openings are formed in the upper end and the lower end of the outer cylinder body, the top cover is fixedly connected with the upper end of the outer cylinder body and seals the opening at the upper end of the outer cylinder body, and the cylinder bottom is fixedly connected with the lower end of the outer cylinder body and seals the opening atthe lower end of the outer cylinder body; a strut is mounted in the center of the cylinder bottom, a suction fan is mounted at the top end of the strut, and the top end of the upper part of the side wall of the outer cylinder body is provided with a material inlet and a hot air pipeline which penetrate through the side wall of the outer cylinder body; the inner drying cylinder and the outer cylinder body are arranged coaxially; a guiding plate with a downward spiral is arranged on the area between the inner wall of the outer cylinder body and the outer wall of the inner drying cylinder, and agroove with an upward spiral is formed in the inner wall of the inner wall of the inner drying cylinder; and a first heating element is arranged in the cylinder wall of the inner drying cylinder, anda second heating element is arranged in the guiding plate. According to the double spiral structure of the spiral type heating dryer, damp materials can be quickly and evenly dried, and adhesion and hardening of the materials in the dryer is not easy to occur.

Owner:兰溪市捷喜食品加工技术有限公司

High modulus glass fibre composition, and glass fibre and composite material thereof

A high modulus glass fiber composition, and a glass fiber and a composite material thereof. The glass fiber composition comprises the following components expressed as percentage by weight: 53-68% of SiO2, 13-24.5% of Al2O3, 0.1-8% of Y2O3+La2O3, less than 1.8% of La2O3, 10-23% of CaO+MgO+SrO, less than 2% of Li2O+Na2O+K2O, and less than 1.5% of Fe2O3, and the range of a weight percentage ratio C1 is more than 0.5, wherein C1=Y2O3 / (Y2O3+La2O3). The composition significantly increases the elastic modulus of glass, significantly reduces the liquidus temperature and the forming temperature of glass, and under equal conditions, significantly reduces the crystallization rate and the bubble rate of glass. The composition effectively improves the material properties of glass, and is particularly suitable for the tank furnace production of a high modulus glass fiber having a low bubble rate.

Owner:JUSHI GRP CO

Defoaming agent for polystyrene

InactiveCN105419133ASmall physical propertiesReduce the probability of air bubblesGeneration ratePolystyrene

The invention relates to a defoaming agent for polystyrene. The defoaming agent is prepared from, by weight, 2-4 parts of dimethyl silicone oil, 1.2-1.5 parts of sodium dodecyl benzene sulfonate, 2-3 parts of diphenyl carbazone, 2.5-4 parts of sodium tripolyphosphate, 3-5 parts of triethanolamine, 4-6 parts of dispersing agent NNO and 2-3 parts of chlorinated paraffin. After the defoaming agent for polystyrene is matched, the defoaming agent is reasonably matched aiming at the characteristics of polystyrene materials, the bubble generation rate of polystyrene products in the processing process is reduced, the quality of the products is improved, the yield of the products is increased, the defects of the products are reduced, and meanwhile the physical performance of polystyrene cannot be reduced.

Owner:QUANJIAO XIANGRUI PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com