A kind of photothermal dual curing poe encapsulation adhesive film for photovoltaic and preparation method thereof

An encapsulating adhesive film and dual curing technology, which is applied in the direction of photovoltaic power generation, adhesives, films/sheets without carriers, etc., can solve the problems of easy migration and reduction of adhesion, and achieve good fluidity, less glue overflow, and energy consumption. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

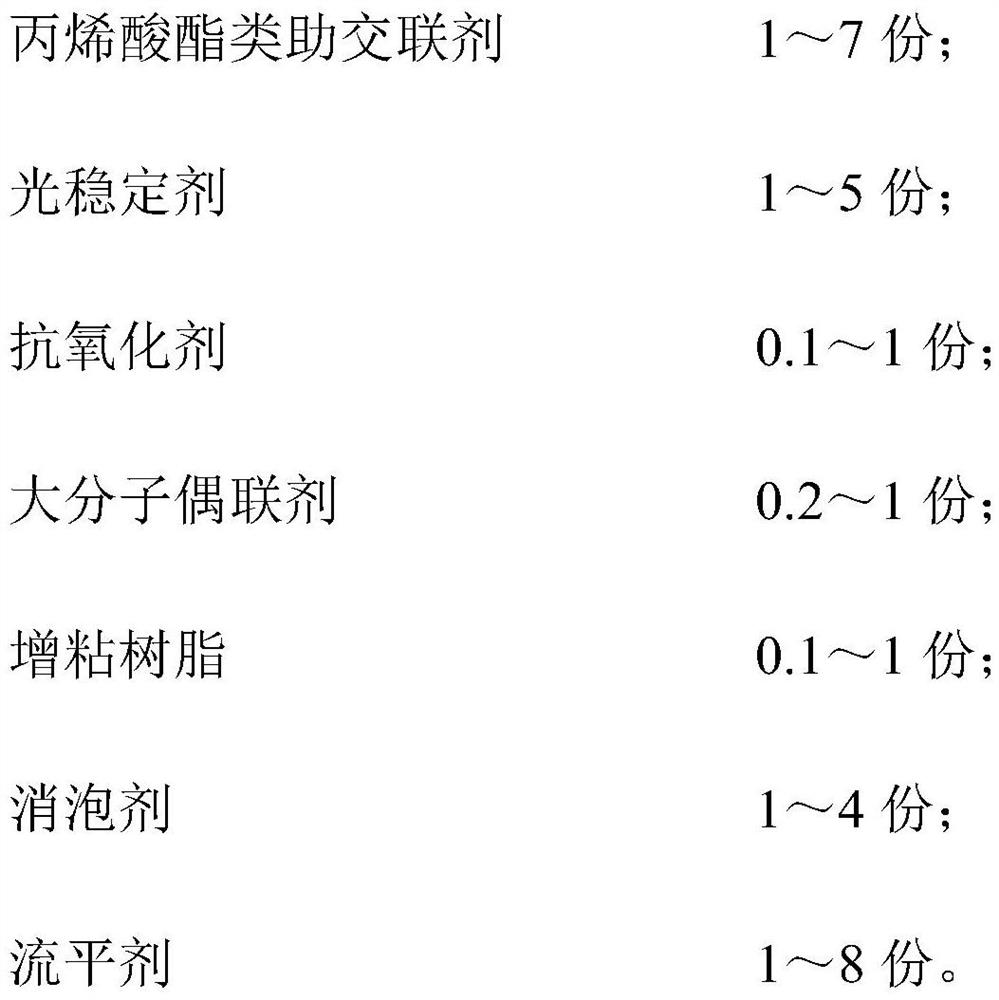

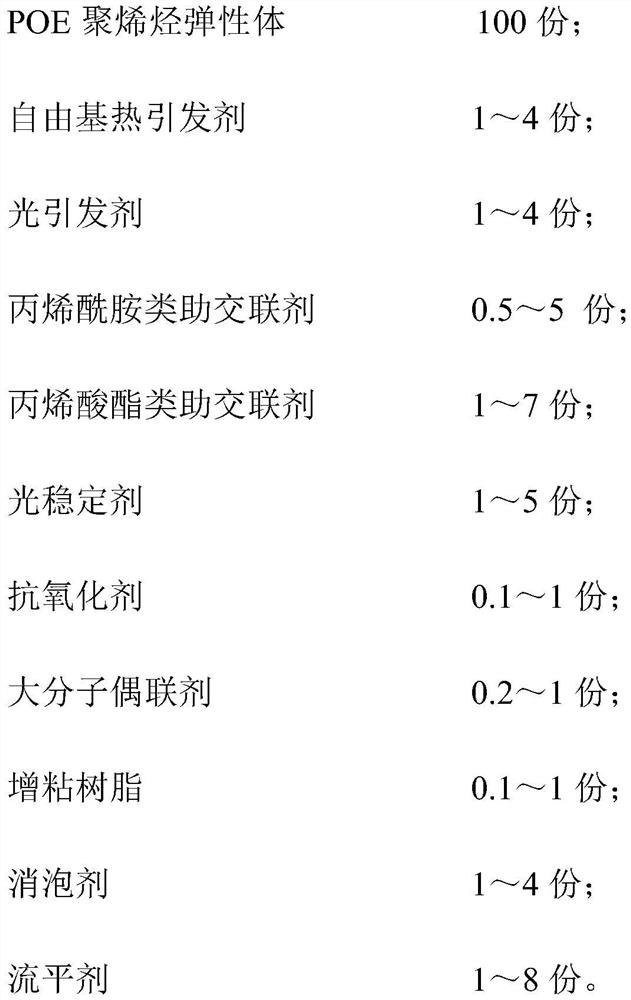

Method used

Image

Examples

Embodiment 1

[0058] Take 27 parts of 10-15g / 10min POE, 55 parts of 30-40g / 10min POE, stir and mix evenly, then take 18 parts of 3-5g / 10min POE particles, under the condition of temperature 60°C and stirring speed 20rpm, heating and mixing for 50min to form the first mixture;

[0059]Take 5 parts of acrylamide auxiliary crosslinking agent, 7 parts of acrylate auxiliary crosslinking agent, 1 part of macromolecular coupling agent and 1 part of tackifying resin, and add them into the first mixture at a speed of 60 g / min. Under the conditions of a temperature of 60° C. and a stirring speed of 20 rpm, heat and mix for 40 minutes to form a second mixture;

[0060] The second mixture is uniformly mixed and extruded by a twin-screw granulator, and the extrusion temperature is controlled at 100 ° C. The extruded product is cooled, drawn and pelletized to make a graft masterbatch;

[0061] Take 4 parts of free radical thermal initiator, 4 parts of photoinitiator, 5 parts of light stabilizer, 1 part ...

Embodiment 2

[0063] Take 33 parts of 10-15g / 10min POE, 45 parts of 30-40g / 10min POE, stir and mix evenly, then take 22 parts of 3-5g / 10min POE particles, under the condition of temperature 60°C and stirring speed 20rpm, heating and mixing for 60min to form the first mixture;

[0064] Take 2.5 parts of acrylamide auxiliary cross-linking agent, 7 parts of acrylate auxiliary cross-linking agent, 0.5 part of macromolecular coupling agent and 0.5 part of tackifying resin, and add them into the first mixture at a speed of 60 g / min. Under the conditions of a temperature of 50° C. and a stirring speed of 20 rpm, heat and mix for 40 minutes to form a second mixture;

[0065] The second mixture is uniformly mixed and extruded by a twin-screw granulator, and the extrusion temperature is controlled at 150 ° C. The extruded product is cooled, drawn and pelletized to make a graft masterbatch;

[0066] Take 2 parts of free radical thermal initiator, 2 parts of photoinitiator, 2.5 parts of light stabiliz...

Embodiment 3

[0068] Take 42 parts of 10-15g / 10min POE, 30 parts of 30-40g / 10min POE, stir and mix evenly, then take 28 parts of 3-5g / 10min POE particles, under the condition of temperature 60°C and stirring speed 30rpm, heating and mixing for 50min to form the first mixture;

[0069] Take 0.5 part of acrylamide auxiliary cross-linking agent, 1 part of acrylate auxiliary cross-linking agent, 0.2 part of macromolecular coupling agent and 0.1 part of tackifying resin and mix them into the first mixture at a speed of 60 g / min. Under the conditions of a temperature of 50° C. and a stirring speed of 20 rpm, heat and mix for 40 minutes to form a second mixture;

[0070] The second mixture is uniformly mixed and extruded by a twin-screw granulator, and the extrusion temperature is controlled at 200 ° C. The extruded product is cooled, drawn and pelletized to make a graft masterbatch;

[0071] Take 1 part of free radical thermal initiator, 1 part of photoinitiator, 2 parts of light stabilizer, 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com