Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Small physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel rubber activator and preparation method thereof

The invention discloses a novel rubber activator and a preparation method thereof. The rubber activator particularly comprises 20 to 80 percent of aromatic group-containing formic acid type metal salt and 20 to 80 percent of zinc oxide, wherein the aromatic group-containing formic acid type metal salt is mixed with the zinc oxide at normal temperature and the two are stirred for 5 to 15 minutes at the rotation speed of between 2,000 and 3,500rpm. Compared with the prior art, the problems of high zinc content and high heavy metal element content in the zinc oxide can be effectively solved, density is reduced, dispersibility is improved, and the novel rubber activator improves rubber tensile property, broken chain elongation rate and rubber cross-linking effect.

Owner:江苏爱特恩高分子材料有限公司

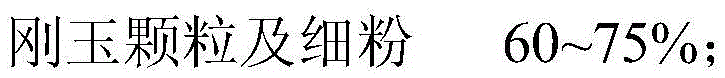

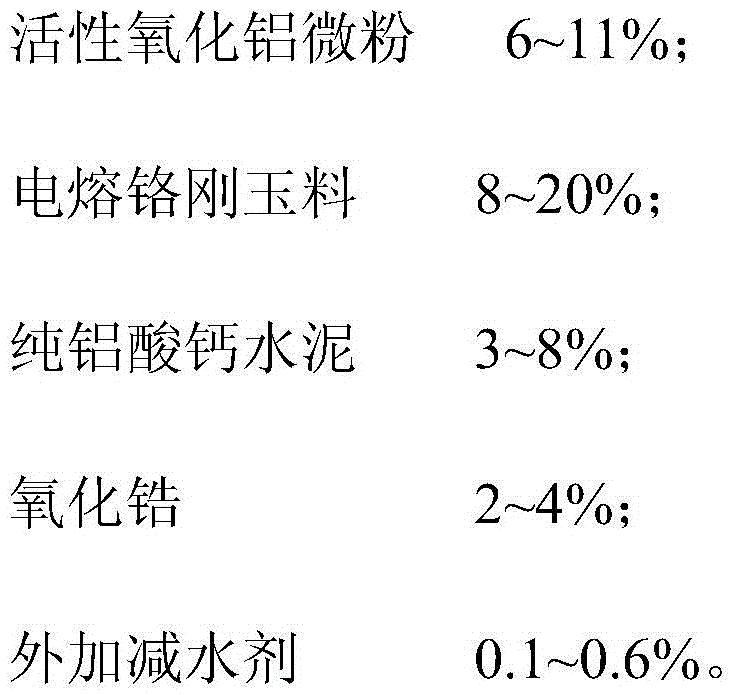

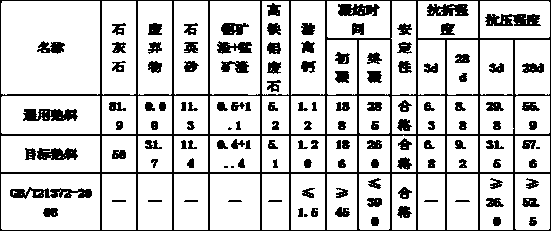

Air brick for special steel refining and preparation method thereof

InactiveCN105645977AReduce the amount of water addedImprove liquidityMelt-holding vesselsBrickCalcination

The invention relates to an air brick for special steel refining, particularly an air brick for special steel refining and a preparation method thereof. The air brick is composed of the following components in percentage by mass: 60-75% of corundum particle and fine powder, 6-11% of activated alumina micropowder, 8-20% of electrofused chrome corundum material, 3-8% of pure calcium aluminate cement, 2-4% of zirconium oxide and 0.1-0.6% of additional water reducing agent. The air brick is suitable for smelting of special steel grades, and has the advantages of excellent high-temperature properties, excellent air permeability, low breaking possibility, favorable high-temperature folding strength and favorable thermal shock resistance. By adopting the curing schedule, the cement in the material can be sufficiently hydrated, thereby enhancing the strength of the semifinished product, and avoiding generating microcracks of possible collisions in the transportation process (the cracks can further extend in the high-temperature calcination process). The firing schedule is adopted to prevent the air brick cracks from generation and enhance the yield of the air bricks.

Owner:LUOYANG LIER REFRACTORY MATERIAL

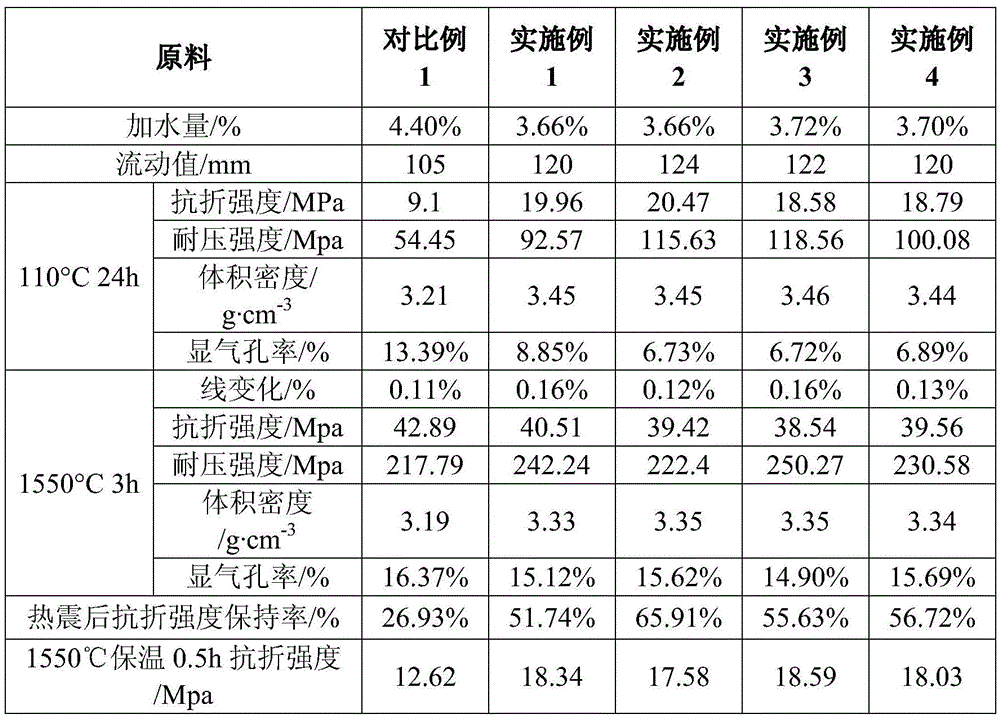

Method for preparing haydite by sintering urban domestic sewage sludge

InactiveCN101148348ACause secondary pollutionImprove performanceCeramic materials productionClaywaresSludgeSewage

The present invention relates to solid waste treating technology, and discloses sewage sludge treating and utilizing process. Sewage sludge in over 70 %, fly ash and clay as the material are treated through drying, crushing, mixing, press forming, preheating and roasting to obtain haydite product. The roasted haydite has one compact glaze layer in the surface and great amount of inside pores, and possesses compressive strength, water absorption, environment safety, etc reaching relevant standard. Using sewage sludge in making building material is significant.

Owner:TSINGHUA UNIV

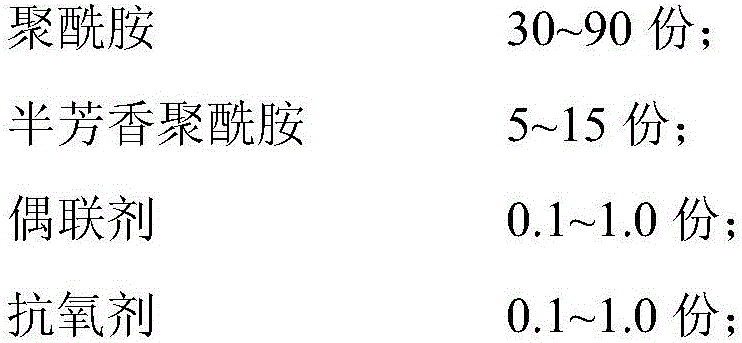

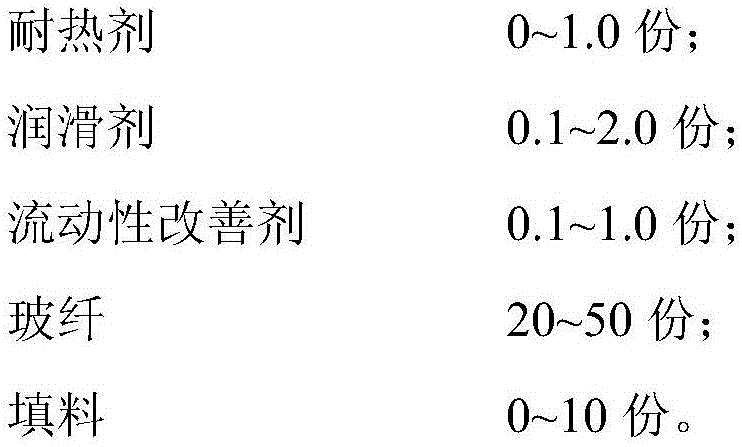

High-surface glossiness and high-dimensional stability polyamide composite material and preparation method thereof

The invention belongs to the technical field of polymeric composite materials, and particularly relates to a high-surface glossiness and high-dimensional stability polyamide composite material and a preparation method thereof. In parts by weight, the polyamide composite material is prepared from the following components: 30 to 90 parts of polyamide; 5 to 15 parts of semi-aromatic polyamide; 0.1 to 1.0 part of coupling agent; 0.1 to 1.0 part of antioxidant; 0 to 1.0 part of heat-resistant agent; 0.1 to 2.0 parts of lubricating agent; 0.1 to 1.0 part of fluidity-improving agent; 20 to 50 parts of glass fibers; and 0 to 10 parts of filler. The polyamide composite material disclosed by the invention has high glossiness, high fluidity, chemical resistance and good mechanical properties; moreover, after moisture is absorbed, the decrease of the physical properties of the material is little, the dimensional stability is high, wear and abrasion can be resisted, heat resistance is good, and the processability is good.

Owner:江苏沃特新材料科技有限公司

Asphalt mixture anti-rutting additive and preparation and use method thereof

ActiveCN101805470AEnhanced recovery from deformationImprove toughnessBuilding insulationsPolypropylenePitch blende

The invention relates to an asphalt mixture anti-rutting additive and a preparation and use method thereof. The anti-rutting additive which is in common use at present has insufficient toughness and poor deformation recovery capability under the condition of heavy load, or has poor adaptability and small application range because the existing anti-rutting additive needs to take chemical reaction with the asphalt. The invention provides the asphalt mixture anti-rutting additive, which is prepared from the following ingredients in weight parts: 25 to 75 percent of polyethylene, 5 to 35 percent of polypropylene, 5 to 25 percent of PVC, 3 to 5 percent of rubber, 5 to 10 percent of asphalt, 1 to 5 percent of tougheners and 1 to 3 percent of UV ageing resistant agents. The ingredients are mixed and uniformly stirred according to the ingredient mixture ratio, and are put into a screw extruder to be heated into 110 to 180 DEG C, the materials are extruded into granules after being fused and prepared into uniform substances, and the asphalt mixture anti-rutting additive can be directly mixed with the asphalt mixture in a dry mode when in use. The additive of the invention has the advantages of low asphalt cost and stable structure, the wear resistance and pressure resistance performance is improved by 15 to 30 percent, the elasticity recover performance index of the asphalt is improved by 10 to 25 percent, and the time limitation of the road surface antifatigue performance is prolonged by 10 to 25 percent.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH +1

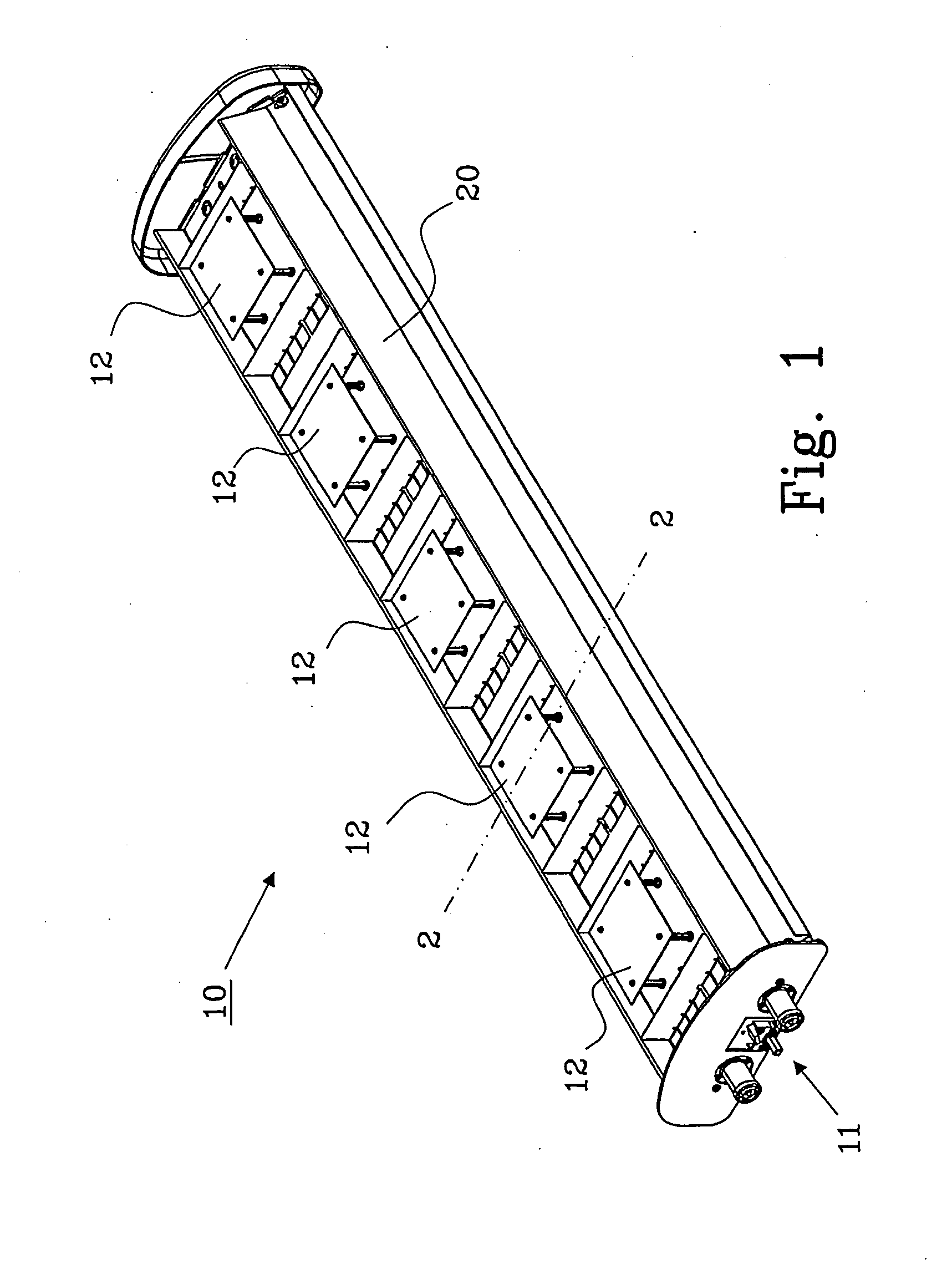

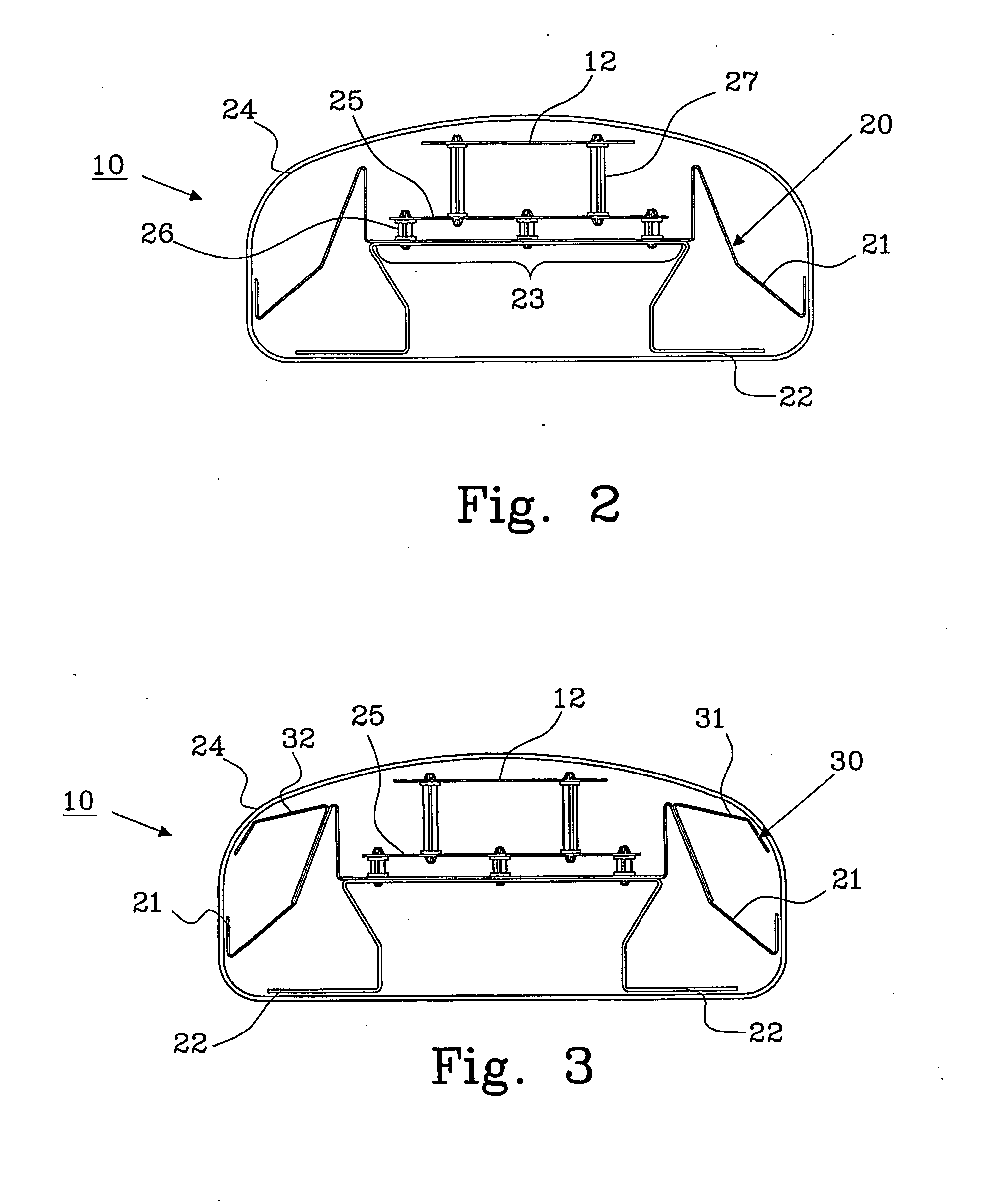

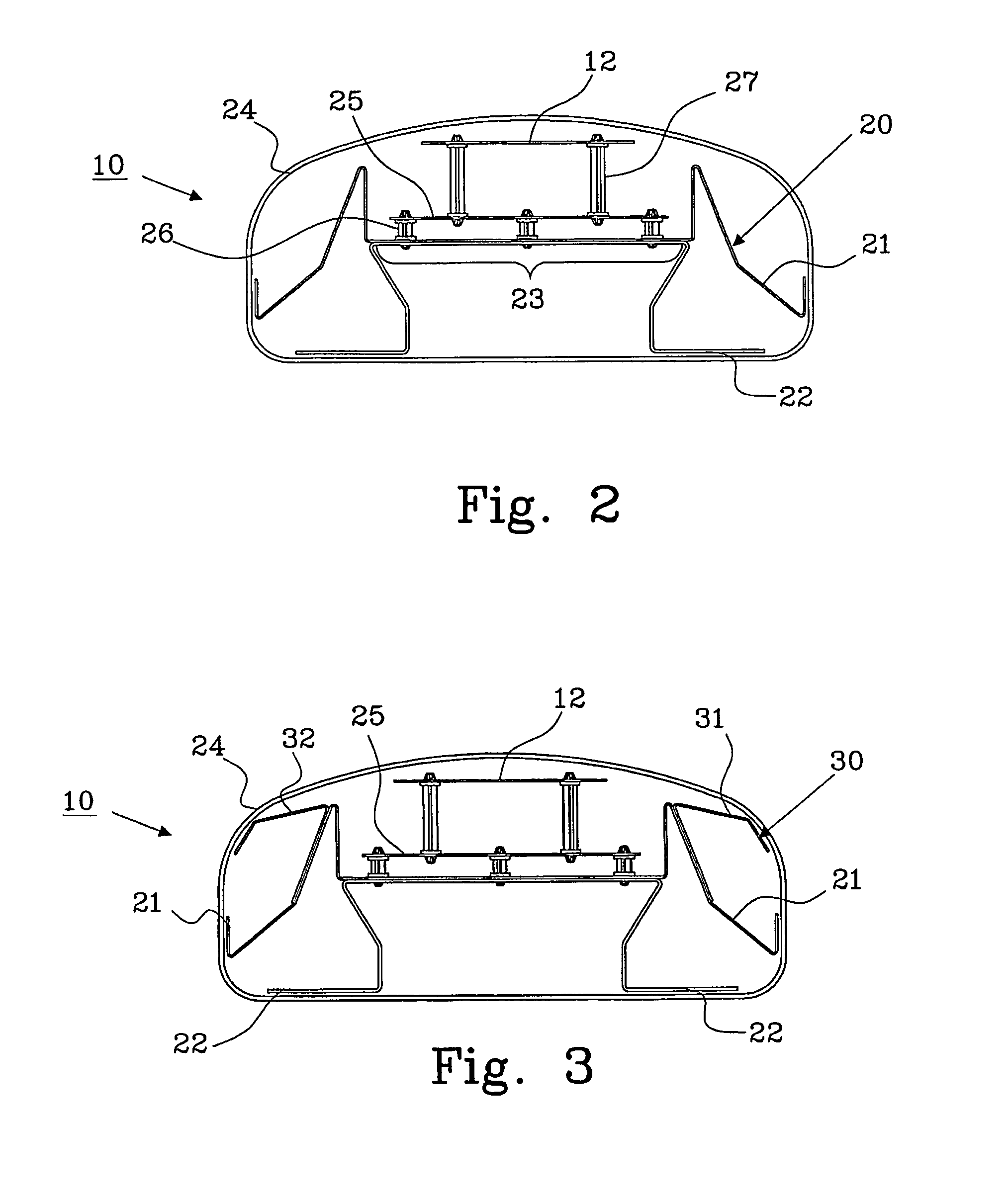

Reflector, an antenna using a reflector and a manufacturing method for a reflector

ActiveUS20090066602A1Low costSmall physical propertiesAntenna supports/mountingsAntenna earthingsEngineeringMechanical engineering

Owner:INTEL CORP

Composite calcium-based solid desulfurizer and production method thereof

InactiveCN102068898ALow costImprove desulfurization effectSolid waste disposalDispersed particle separationComposite effectSlag

The invention relates to a solid desulfurizer and a production method thereof, in particular to a composite calcium-based solid desulfurizer which is prepared from industrial waste residues and the production method thereof. The desulfurizer is prepared by the following steps of: directly mixing carbide slag slurry, dicyandiamide slag serving as a modifier, a chemical drying agent and magnesium slag powder which serves as another modifier; stirring and mixing; performing wet milling to prepare slurry; performing dry milling to prepare powder; and sieving. The prepared composite calcium-based solid desulfurizer is mainly compounded by calcium hydroxide or calcium hydroxide and calcium carbonate, wherein the desulfurizer contains an active magnesium oxide component, integrates the characteristics of a single calcium base or a magnesium-based desulfurizer and has composite effects. Moreover, the desulfurizer has the characteristics of saving a large amount of energy, protecting environment and reducing the cost of a flue gas desulfurizer, along with cheap and wide raw material resource, large amount of doped magnesium slag, carbide slag and dicyandiamide slag, no heat source, high dehydration speed, stable physical performance and the like; in addition, the desulfurizer has the advantages of small equipment investment, low operation cost, capability of eliminating the damage of limestone exploitation to the environment and the like.

Owner:宁夏博浩环保技术有限公司

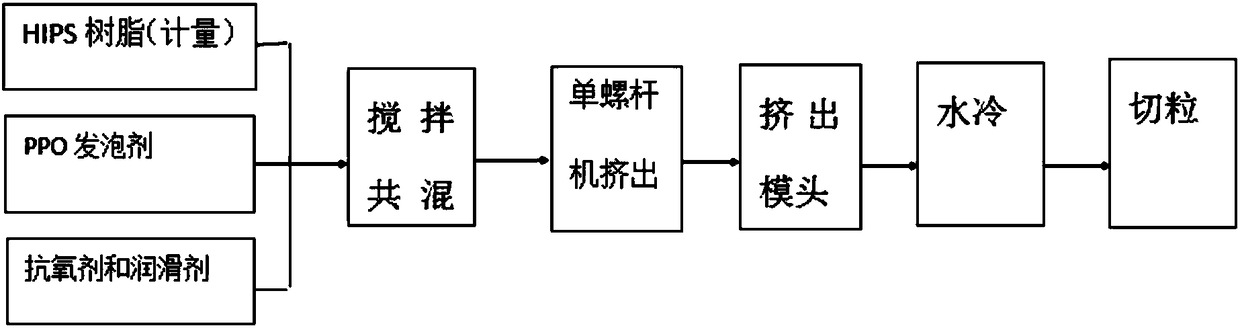

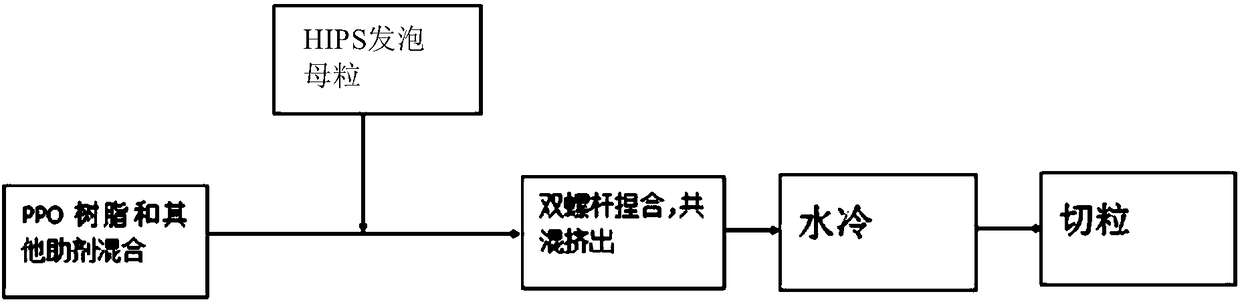

High-dielectric polyphenyl ether material as well as preparation method and application thereof

The invention provides a high-dielectric polyphenyl ether material as well as preparation method and application thereof. The high-dielectric polyphenyl ether material comprises the following raw materials in parts by weight: 30-70 parts of PPO (Poly-p-Phenylene Oxide), 20-40 parts of a shock resistant polystyrene (HIPS) foamed master batch, 3-10 parts of single-walled carbon nanotubes, 0.5-1.5 parts of graphene, 10-20 parts of a high-dielectric filling agent, 1-4 parts of a toughening agent, 0.3-0.8 part of an antioxidant and 0.5-2 parts of a lubricant. The high-dielectric polyphenyl ether material provided by the invention is excellent in mechanical property of a PPO / HIPS alloy, good in thermal property, low in water absorption rate, in addition high in dielectric constant and low in dielectric consumption.

Owner:广东中塑新材料股份有限公司

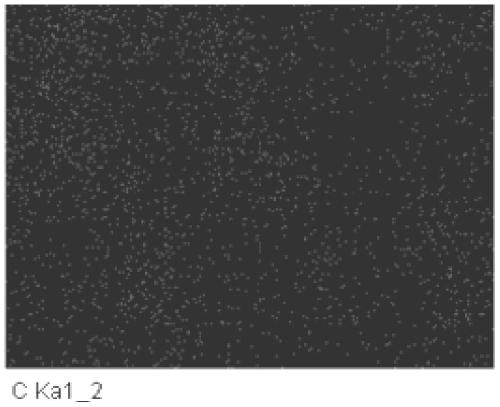

Preparation method of graphene-reinforced silicon nitride-based ceramic

InactiveCN111233484AGood mechanical propertiesImprove fracture toughnessCarbon compoundsCeramicSilicon nitride

The invention discloses a preparation method of a graphene-reinforced silicon nitride-based ceramic. The preparation method adopts silicon nitride and graphene as raw materials and a mixture of aluminum oxide and yttrium oxide as a composite sintering aid. The preparation method sequentially comprises the steps of independent dispersion of raw materials, composite dispersion, ball milling, dryingand sieving, three-dimensional mixing and hot press sintering. The mechanical property of the silicon nitride ceramic material is enhanced, and the added graphene improves the friction property of theceramic, so that the silicon nitride can be used as a good wear-resistant and friction-resistant material by improving the mechanical properties.

Owner:SHAANXI UNIV OF SCI & TECH

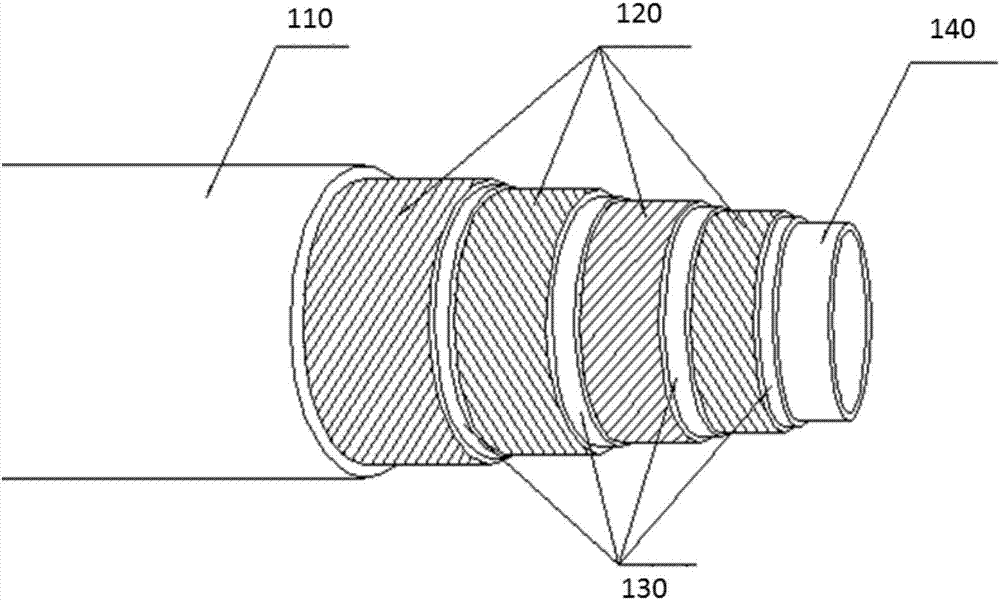

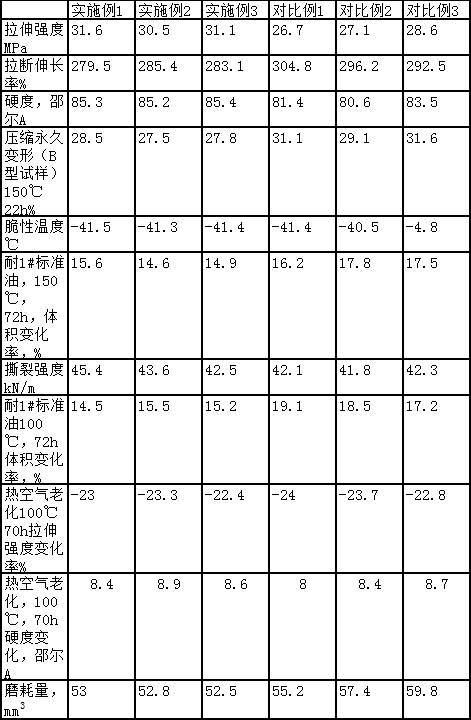

Rubber compound, rubber product, hydraulic rubber hose and preparation method of hydraulic rubber hose

ActiveCN106987040AImprove aging resistanceImproved liquid resistanceFlexible pipesRubber materialPolymer science

The invention relates to a rubber compound, a rubber product, a hydraulic rubber hose and a preparation method of the hydraulic rubber hose. The rubber compound comprises (i) hydrogenated butadiene-acrylonitrile rubber, (ii) thermal cracking carbon black and (iii) other selectable matching agents. A rubber material prepared by the rubber compound has excellent oil resistance and temperature resistance.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

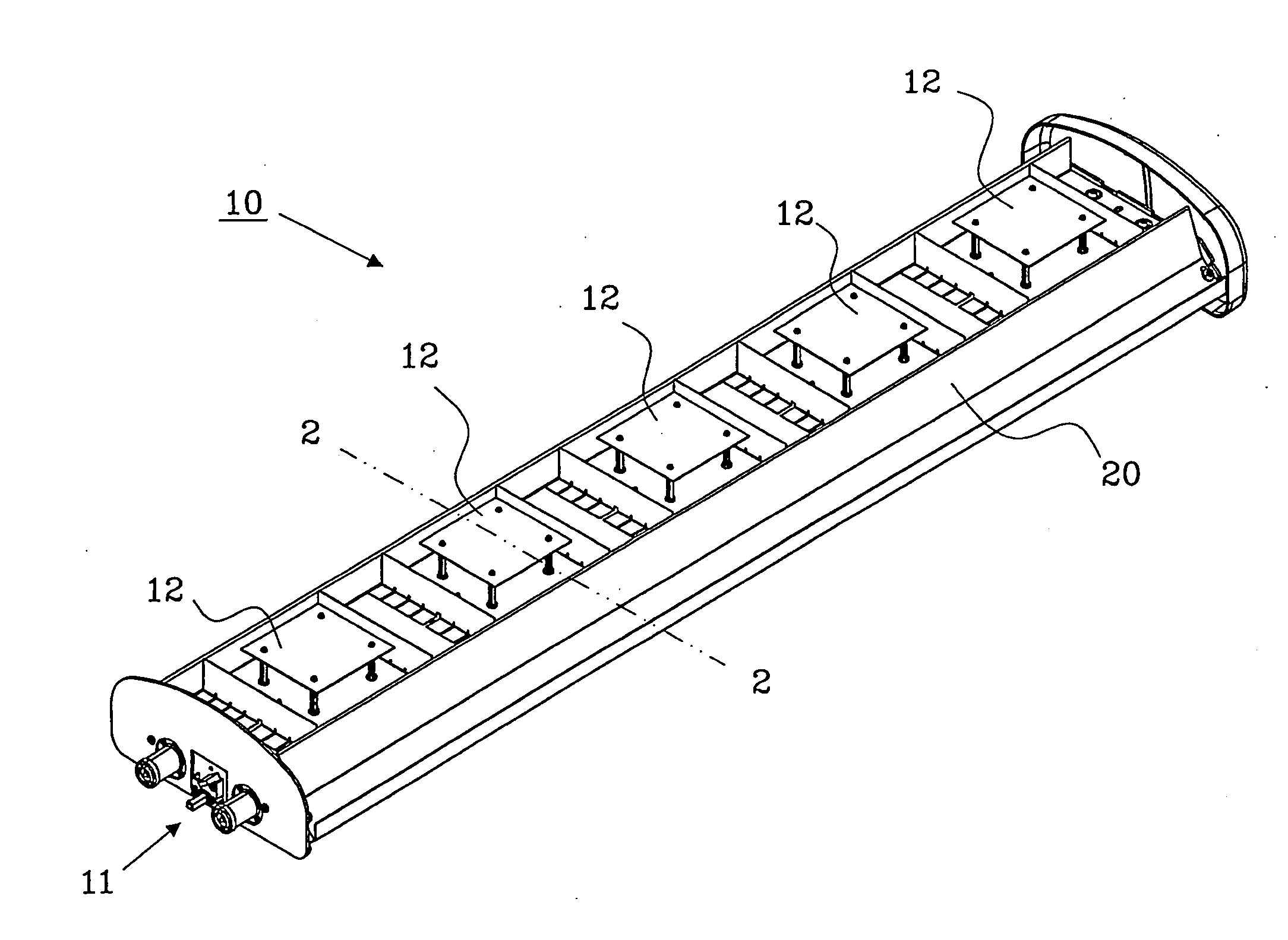

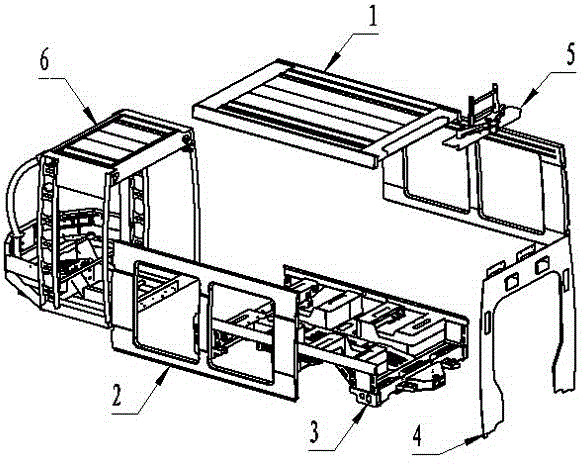

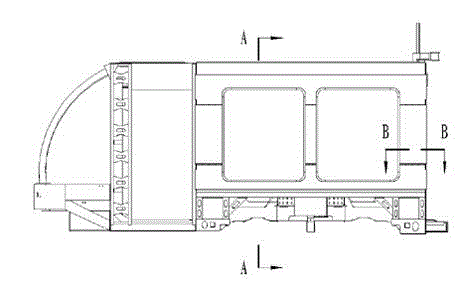

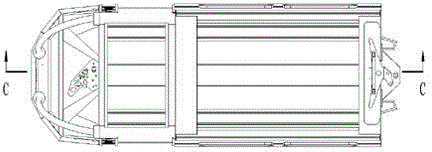

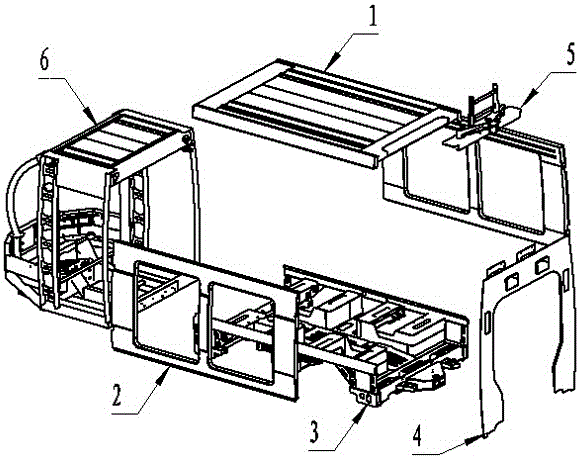

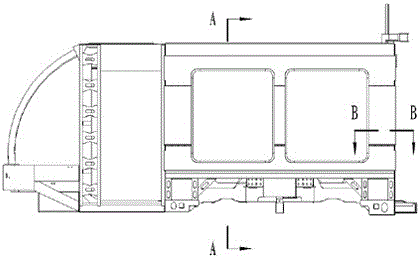

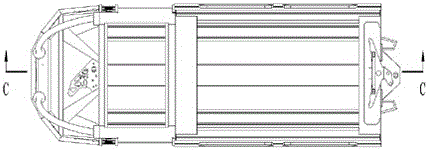

Motor car of 100% low-floor tramcar and assembly method of motor car

ActiveCN104015742AGood production independenceReduce maintenance costsRailway transportAxle-box lubricationAutomotive engineeringHinge angle

The invention discloses a motor car of a 100% low-floor tramcar and an assembly method of the motor car. The motor car comprises a few of large components, such as a top rack, a side wall, a bottom rack, an end wall, an upper hinge component and a cab, wherein the components adopt a riveting mode instead of a traditional welding mode. A car body component adopts a modular design, the components are riveted, each component has good production independence, maintenance universality and interchangeability, and each component can synchronously develop production. Riveting is free of a heat effect, or even coating can be carried out before general assembly, so that the production efficiency is greatly improved, other components of the car body adopt an aluminum profile welding structure except for that the components with large stress adopt a steel structure, the total weight of the car body is greatly relieved in comparison with an all-steel structure, and the lightweight purpose is achieved.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

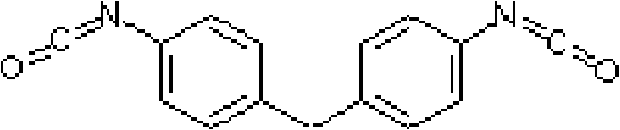

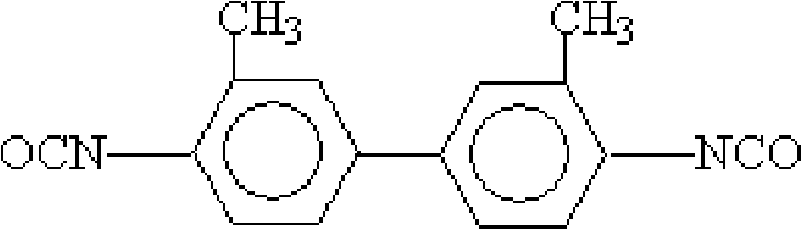

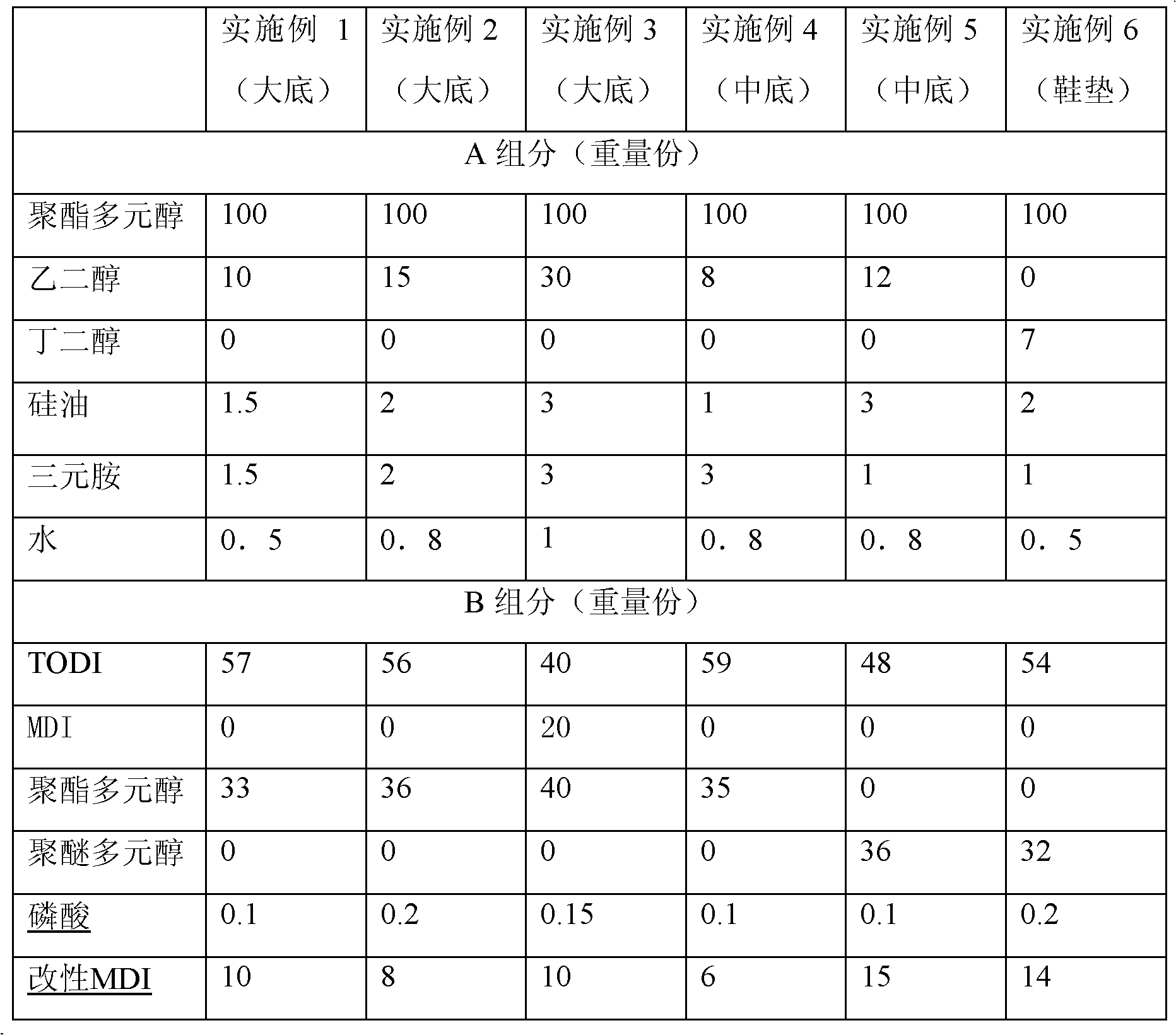

Polyurethane resin for shoes

The invention discloses polyurethane resin for shoes, comprising a component (A) and a component (B). The polyurethane resin for shoes is characterized in that the component (A) comprises 100 parts of polyester polyol and 8-30 parts of ethylene glycol and / or butanediol, the component (B) comprises 40-60 parts of 3,3'-dimethyl-4,4' diphenyl diisocyanate and 30-45 parts of polyester polyol and / or polyether glycol. A finished product prepared by substituting TODI (3,3-Tolidine-4,4-Diisocyanate) for MDI (4,4'-Diphenylmethane Diisocyanate) through a foaming reaction has the matter properties, suchas excellent compression ratio, better wear resistance, bending resistance, tensile strength, tearing strength, and the like under low density. Because of the steric hindrance effect and the electronic effect of 3,3'-dimethyl-4,4'diphenyl diisocyanate methyl-o-side, the activity of the polyurethane resin is weaker than the activity of the diphenylmethane diisocyanate, and the prepared prepolymer is stable and mild in the foaming reaction without generating a bubble falling phenomenon. Because the activity of the TODI reaction is weaker than that of the MDI reaction, the storage stability of the isocyanate combination liquid is greatly improved.

Owner:山东崇舜新材料科技有限公司

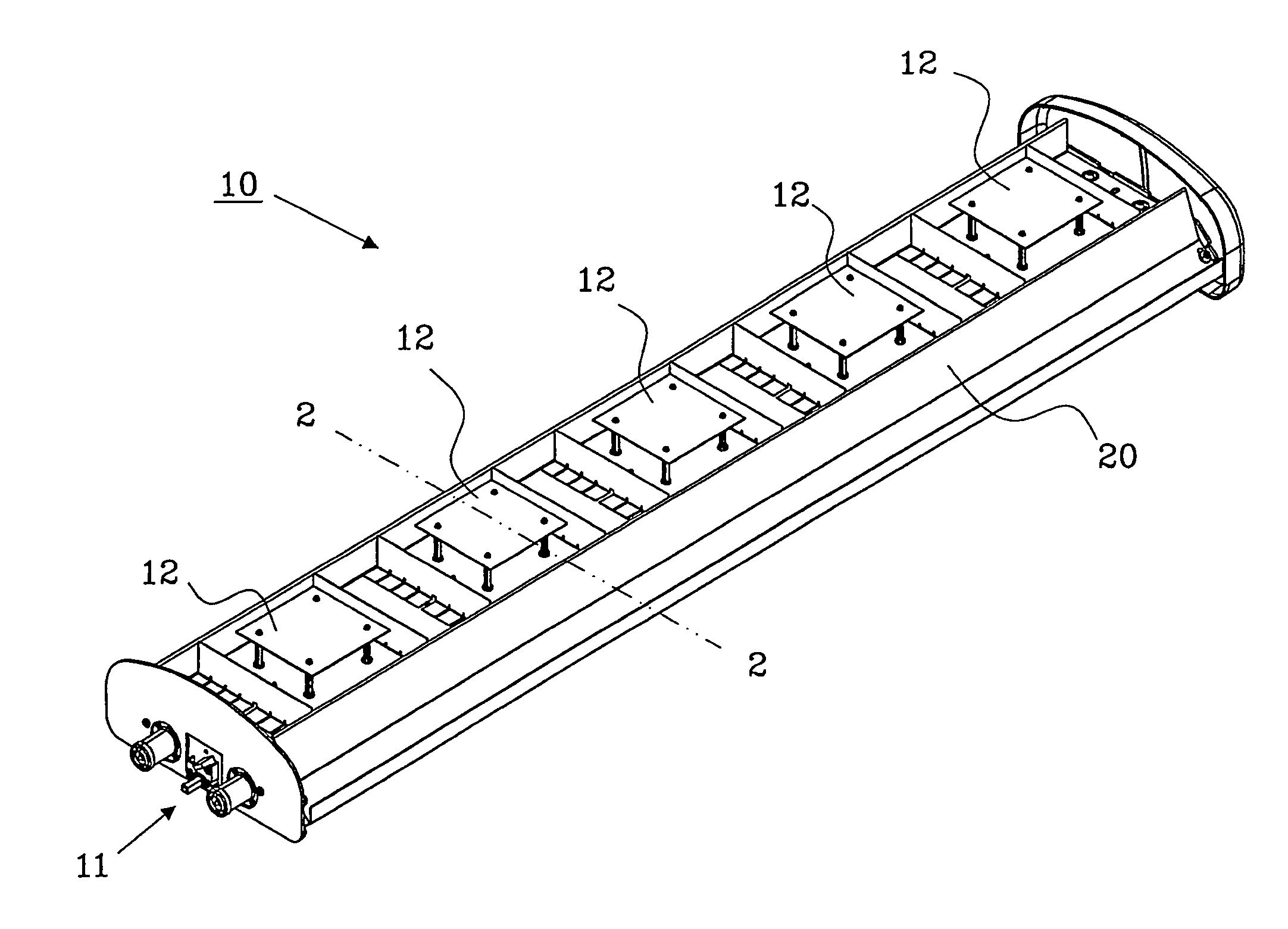

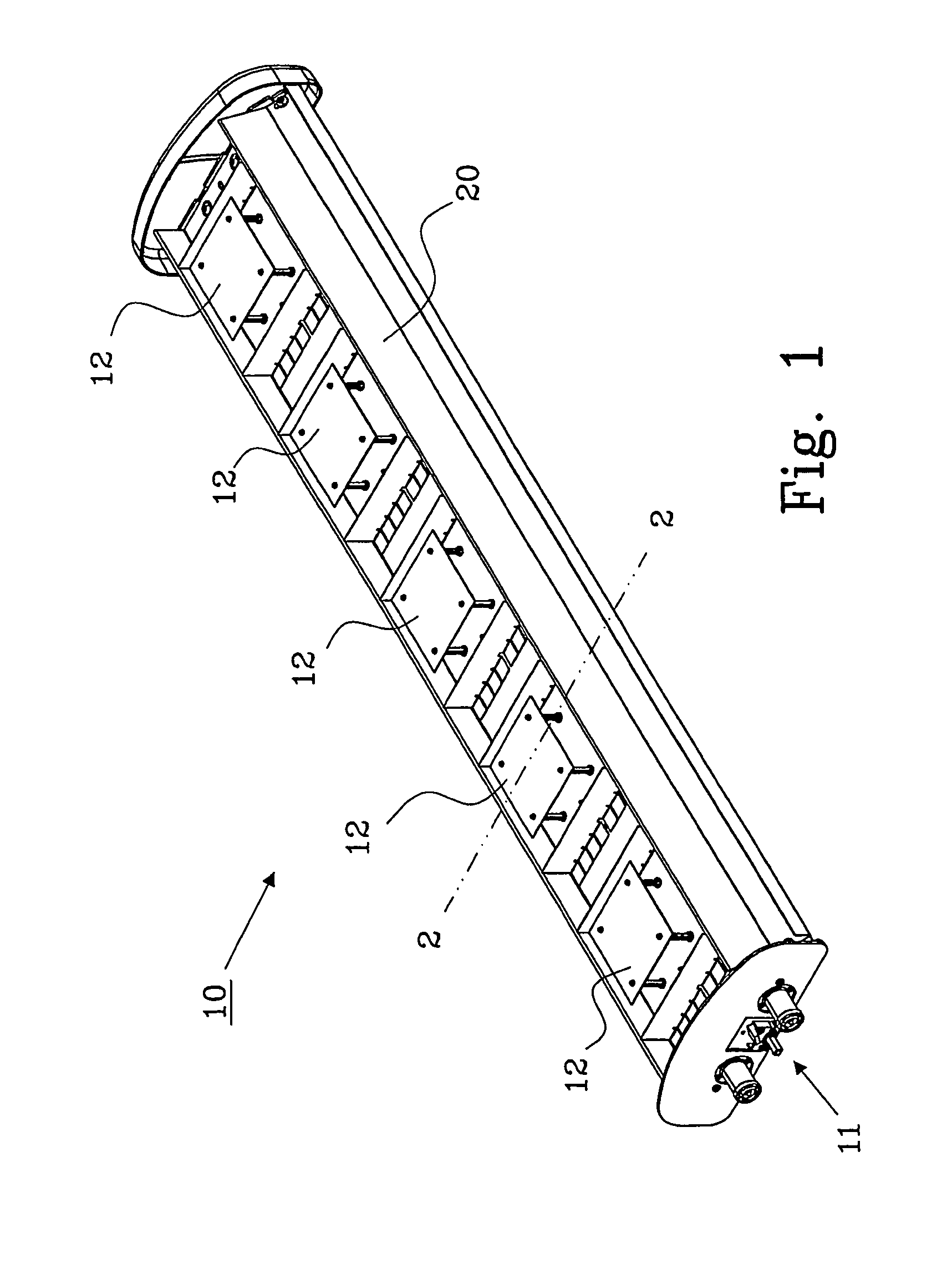

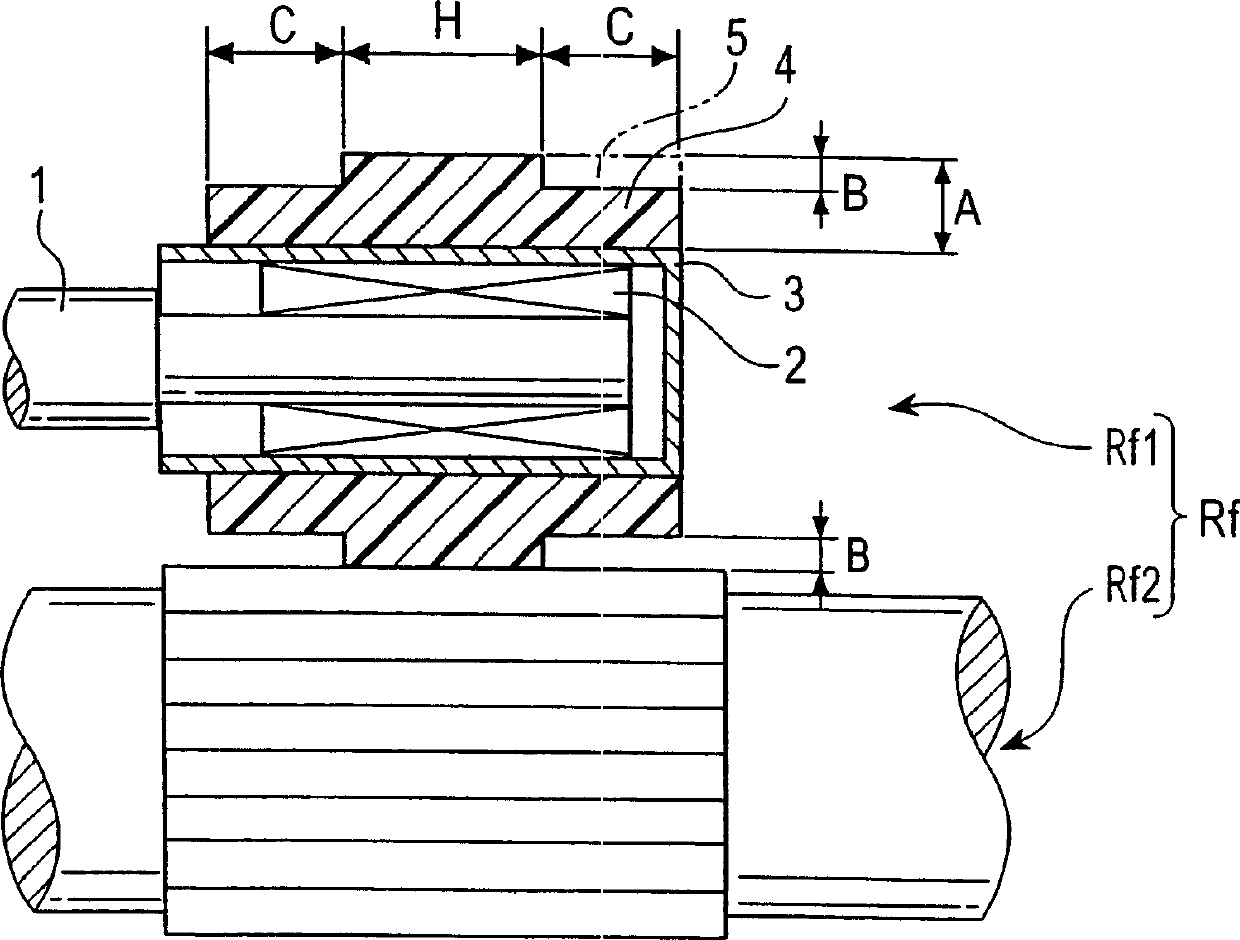

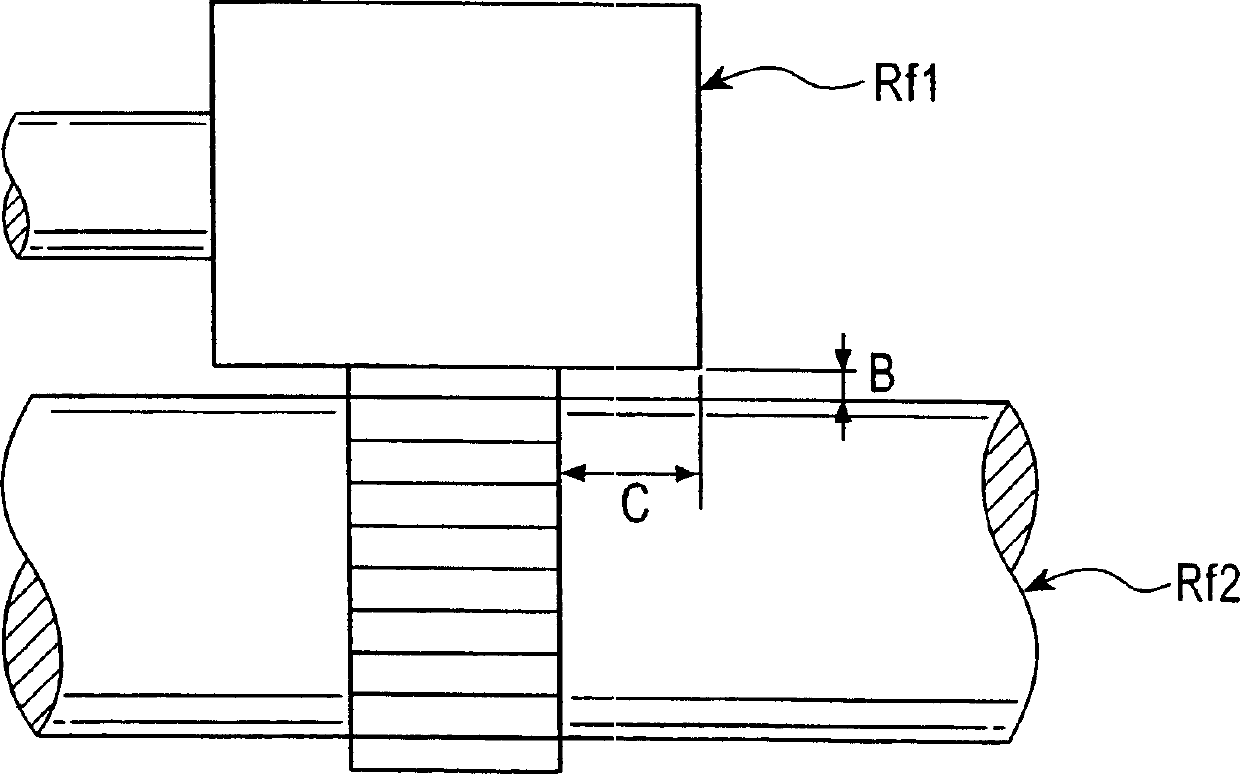

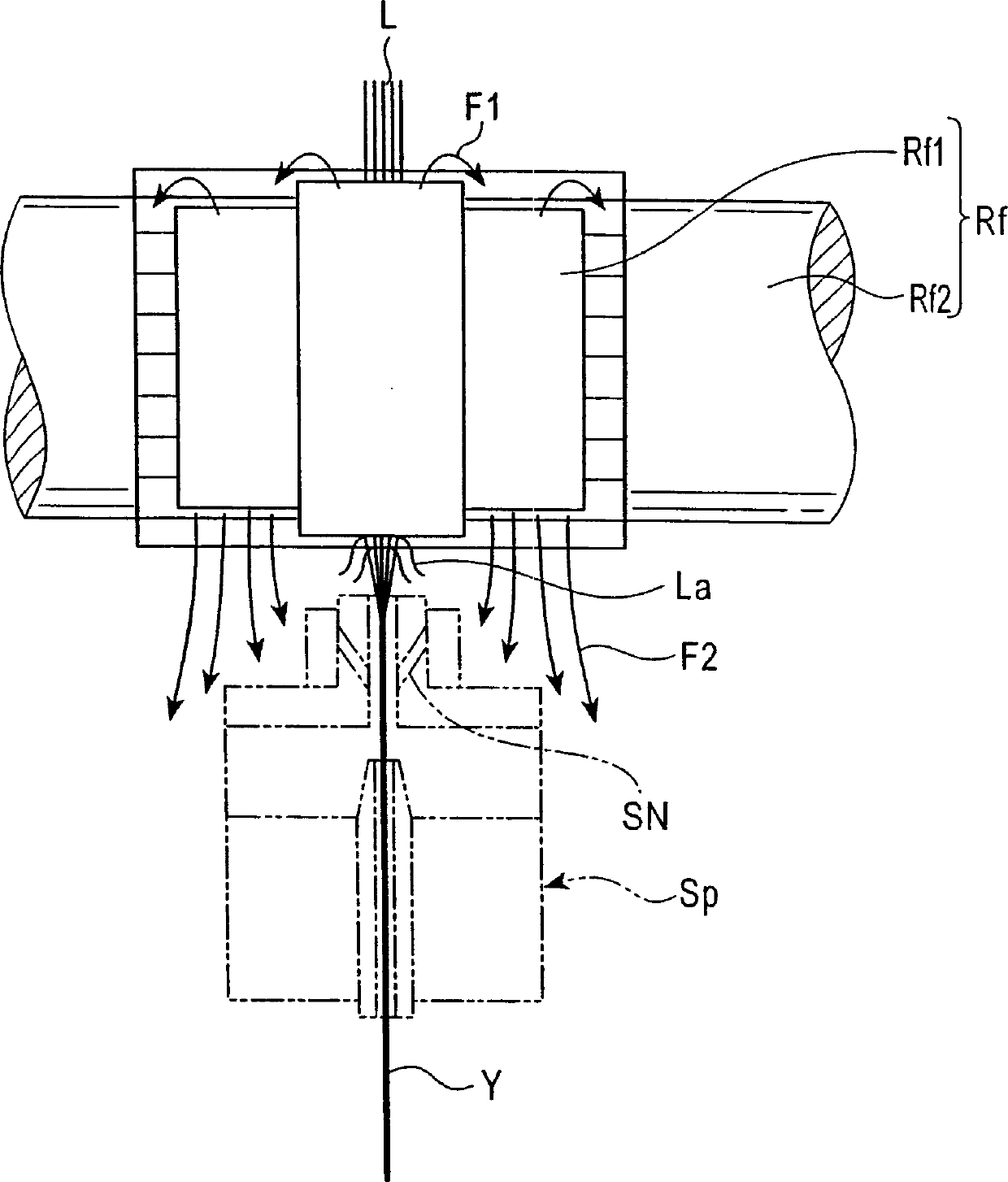

Draft device

InactiveCN1603483ASmall physical propertiesDrafting machinesContinuous wound-up machinesFiberGrip force

It is an object of the present invention to provide a draft device DR including draft rollers which, when a draft device composed of a plurality of draft roller pairs is used, can reduce the adverse effect of associated air currents resulting from the rollers rotating at high speed while maintaining a gripping force and can effectively utilize the associated air currents to suppress the spread of a bundle of fibers L. The present invention provides a draft device DR including a plurality of roller pairs that pull a bundle of fibers L while feeding the bundle downstream, wherein associated air currents resulting from a roller constituting the roller pair are passed through ends of the roller, and gaps are provided which form air passages in which the air currents act as air flows forming a prevention wall that hinders spread of the bundle of fibers fed while being drafted.

Owner:MURATA MASCH LTD

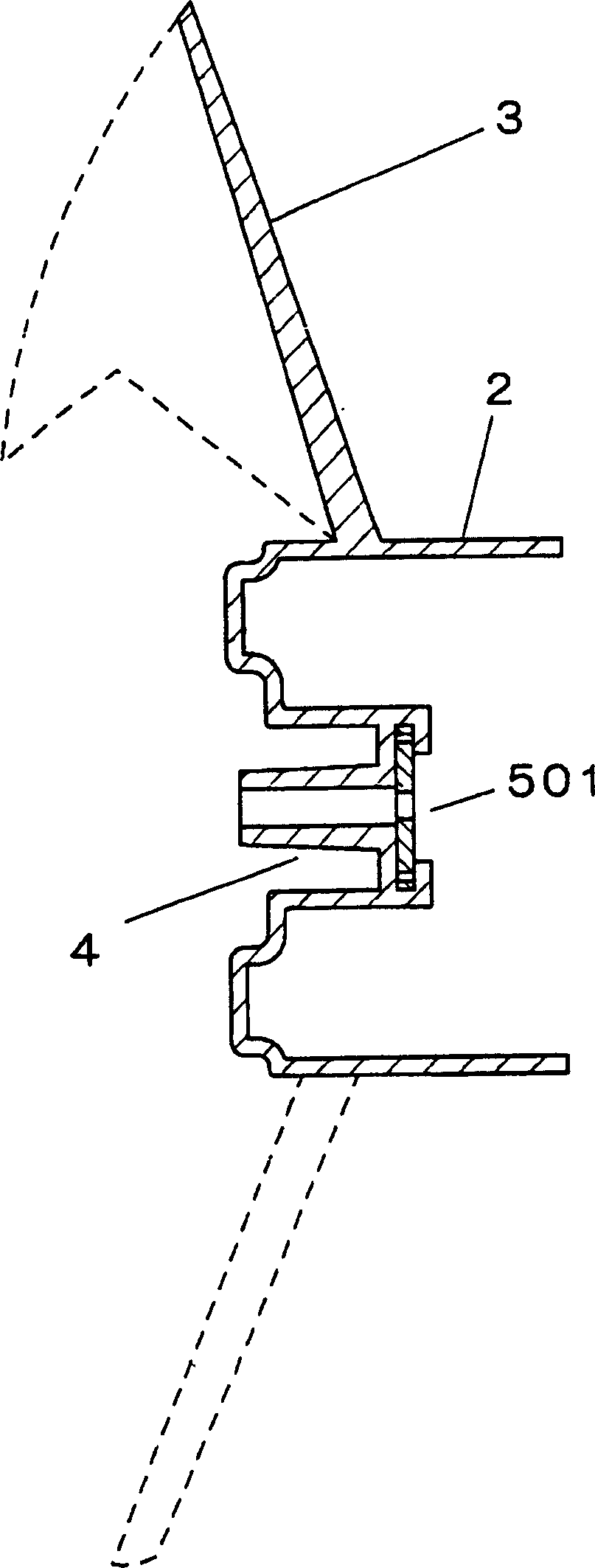

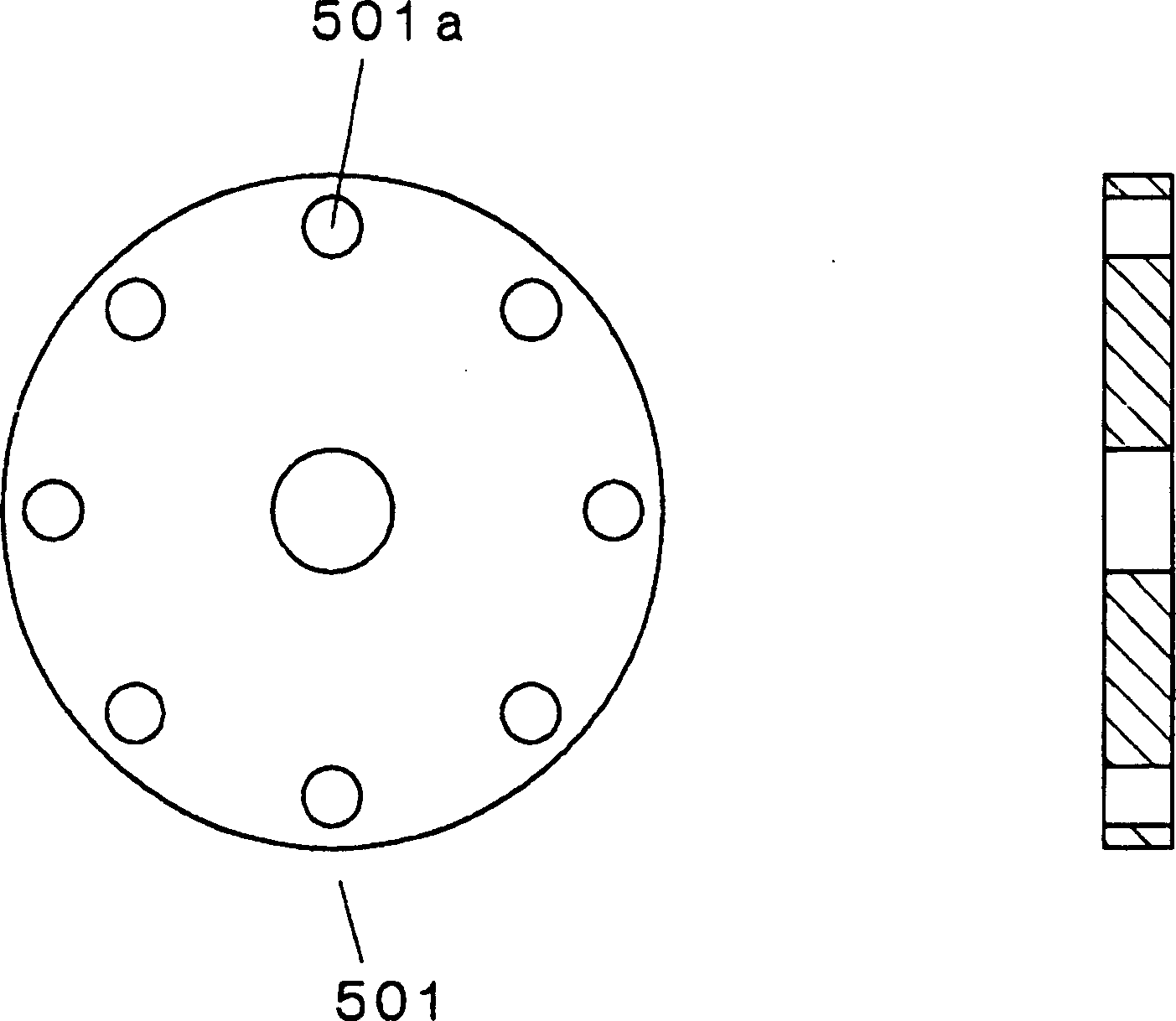

Blower impeller

Provided is an impeller for a blower using a highly rigid resin at a flat component without using a metal flat component particularly at a bearing portion and having an improved recycling property. The impeller for the blower comprises a plurality of blades 3 around a hub 2. It has a cylindrical resin bearing portion 4 at the center of the hub for serving as a bearing for a motor shaft and a resin flat component 501 at the bearing portion for fixing the impeller for the blower to the motor shaft with a nut.

Owner:PANASONIC CORP

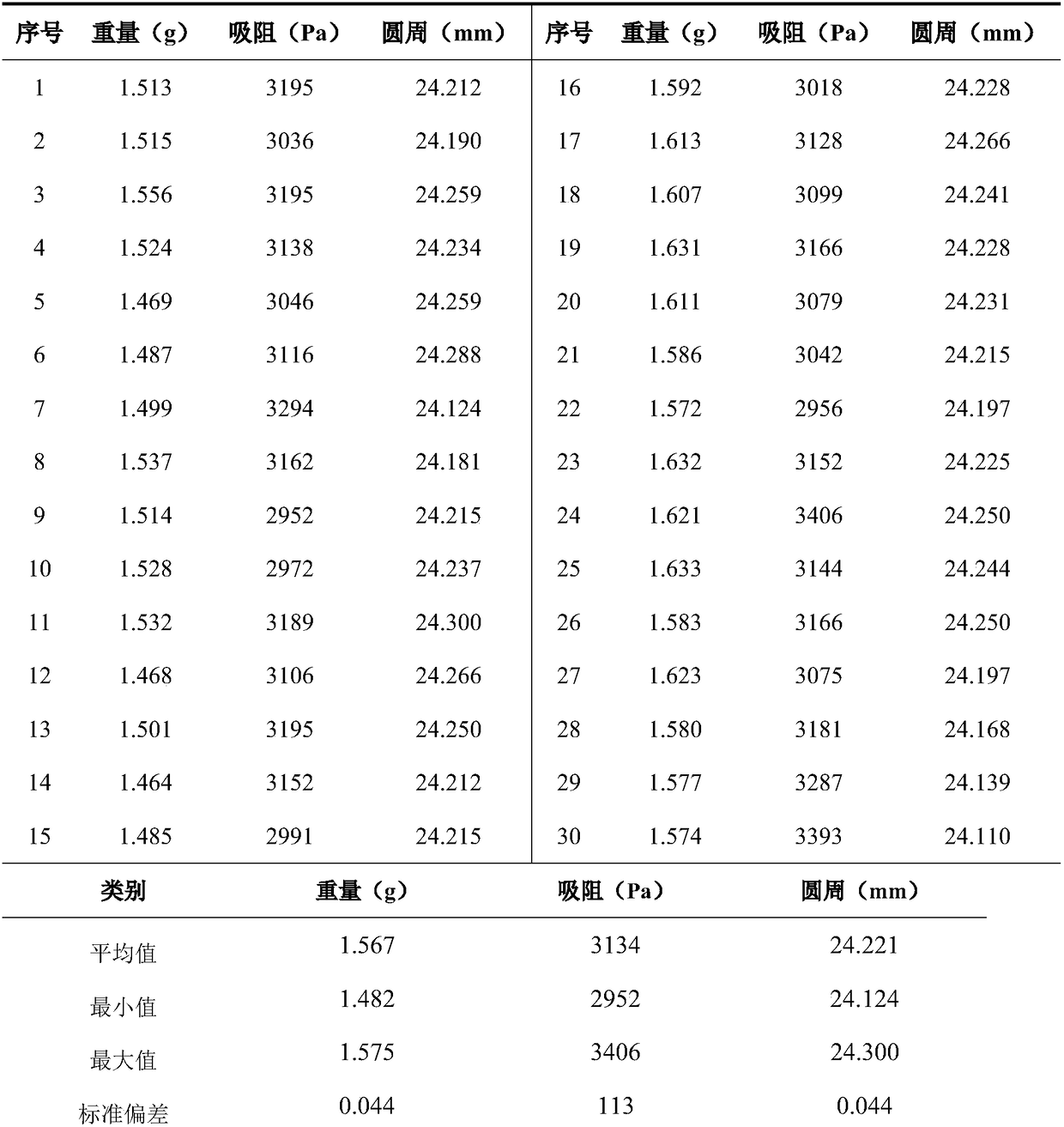

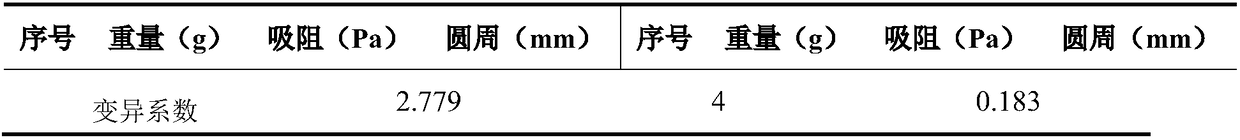

Preparation method for heat-not-burn cigarette core stick of rolling cigarette

ActiveCN108323800AAvoid loss of tobacco contentReduced opening and wrinkling stepsTobacco treatmentTobacco smoke filtersHeat not burnEngineering

The invention discloses a preparation method for a heat-not-burn cigarette core stick of a rolling cigarette. The preparation method comprises the following steps that (1) a remanufactured tobacco roll is selected and is rolled and placed on a rolling shaft, the tobacco roll is divided into strips and cut into shreds to form a lateral half-cut and longitudinal continuous state, and a rolling machine rolls the tobacco roll to a cannular remanufactured tobacco roll; (2) machine shaping is carried out on the cannular remanufactured tobacco roll of the step (1) by conventional paper-based mouth stick shaping equipment, the cannular remanufactured tobacco roll is gathered to form a stick and cut for shaping, and the heat-not-burn cigarette core stick of the rolling cigarette is obtained. The preparation method solves the problems of complex preparation and shaping and sensory quality deficiencies, and the process is simple.

Owner:CHINA TOBACCO YUNNAN IND

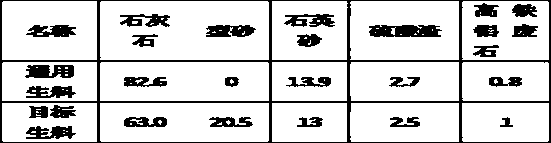

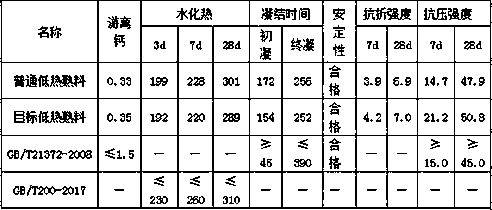

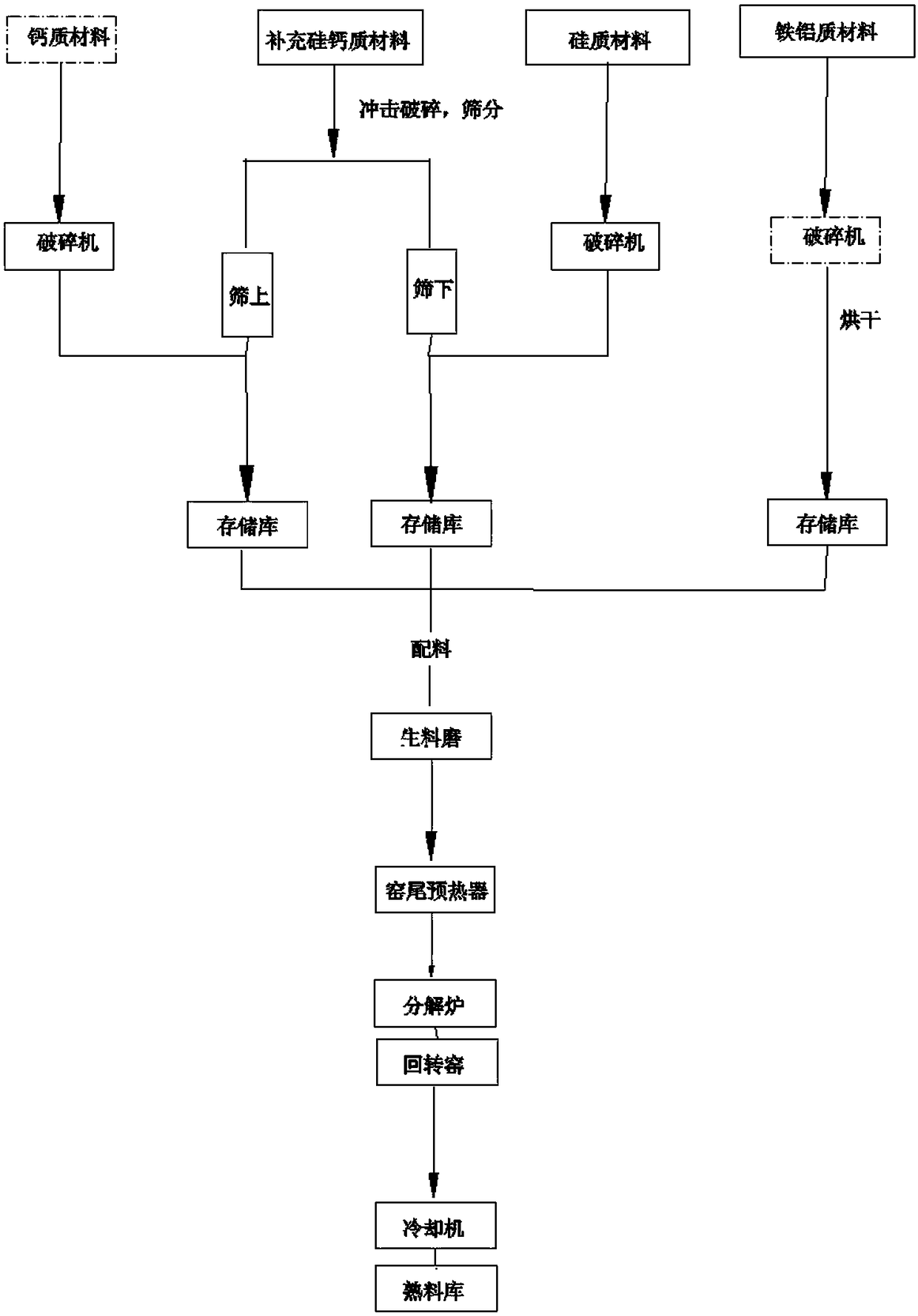

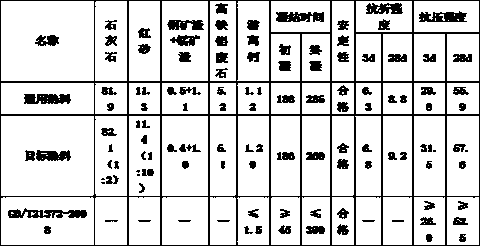

Silicate cement clinker and preparation method thereof

The invention discloses silicate cement clinker and a preparation method thereof, and relates to the technical field of preparation of cement. The silicate cement clinker prepared by the invention isprepared from the following raw materials in percentage by weight: 42-72% of limestone as a calcium material, 1-20% of a silicon material, 10-40% of a supplement calcium material, 0-5% of an iron material, and 3-15% of an iron-aluminium material. The supplement calcium material is limestone moulding sand waste. According to the invention, the limestone moulding sand waste is applied to the cementclinker, so that cost of the enterprises can be reduced; waste can be changed into things of value; and great social benefits and economic benefits are achieved for society and the enterprises.

Owner:JIAHUA SPECIAL CEMENT

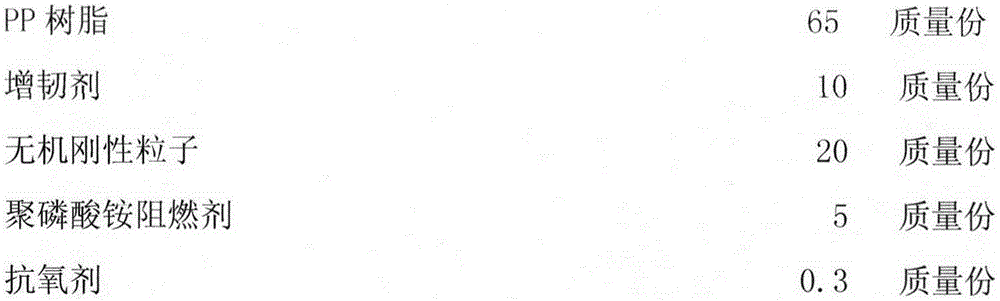

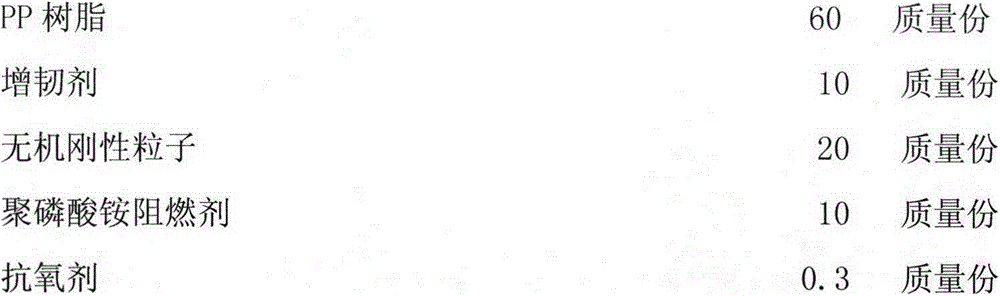

Method for preparing halogen-free flame retardant polypropylene modified material

The invention relates to a modifying method of a polypropylene modified material and belongs to the high polymer material modification process. The invention discloses a method for preparing the halogen-free flame retardant polypropylene modified material, so that a V-0 stage flame retardant property can be obtained and an excellent mechanical property can be kept. The polypropylene modified material is composed of the following components in parts by weight: 45-95 parts of polypropylene resin (PP), 0-15 parts of POE elastomer, 0-25 parts of inorganic rigid particle, 5-20 parts of ammonium polyphosphate fire retardant (APP), and 0.2-0.4 part of antioxidant. Each component is blended and squeezed so that the prepared modified polypropylene modified material is high in flame retardant efficiency, excellent in mechanical property, halogen-free, non-poisonous and environmentally friendly and can be widely used for the automobile and electric product material.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

A 100% low-floor tram car and its assembly method

ActiveCN104015742BImprove mechanical propertiesSmall physical propertiesRailway transportAxle-box lubricationGeneral assemblyModular design

The invention discloses a motor car of a 100% low-floor tramcar and an assembly method of the motor car. The motor car comprises a few of large components, such as a top rack, a side wall, a bottom rack, an end wall, an upper hinge component and a cab, wherein the components adopt a riveting mode instead of a traditional welding mode. A car body component adopts a modular design, the components are riveted, each component has good production independence, maintenance universality and interchangeability, and each component can synchronously develop production. Riveting is free of a heat effect, or even coating can be carried out before general assembly, so that the production efficiency is greatly improved, other components of the car body adopt an aluminum profile welding structure except for that the components with large stress adopt a steel structure, the total weight of the car body is greatly relieved in comparison with an all-steel structure, and the lightweight purpose is achieved.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Rubber hose and preparation method thereof

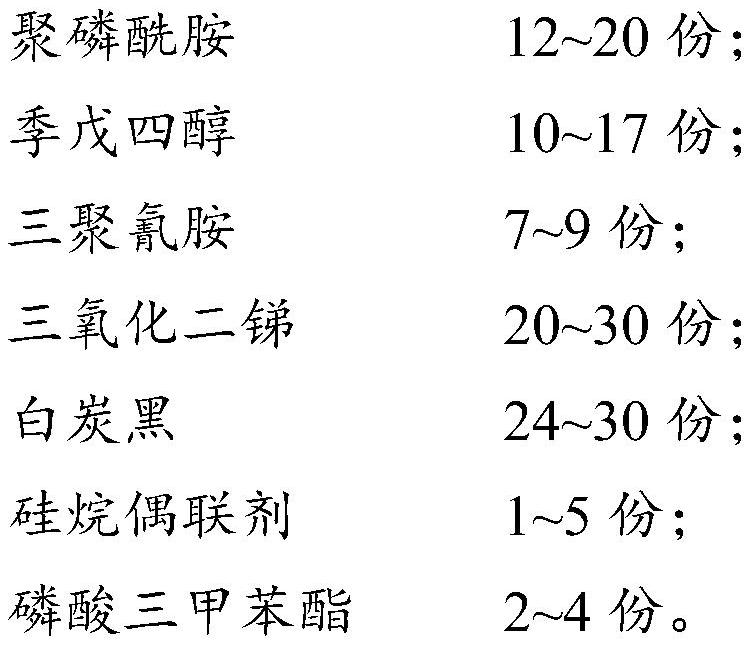

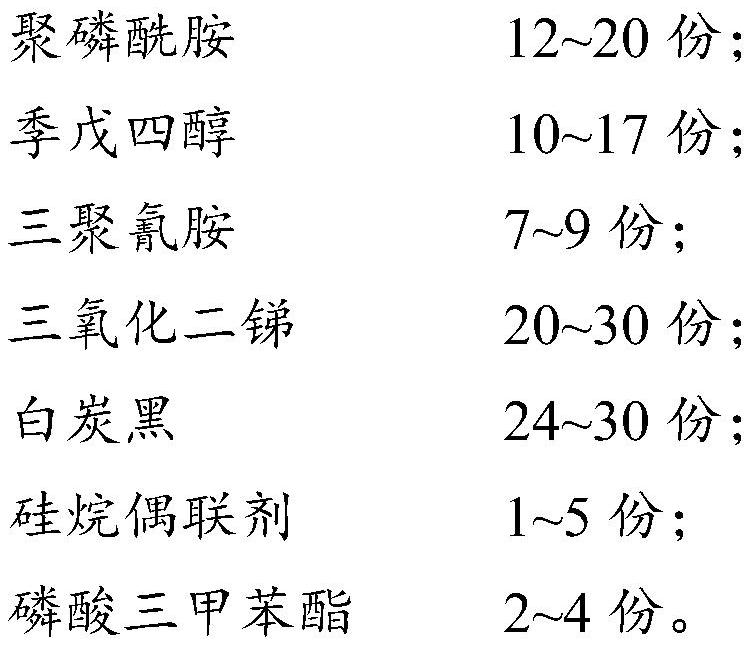

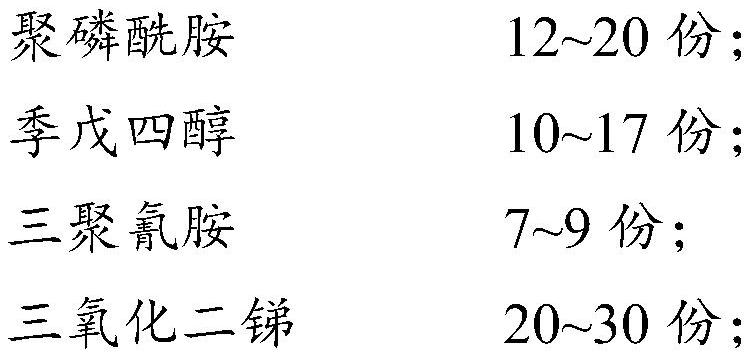

PendingCN113513640AAvoid heat agingAvoid crackingNon-macromolecular adhesive additivesFlexible pipesPolymer sciencePhosphoric acid

The invention relates to the technical field of fireproof materials, in particular to a rubber hose and a preparation method thereof. The rubber hose sequentially comprises a lining layer, a first steel wire framework layer, a middle rubber bonding layer, a second steel wire framework layer and an outer rubber layer in the pipe diameter direction; the lining layer is prepared from nitrile rubber and NBR / PVC rubber and plastic alloy; the first steel wire framework layer is compounded on the lining layer; the middle rubber bonding layer is compounded on the steel wire framework layer; the middle rubber bonding layer is prepared from nitrile rubber and chloroprene rubber; the second steel wire framework layer is compounded on the middle rubber bonding layer; the outer rubber layer is compounded on the second steel wire framework layer; the outer rubber layer is prepared from nitrile rubber, rubber and plastic alloy and a compound flame retardant; the compound flame retardant is prepared from the following components in parts by weight: 12 to 20 parts of polyphosphamide, 10 to 17 parts of pentaerythritol, 7 to 9 parts of melamine, 20 to 30 parts of antimony trioxide, 24 to 30 parts of white carbon black, 1-5 parts of a silane coupling agent, and 2 to 4 parts of tricresyl phosphate. The rubber hose has excellent fire resistance and ultrahigh pressure performance.

Owner:LUOHE LETONE RUBBER

Low-gloss polypropylene composite and preparation method thereof

The invention provides a low-gloss polypropylene composite and a preparation method thereof. Modified polypropylene has low gloss while maintaining excellent mechanical properties. The low-gloss polypropylene composite comprises components in parts by mass as follows: 40-90 parts of polypropylene resin, 5-30 parts of inorganic filler, 5-30 parts of a matting agent and 0.2-0.4 parts of an antioxidant. The modified polypropylene prepared by blending and extruding the components has low gloss and excellent mechanical properties, and can be widely used as a material for automobiles and electronics.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

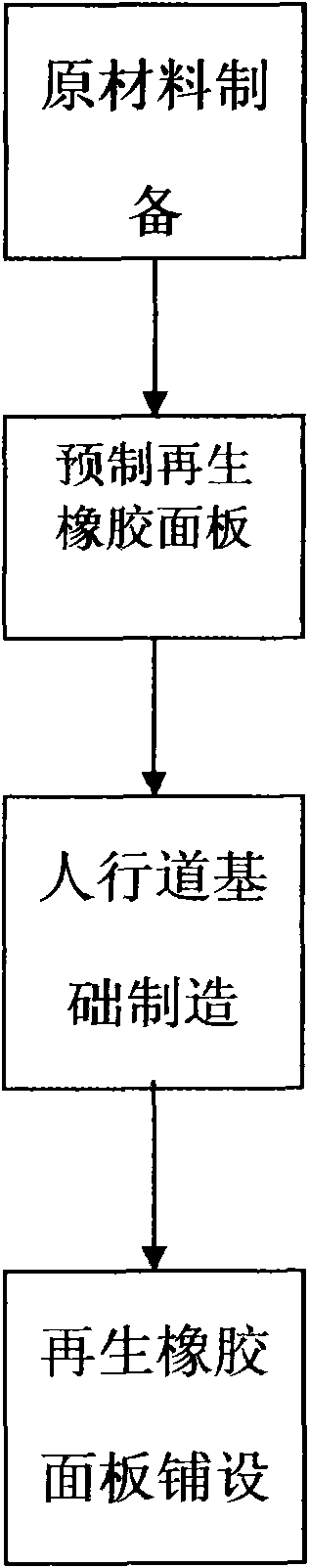

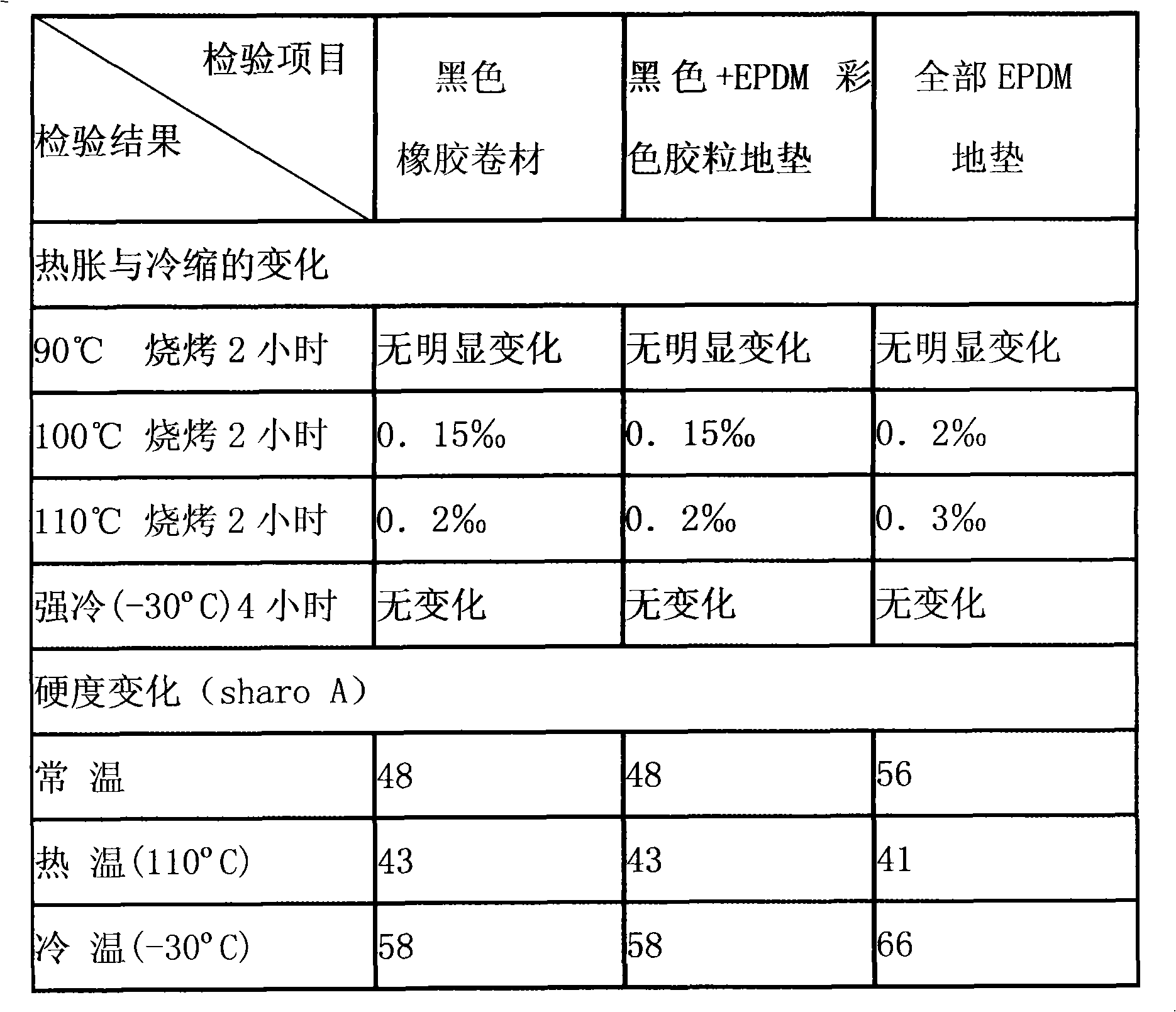

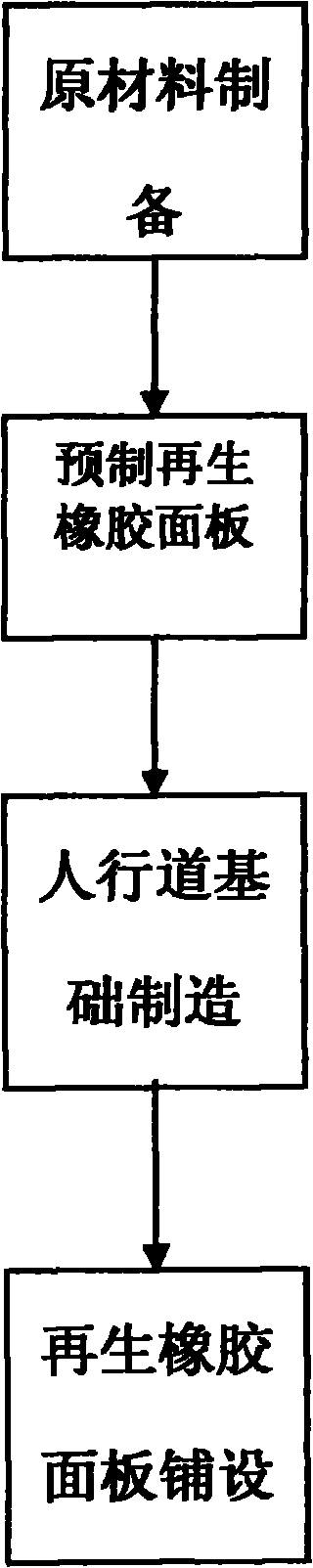

Process for manufacturing and paving sidewalk rubber floor mat

InactiveCN101871195AReduce energy consumptionSmall physical propertiesSidewalk pavingsAdhesiveResource recovery

The invention discloses a process for manufacturing and paving a sidewalk rubber floor mat. The process flow comprises preparation of raw materials, prefabrication of reclaimed rubber panels, manufacture of sidewalk groundwork, pavement of the rubber panels and the like. The steps are as follows: uniformly stirring the prepared colloidal particles and polyurethane glue in a mixer according to a certain ratio to prefabricate into the reclaimed rubber panels; cleaning a basic road surface and then smearing an MDI environmentally friendly adhesive; and finally cutting the rubber panels into the thickness of 3.2-6mm as required, roll-pressing, checking and then trimming to put the obtained rubber floor mat into service in 48 hours. The process of the invention takes waste rubber products such as waste tires and the like as raw materials and has no secondary pollution, thus effectively solving the problems of resource recovery and utilization of the waste rubber products such as the waste tires and the like; and the process is applied to sidewalk pavement, thus effectively reducing the incidence of accidents.

Owner:上海杰唯时新材料技术有限公司 +1

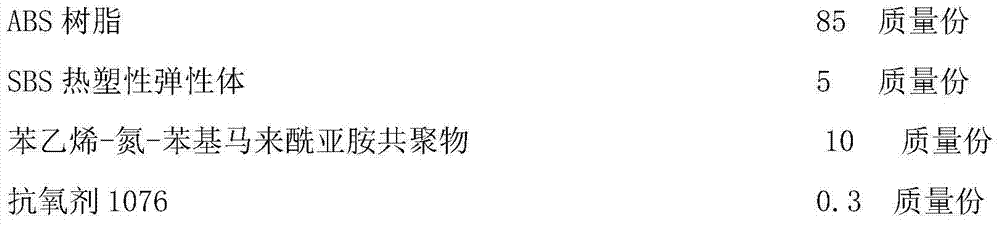

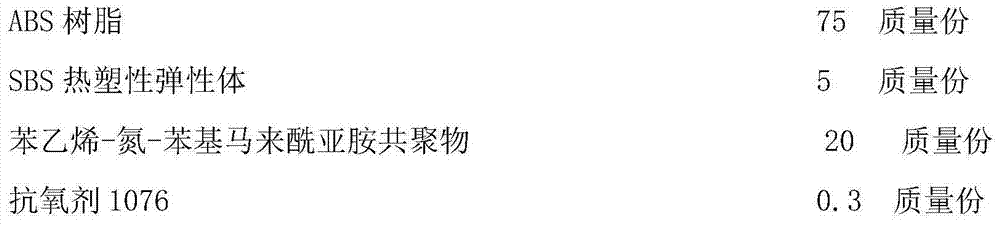

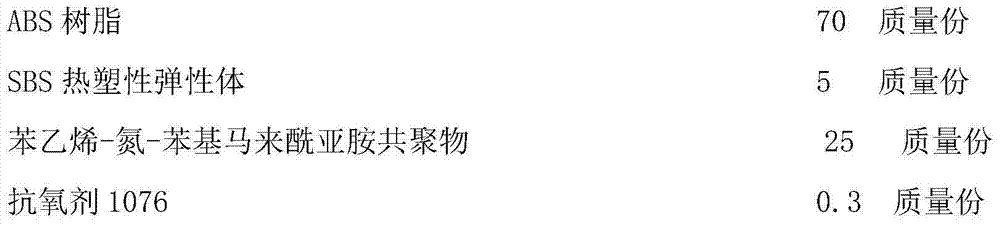

Low/high-heat-resistant ABS resin and preparation method thereof

The invention relates to low / high-heat-resistant ABS resin and a preparation method thereof and belongs to a high molecular material modification processing technology. The invention provides the preparation method of the low / high-heat-resistant ABS resin, which enables ABS resin to have high heat resistance and simultaneously keeps favorable mechanical properties. The low / high-heat-resistant ABS resin comprises the following components in parts by mass: 50-85 parts of ABS resin, 5-20 parts of SBS thermoplastic elastomer, 10-45 parts of a styrene-nitrogen-phenyl maleimide copolymer and 0.2-0.4 part of an antioxidant. The components are blended and extruded to prepare the modified ABS resin which has high heat resistance and favorable mechanical properties and can be widely used as a material for automobiles and electric products.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

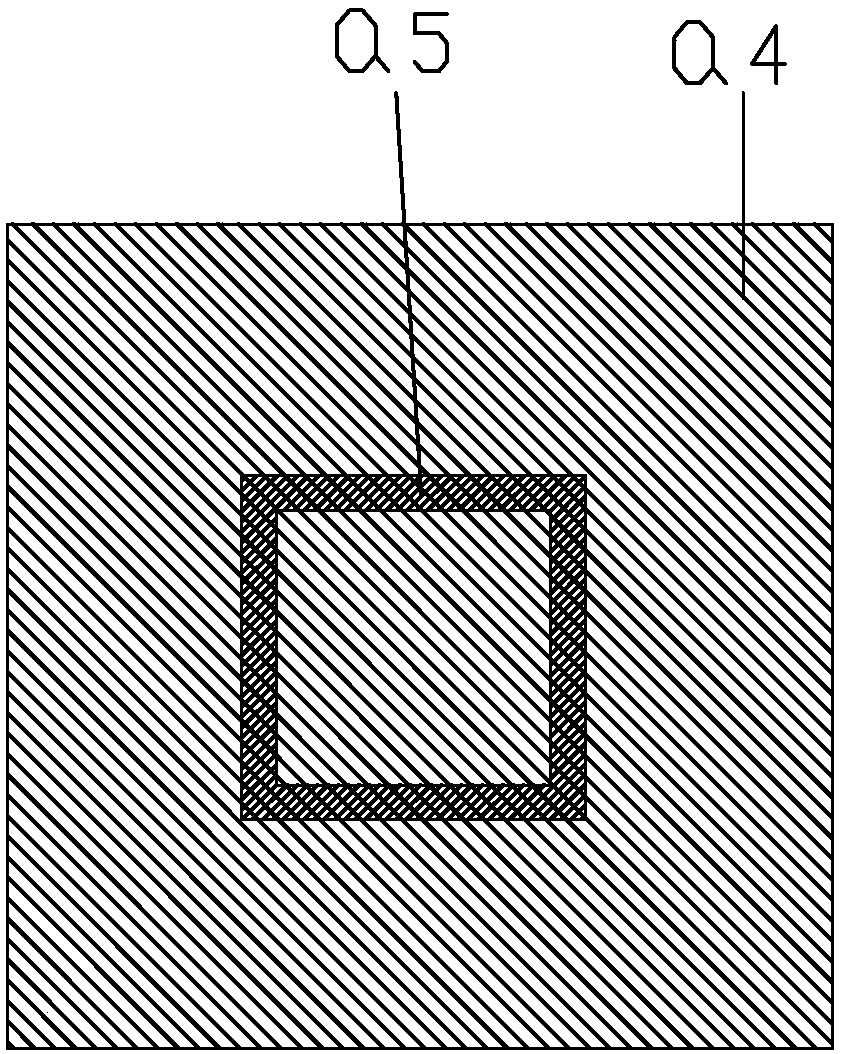

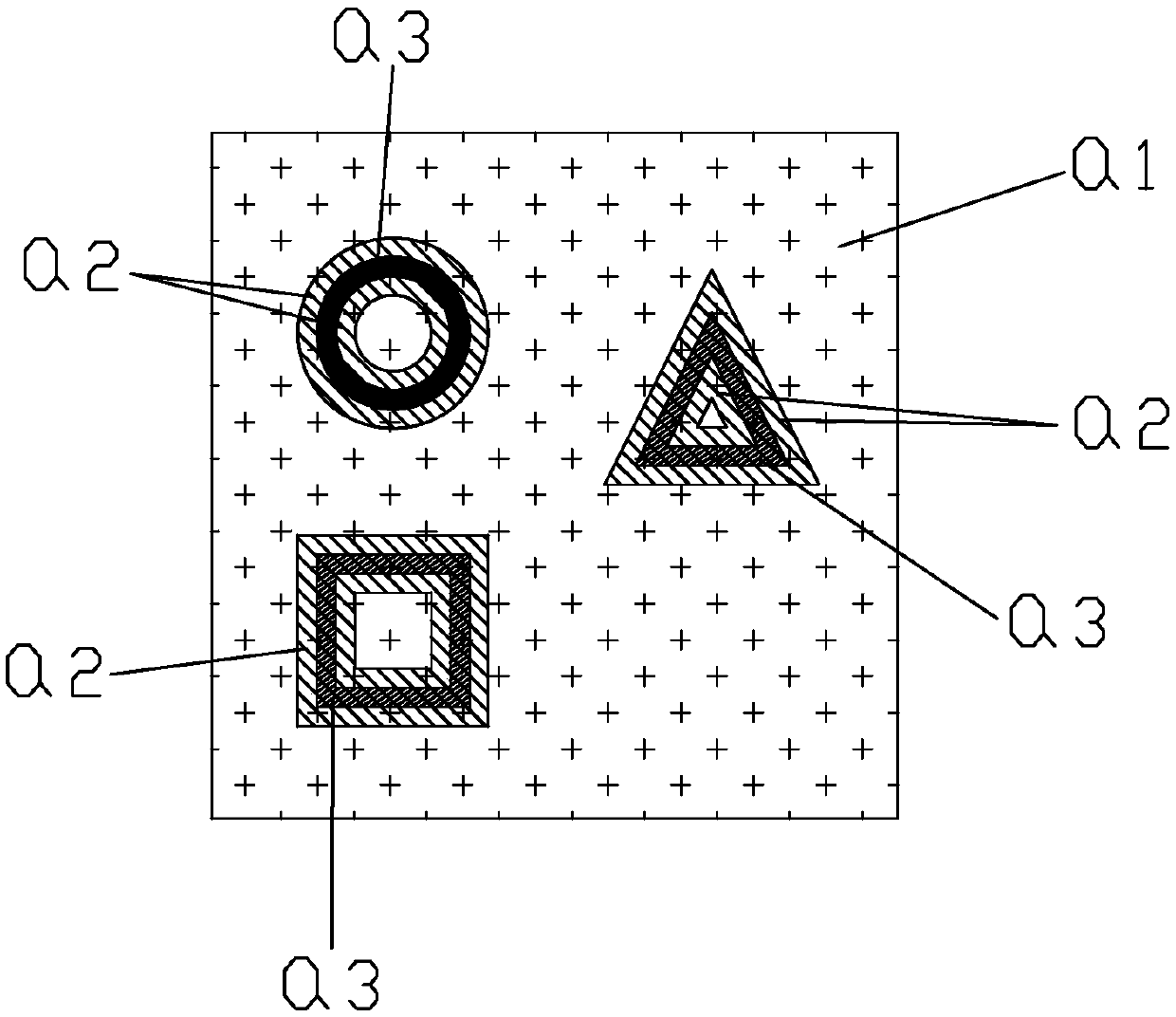

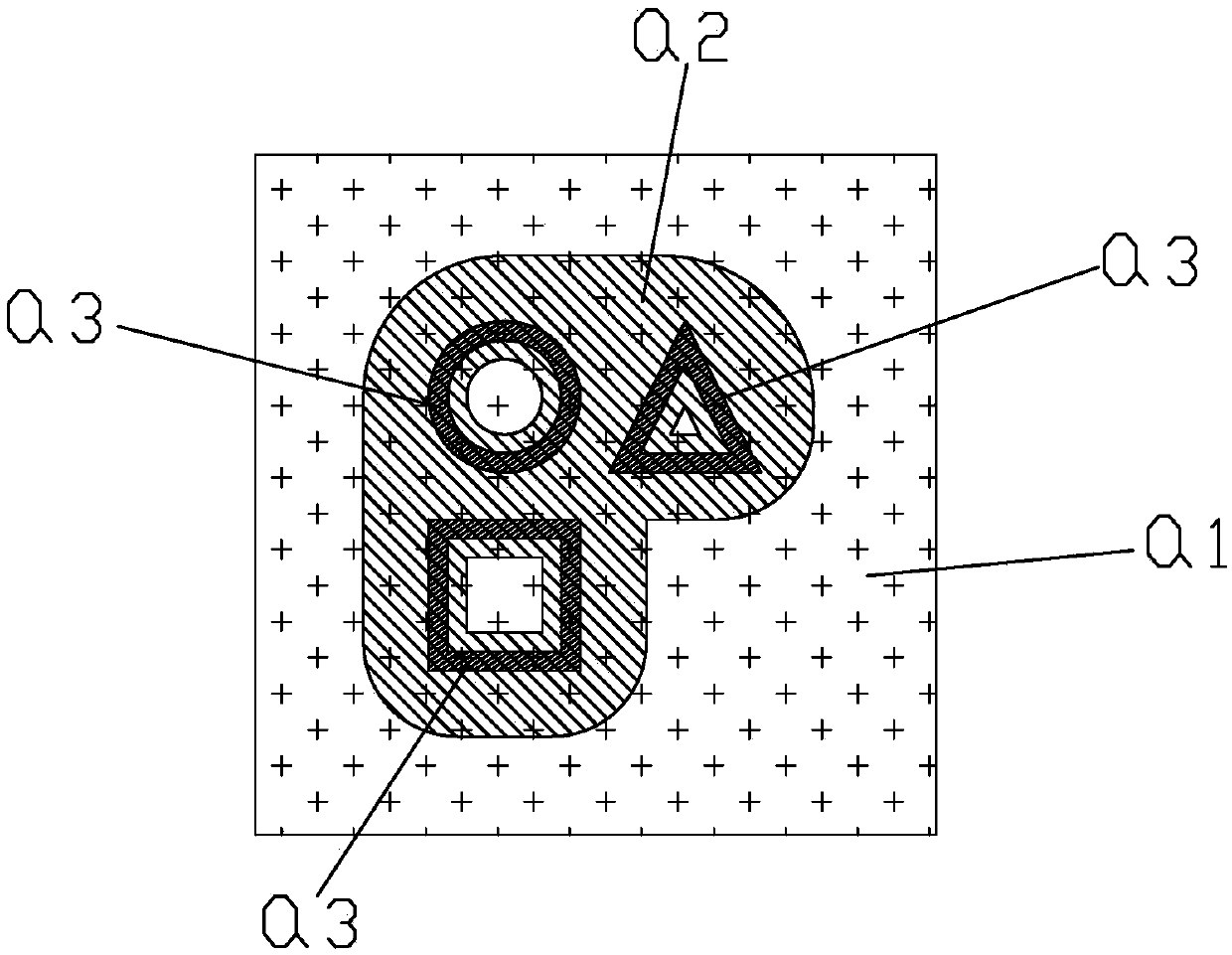

Additive manufacturing method for plastic powder shape-following staircase temperature bed

ActiveCN108044930AReduce use costPrevent physical performance degradationAdditive manufacturing apparatus3D object support structuresForming processesMaterials science

The invention discloses an additive manufacturing method for a plastic powder shape-following staircase temperature bed. The method comprises the steps that a powder is added, the powder is scrapped,first heating is carried out, selection domain for second heating is carried out, laser sintering is carried out, one layer is dropped, and then the steps are repeated. The additive manufacturing system stops all the heating of the plastic powder; a temperature of a molding cylinder drops; and after sintering and melting, plastic powder is cooled and solidified, and a plastic products is formed. The technical defect of plastic powder degradation or excessive cross-linking during the forming process of a existing laser sintered plastic powder is overcome, the reduction of the physical propertyof the plastic powder except a sintered product in the molding cylinder due to a high temperature is prevented, recycling is carried out by avoiding being abandoned or avoiding adding a high proportion of a new powder, so that the cost of the plastic powder of the sintered plastic products is greatly reduced.

Owner:SHANGHAI HANSUN MOLDING CO LTD

Preparation process for silicate cement clinker

ActiveCN109437617AReduce burning energy consumptionLow costCement productionSilicate CementCement manufacturing

The invention discloses a preparation process for silicate cement clinker, and relates to the technical field of cement manufacturing. According to the invention, limestone moulding sand waste is applied to calcination of clinker to the greatest extent by adopting a limestone moulding sand waste harmful component stripping method, and limestone moulding sand waste partly or completely replace limestone. According to the invention, the limestone moulding sand waste is applied to the calcination of the cement clinker, so that cost of enterprises can be reduced, and waste is changed into things of value, and therefore, great social benefits and economic benefits are achieved for society and the enterprises.

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

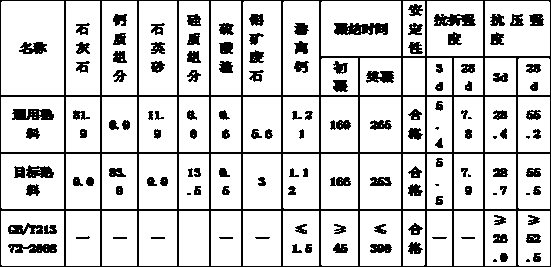

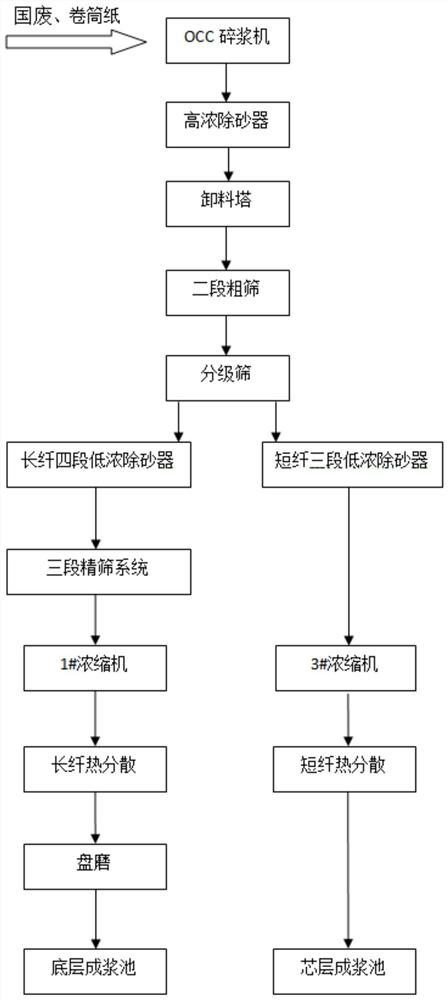

Production process of high-strength environment-friendly liner cardboard paper

PendingCN114293392ASolve limited problemsLow costPaper recyclingPulp beating/refining methodsCardboardFiber

The invention belongs to the technical field of cardboard paper, and provides a production process of high-strength environment-friendly liner cardboard paper, which comprises the following steps: taking domestic bamboo fiber pulp, imported wet paper pulp, imported roll paper and national waste as raw materials according to a specific ratio; the wet paper pulp and the bamboo fiber pulp are mixed and pulped through a medium-concentration pulper, a sand remover, a pre-grinding pool, a disc mill and a post-grinding pool in sequence, and first mixed pulp is obtained; in the OCC pulping line, the cut roll paper and national waste are treated through an OCC pulper, a high-concentration sand remover, a discharging tower, a two-section coarse screen and a classifying screen in sequence to obtain long fibers and short fibers, and then the long fibers and the short fibers are subjected to aftertreatment to obtain long fiber pulp and short fiber pulp; and mixing the long fiber pulp, the short fiber pulp and the first mixed pulp, and performing papermaking to obtain the liner cardboard paper. According to the production process, national waste is mainly used, quantitative roll paper, wet paper pulp and bamboo fiber pulp are matched, and the production process is optimized, so that the cost is reduced, the production efficiency is improved, the quality of finished paper can be improved, and the problem that external waste import is limited is solved.

Owner:东莞理文造纸厂有限公司

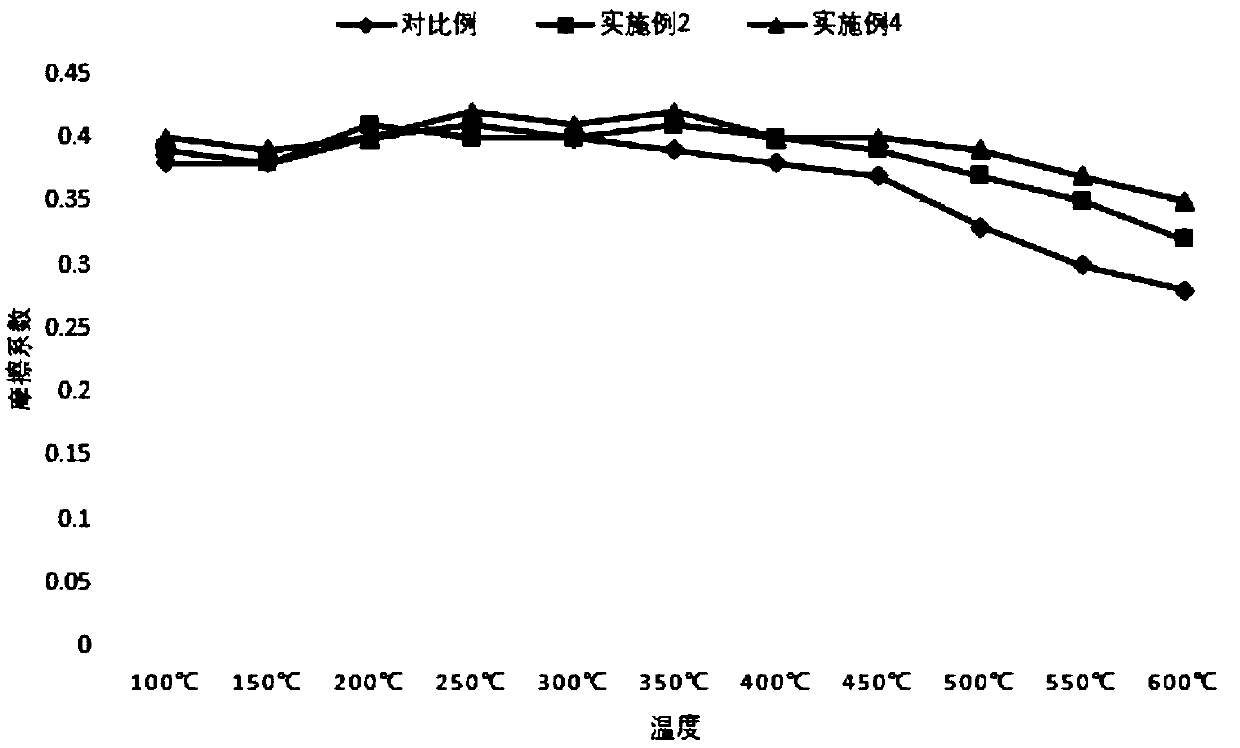

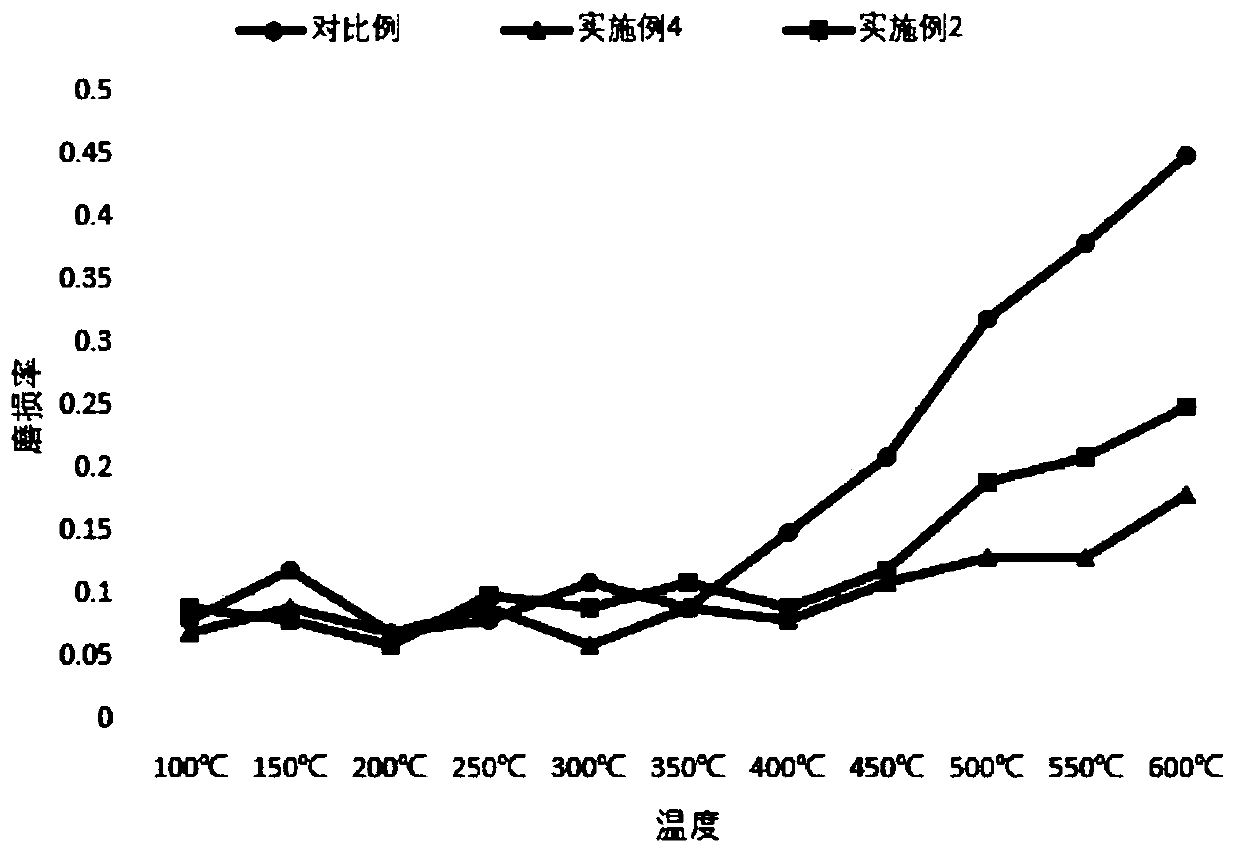

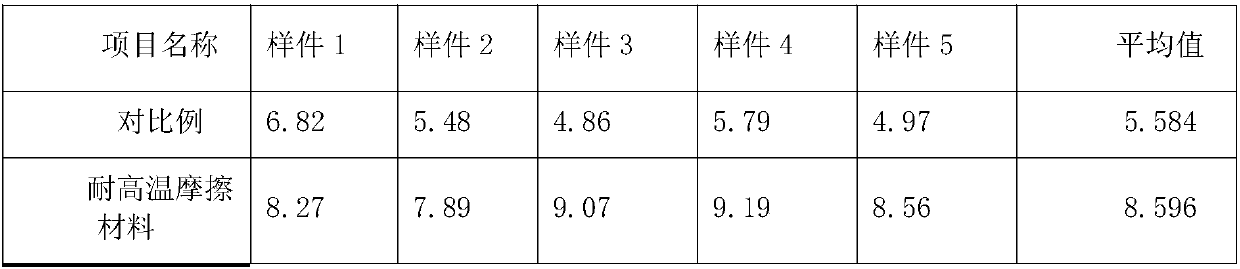

High-temperature resistant friction material and preparation method thereof

InactiveCN107740828AAvoid carbonizationReduce hardnessOther chemical processesFriction liningFiberMass ratio

The invention discloses a high-temperature resistant friction material. The high-temperature resistant friction material comprises heat-conduction mineral fibers, inorganic high-temperature adhesivesand porous mineral powder. A preparation method of the high-temperature resistant friction material comprises the following steps of (1) taking and mixing the heat-conduction mineral fibers, the inorganic high-temperature adhesives and the porous mineral powder according to the mass ratio; (2) cleaning, degreasing and polishing the surface of a steel backing and spraying the adhesives to the surface of the steel backing for standby application; (3) conducting pressing; (4) conducting heat treatment; (5) conducing grinding treatment; and (6) spraying plastic paint to the surface of the steel backing. The high-temperature resistant friction material is scientific in proportion, easy to manufacture and low in cost, has remarkable physical performance and stable friction coefficient. Meanwhile, the high-temperature resistant friction material is stable in friction coefficient, small in degeneration, good in recovery performance, moderate in hardness, comfortable and reliable in braking andcapable of lowering braking noise.

Owner:WUHAN YOUFIN FRICTION MATERIAL

Method for removing scales on surface of wool

The invention relates to a method for removing scales on surface of wool and belongs to the technical field of spinning. The method includes: disposing to-be-treated wool into a mixed solution of oxidant and alcohol for soaking to remove the scales on the surface of the wool; heating the mixed solution to volatilize the oxidant and the alcohol to obtain dry wool with the scales removed; repeatedly cleaning the dry wool by using an alcohol solution, and drying the cleaned wool to obtain the wool with the scales on the surface removed. A heating method is adopted to enable the solution formed by the oxidant and the alcohol for removing the wool scales to be volatilized and removed. The problem of water pollution caused by conventional methods for removing the scales on the surface of the wool is solved. In addition, the method is simple to operate, low in cost and good in wool scale removing effect, and change on physical performance of the wool after being treated by the method is small.

Owner:WUHAN TEXTILE UNIV

Preparation method of slurry pump wear-resistant corrosion-resistant valve rubber material

The invention belongs to the technical field of high polymer materials, and particularly relates to a preparation method of a wear-resistant and corrosion-resistant valve rubber material for a slurrypump. Chlorinated polyether and acrylate rubber are used for blending modification, and the prepared wear-resistant corrosion-resistant valve rubber material has excellent performance on resisting acid, alkali, muddy water, cement paste and the like. The material has the characteristics of wear resistance, scouring resistance, aging resistance, long service life and the like, and has good tensiletear resistance and high temperature resistance.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

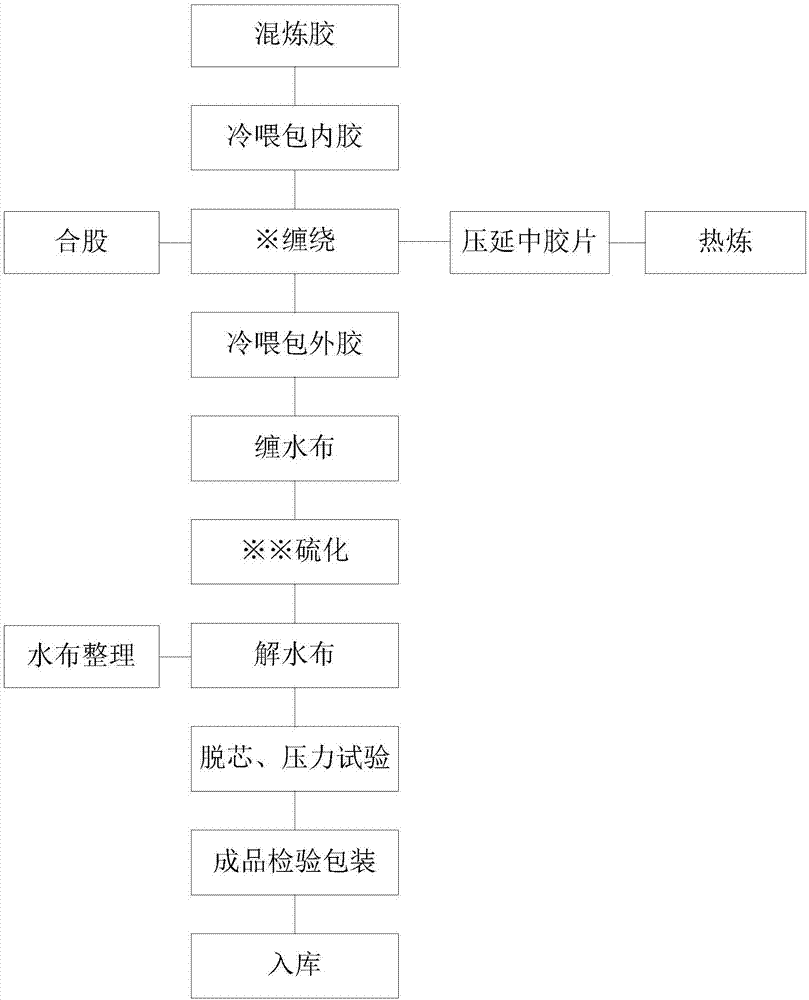

New rubber riding wheel and fabricating process thereof

ActiveCN101586594ASolve \"oversulfur\", poor surface compactnessSolve problems such as \"flow traces\"Shaft and bearingsParaffin waxRubber material

The invention relates to a new rubber riding wheel and fabricating process thereof. The fabricating process of the invention comprises steps of: 1) first mixing, masticating and thinning natural rubber NR and synthetic rubber SBR on an open mill, controlling plasticity of rubber at 0.44 to 0.45; 2) casting the rubber to a mixer, injecting for 3min to 5min, adding accelerator, octadecoic acid, zinc oxide, antiager, coumarone resin and tert-butyl phenolic resin in sequence, injecting for 4min to 6min, adding carbon black, machine oil and paraffin, after pressurizing load, adding sulfur within 60s to mix, discharging immediately and making pieces, cooling after turning evenly on a flat-bed machine, controlling mixing plasticity of rubber at 0.4 to 0.5; 3) casting mixed rubber material to the open mill to warm, then coiling or making pieces, supplying the same to a squeezer to squeeze, distributing pieces and weighing the rubber material according to product requirements for spare use; 4) packing weighed rubber material to a die cavity to enter a flat vulcanizing machine; pressurizing to vulcanize by using low temperature in grads gradually; 5) completing vulcanization.

Owner:JIHUA 3517 RUBBER PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com