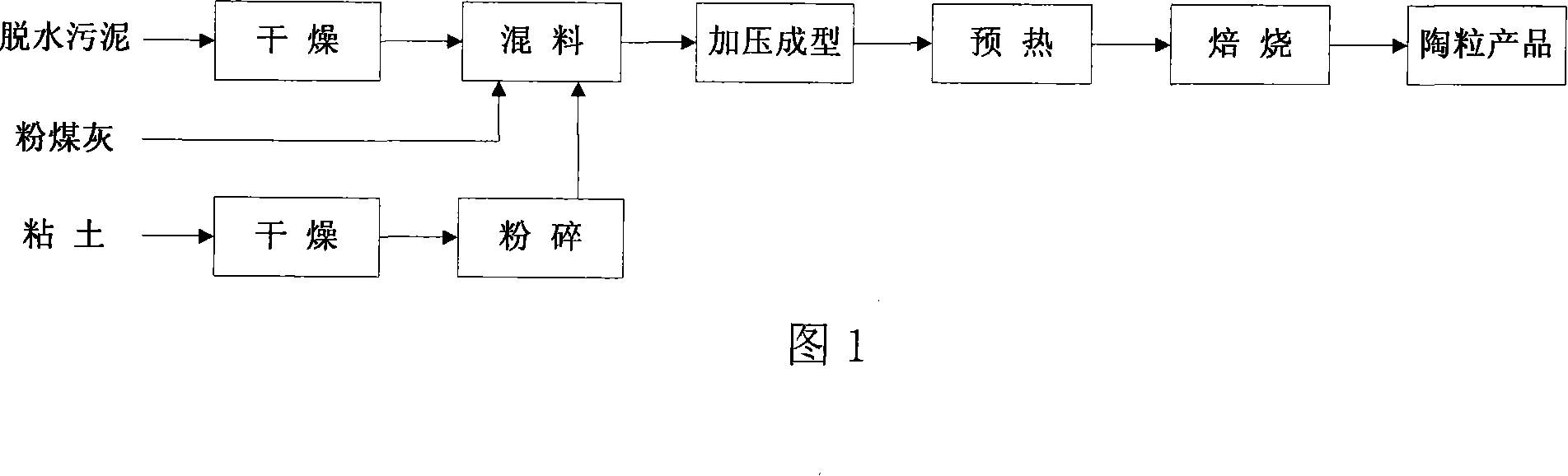

Method for preparing haydite by sintering urban domestic sewage sludge

A technology of urban sewage and ceramsite, which is applied in the production of clay products, ceramic materials, and other household utensils. It can solve the problems of poor fertilizer quality, a large amount of clay and shale resources, and easy to produce odors, and achieve lower roasting temperature. The effect of improving processing efficiency and preventing ceramsite from bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The dewatered sludge produced by an urban sewage treatment plant has a water content of 80.6%, an organic matter content (dry basis) of 50.4wt%, and a bulk density of 1.07g / cm 3 , The melting point of dry sludge is 1050°C. Dry the dewatered sludge at 105°C and pulverize it with a pulverizer, dry the clay at 105°C and pulverize it with a pulverizer, sieve the fly ash, fully mix the three raw materials in a weight ratio of 7:2.5:0.5, and then use Powder tablet press press molding. The molding pressure is 7.5MPa, and the pressure is maintained for 30 seconds. A cylinder with a diameter of 2 cm and a height of about 1 cm is obtained, and each piece weighs about 6 g. After forming, the blank is preheated at 320°C for 20 minutes, and then fired at 1050°C for 35 minutes. The ceramsite product obtained after cooling has a relatively dense glaze layer on the surface, and the interior is lead gray and has a large number of tiny pores. The obtained ceramsite has a compressive ...

Embodiment 2

[0027] The dewatered sludge produced by an urban sewage treatment plant has a water content of 80%, an organic matter content (dry basis) of 52wt%, and a bulk density of 1.01g / cm 3 , The melting point of dry sludge is 1049°C. Dry the dewatered sludge at 105°C and pulverize it with a pulverizer, dry the clay at 105°C and pulverize it with a pulverizer, sieve the fly ash, fully mix the three raw materials in a weight ratio of 8:1.5:0.5, and then use Powder tablet press press molding. The molding pressure is 7.5MPa, and the pressure is maintained for 30 seconds. A cylinder with a diameter of 2 cm and a height of about 1 cm is obtained, and each piece weighs about 6 g. After forming, the blank is preheated at 350°C for 35 minutes, and then fired at 1080°C for 20 minutes. The ceramsite product obtained after cooling has a relatively dense glaze layer on the surface, and the interior is lead gray and has a large number of tiny pores. The obtained ceramsite has a compressive stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com