Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219 results about "Cement manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding. Some of the main ingredients used to make cement include limestone, clay, shale,...

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

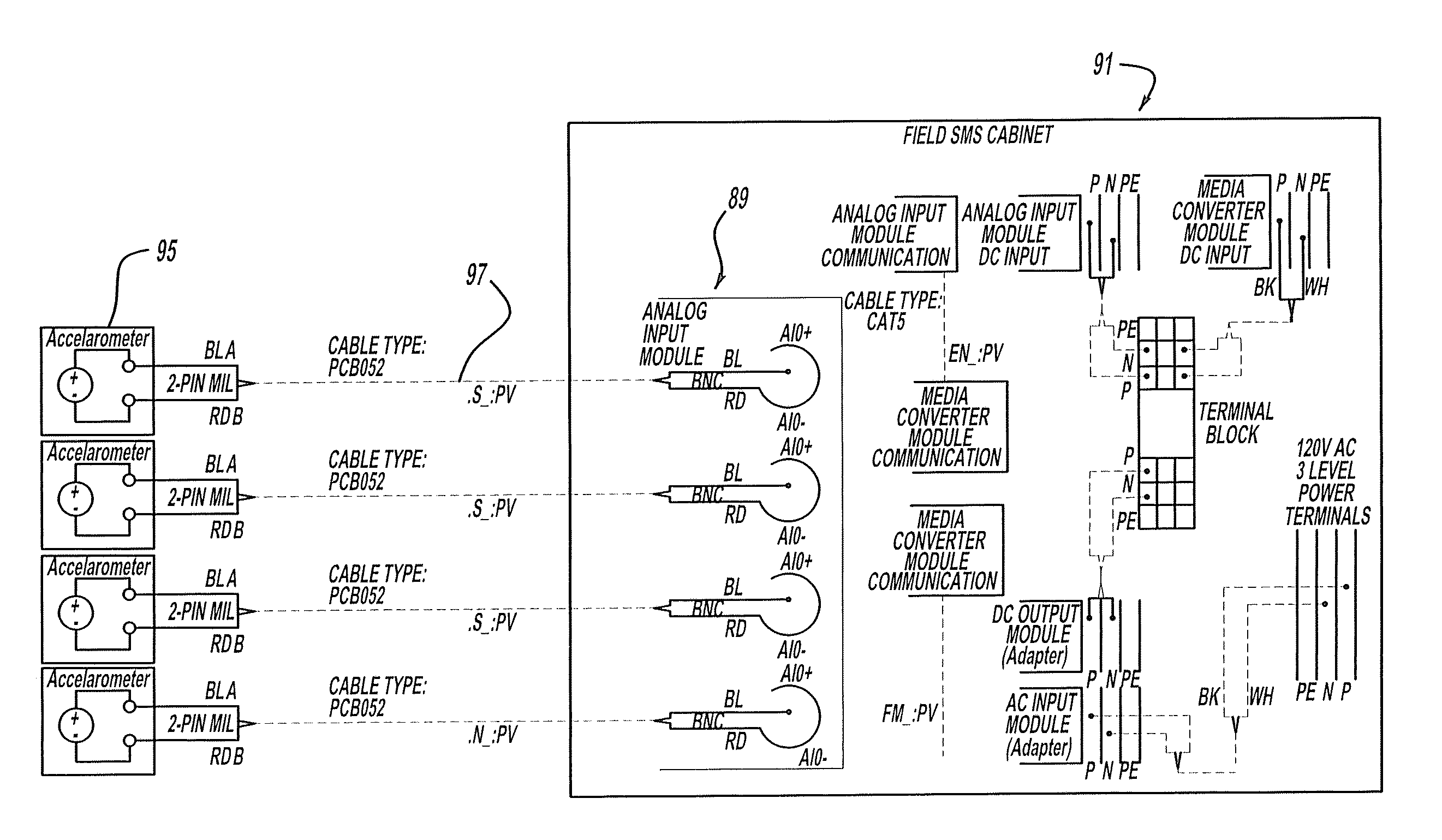

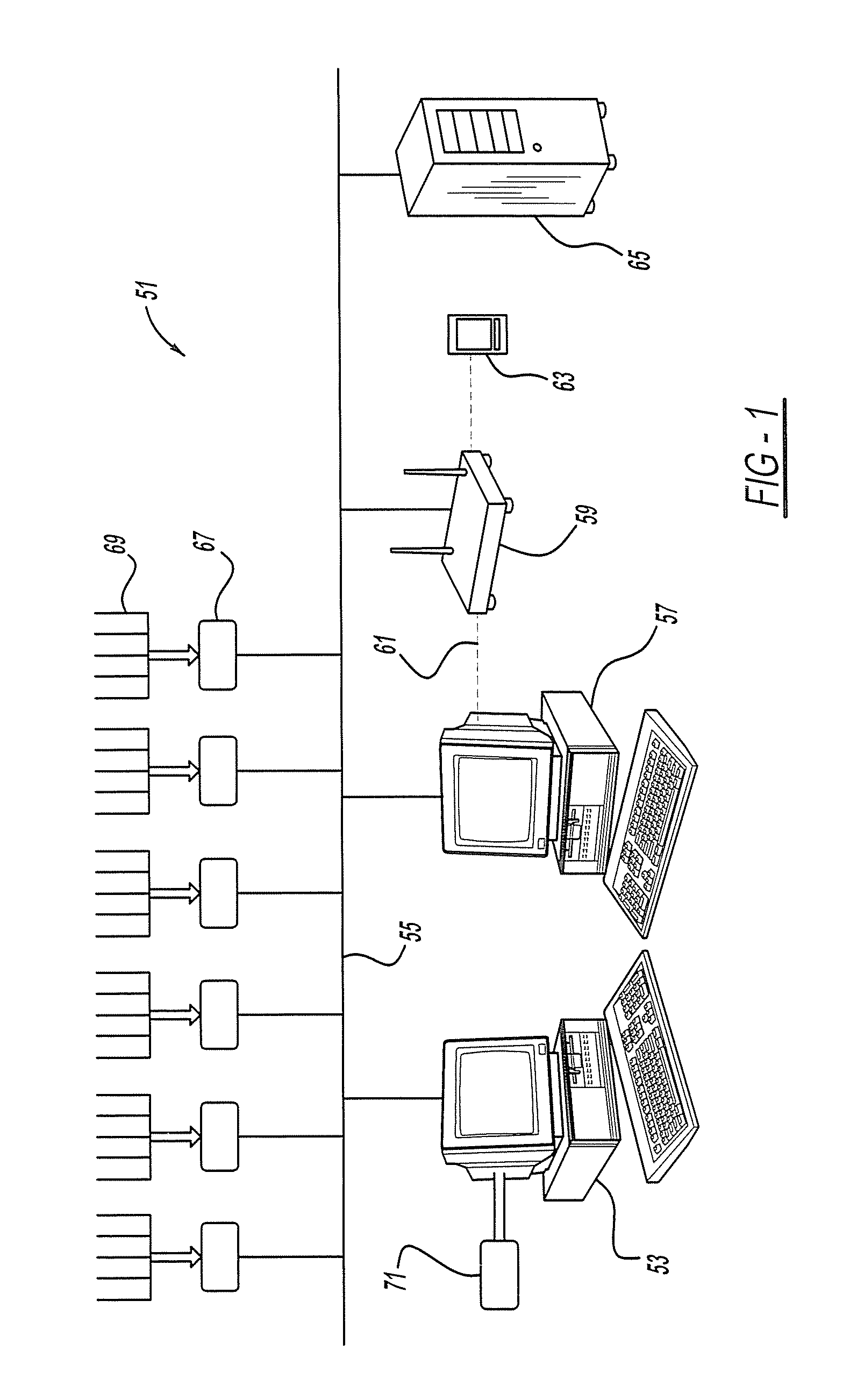

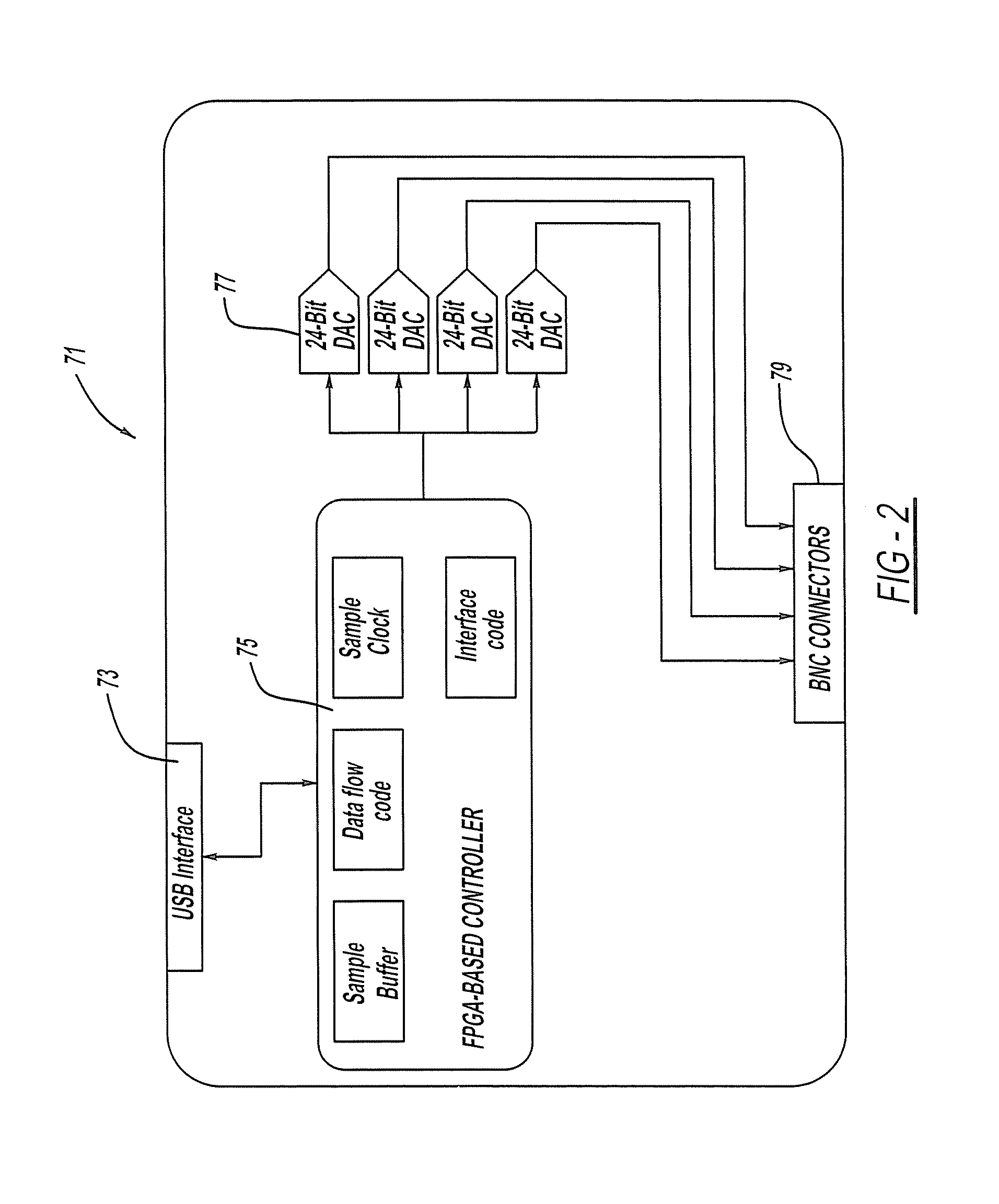

System for monitoring plant equipment

ActiveUS20110184547A1Improve sensed data analysisReduce hardware costsRotary drum furnacesRoads maintainenceCement manufacturingSoftware

A system for monitoring plant equipment is provided. Another aspect provides an automated analysis system wherein software instructions operably compare sensor data to predefined valves and determine mechanical problems in multiple machines. In another aspect, a cement manufacturing system includes sensors for sensing movement conditions of cement making machines. A further aspect provides a central computer connected to vibration sensors associated with cement making machines, where software instructions perform real-time comparisons and machine performance determinations, based at least in part on sensed signals.

Owner:HOLCIM US

Use of organic waste/mineral by-product mixtures in cement manufacturing processes

InactiveUS20050066860A1Reduce nitrogen oxide (NOx) emissionNitrogen compoundsDispersed particle separationNitrogen oxidesCement manufacturing

The use of organic waste / mineral by-product mixtures as raw materials in the manufacture of cement clinker; as alternative or supplemental fuel sources for heating a kiln used in a cement clinker manufacturing process; and, to reduce nitrogen oxide (NOx) emissions generated during cement manufacturing processes are disclosed.

Owner:N VIRO INT

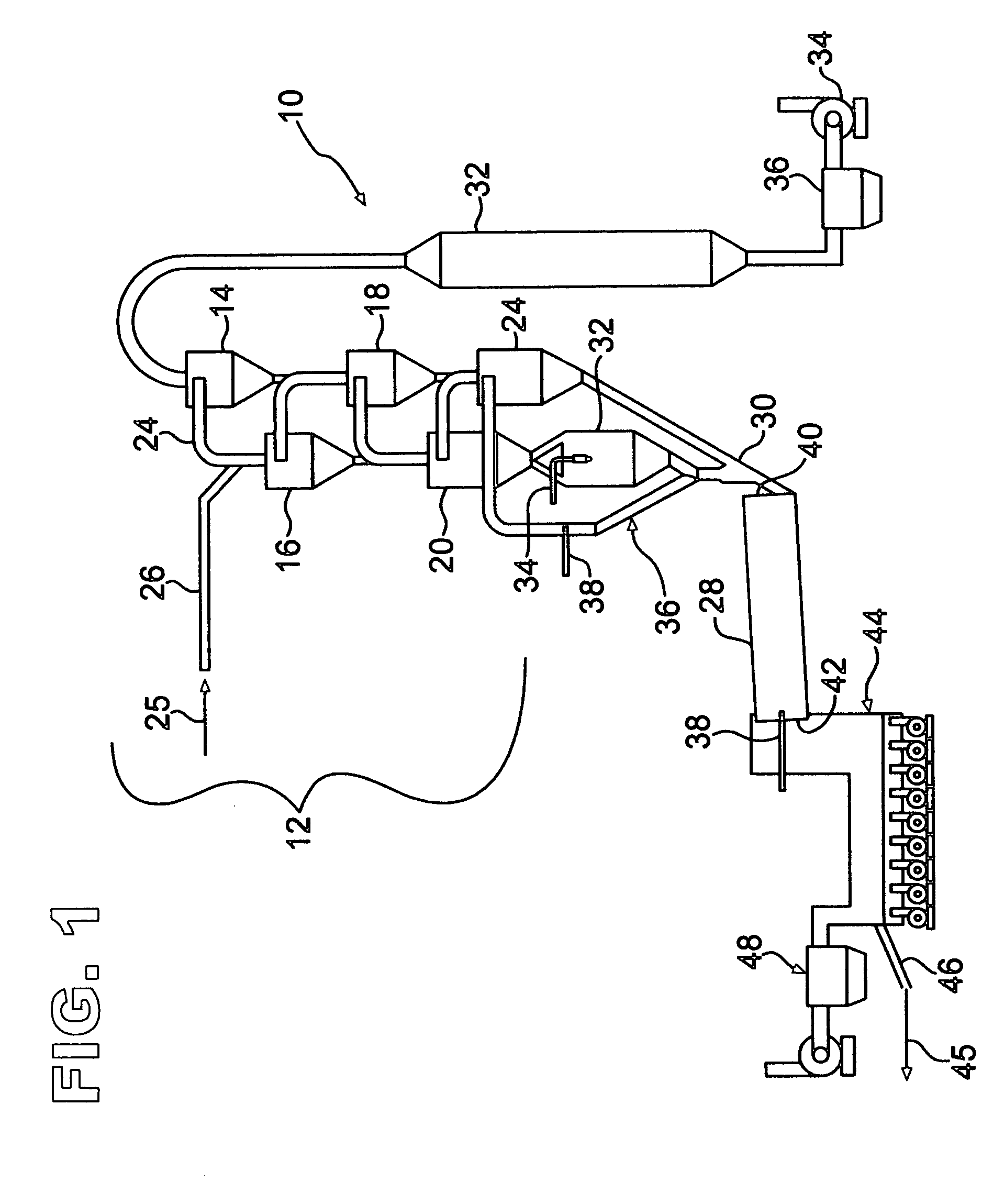

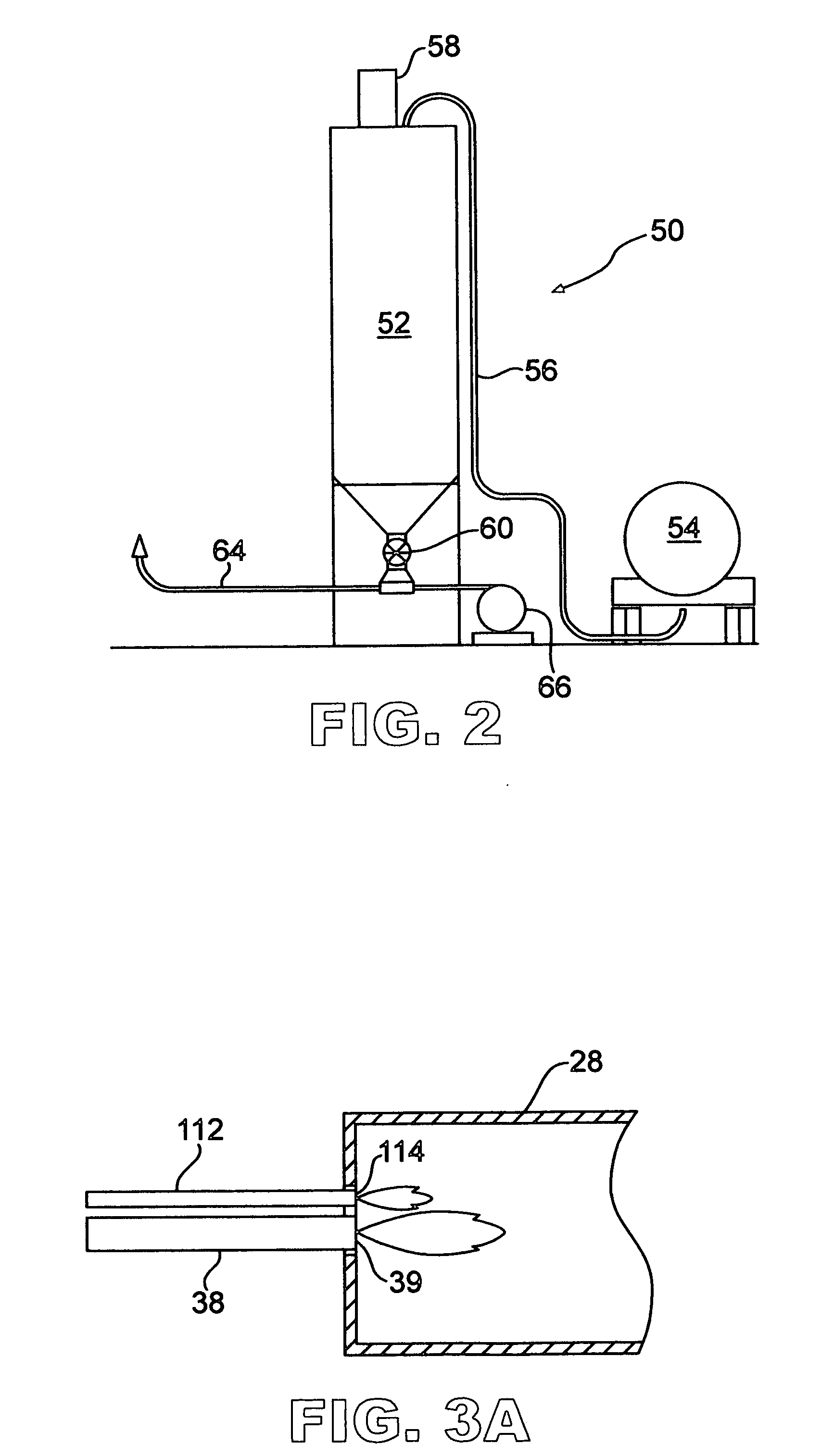

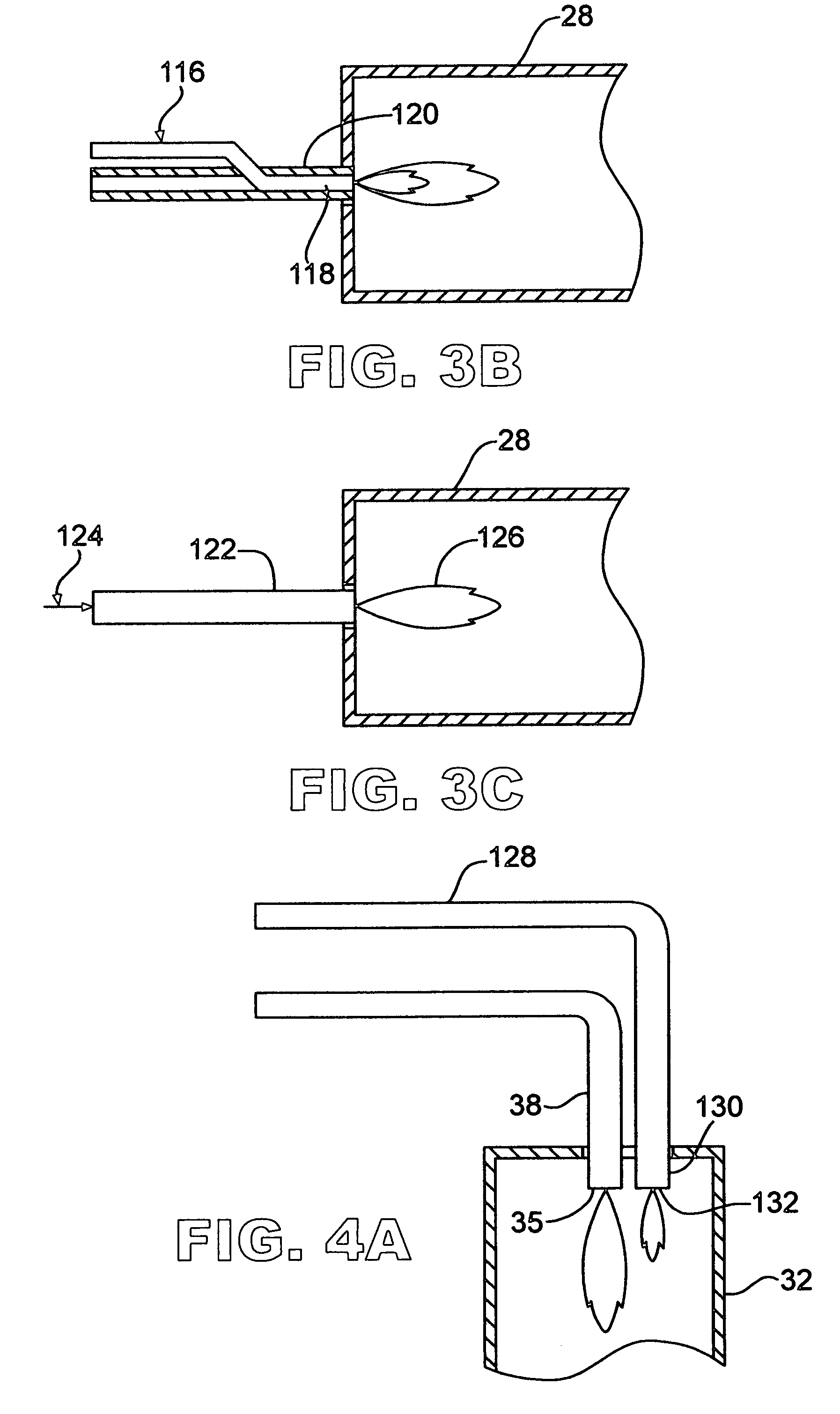

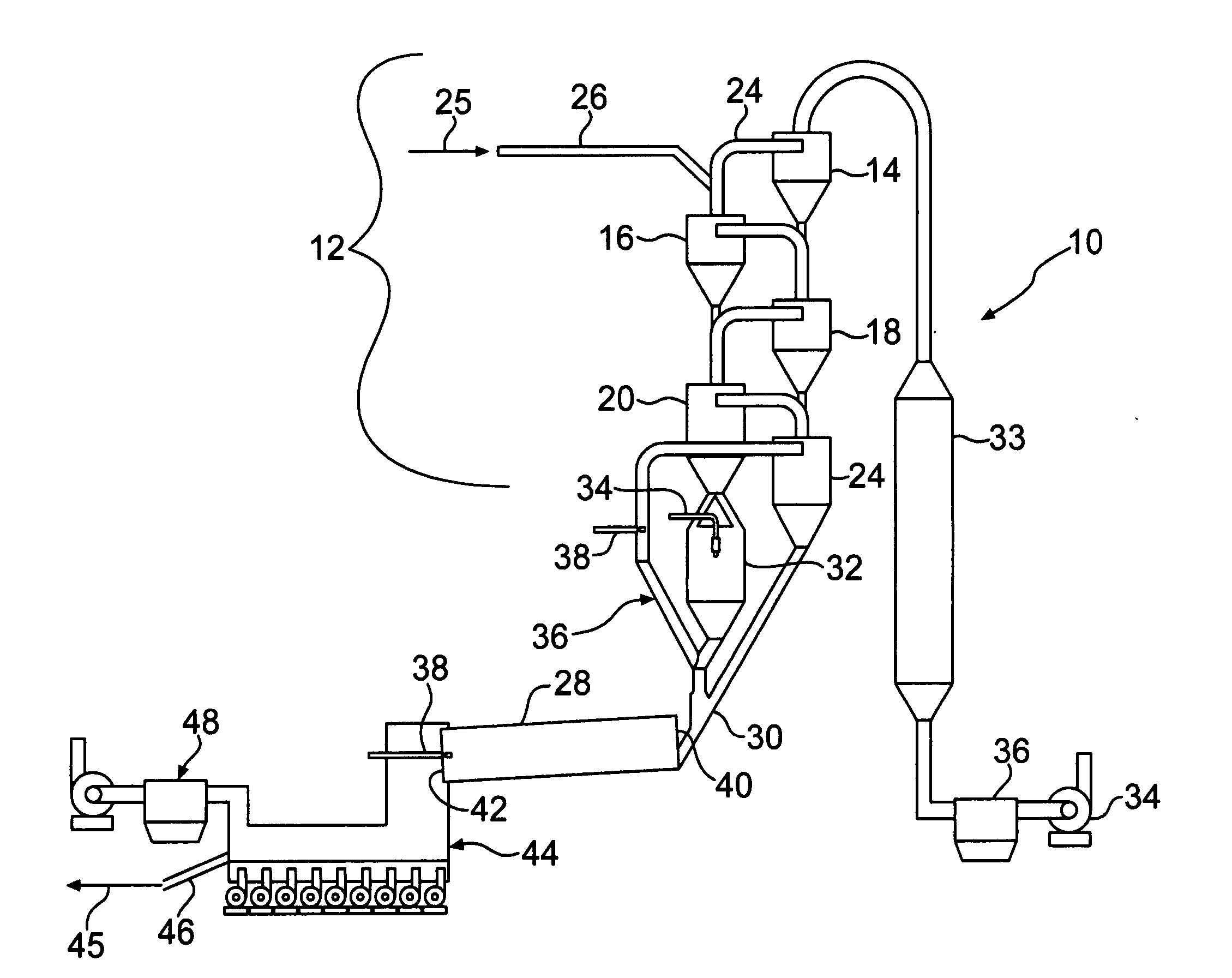

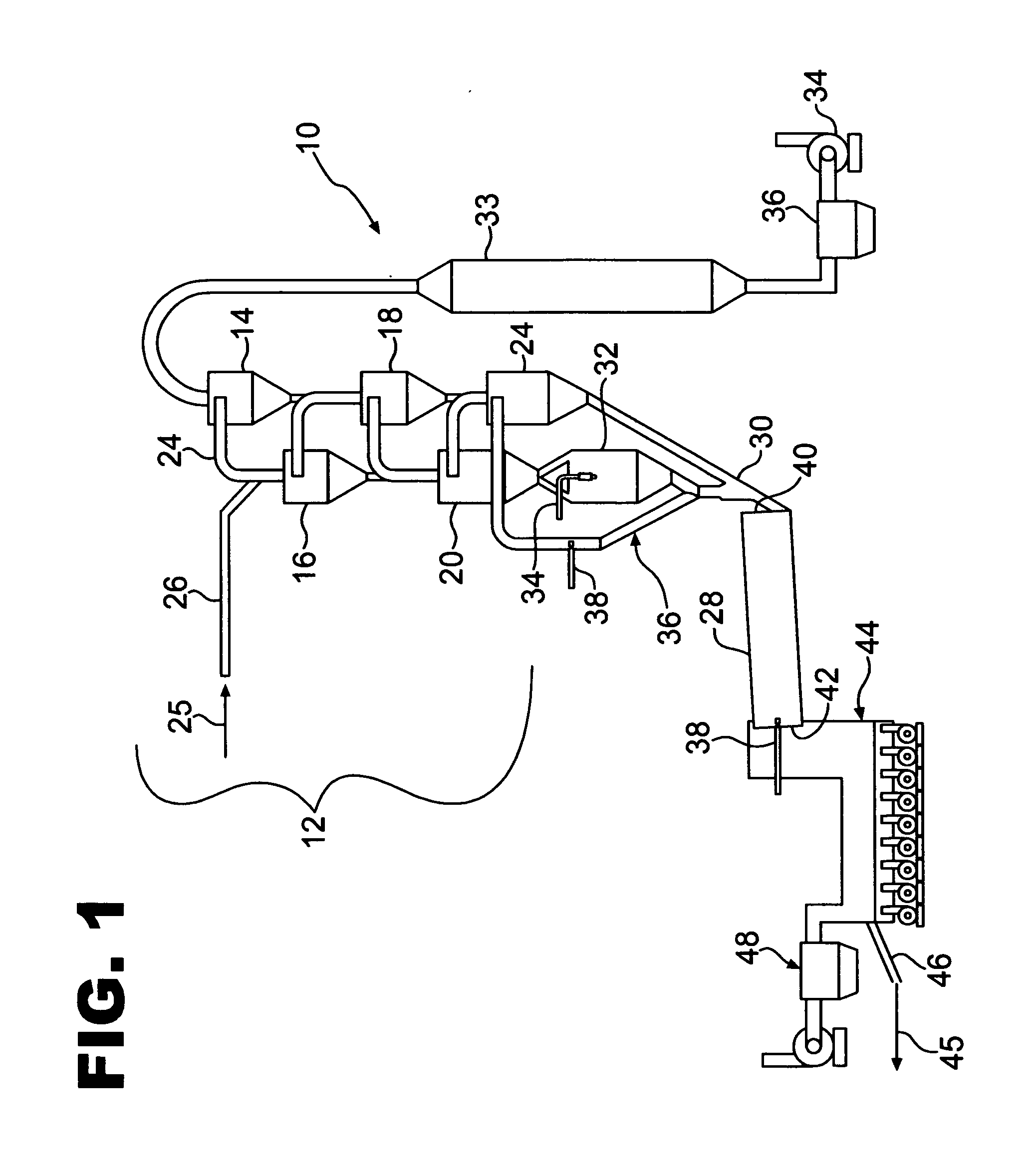

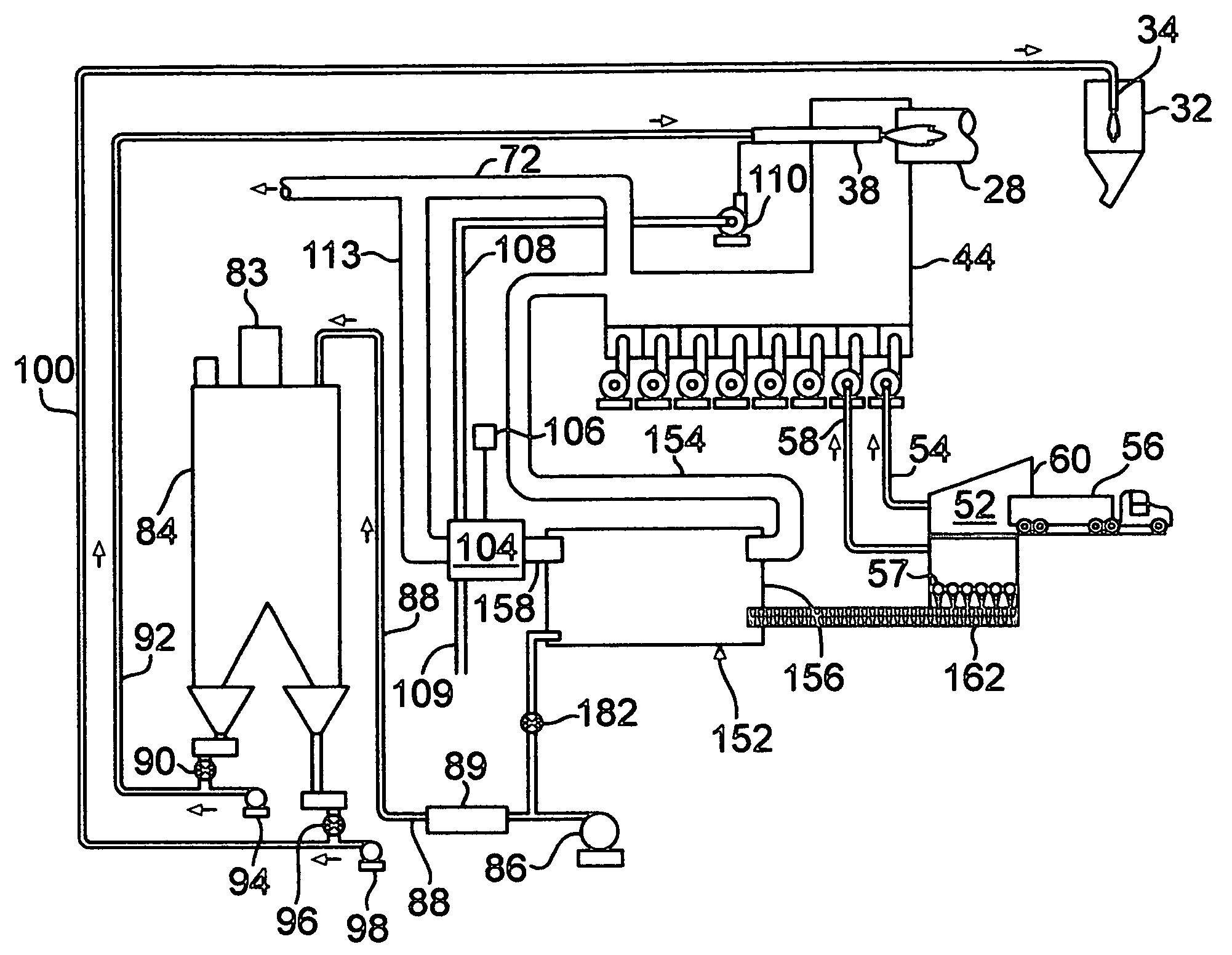

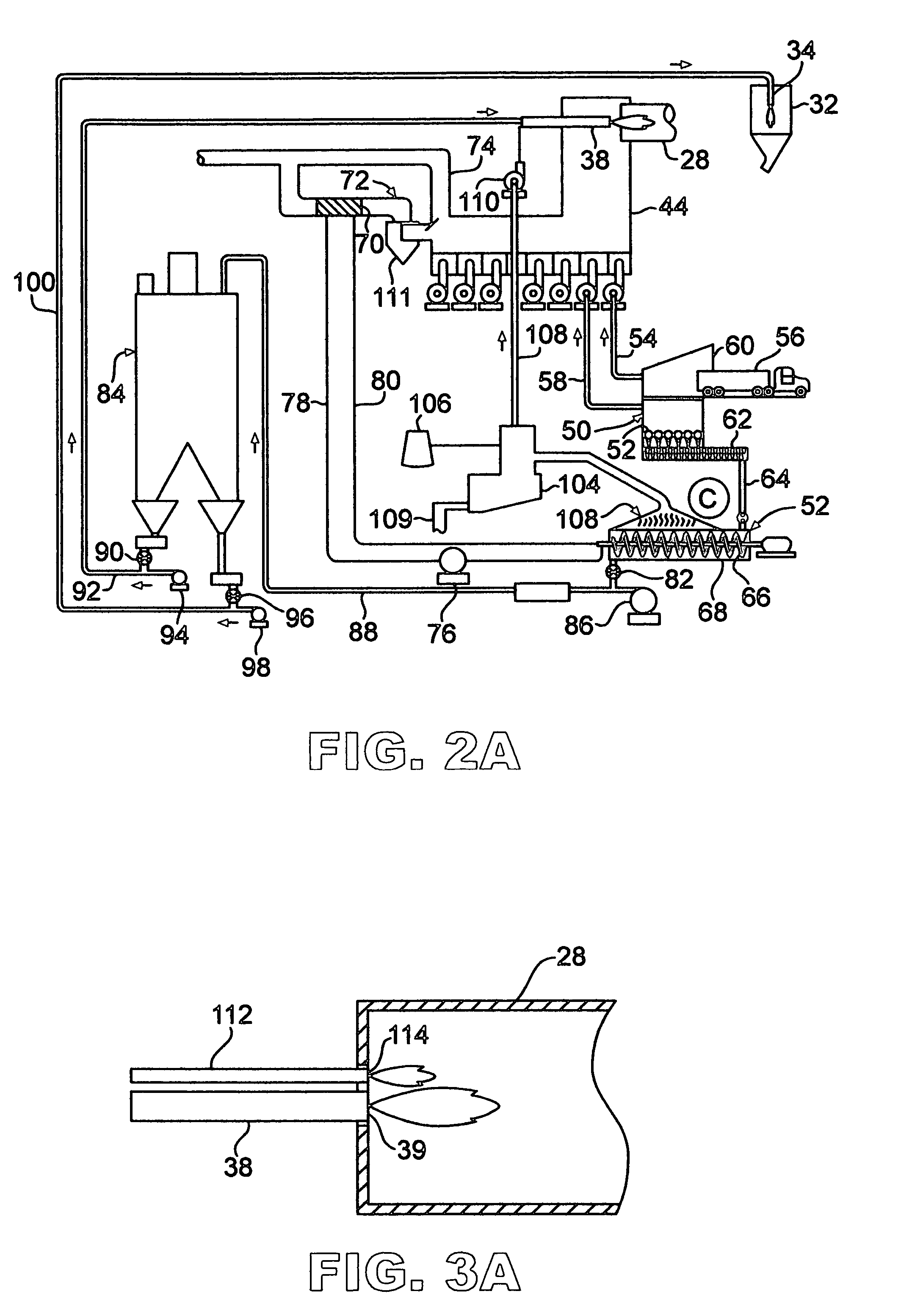

Method and apparatus for drying wet bio-solids using excess heat from a cement clinker cooler

InactiveUS20050274067A1Avoid landfill disposalDrying solid materials with heatBiofuelsCement manufacturingChiller

Method and apparatus for drying wet bio-solids by utilizing waste heat from a clinker cooler in a cement making process.

Owner:LEHIGH CEMENT

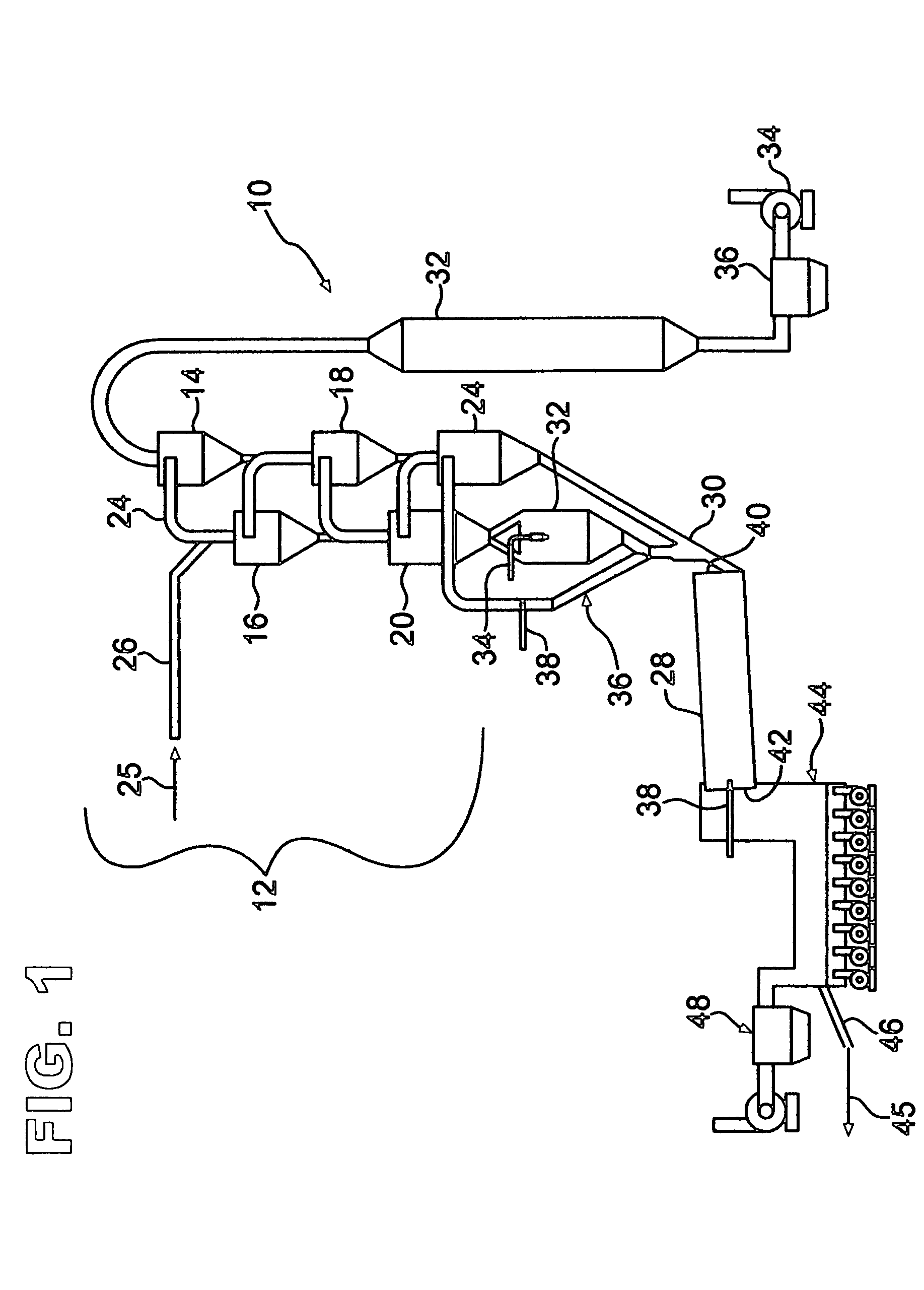

Bio-solid materials as alternate fuels in cement kiln, riser duct and calciner

InactiveUS20050274068A1Avoid landfill disposalBiofuelsSolid fuelsAlternative fuelsProcess engineering

Owner:LEHIGH CEMENT

Method and apparatus for drying wet bio-solids using excess heat recovered from cement manufacturing process equipment

InactiveUS20050274293A1Avoid landfill disposalRotary drum furnacesBiofuelsProcess equipmentProcess engineering

Method and apparatus for drying wet bio-solids by utilizing waste heat from one of a clinker cooler or kiln exhaust gases in a cement making process.

Owner:LEHIGH CEMENT

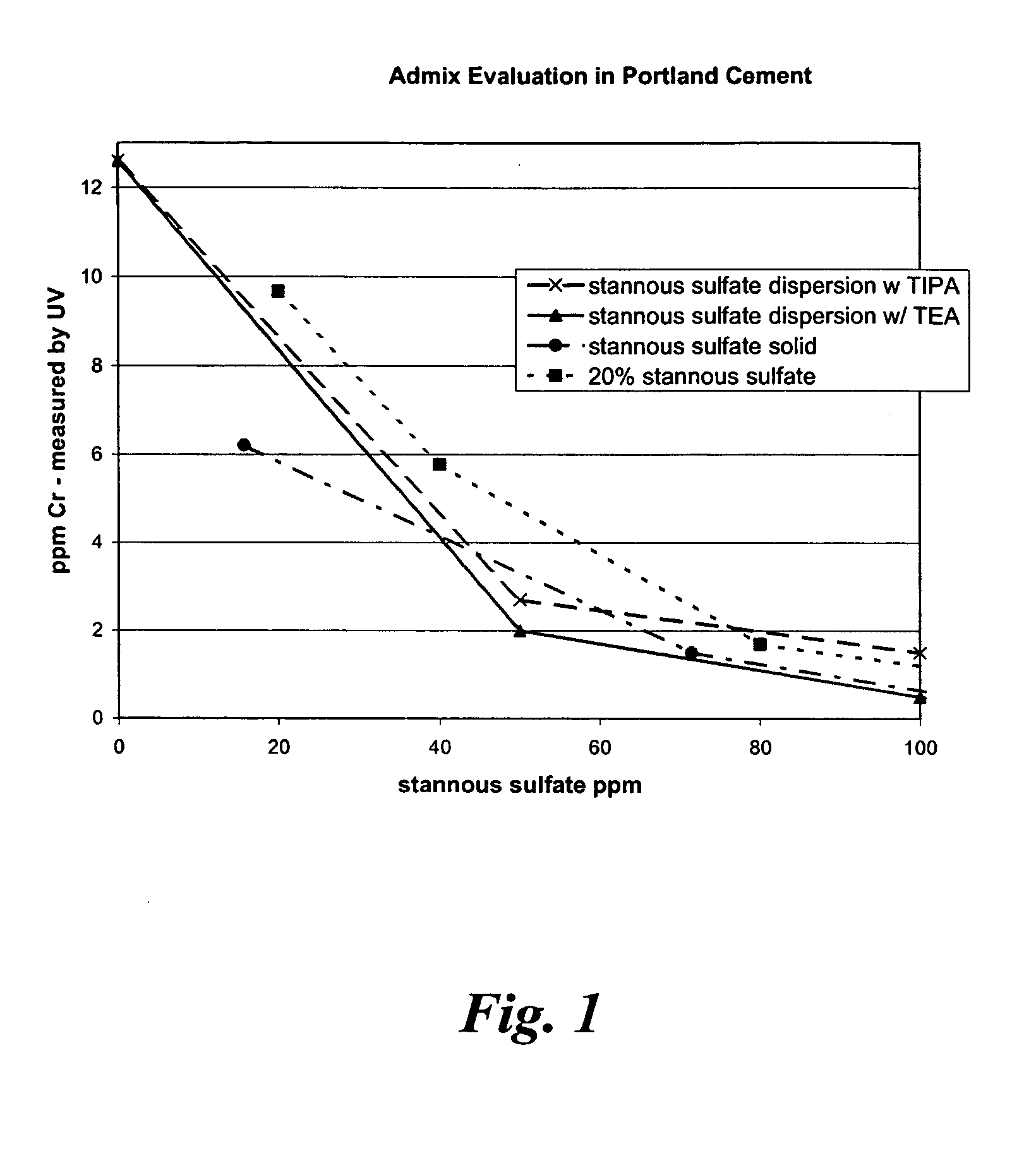

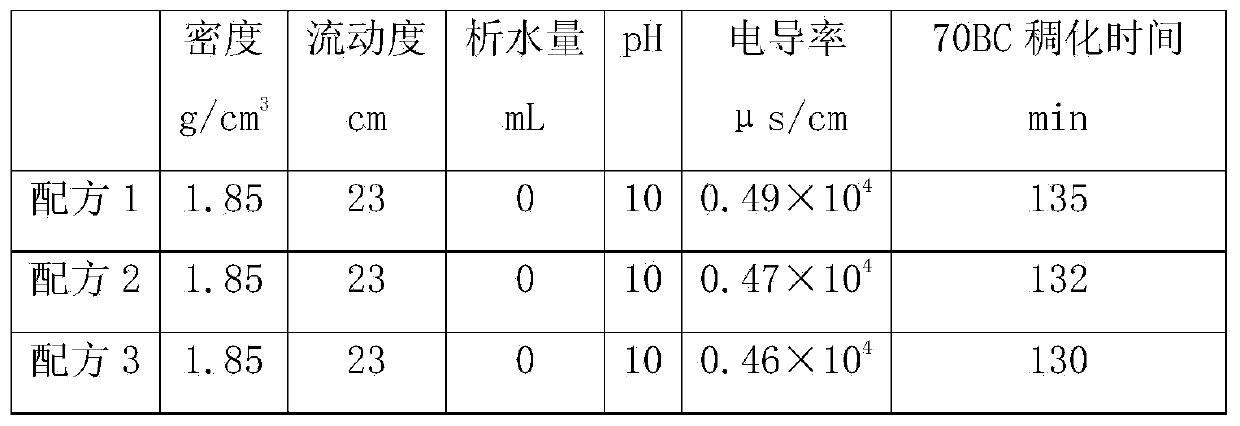

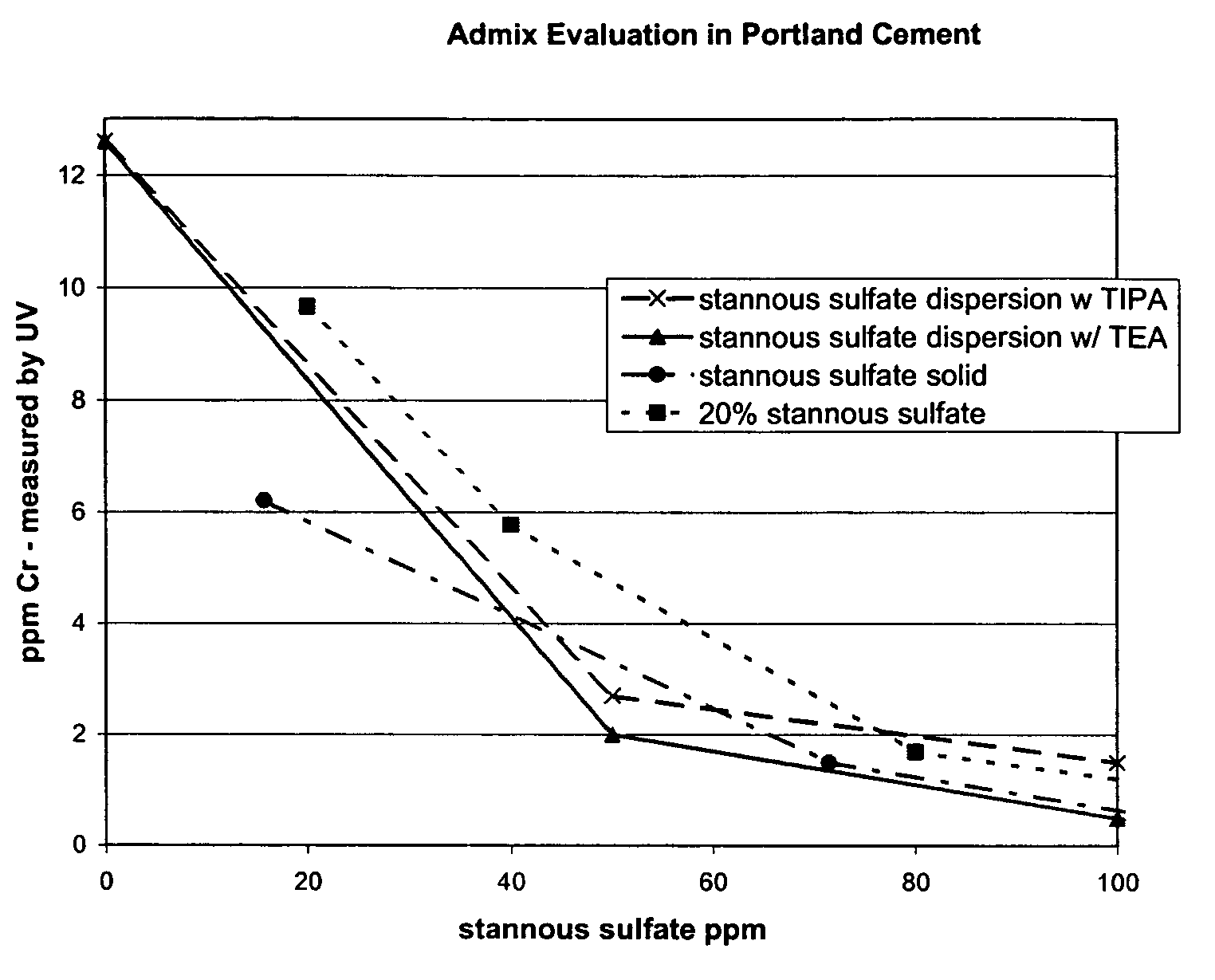

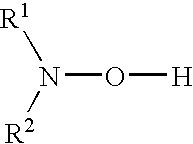

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:GCP APPL TECH INC

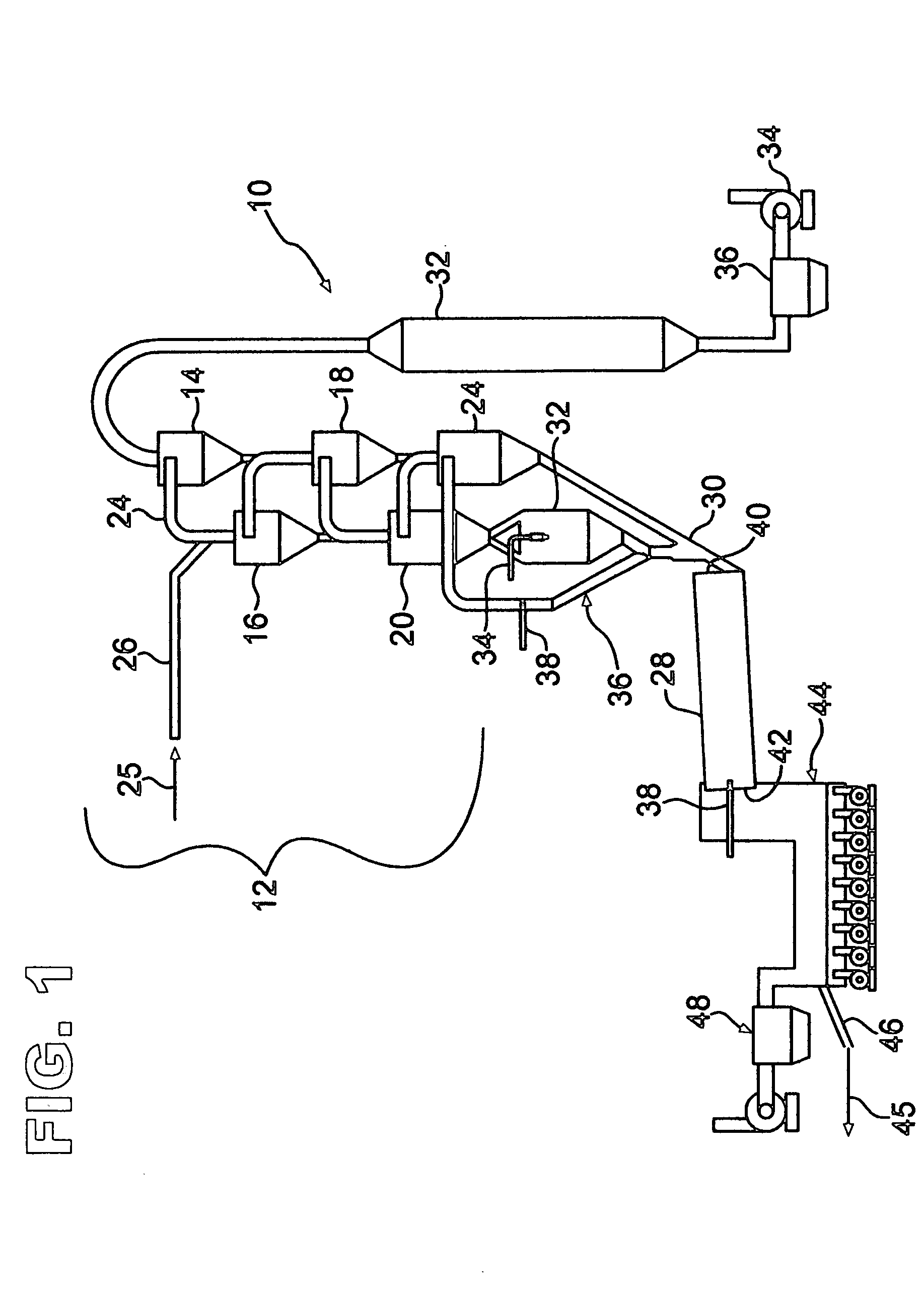

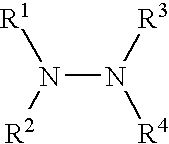

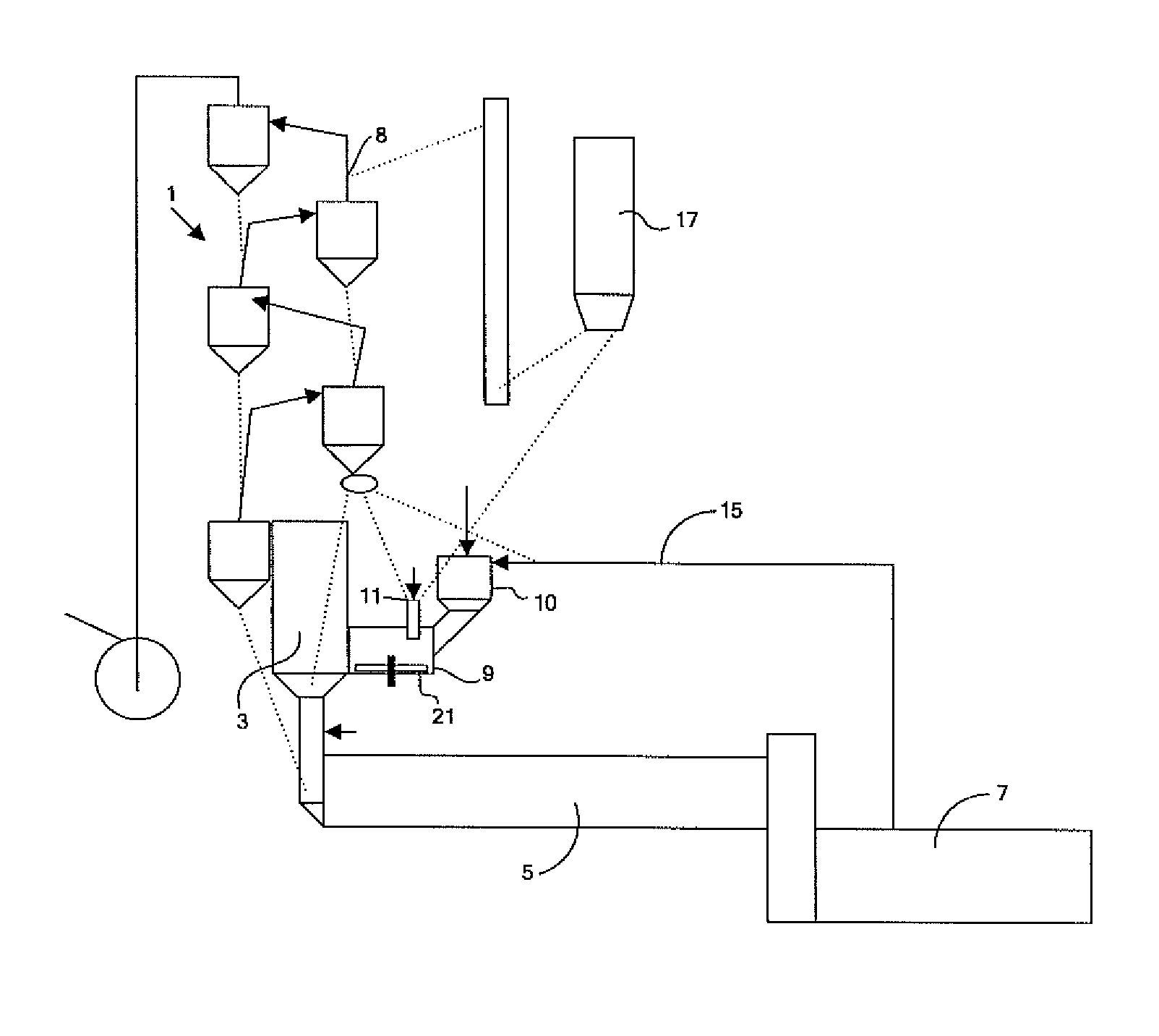

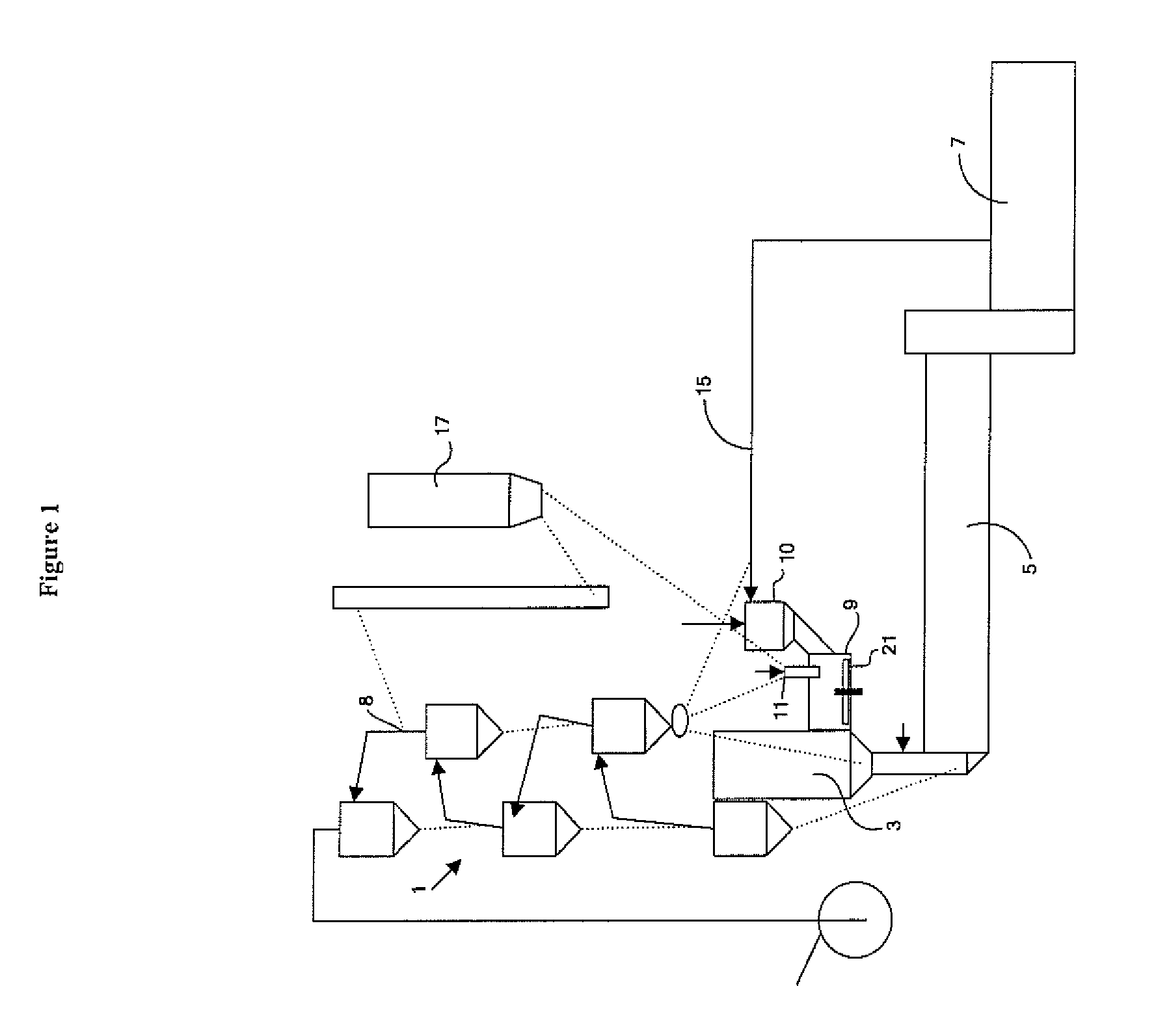

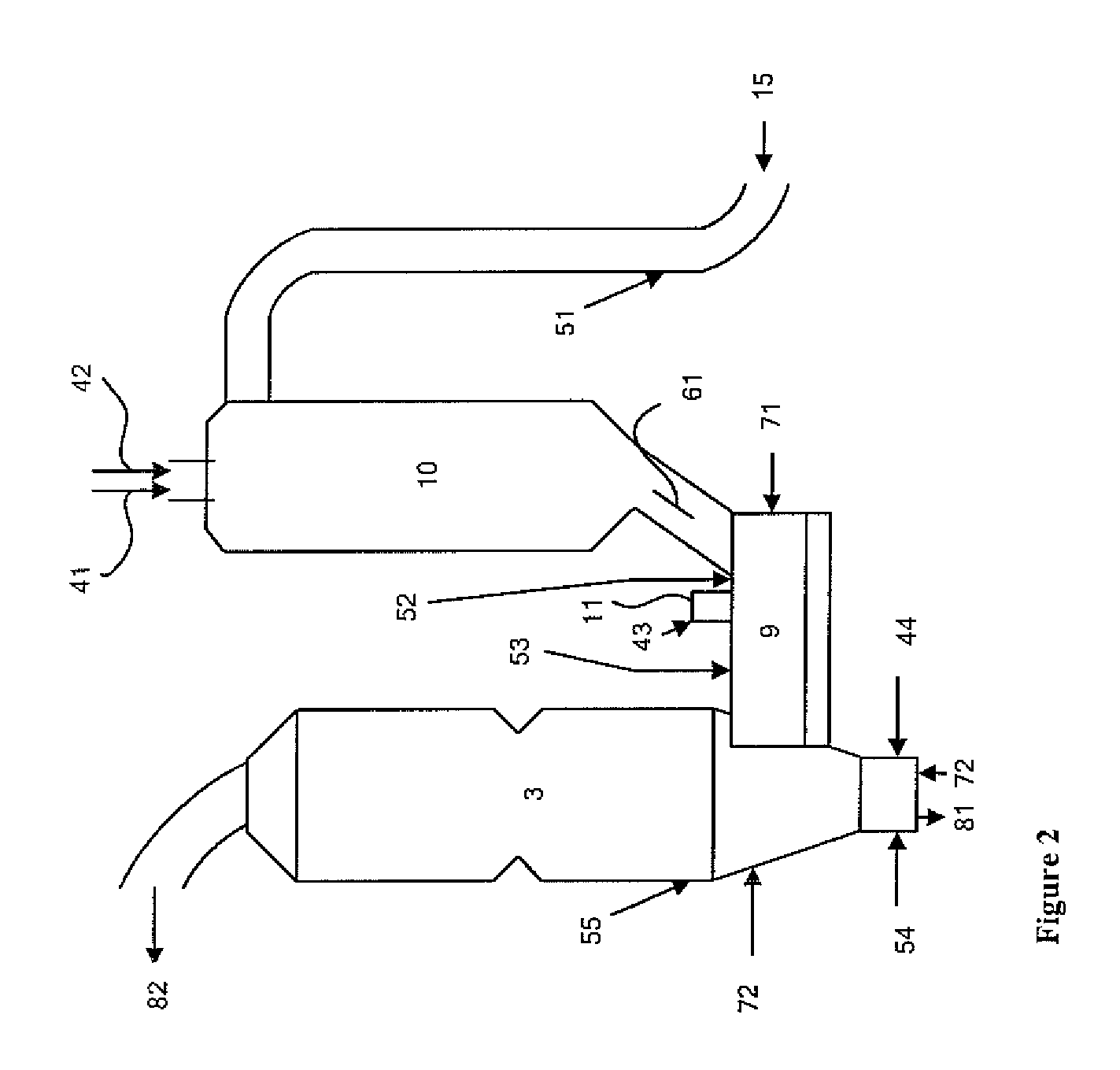

Apparatus and method for processing wastes

InactiveCN101434461AEfficient use ofLow costClinker productionSpecial form destructive distillationWaste processingProcess engineering

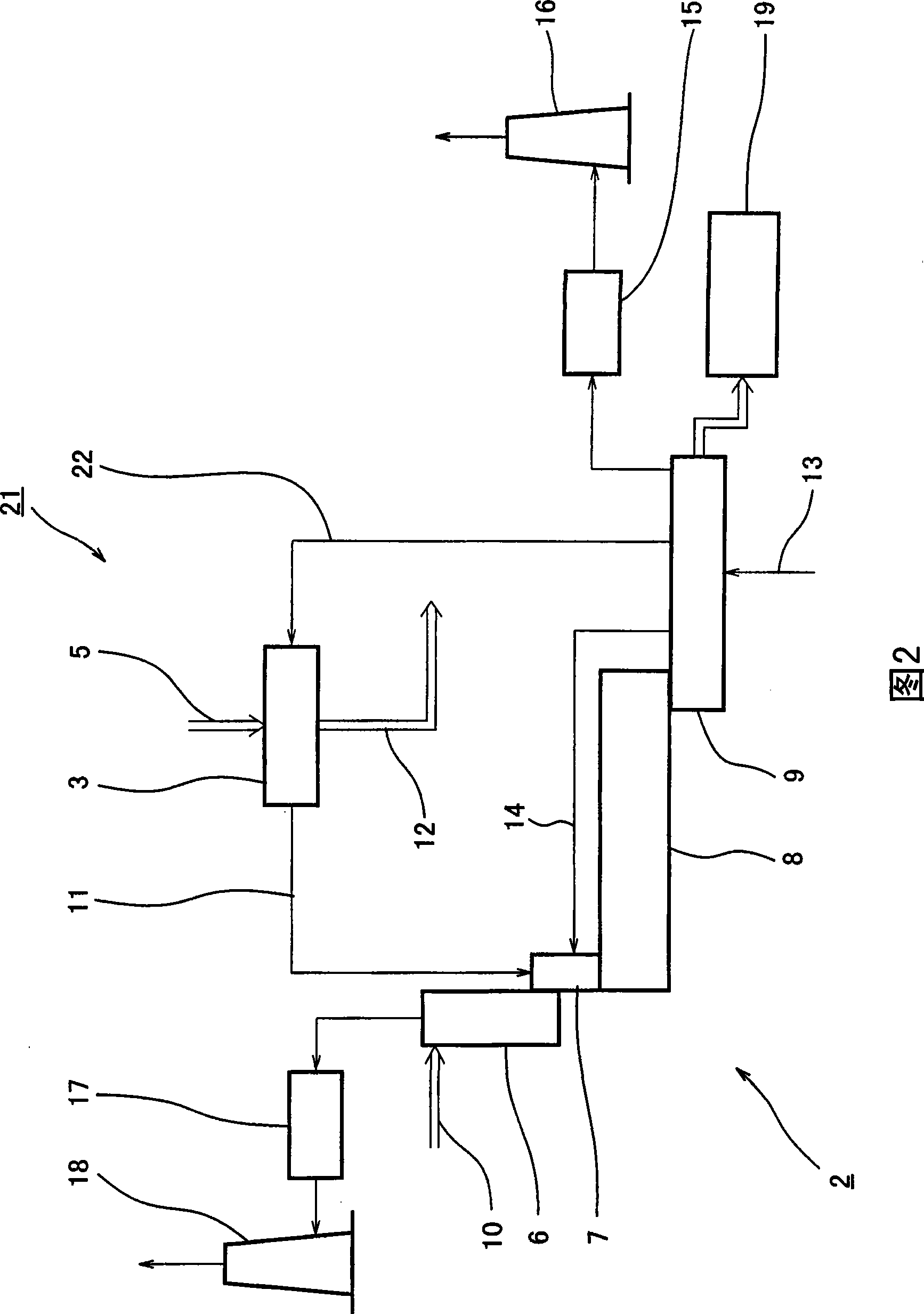

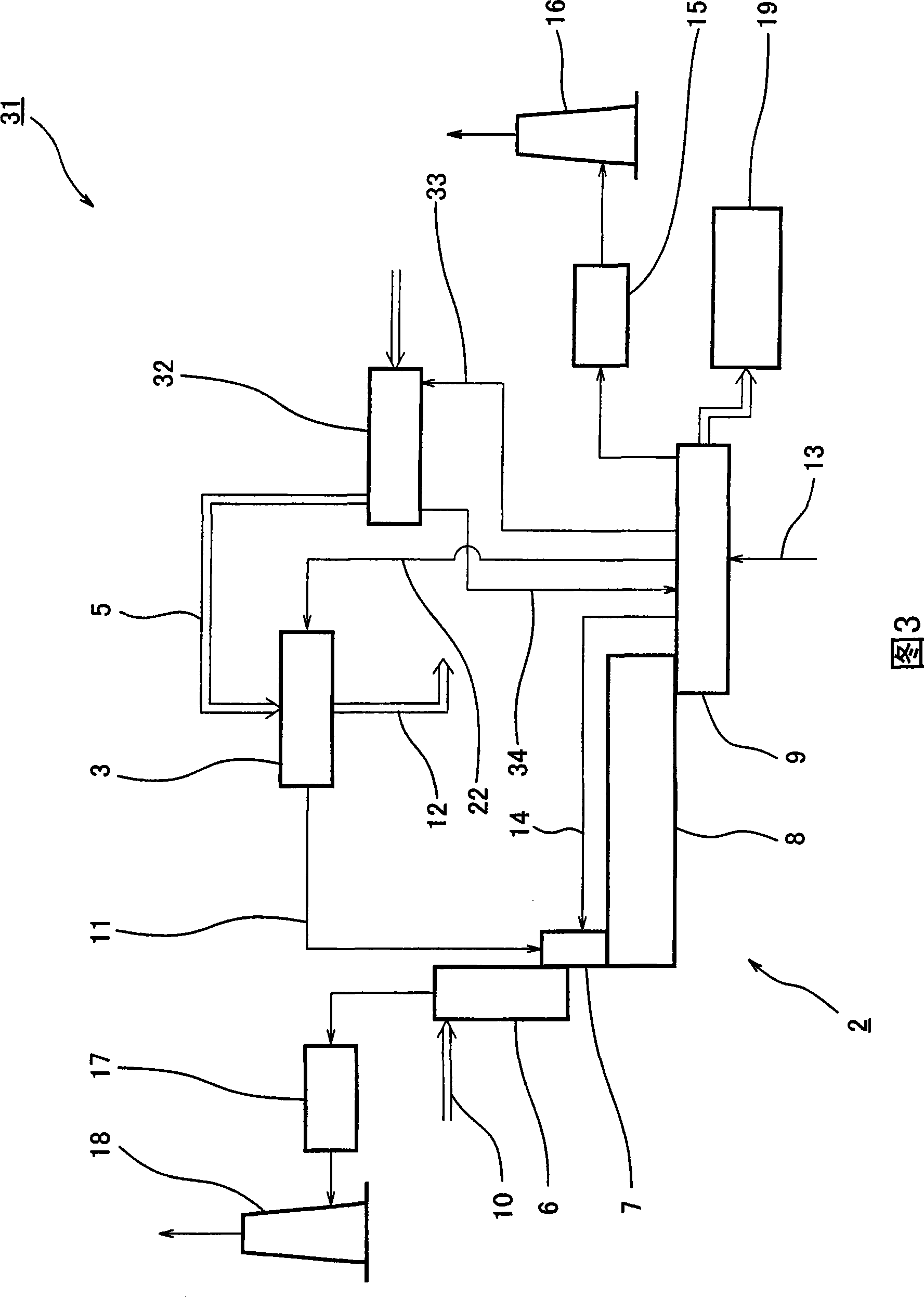

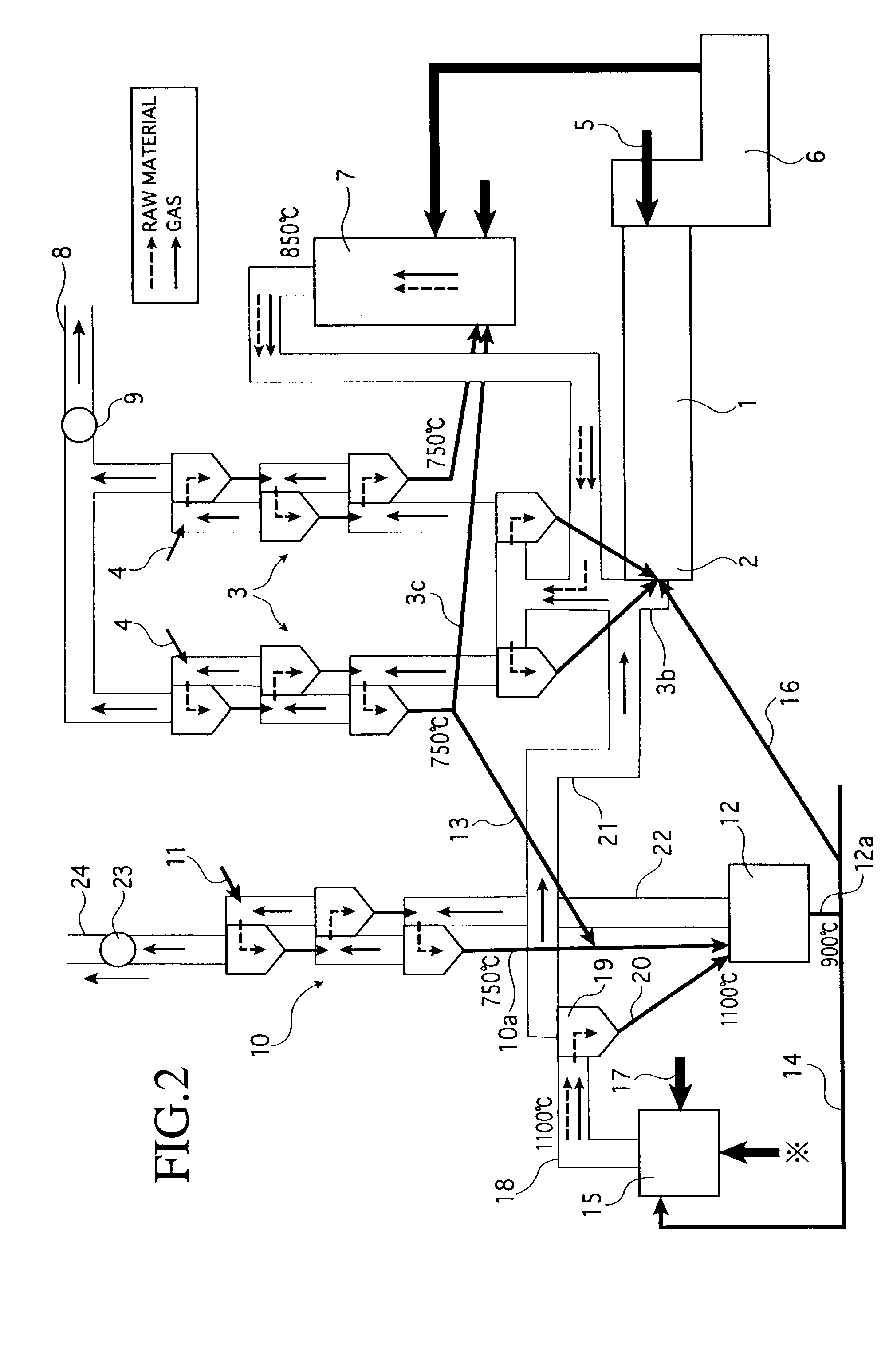

The invention provides waste processing equipment which is expected for improving utilization of heat energy and lowering equipment cost by means of a cement manufacturing process. The method for solving the problems is the waste processing equipment of the invention which is provided with a gasifier (3) for heating the waste and enabling the waste to generate thermal decomposition gas, a preheater (6) for preheating cement stone of cement manufacturing complete plant (2), a calcinator (7), a welding furnace (8), and a clinker cooler (9), and a gas delivery passage (11) for delivering particle-shaped carbon and ash and pyrolytic eumatolytic gas generated from the gasifier (3) to at least one of the calcinator (7) and the welding furnace (8).

Owner:KAWASAKI HEAVY IND LTD +3

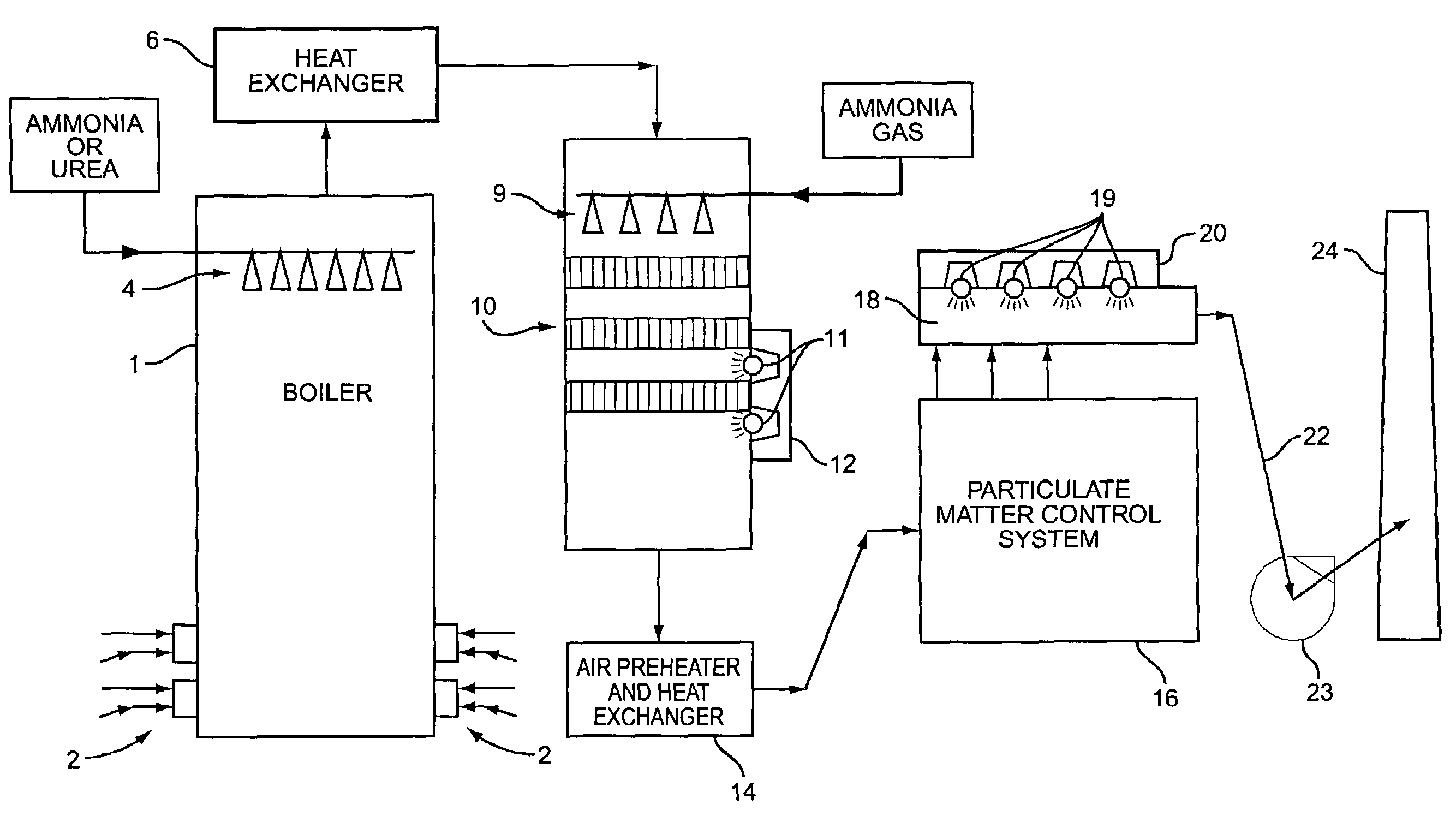

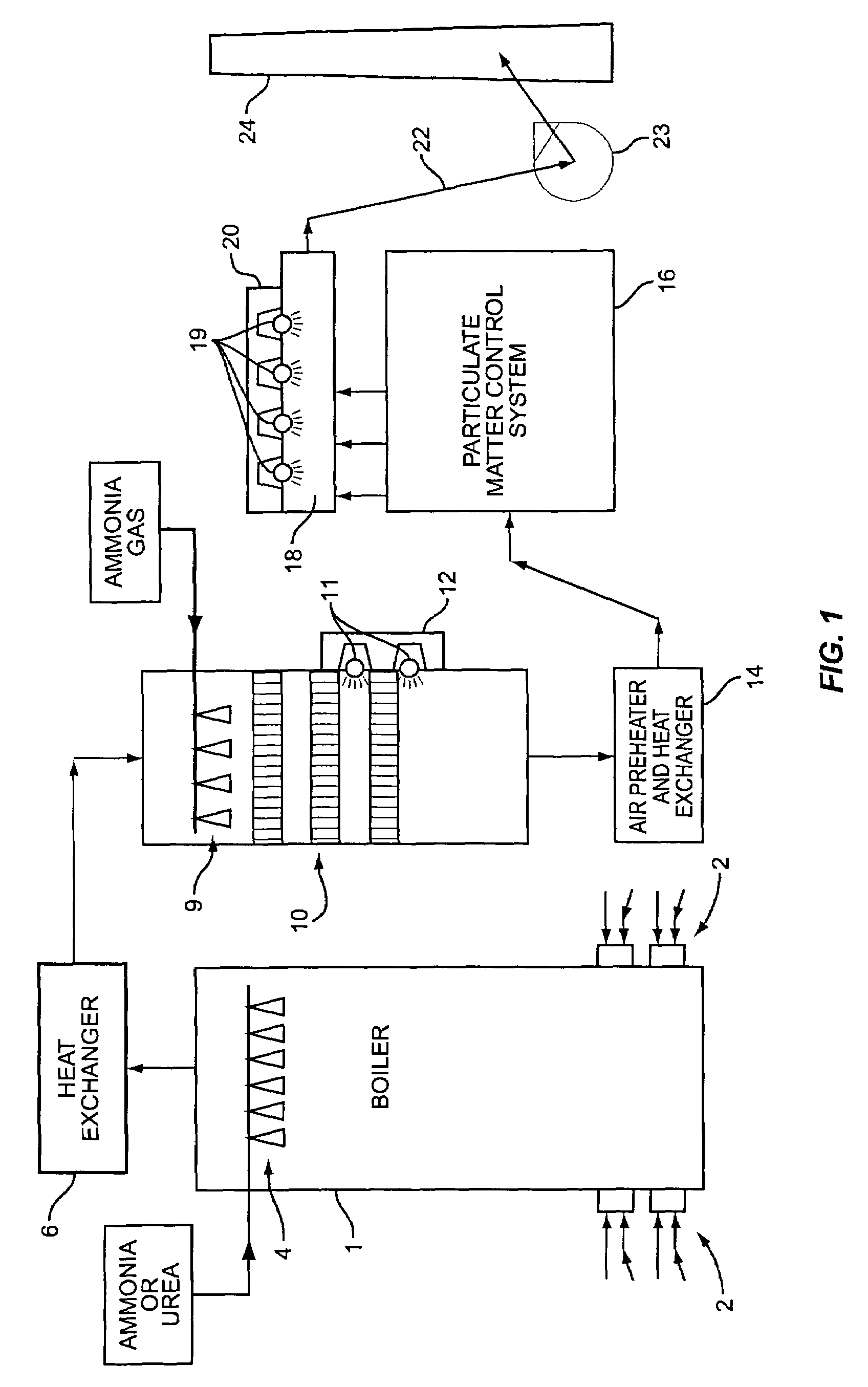

Method of photochemically removing ammonia from gas streams

InactiveUS7198698B1Rapid and efficient direct photolytic destructionEffective treatmentGas treatmentDispersed particle separationHydrogenPyroprocessing

The present invention entails a method of removing ammonia from a gas stream. The method entails irradiating the gas stream with light in the spectral range of 200–350 nanometers and disassociating hydrogen free radicals from ammonia to form NH2. Once NH2 is formed, then reacting the NH2 with NOx to form N2 and water. In one specific embodiment of the present invention, the method entails removing ammonia from a gas stream associated with a cement producing process. In particular, a raw feed is directed into a pyroprocessing system of a cement manufacturing facility. This raw feed is heated and in the process of producing cement, a gas stream results. Ammonia present in the gas stream is removed or substantially reduced by irradiating the gas stream and disassociating hydrogen free radicals from the ammonia to form NH2. NH2 is then reacted with NOx to form water.

Owner:AIR CONTROL TECHN P C

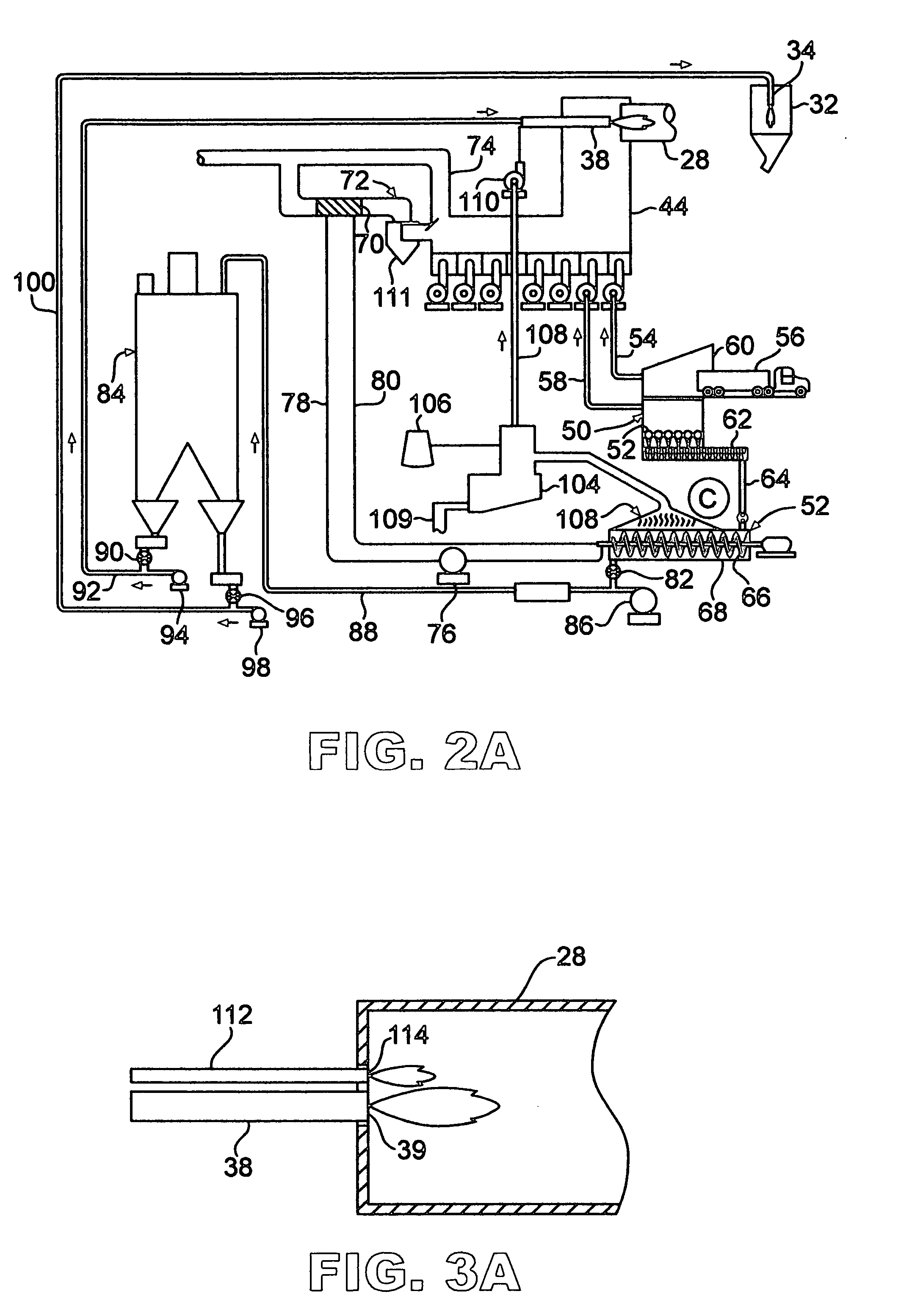

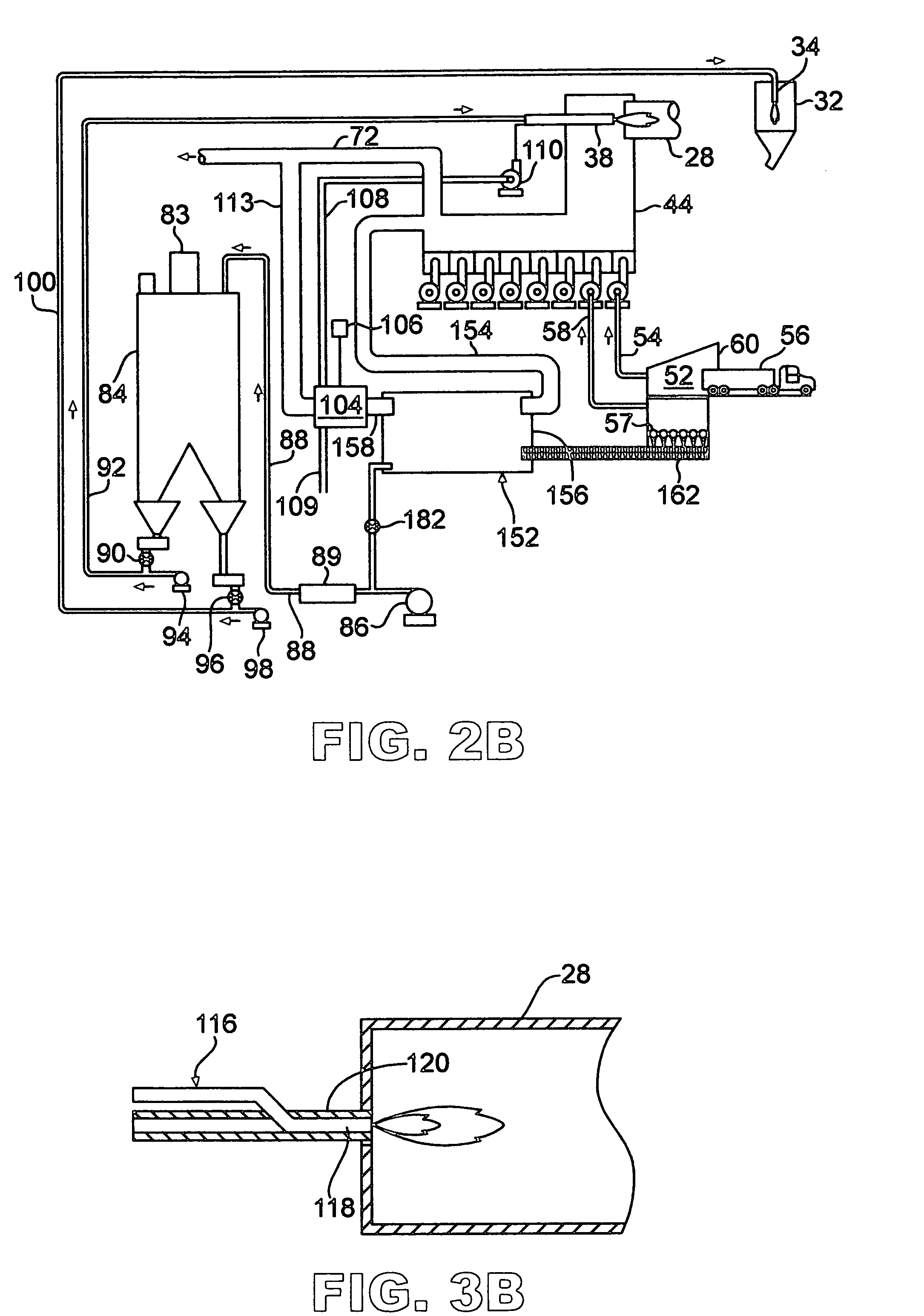

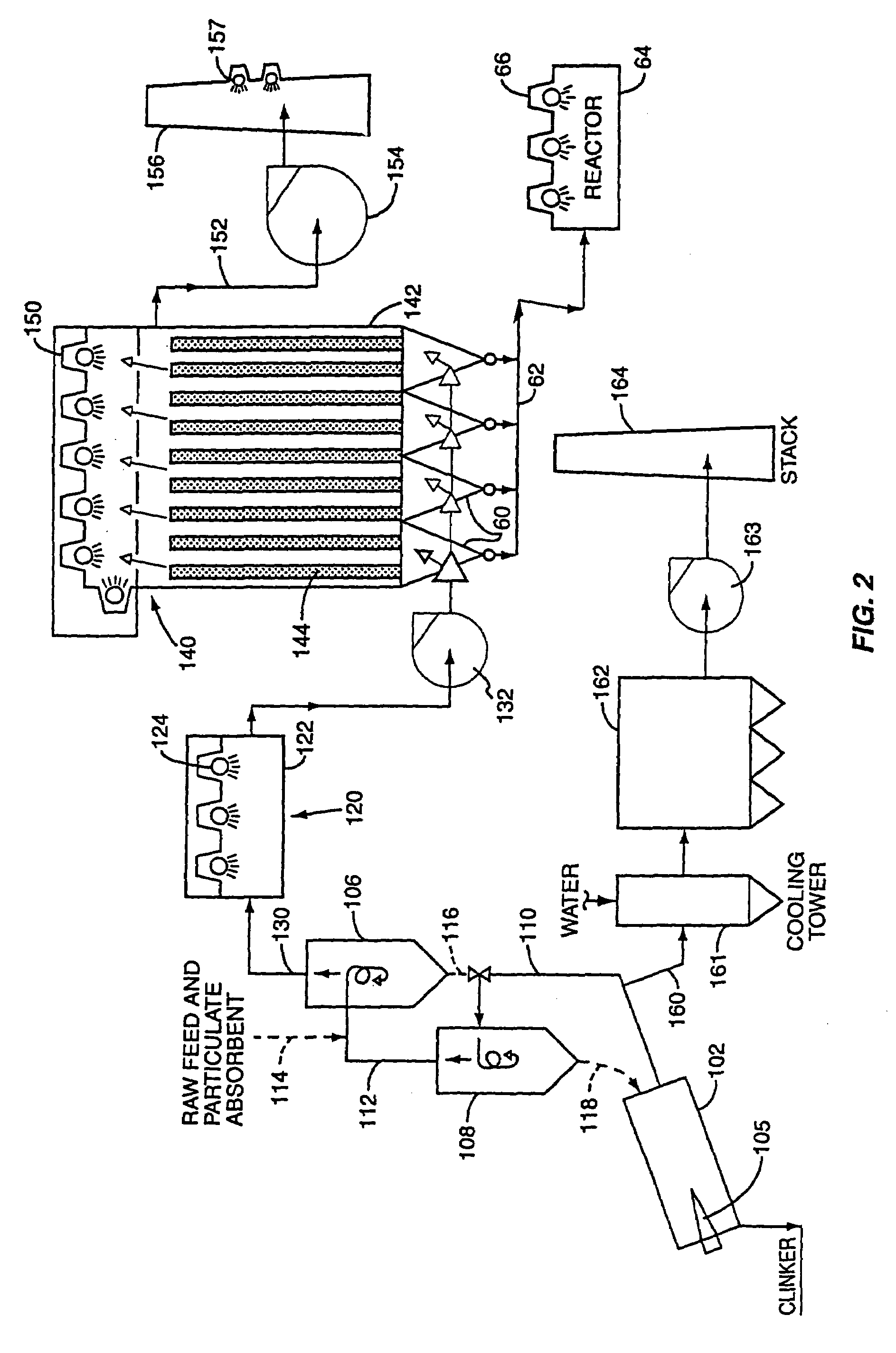

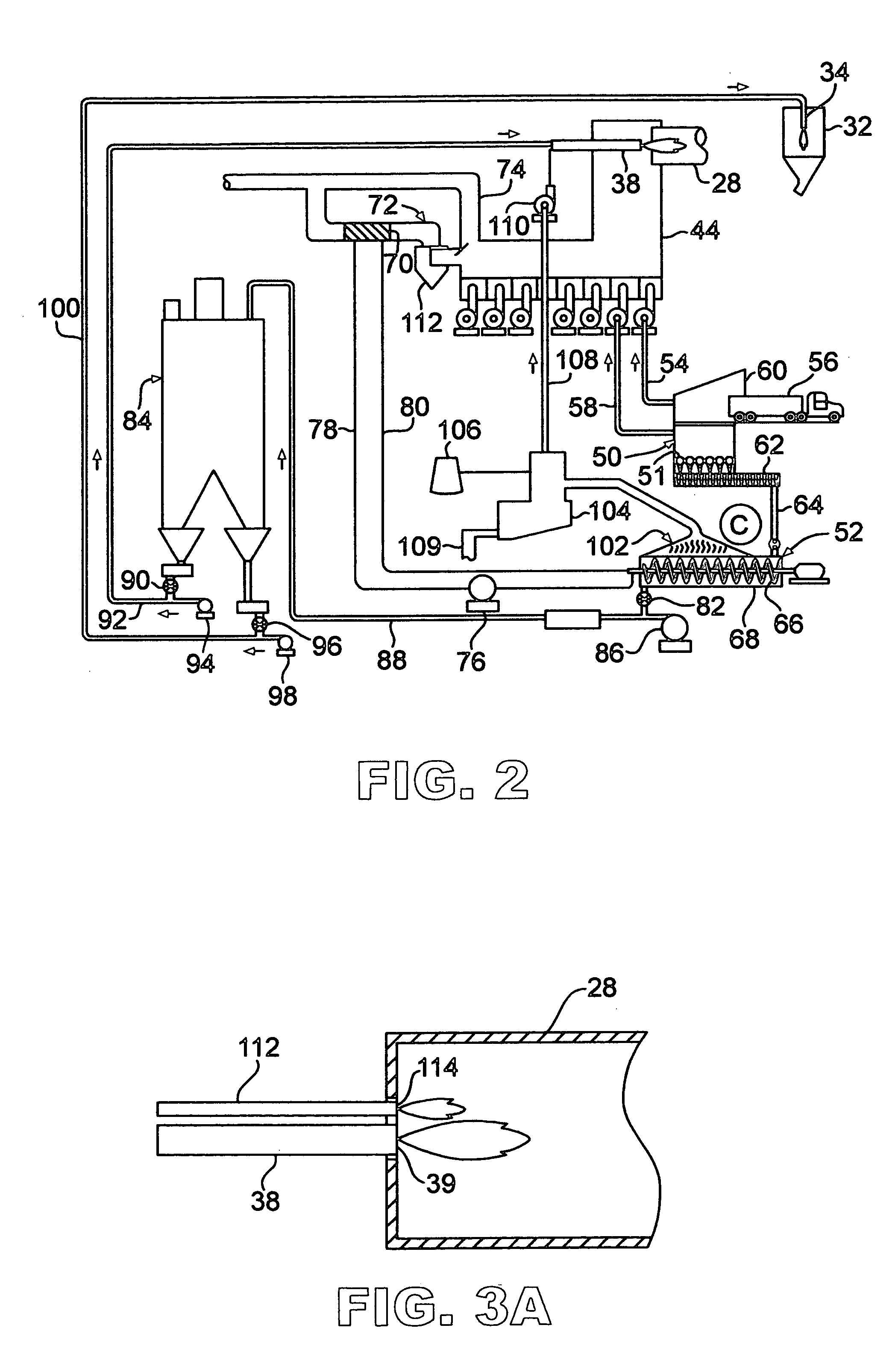

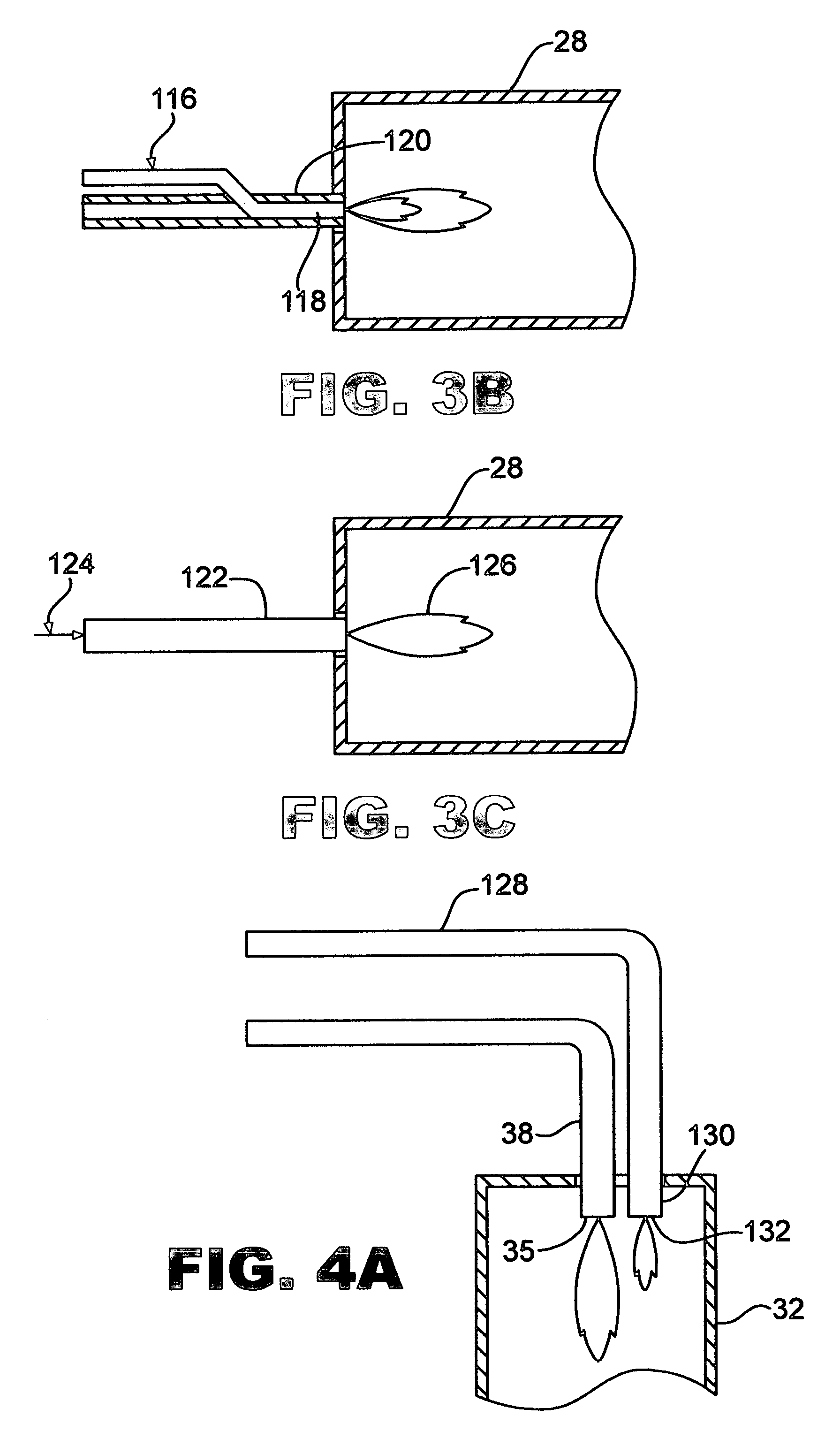

Apparatus and method for controlling mercury pollution from a cement plant

ActiveUS20100000406A1Emission reductionGas treatmentIsotope separationAtmospheric airMercury pollution

A method and apparatus for reducing discharges into the atmosphere of mercury pollutants associated with dry process, precalciner cement manufacturing is shown. Raw feed meal used in cement production is heated in a special heating chamber to drive off volatile mercury pollutants, such as elemental mercury and mercury oxides. Preferably, the feed meal is heated to a temperature of at least 175° C. The gases that are driven off flow are then cooled to condense the mercury pollutants causing them to be adsorbed on carbon particles injected into the gas flow. The carbon particles containing the condensed mercury pollutants are then filtered out of gas flow, for example, using a fabric filter. The gas flow may be burned to destroy other volatile pollutants such as hydrocarbons and / or ammonia.

Owner:ENVIROCARE INT +1

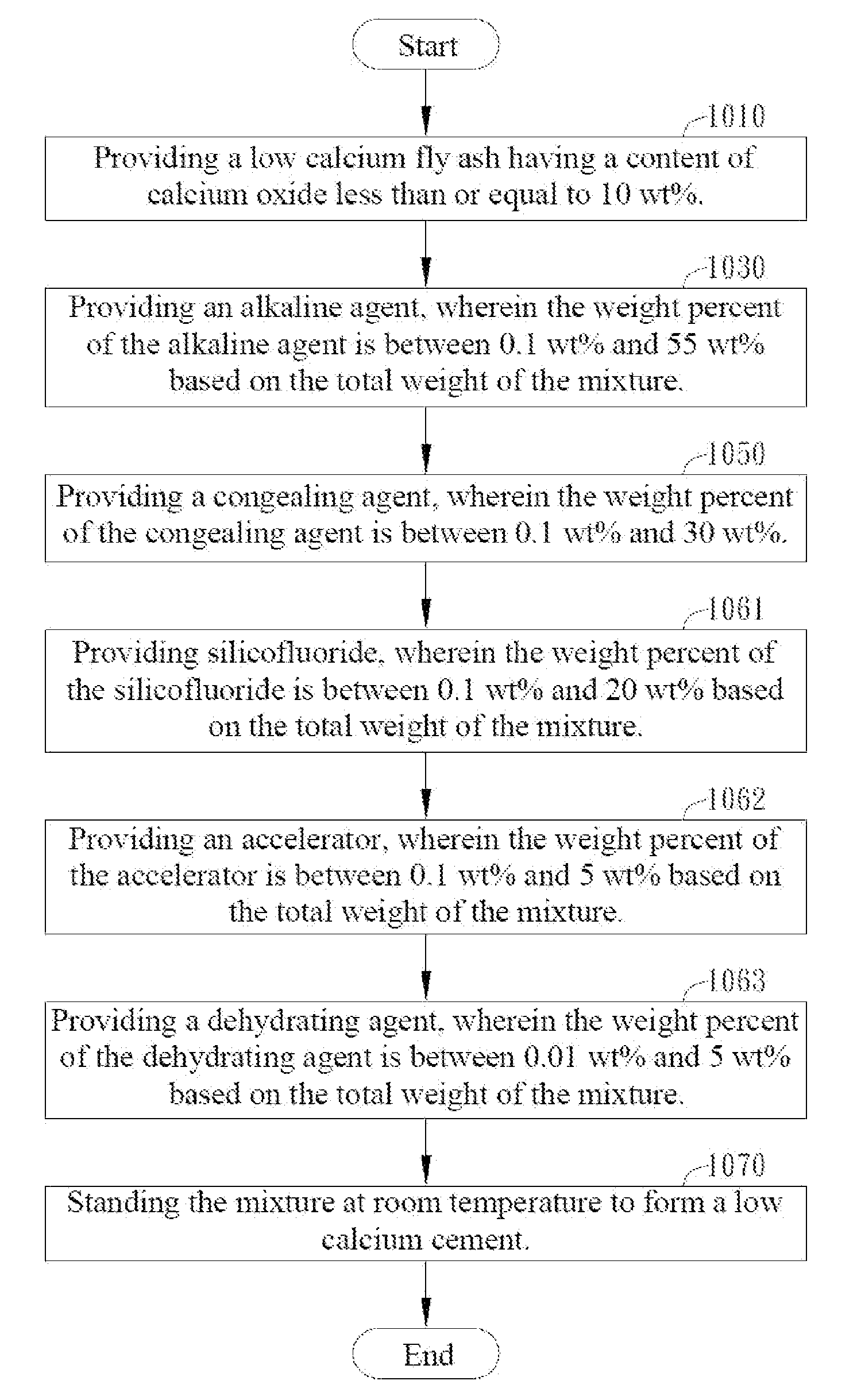

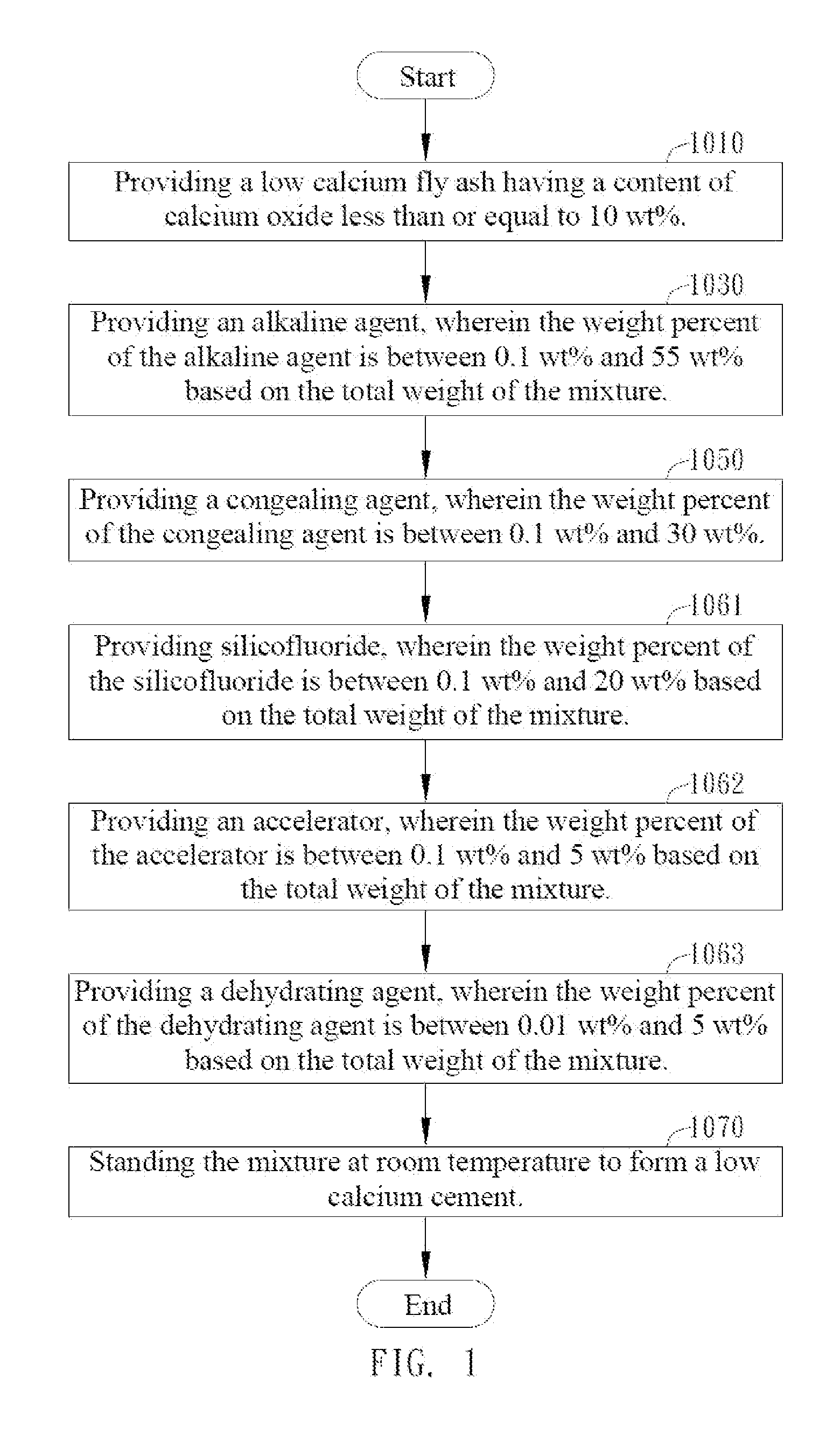

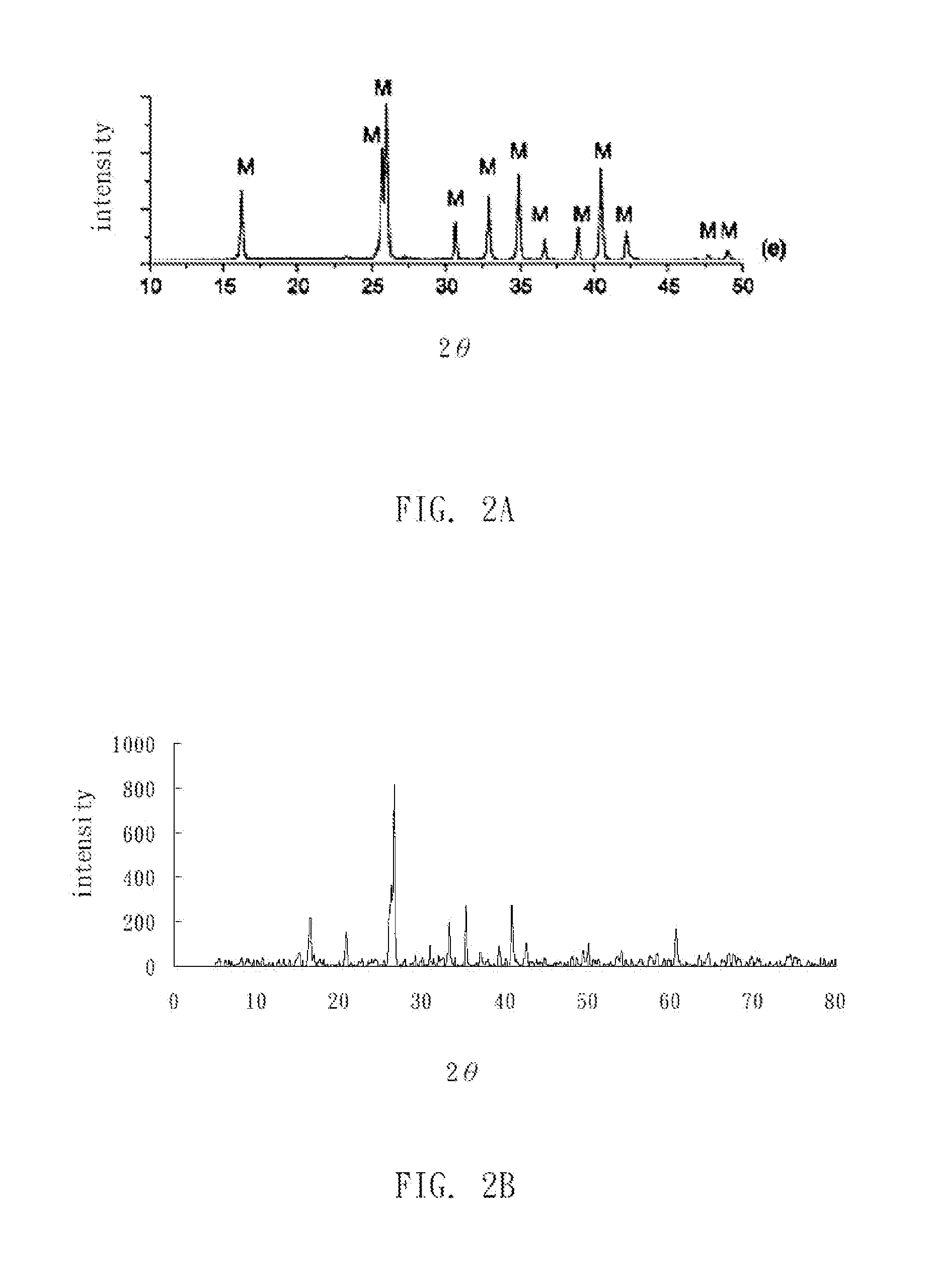

Low calcium cementitious material and method of manufacturing low calcium cement

ActiveUS20120152152A1High economic valueSolid waste managementAlkali metal silicate coatingsMulliteRoom temperature

A low-calcium-cementitious material having a calcium oxide content less than or equal to 10 wt % which is processed at room temperature into a low calcium cement mainly composed of mullite and a method manufacturing of the low calcium cement are provided. The low-calcium-cementitious material includes low calcium fly ash, an alkaline agent, and a congealing agent, wherein the calcium oxide content of the low-calcium-cementitious material is less than or equal to 10 wt %. The low calcium fly ash has a calcium oxide content less than or equal to 10 wt %. The low calcium cement manufacturing method includes providing a low calcium fly ash having a calcium oxide content less than or equal to 10 wt %; providing an alkaline agent; providing a congealing agent; and mixing the low-calcium-content fly ash, the alkaline agent, and the congealing agent and standing the mixture at room temperature to form a low calcium cement.

Owner:RUENTEX MATERIALS CO LTD

Cement presintering production method and system

ActiveCN101139175AIncrease productionQuality improvementRotary drum furnacesCharge manipulationElectricityBottle neck

The present invention relates to a new cement manufacturing technology. By enhancing the temperature of the kiln feed of a rotary kiln, the inefficient heat transfer process remaining in the cement rotary kiln is greatly reduced or eliminated and the thermal bottle-neck problem in the cement calcinations is solved so as to realize the fast firing of the fine particles and highly efficient cooling of the clinkers, and the anti-skinning materials, high temperature resistant materials and insulating materials are adopted and the aspect ratio, rotation speed and slope of the rotary kiln are changed so as to realize the present invention, thus generating the very obvious comprehensive effects of enhancing the output of the cements, lowering the burning heat consumption and the grinding pow consumption and enhancing the clinker quality.

Owner:CHINA BUILDING MATERIALS ACAD

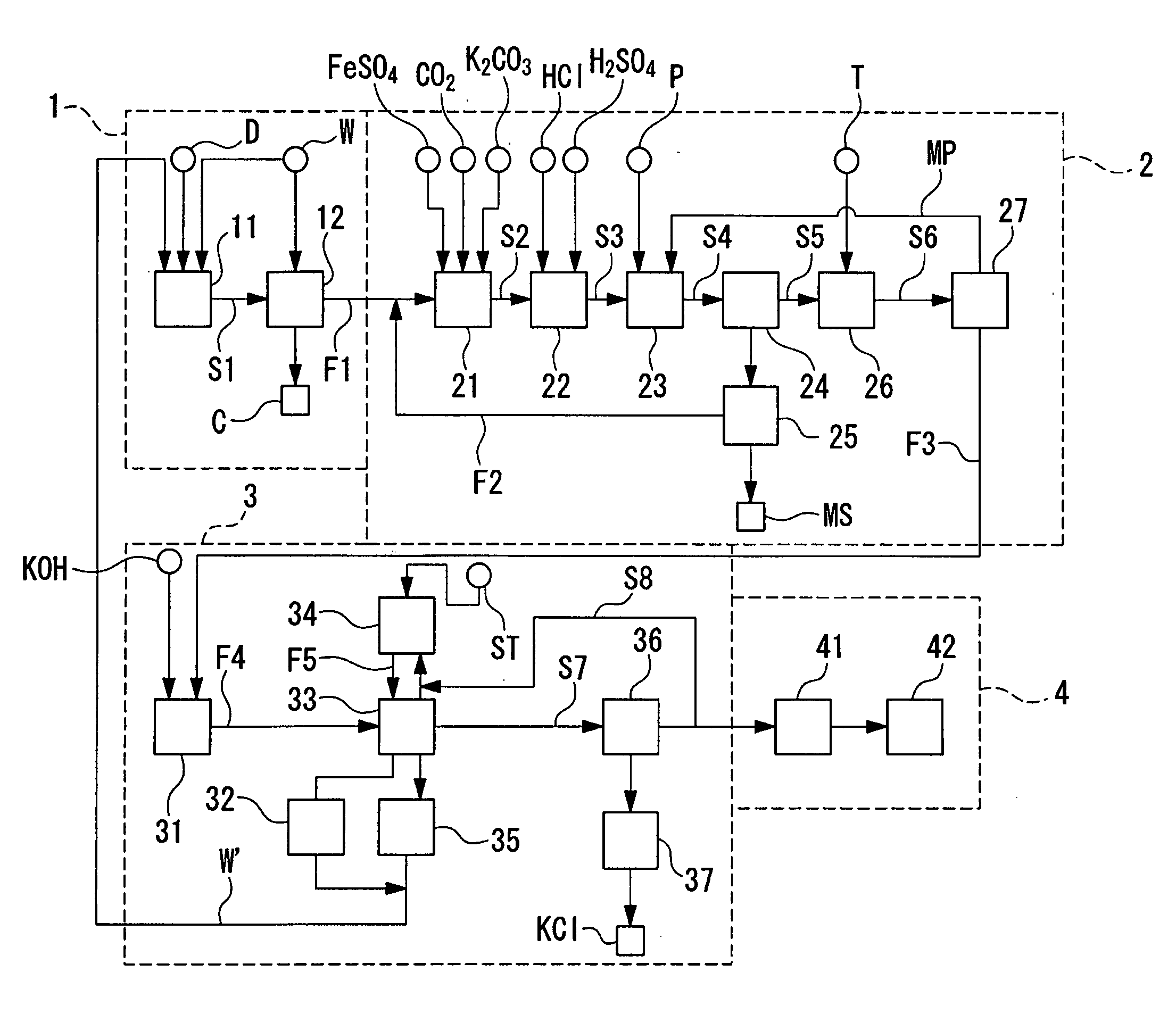

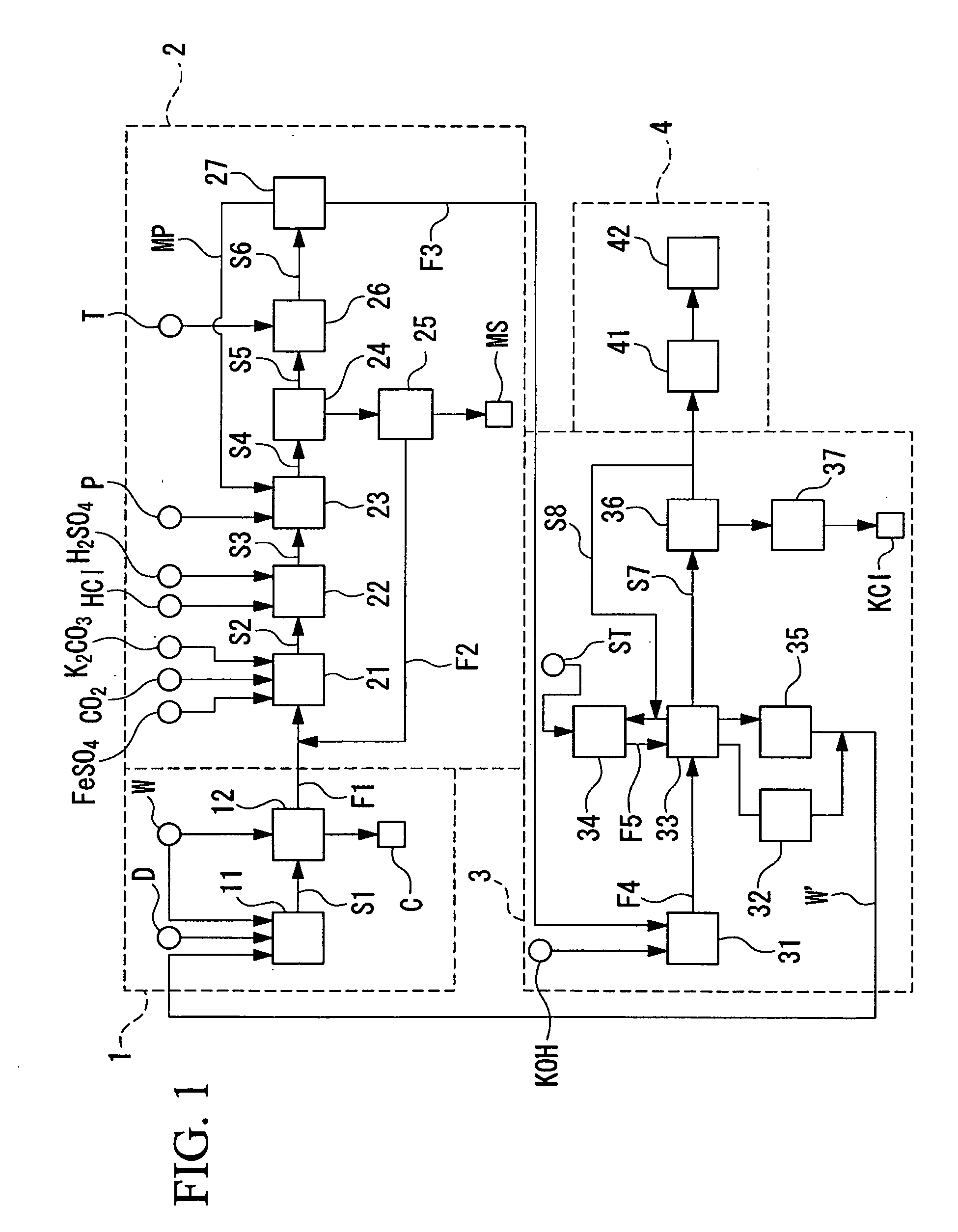

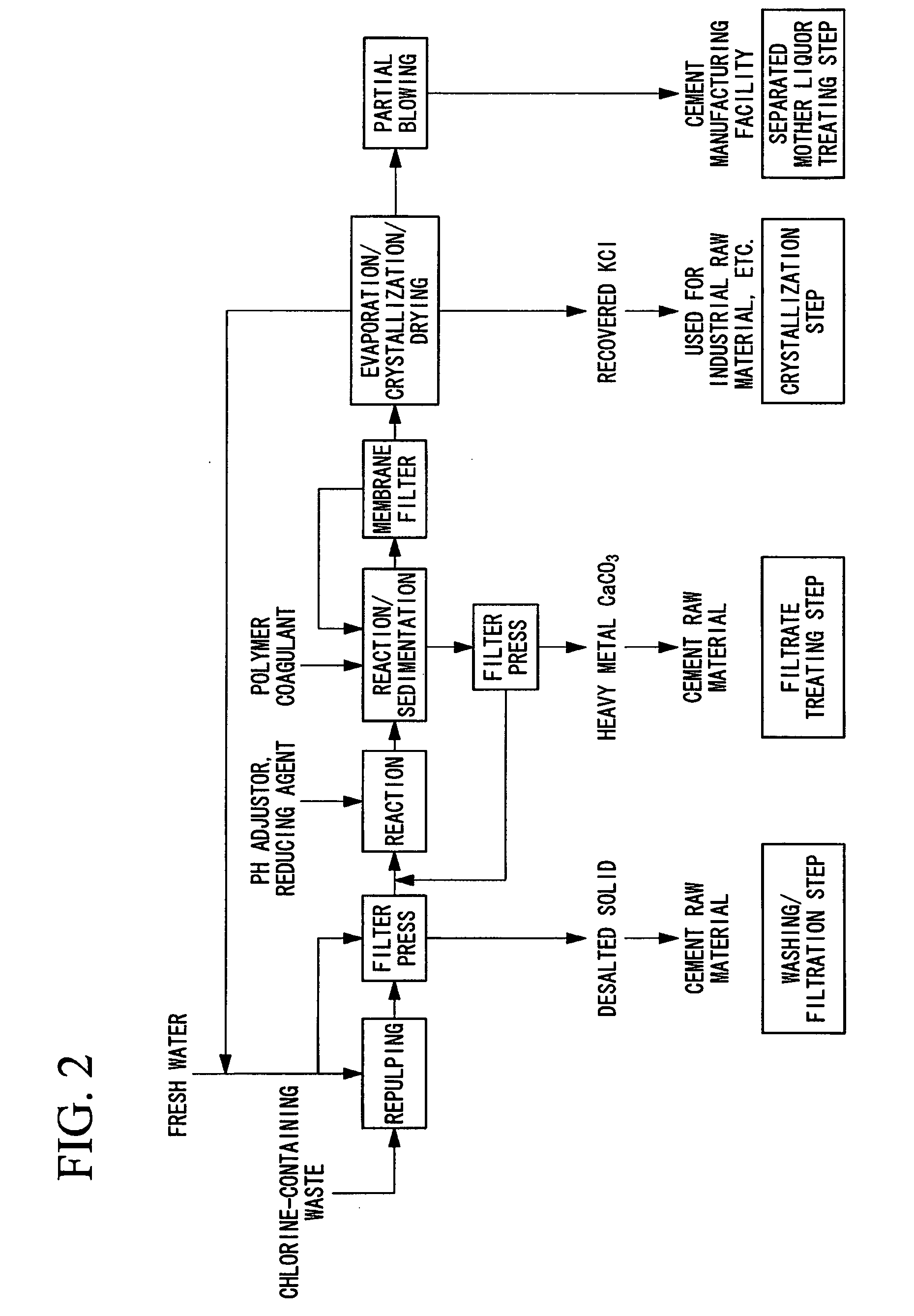

Method of and Apparatus for Treating Chlorine-Containing Waste

The present invention provides a method and an apparatus for treating a chlorine-containing waste, which can separate and recover a chlorine component from a chlorine-containing waste, and also can achieve a high chlorine removal thereby obtaining a high purity chlorine compound, and can decrease the amount of water for recovering chlorine. The method for treating a chlorine-containing waste of the present invention comprises a washing / filtrating step of adding water to the chlorine-containing waste, followed by mixing to form a first slurry, separating the first slurry into a solid and a filtrate through filtration, and using the resulting solid as a cement raw material; a filtrate treating step of adding a reducing agent and a pH adjustor to the filtrate to form a sediment containing heavy metal and calcium contained in the filtrate, and separating the sediment through filtration; a crystallization step of concentrating the filtrate, from which the sediment has been removed, through heating and evaporation to form a second slurry in which a chlorine compound contained in the filtrate has been crystallized, separating the second slurry into a solid containing a chlorine compound and a mother liquor, and recovering the solid; and a separated mother liquor treating step of returning a portion of the mother liquor to a cement manufacturing facility.

Owner:JAPAN WATER SYST CORP +1

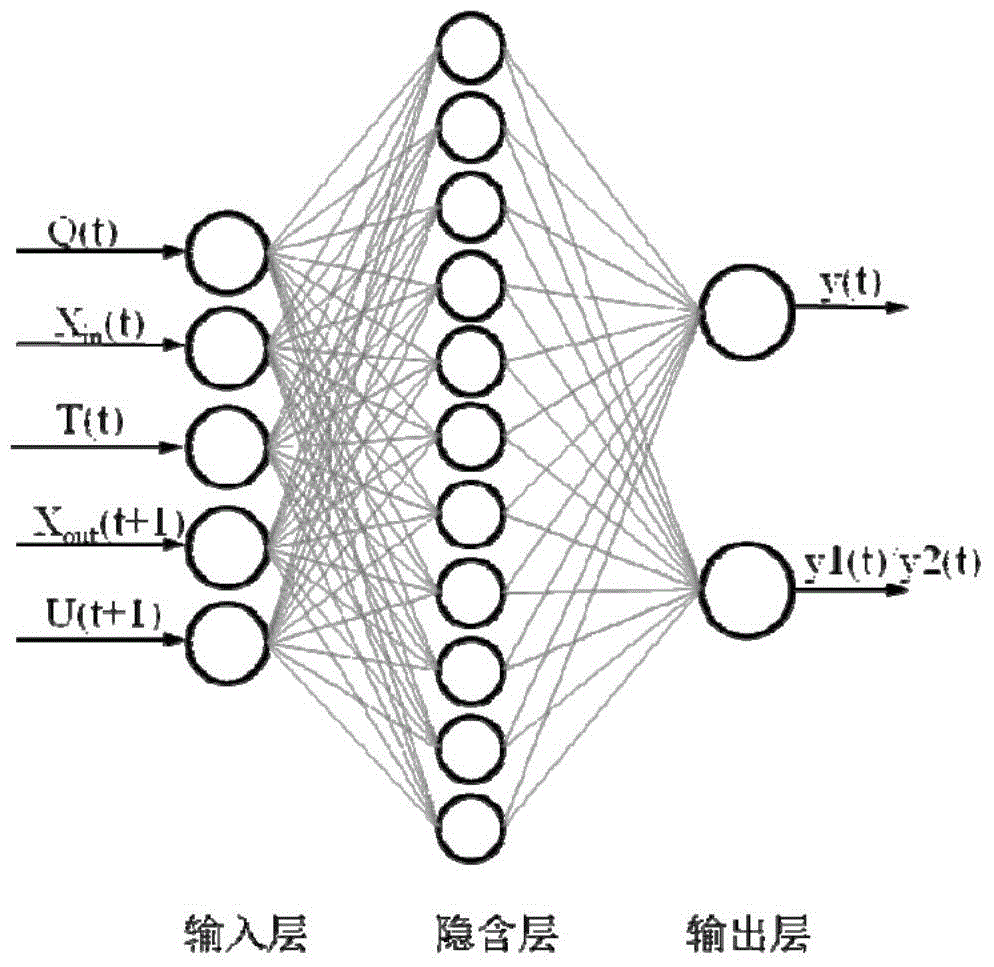

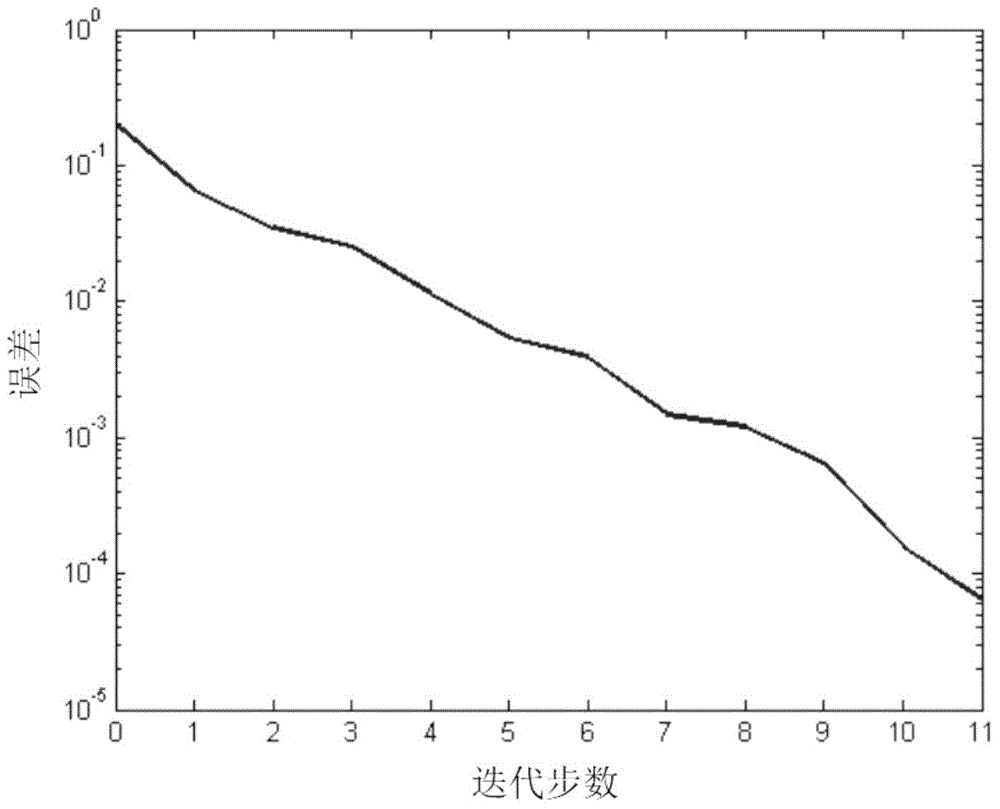

Ammonia spraying amount controlling method for SNCR (selective no catalytic reduction) flue gas denitrating system for cement manufacturing

InactiveCN104793651AReduce escapeAchieve emission standardsFlow control using electric meansProportional controlFlue gas

An ammonia spraying amount controlling method for an SNCR (selective no catalytic reduction) flue gas denitrating system for cement manufacturing includes the steps of firstly, arranging at least two layers of ammonia spraying areas in a cement kiln decomposing furnace; secondly, arranging a temperature sensor, a glue gas flow detecting sensor and a first NOx concentration detecting sensor at an entrance of the ammonia spraying areas, and arranging a second NOx concentration detecting sensor and an NH3 concentration detecting sensor at an exit of the cement kiln decomposing furnace; thirdly, by the aid of an ammonia spraying amount controlling system which is provided with an ammonia spraying amount BP (back propagation) neural-network predicting model, giving a total ammonia spraying amount and an ammonia spraying amount proportion between each two layers of the ammonia spraying areas via the ammonia spraying amount BP neural-network predicting model according to received flue gas temperature information, flue gas flow information and concentration information of NOx in flue gas at an entrance of the cement kiln decomposing furnace and concentration information of the NOx in the flue gas and NH3 concentration information at the exit of the cement kiln decomposing furnace, and controlling states of a total ammonia flow adjusting valve and branch ammonia flow adjusting valves according to the total ammonia spraying amount and the ammonia spraying amount proportions among the layers of the ammonia spraying areas to achieve real-time controlling of the ammonia spraying amount.

Owner:SICHUAN UNIV

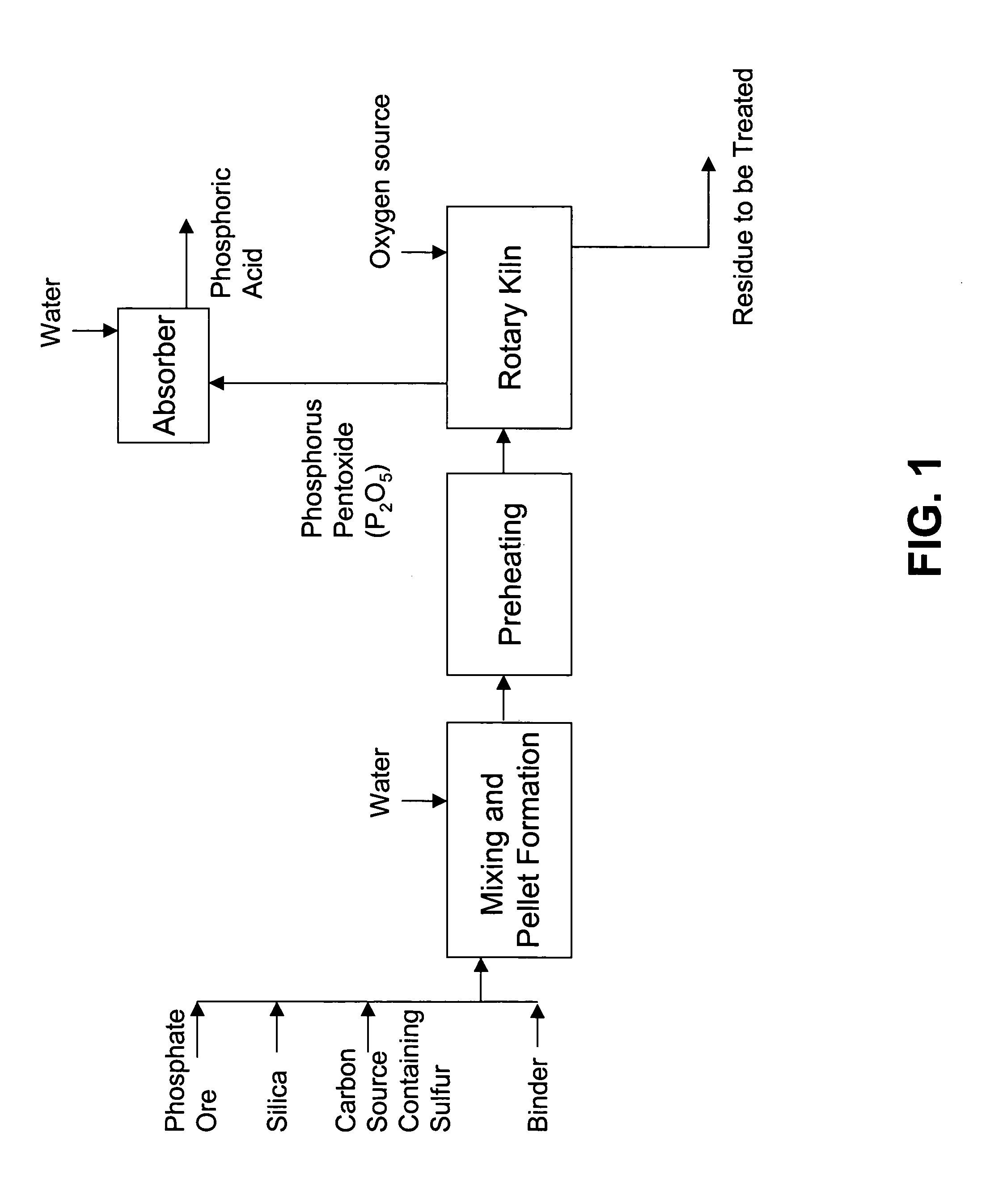

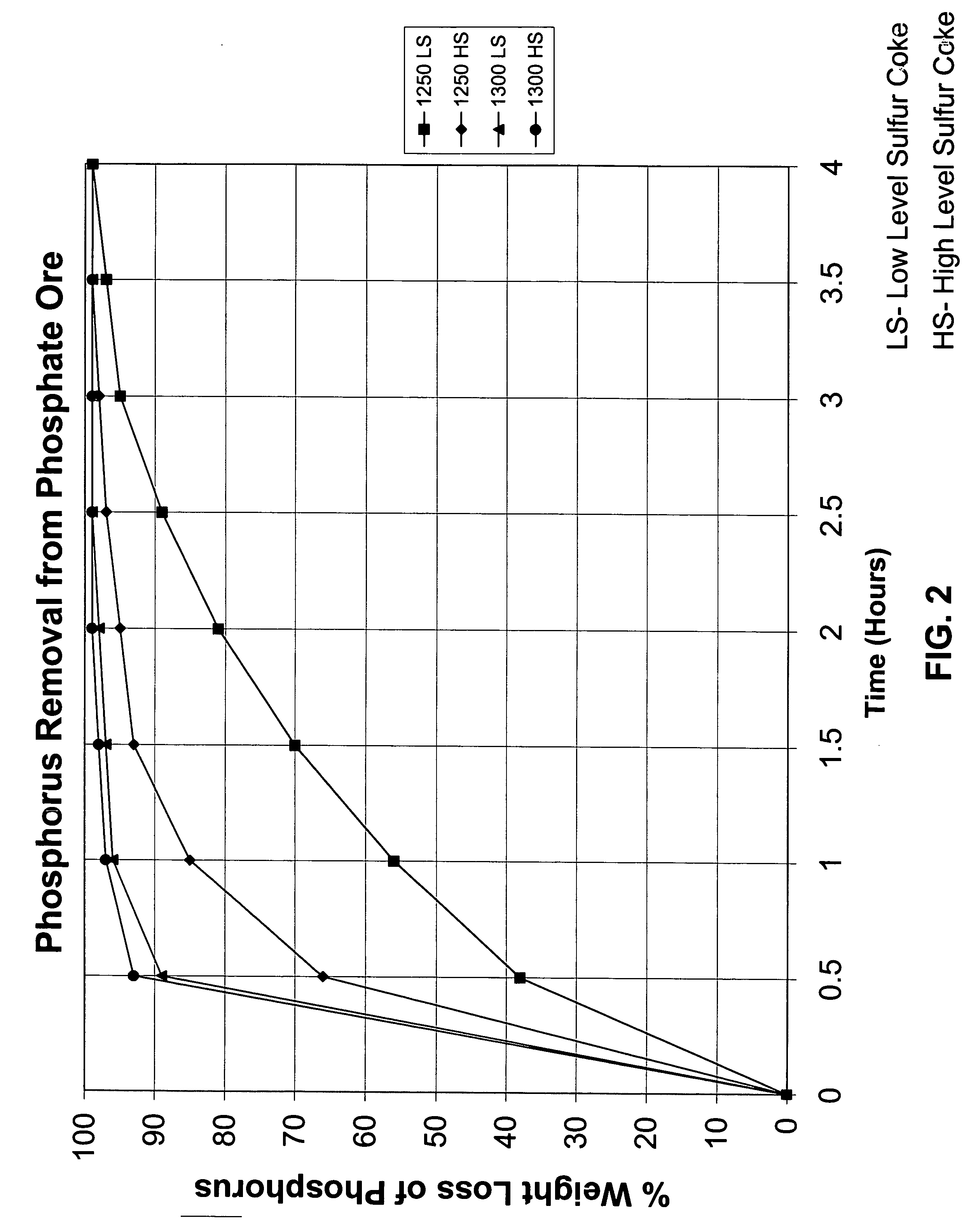

Method of forming phosphoric acid from phosphate ore

The process disclosed herein involves the high temperature processing of phosphate ore in a solid state using a ported rotary kiln. Prior to insertion into the kiln, the ore is pulverized and beneficiated to remove excessive quantities of unwanted materials such as clay, silica, iron, sodium, potassium, and alumina. The calcium oxide to silica ratio of the beneficiated is then adjusted to within a specific acceptable range, a carbon source containing sulfur such as petroleum coke is added and the resulting feed material is pelletized using a binding agent if necessary. The pelletized feed material is then dried, preheated, and fed into a ported rotary kiln. At the elevated temperature maintained in the reducing kiln, tricalcium phosphate undergoes a reduction reaction to produce phosphorus gas and carbon monoxide. Atmospheric air is injected into the rotating kiln chamber, which facilitates the oxidation of phosphorus gas to phosphorus pentoxide and the oxidation of carbon monoxide to carbon dioxide. The reducing kiln exhaust gas stream containing the phosphorus pentoxide and carbon dioxide gas components is processed in an absorption column in which the phosphorus pentoxide is hydrolyzed by water to phosphoric acid. The phosphoric acid is then recovered and concentrated to a commercial grade strength. The slag residue serves as a raw material for cement manufacture.

Owner:CAROLINA PROCESS ASSOC

Method and apparatus for drying wet bio-solids using excess heat from a cement clinker cooler

InactiveUS7434332B2Avoid landfill disposalDrying solid materials with heatBiofuelsCement manufacturingChiller

Owner:LEHIGH CEMENT

Method and apparatus for drying wet bio-solids using excess heat from a cement clinker cooler

InactiveUS20050274066A1Avoid landfill disposalDrying solid materials with heatBiofuelsCement manufacturingChiller

Method and apparatus for drying wet bio-solids by utilizing waste heat from a clinker cooler in a cement making process.

Owner:LEHIGH CEMENT

Method for producing waste residue foam concrete and nanopore vacuum plate composite material

InactiveCN103193446AReduce consumptionAddressing Excessive Carbon FootprintsSolid waste managementCeramic shaping apparatusFoam concreteToxic industrial waste

The invention relates to a method for producing a waste residue foam concrete and nanopore vacuum plate composite material, and belongs to the fields of comprehensive utilization of resources and building materials. According to the invention, various industrial waste residues or sorted part of construction waste are used as the main raw material to produce a high-strength foam concrete and nanopore vacuum insulation plate composite material. Shock resistant sealing layer having self decorative function is formed by one-time pouring molding through placing a nanopore vacuum insulation plate in the foam concrete. The heat transfer capacity of the composite wall material is decreased by 100% than that of ordinary wall materials, so that the total thickness and the total weight of the wall are reduced by 30% or more. The invention solves a bottleneck problem that conventional wall materials of housing industry are inconvenient for installation. Because wall thickness and weight are reduced, the costs of steel structure and building foundation are reduced. The shock resistant strength of the wall material is greatly improved compared with wall materials of housing industrialization manufactured by conventional cement. The weather resistance is improved significantly.

Owner:浙江翊善环保科技有限公司

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:WR GRACE & CO CONN

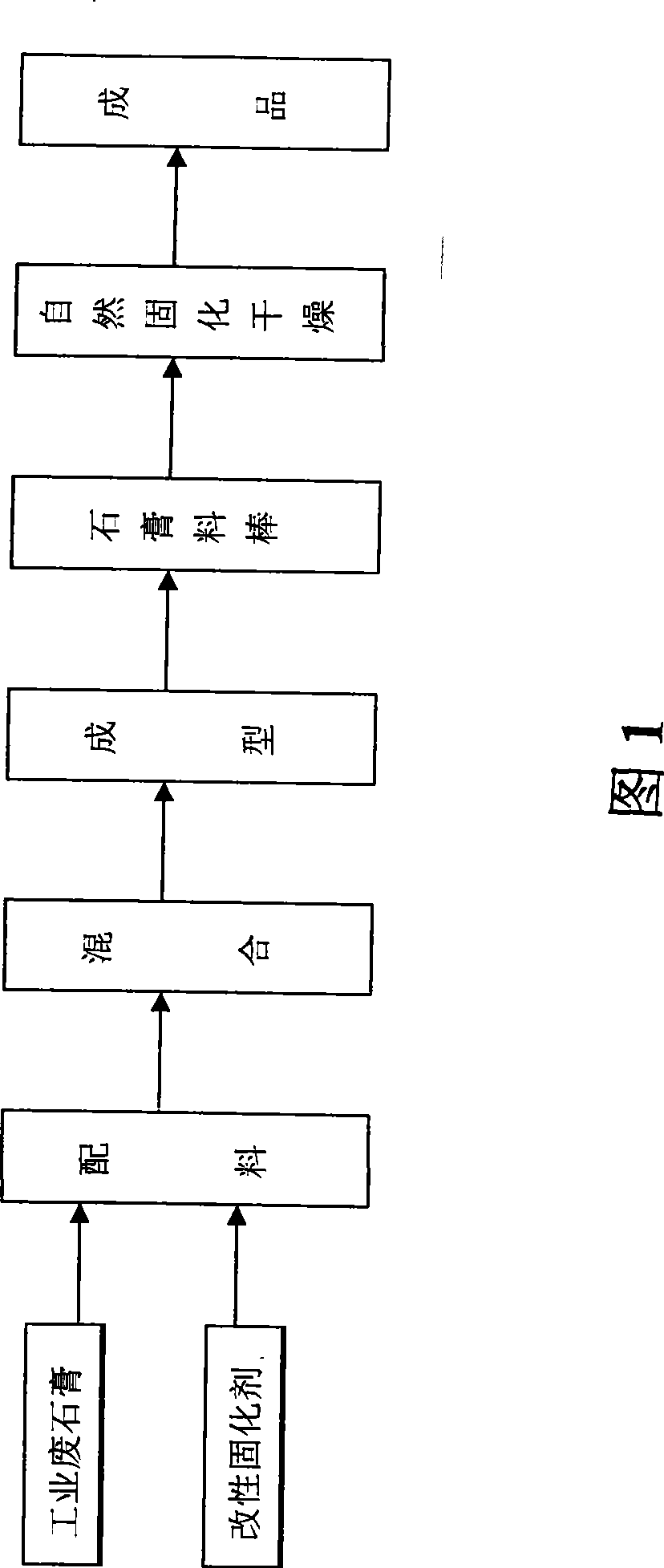

Novel industrial waste gypsum self forming energy-saving process

The invention relates to a novel self-curing and shaping energy-saving process for industrial waste gypsum, and belongs to the technical field of building material. The industrial waste gypsum is mixed with modifying and solidifying agent and shaped into a gypsum bar capable of self-curing and drying. The modifying and solidifying agent is prepared by two or a plurality of lime, magnesite, cement, acetylene sludge, bentonite, fluorite powder, attapulgite powder, industrial residue powder, water glass, eleven salt classes such as sulfate and the like, boric acid, alcohol amine, isopropanol amine, polyvinyl alcohol, water-soluble cellulose, glutaric acid, butane diacid, tartaric acid and water-reducing agent. The process is used for preparing solidification adjusting agent or preparing gypsum powder in the cement manufacturing industry, has the advantages of simple technology, low investment and excellent performance, changes waste into valuable, saves energy and reduces consumption.

Owner:尹小林

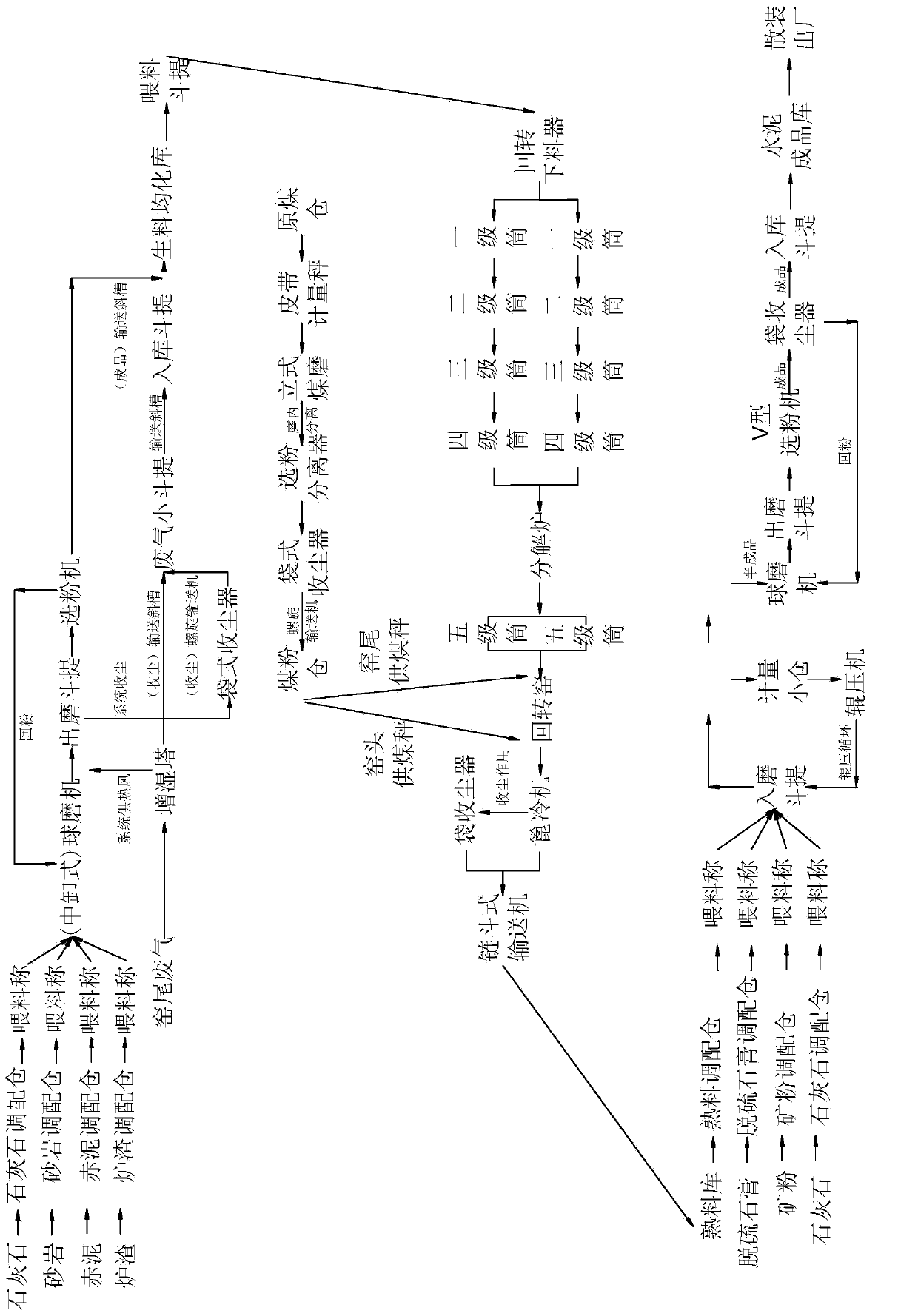

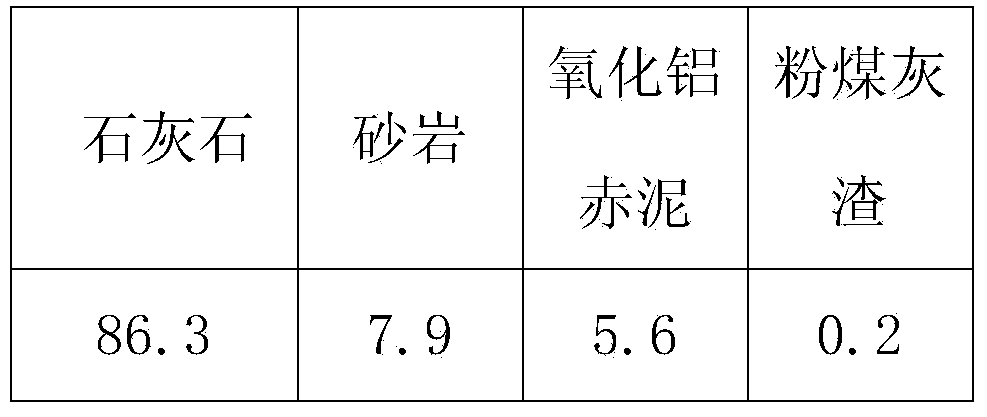

Micro-expansion moderate heat portland cement and preparation method thereof

The invention relates to micro-expansion moderate heat portland cement and a preparation method thereof and belongs to the technical field of dry method cement manufacturing. The micro-expansion moderate heat portland cement is prepared from the following components in parts by weight: 78-83 parts of clinker, 4-6 parts of limestone, 6-8 parts of mineral powder and 5-8 parts of desulfurized gypsum, wherein the clinker is prepared from the following raw materials in parts by weight: 85-88 parts of limestone, 6.5-9 parts of sandstone, 4.5-7 parts of alumina red mud and 0.05-1 part of fly ash slag. The preparation method of the micro-expansion moderate heat portland cement comprises the following steps: (1) clinker procedure, namely heating the limestone, the sandstones, the alumina red mud and the fly ash slag which are used as the raw materials in a decomposing furnace, controlling the temperature at 850-880 DEG C, and calcining the raw materials by virtue of a rotary kiln to prepare the clinker; (2) cement procedure, namely mixing the clinker, the limestone, the mineral powder and the desulfurized gypsum, and carrying out cement grinding to prepare the cement. The preparation method is simple in process, the product performance is stable, indexes of linear expansivity, hydration heat and the like accord with the expected requirements, and the micro-expansion moderate heat portland cement can be widely applied to building construction of high-strength buildings with a large volume, highway tunnels, culverts and the like.

Owner:TIANJIN ZHENXING CEMENT

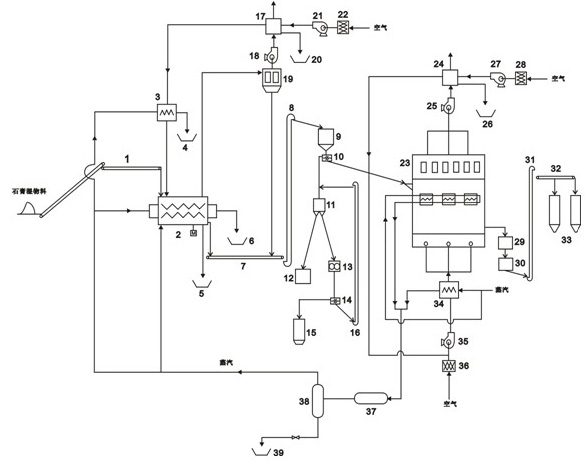

Energy-saving gypsum calcination system and process

The invention discloses an energy-saving gypsum calcination system and an energy-saving gypsum calcination process. The energy-saving gypsum calcinations system comprises a paddle dryer, a vibrating screen, a cement bulk truck, a pelletizer and a cement delayed coagulation device, a fluidized bed calcinator, a building gypsum processing device, and an oscillation flow heat pipe. The paddle dryer is used for drying wet gypsum materials; the vibrating screen is used for screening the dried gypsum; the cement bulk truck is used for manufacturing cement; the pelletizer and the cement delayed coagulation device are used for palletizing the dried gypsum which is used as a cement retarder; the fluidized bed calcinatory with a bag-type dust collector is used for calcining the gypsum; the building gypsum processing device is used for processing the calcined gypsum into building gypsum powder; and the oscillation flow heat pipe is used for utilizing residual heat of the moisture-carrying gas and fluidized gas. Due to the adoption of a device for drying and calcining successively, the calcining efficiency and product quality are improved; and the residual heat is fully utilized, so the energy utilization rate of the system is improved. The process system has the advantages of continuous operation, high heat efficiency, low energy consumption, high yield, stable operation, convenient operation, and automatic control.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

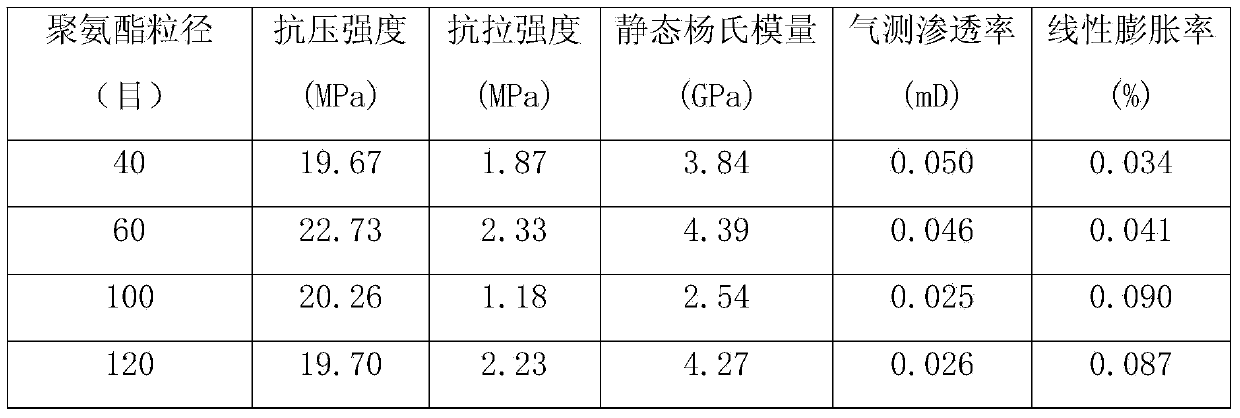

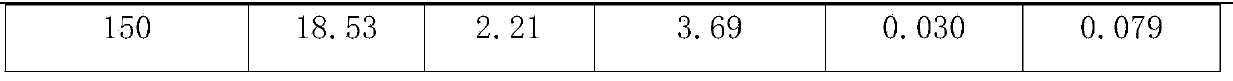

Expansion oil well cement with temperature resistance

InactiveCN103740352AHigh expansion rateIncrease elasticityDrilling compositionManufacturing technologyHigh pressure

The invention discloses an expansion oil well cement with temperature resistance, and relates to the technical field of oil well cement manufacturing of oil and gas well cementing, a certain amount of a polyurethane elastic component is added to oil well cement slurry and is uniformly mixed, by use of the expansion characteristics of the polyurethane elastic component, and oil well cement slurry which can block off cracks and micro annular space gaps and can ensure low permeability of set cement, can be formed at high temperature and under high pressure. The expansion oil well cement with the temperature resistance solves the problem that oil well cement is poor in strain resistant capacity, and can effectively extend the life of oil wells. The expansion oil well cement with the temperature resistance is stable in performance at room temperature and high temperature (150 DEG C), good in rheological property, and controllable in thickening time, and the set cement gas detection permeability is lower than 0.05mD.

Owner:CNPC BOHAI DRILLING ENG

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:GCP APPL TECH INC

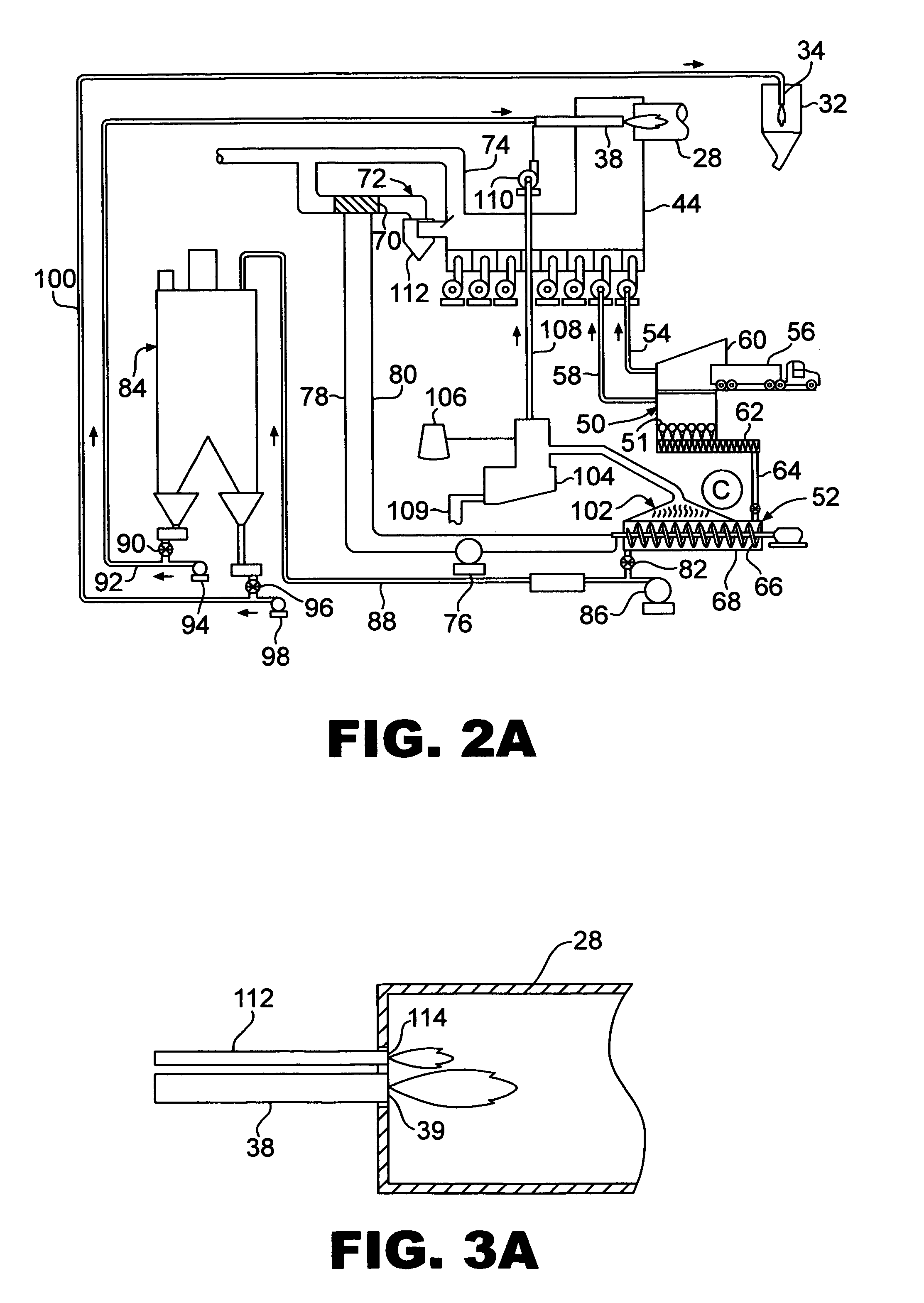

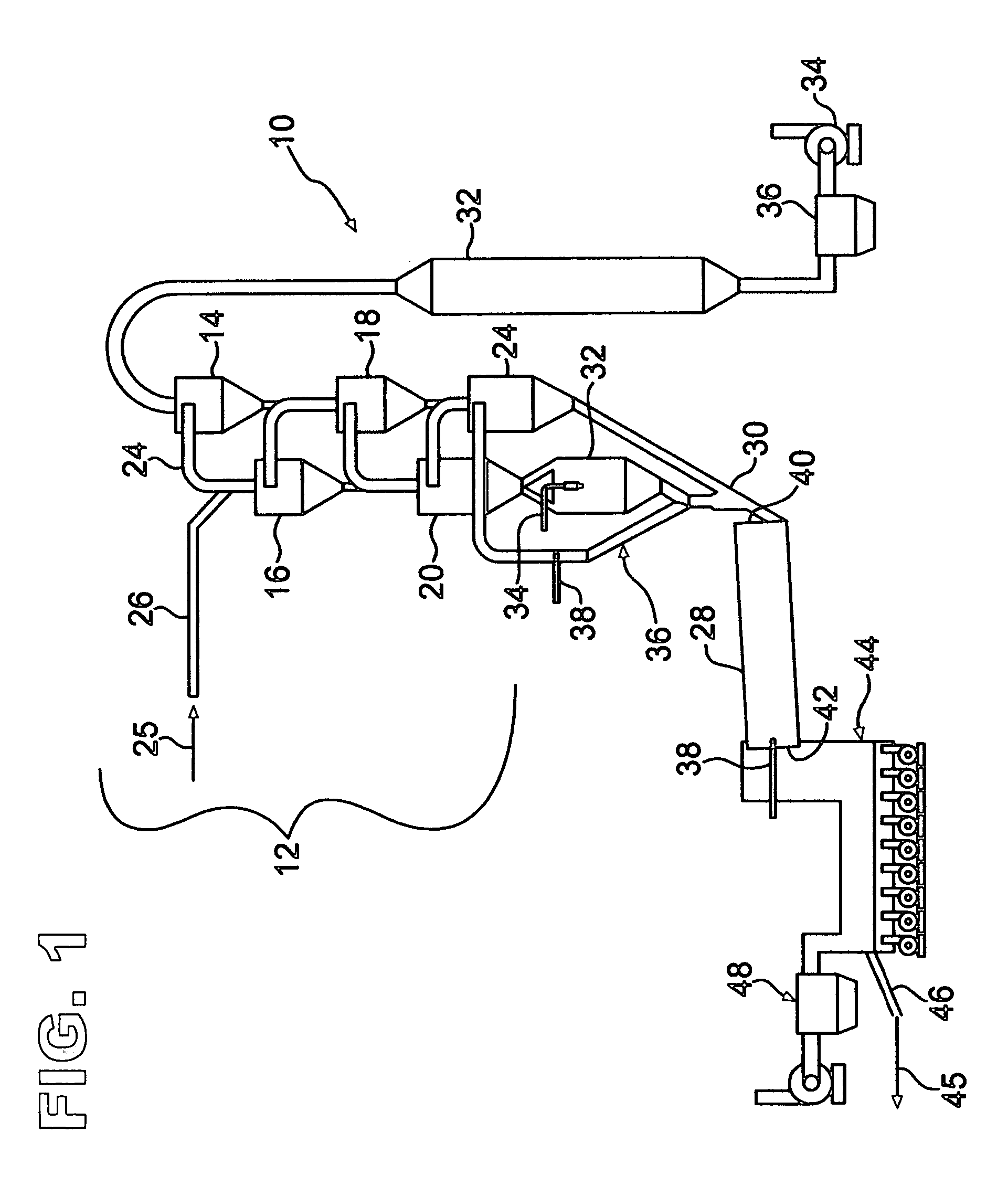

Method and apparatus for incineration of combustible waste

InactiveUS8474387B2Maximize firingShort retention timeHand ironCombustion technology mitigationCombustion chamberExhaust fumes

A method and apparatus for incinerating different types of combustible waste in a cement manufacturing process. Two combustion chambers for incinerating waste are arranged in series, with first combustion chamber being a down draft chamber in which there is a downward flow of combustion gas and waste fuel to a waste and gas outlet. The second chamber is adaptable to support waste on a supporting surface incorporated in the compartment, wherein the waste is transported through the compartment from a waste inlet to a waste outlet along a circular path.

Owner:F L SMIDTH & CO AS

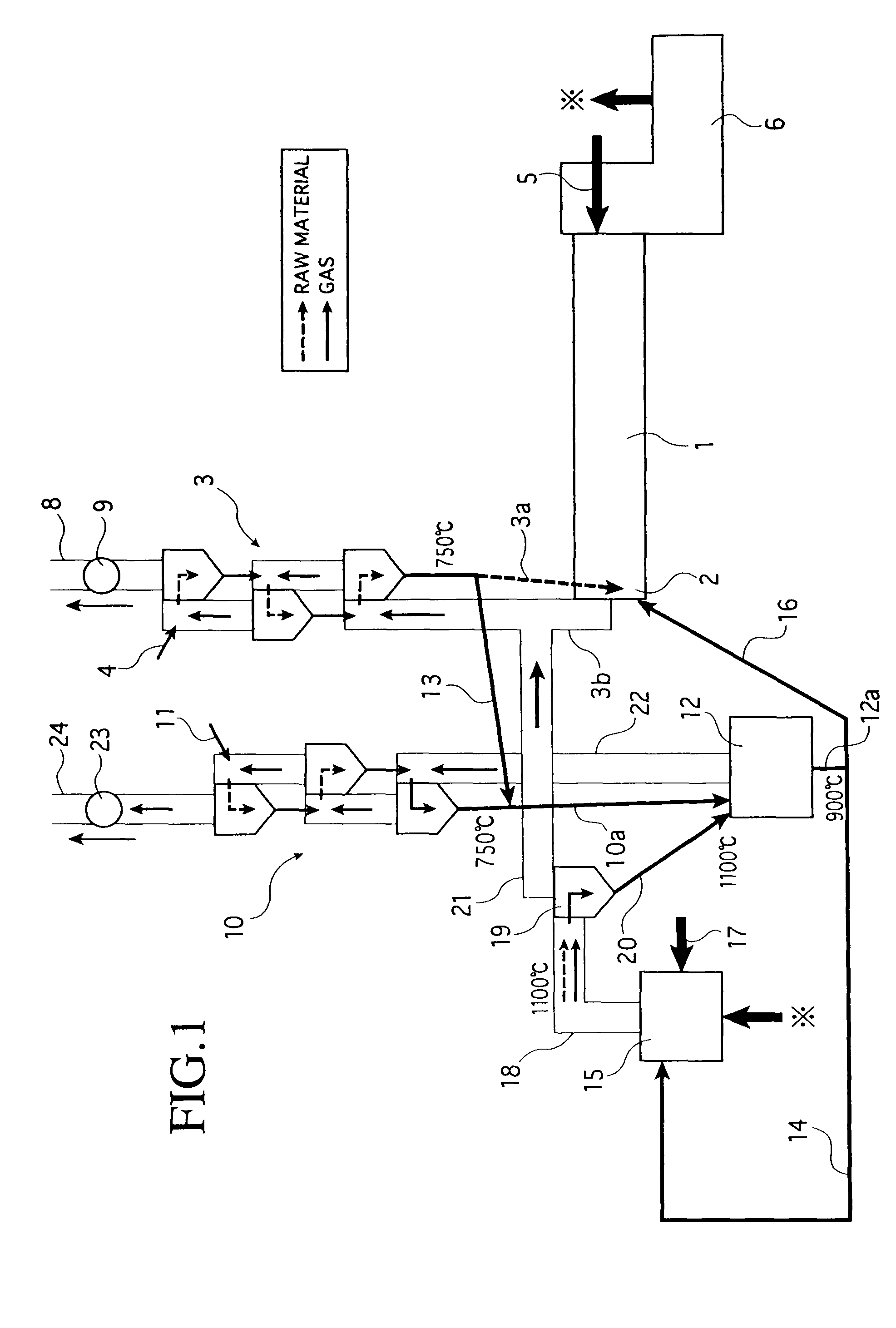

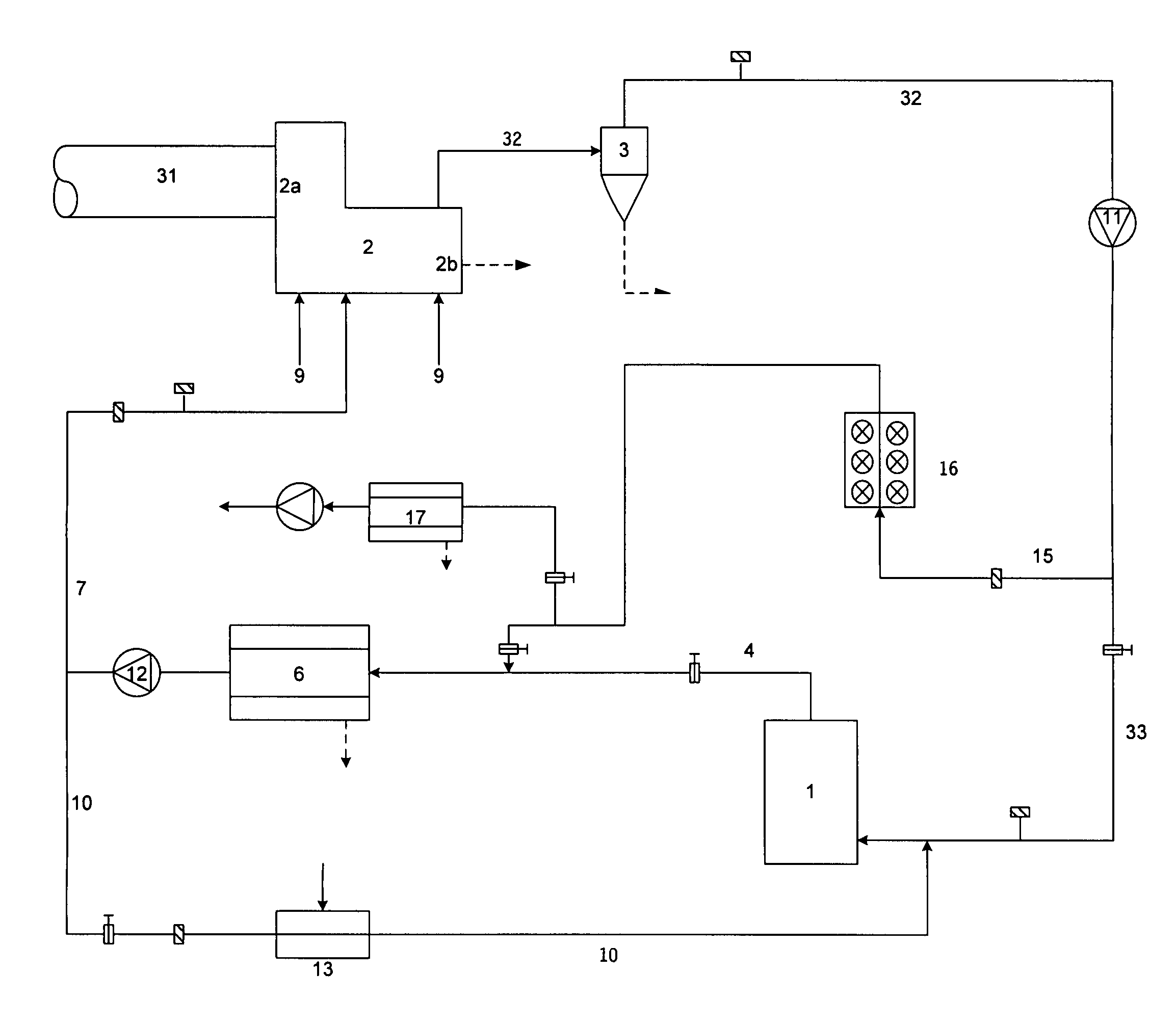

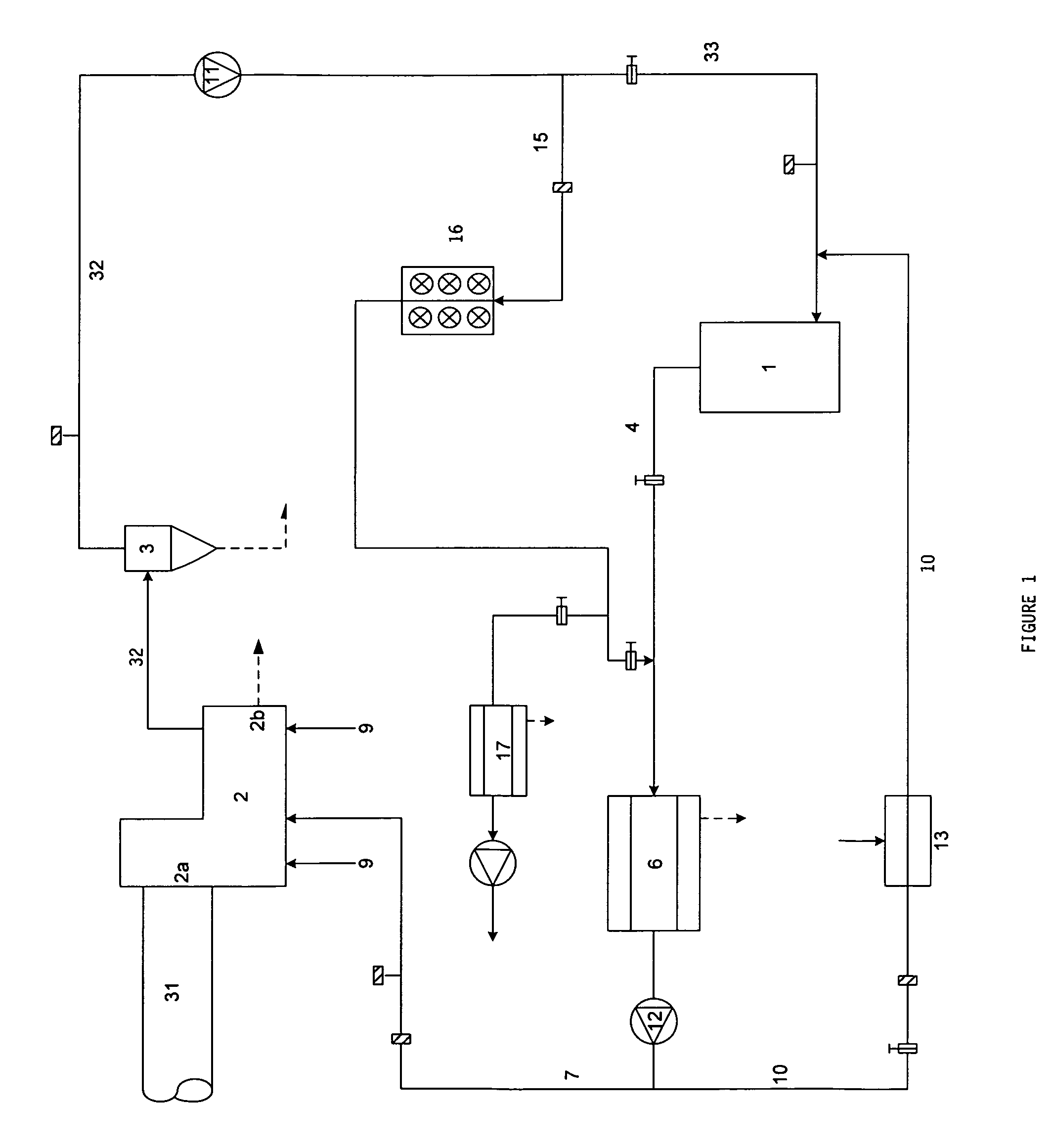

Method and facility for recovering co2 gas in cement manufacturing facility

InactiveUS20110044880A1Easy to useGas treatmentCarbon compoundsHigh concentrationCement manufacturing

To provide a method and facility for enabling CO2 gas generated in a cement manufacturing facility to be separated and recovered at a high concentration. To this end, according to the present invention, the calcination of a cement material and the recovery of CO2 gas generated in a calciner are performed by one of the following steps of: [1] superheating the cement material before calcination to at least the calcination temperature thereof in a superheating furnace and then mixing the superheated cement material with a new cement material before calcination in a mixer / calciner; [2] mixing, in the mixer / calciner, the cement material before calcination with a part of high-temperature cement clinker discharged from a cement kiln; and [3] using an externally heated calciner.

Owner:MITSUBISHI MATERIALS CORP

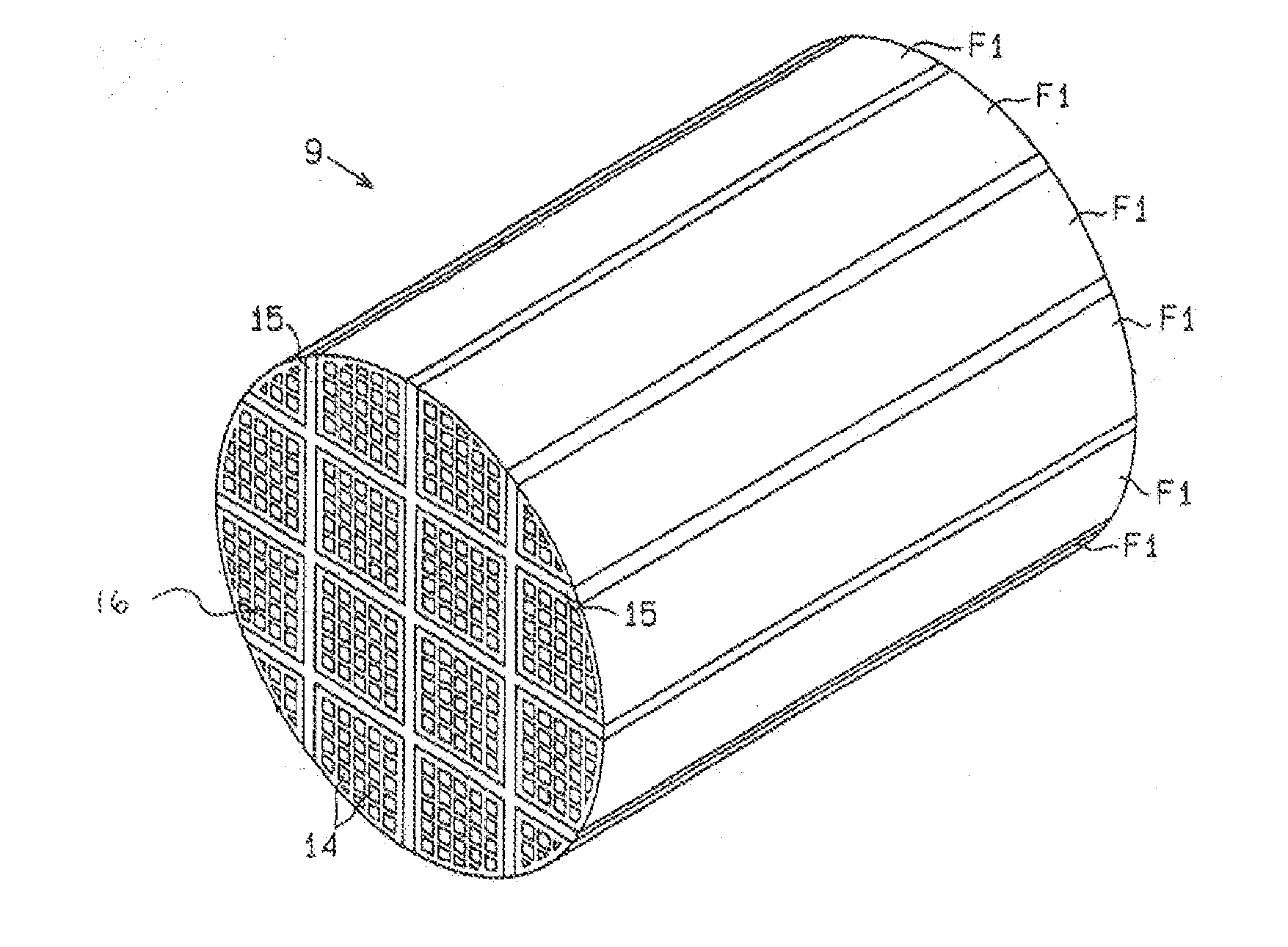

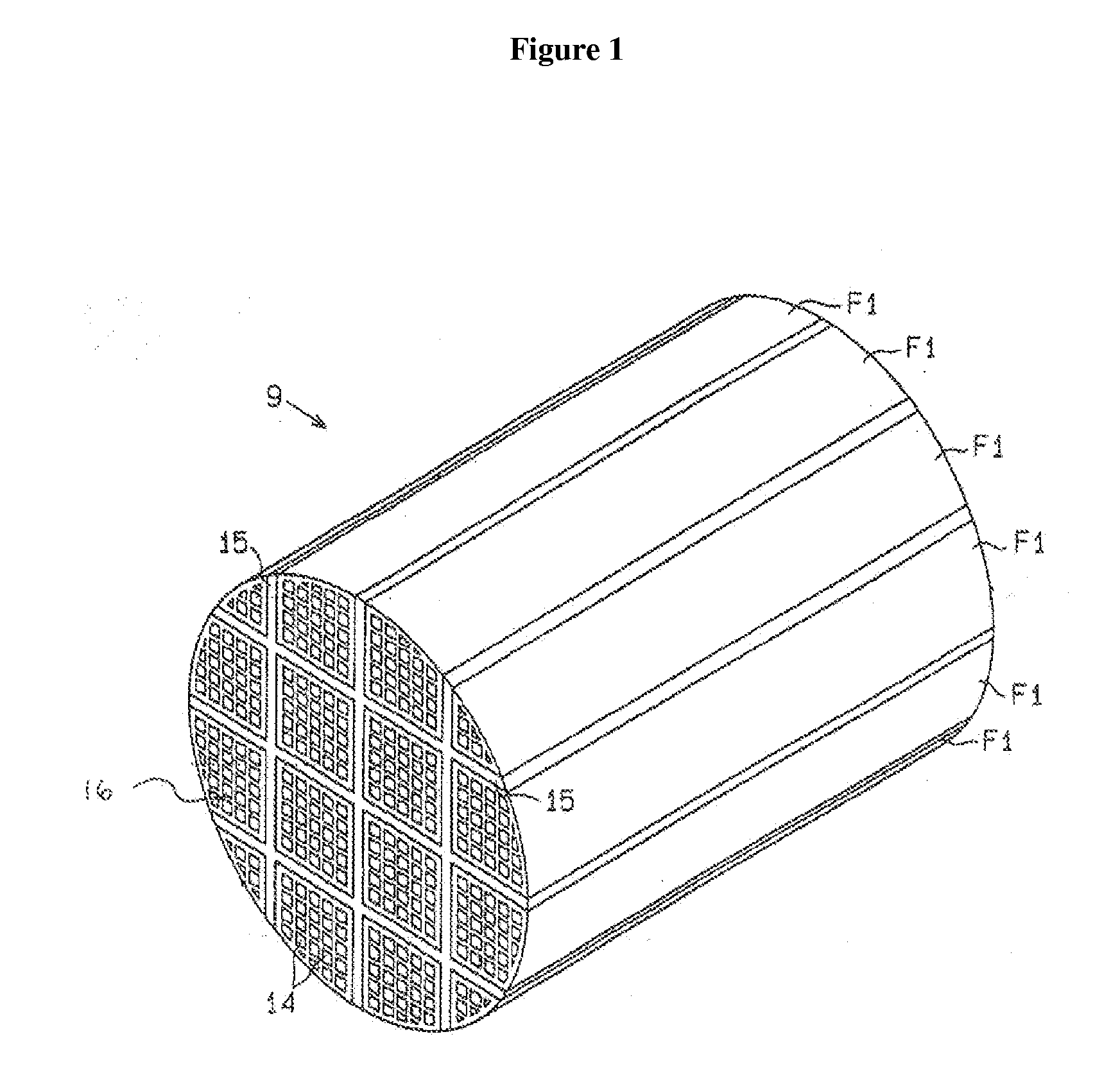

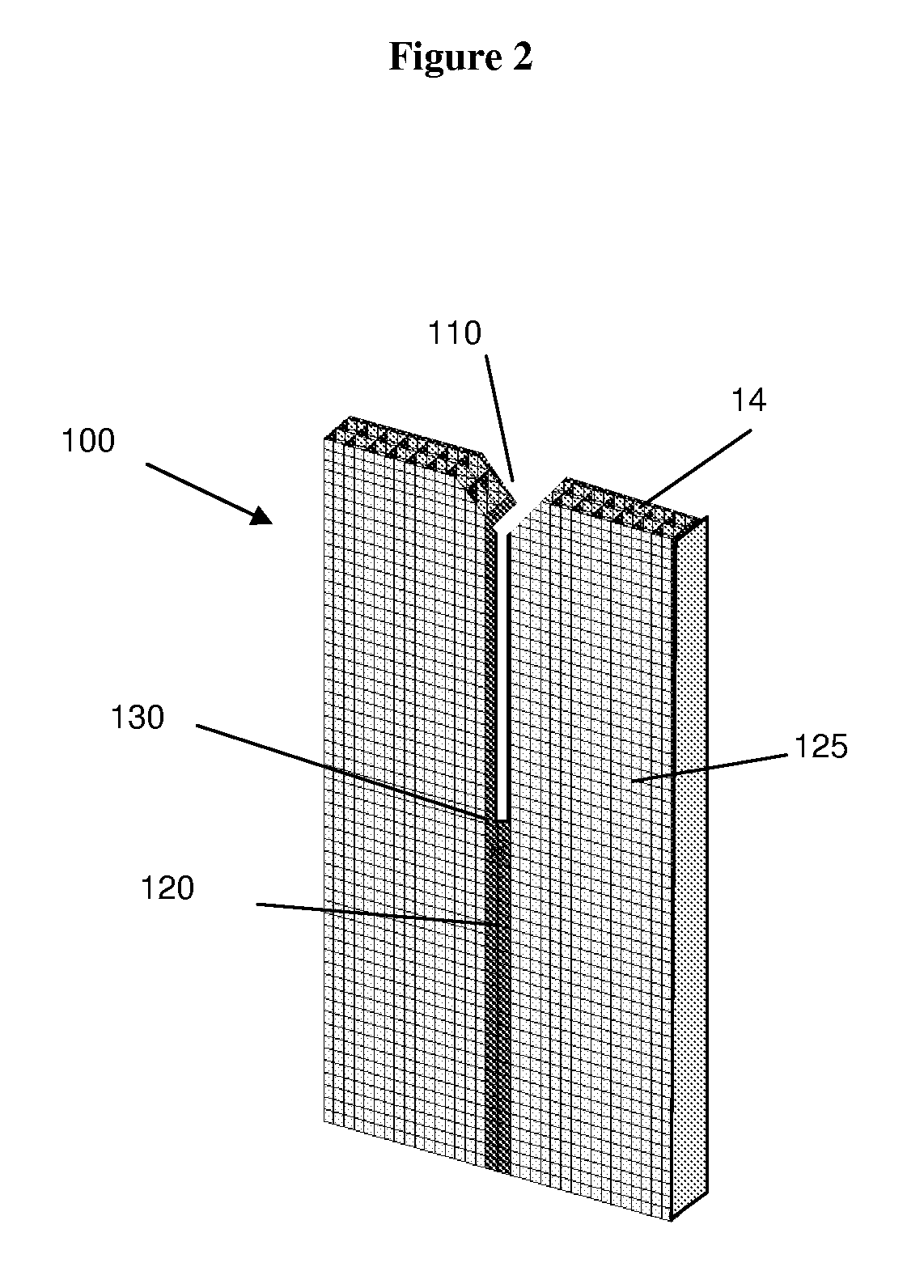

Cement to make thermal shock resistant ceramic honeycomb structures and method to make them

InactiveUS20120207967A1Improve thermal shock resistanceIncrease resistanceDispersed particle filtrationLaminationPorosityYoung's modulus

An improved ceramic honeycomb structure is comprised of at least two separate smaller ceramic honeycombs that have been adhered together by a cement layer comprised of a cement layer has at least two regions of differing porosity or cement layer where the ratio of toughness / Young's modulus is at least about 0.1 MPa·m1 / 2 / GPa.

Owner:DOW GLOBAL TECH LLC

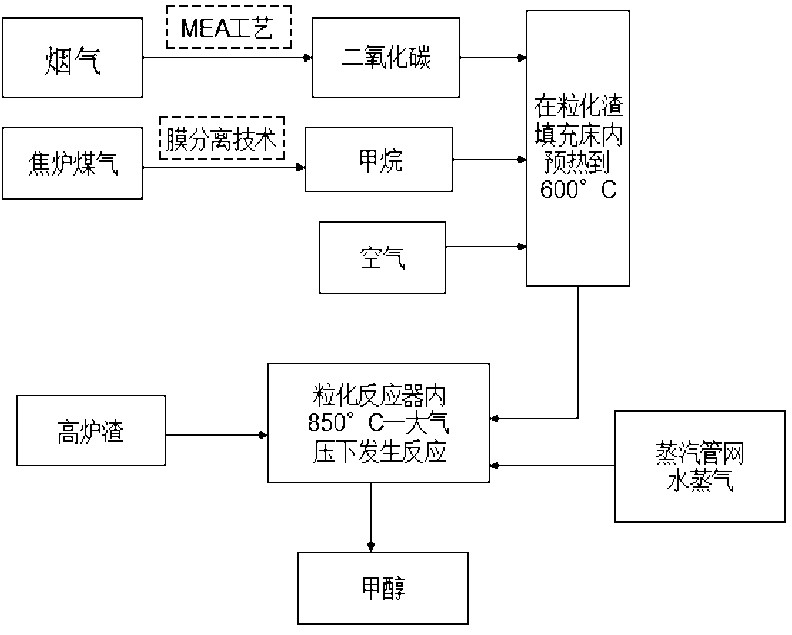

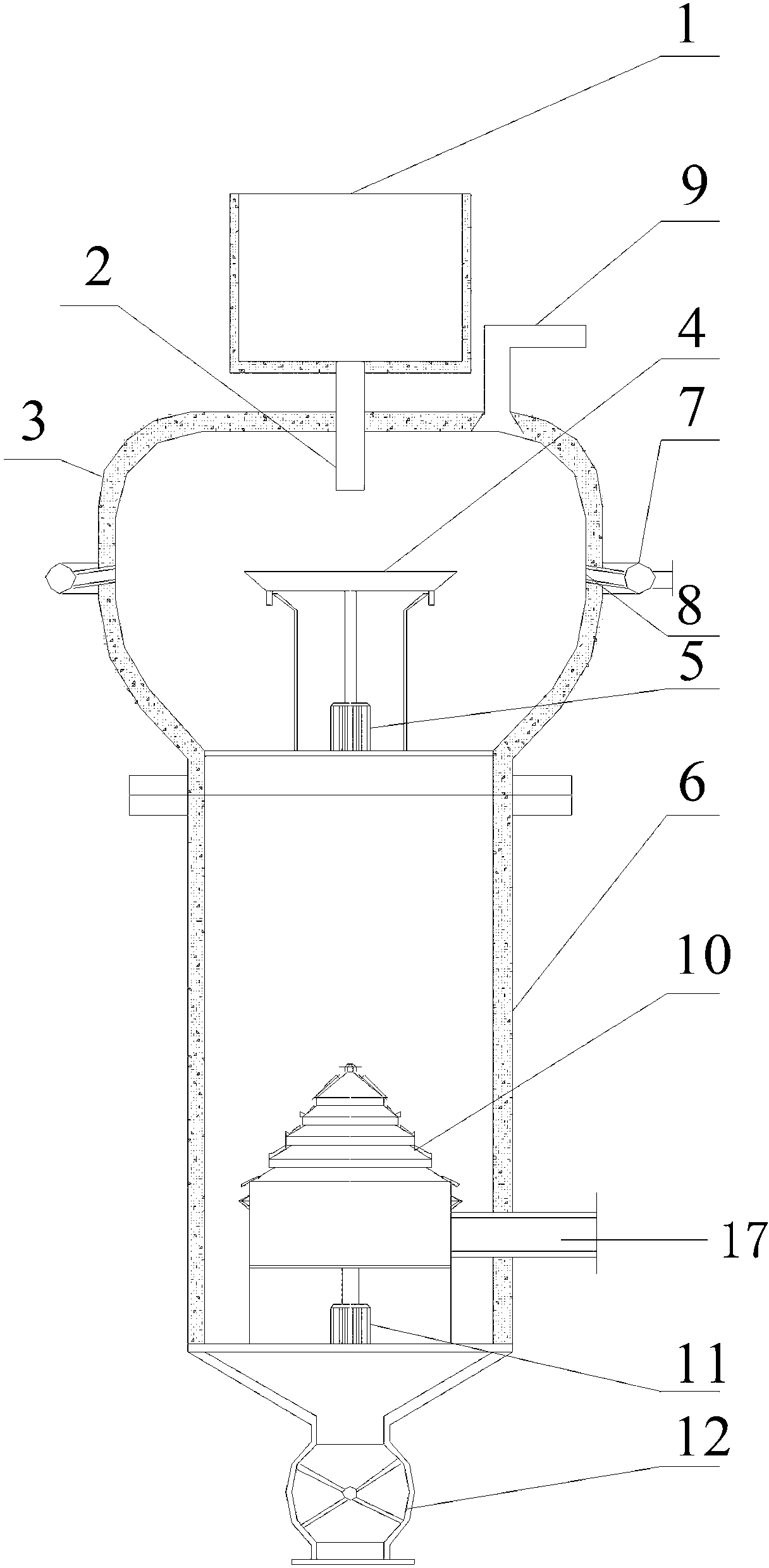

Method for preparing methanol by sensible heat of blast furnace slag

InactiveCN103304372AAlleviate or even eliminate the problem of carbon depositionEmission reductionPreparation by oxidation reactionsChemical industrySlagEnergy recovery

Owner:NORTHEASTERN UNIV

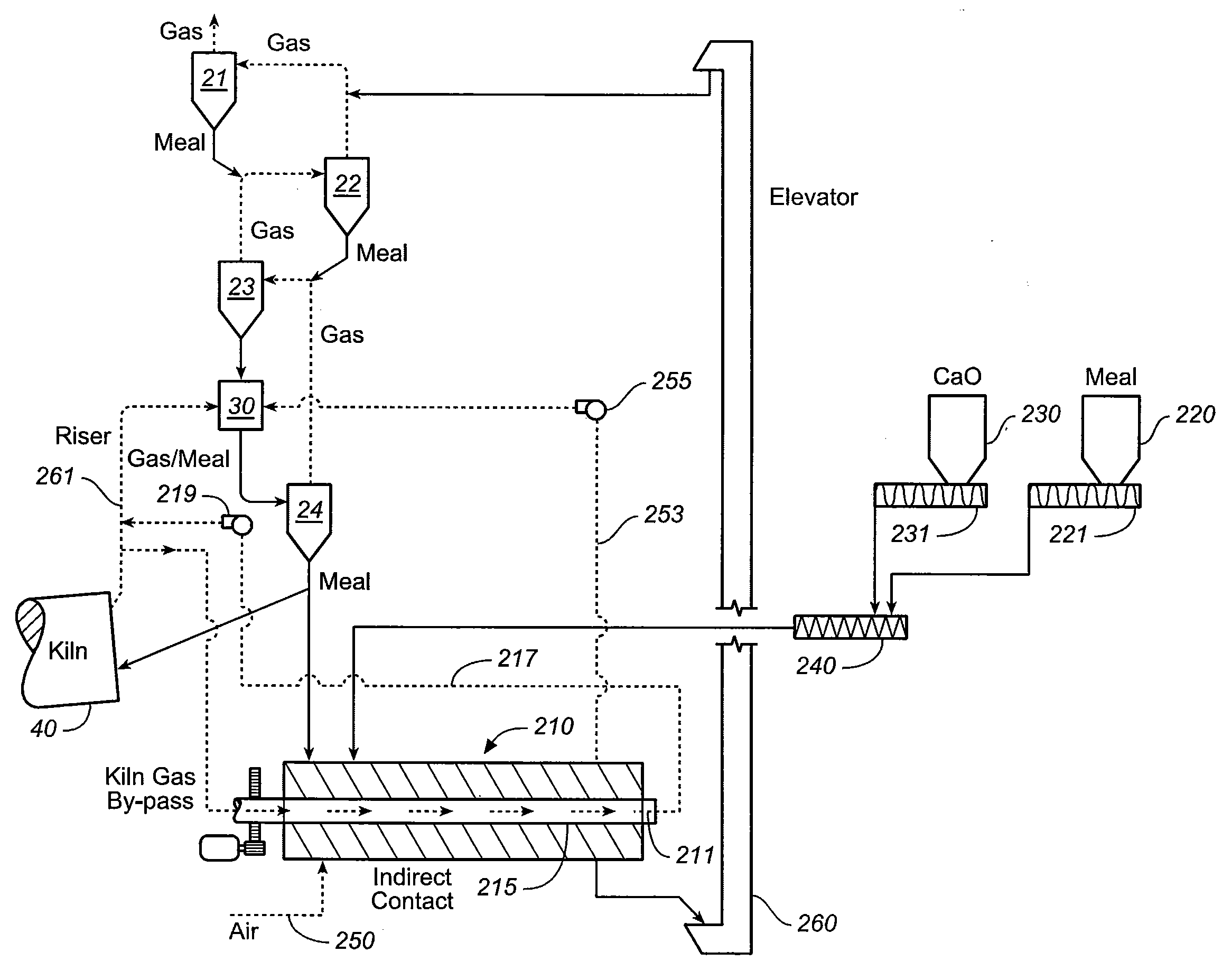

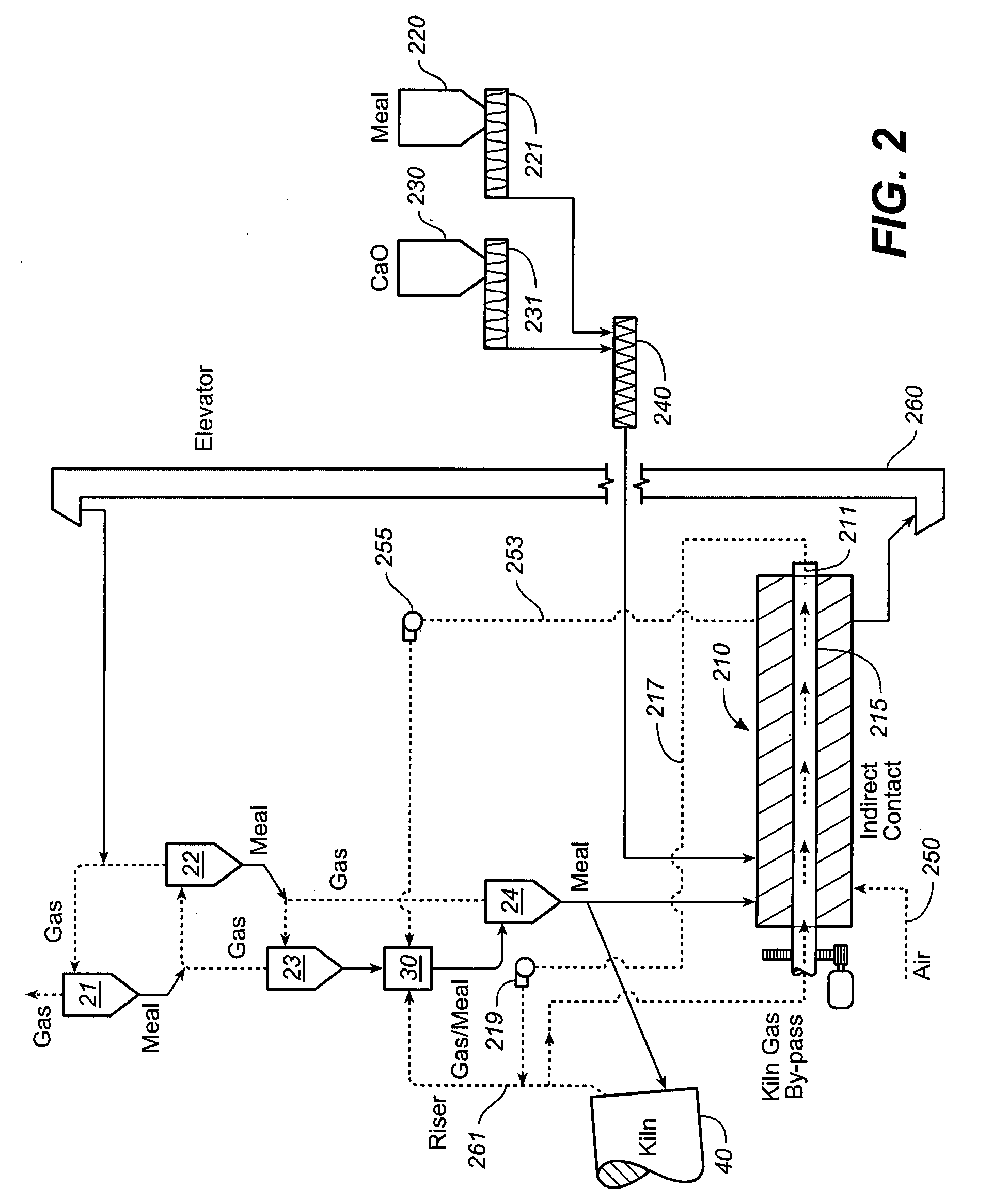

Apparatus and method for reducing emissions resulting from raw meal grinding

InactiveUS7972419B2Emission reductionCombination devicesNitrogen compoundsEnvironmental engineeringCement manufacturing

Disclosed is a method for reducing emissions from exhaust gas generated during the grinding and drying of cement raw meal as part of a cement manufacturing process. The invention comprises circuiting the exhaust gas between a raw mill and a clinker cooler. In the clinker cooler at least a portion of said emissions are delivered to a cement kiln in which said emissions are removed by being combusted and / or absorbed.

Owner:F L SMIDTH & CO AS

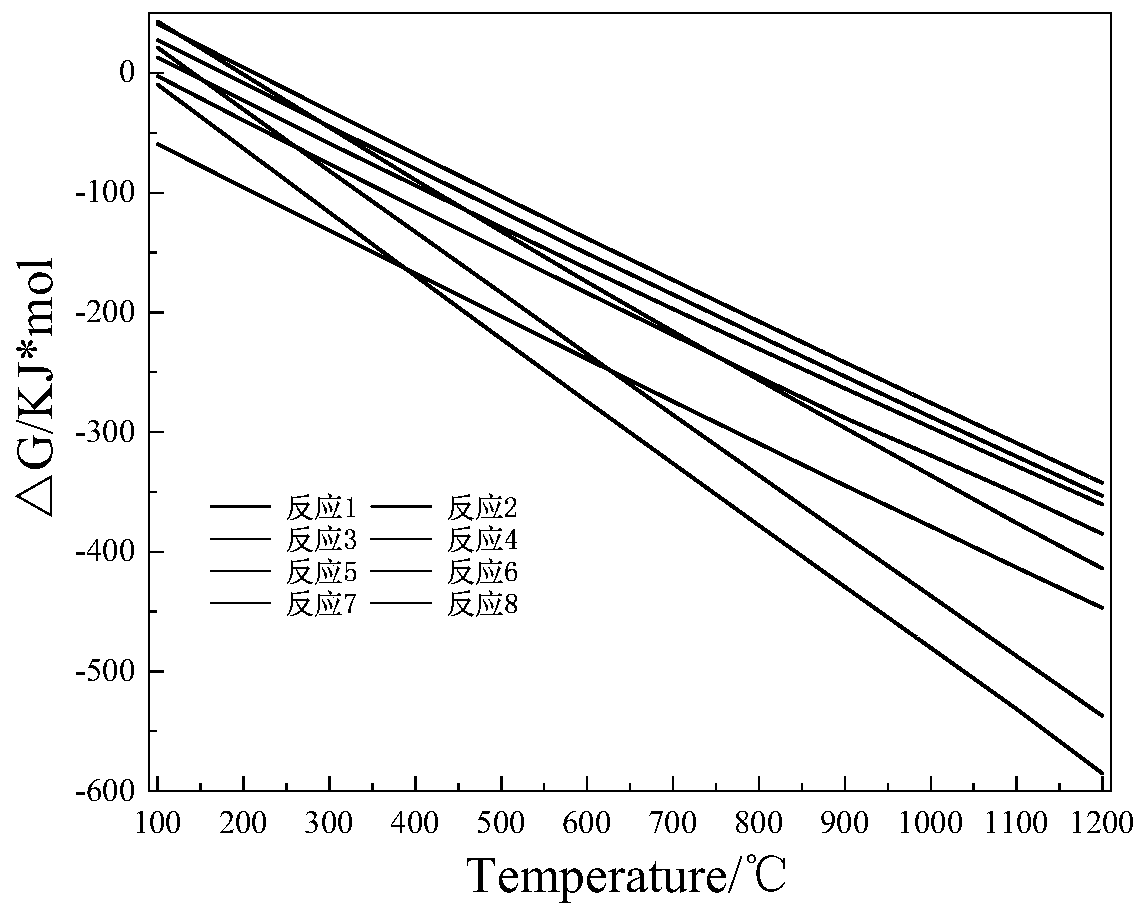

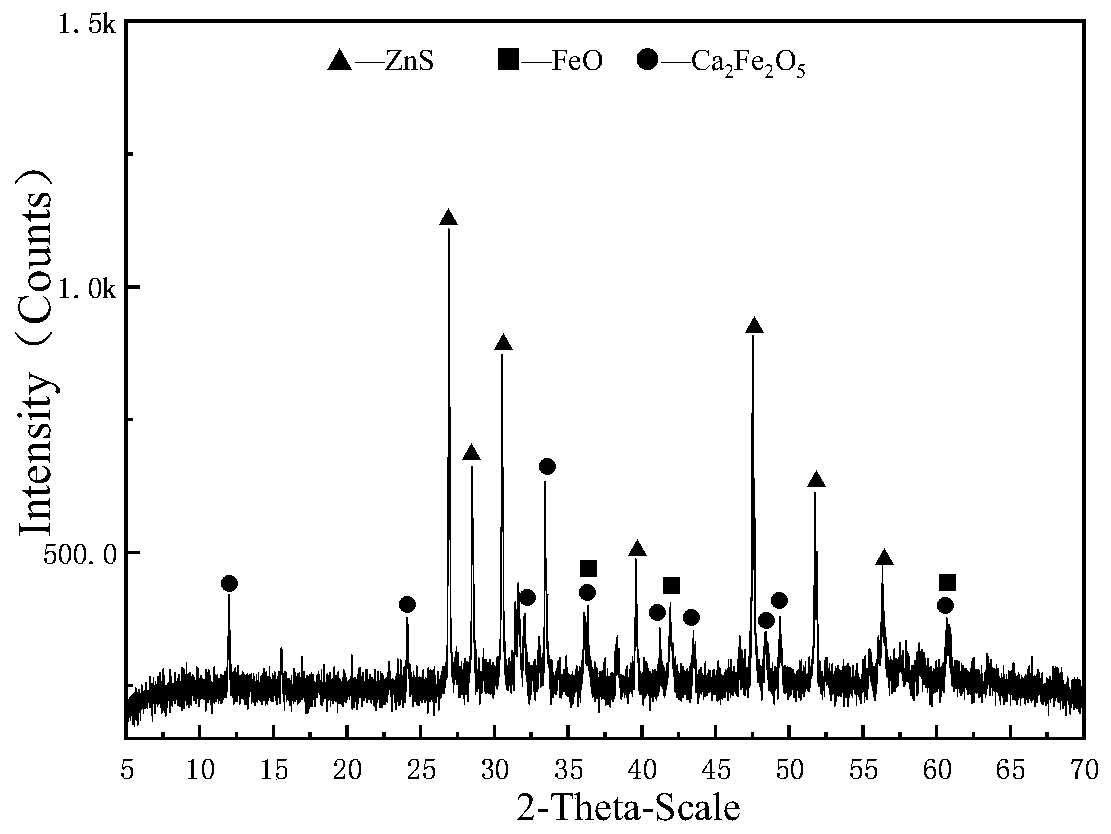

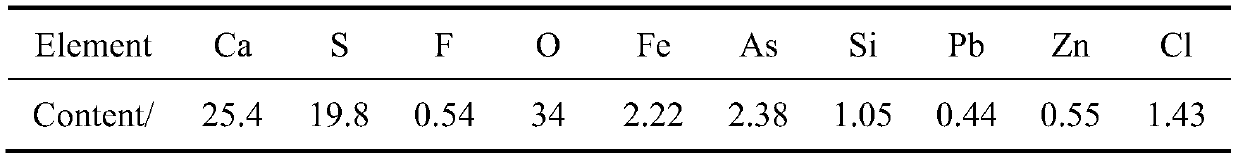

Method of synergistically vulcanizing and roasting lead-zinc smelting slag and gypsum slag

ActiveCN110983029AAchieving clean co-processingAchieve recyclingFlotationCalcium silicateSulfidation

The invention discloses a method of synergistically vulcanizing and roasting lead-zinc smelting slag and gypsum slag. The method comprises the following steps of: mixing lead-zinc smelting slag, gypsum slag and a carbonaceous reducing agent for reducing sulfurization roasting, using the gypsum slag as a vulcanizing agent to directionally convert lead, zinc and other heavy metals in the lead-zinc smelting slag into metal sulfides easy for flotation separation, enabling calcium in the gypsum slag to react with iron and silicon compounds in the lead-zinc smelting slag to generate calcium ferriteand calcium silicate compounds which can be used for manufacturing building materials and cement, and enabling arsenic in the gypsum slag to be volatilized and enriched in smoke dust to be recycled. The method has the advantages of being low in energy consumption and environmentally friendly, can solve the problem of environmental pollution caused by existing gypsum slag and lead-zinc smelting slag treatment, and has good application and popularization prospects.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com