Mechanized construction plastering mortar and preparation method thereof

A plastering mortar and mechanical construction technology, which is applied in the field of building materials, can solve the problems of poor construction site environment, difficult quality control, and increased transportation costs, and achieve the effects of reducing drying costs, reducing material costs, and good environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

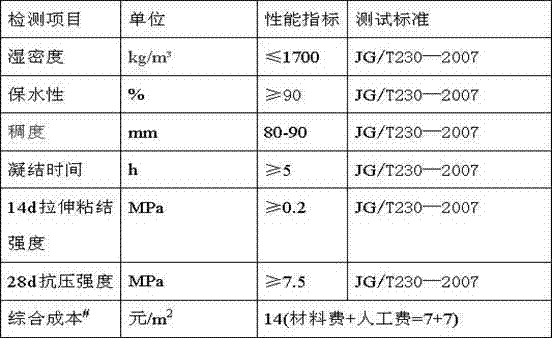

Image

Examples

Embodiment 1

[0017] A kind of plastering mortar for mechanical construction, which is made by mixing powder, aggregate and water, wherein the mass ratio of various components is: powder: aggregate: water = 200:800:160; the aggregate is The artificial sand has a fineness modulus of 2.5, and the moisture content of the aggregate is 0; the water is urban tap water. The powder is made of Portland cement clinker, gypsum, granulated blast furnace slag, fly ash, limestone powder, and chemical additives. The mass ratio of the various components is: Portland cement clinker: Gypsum: granulated blast furnace slag: fly ash: limestone powder: chemical additives = 100:50:200:400:250:2; the fineness of the Portland cement clinker and gypsum is 300m 2 / kg; the fineness of the granulated blast furnace slag is 400m 2 / kg; the fineness of the fly ash is 250m 2 / kg; the fineness of the limestone powder is 600m 2 / kg.

[0018] The preparation method of above-mentioned mechanical construction plastering mor...

Embodiment 2

[0028] A kind of plastering mortar for mechanical construction, which is made by mixing powder, aggregate and water, wherein the mass ratio of various components is: powder: aggregate: water = 250:750:215; the aggregate is River sand, the fineness modulus is 1.0, the moisture content of the aggregate is 10%; the water is urban tap water. The powder is made of Portland cement clinker, gypsum, granulated blast furnace slag, fly ash, limestone powder, and chemical additives. The mass ratio of the various components is: Portland cement clinker: Gypsum: granulated blast furnace slag: fly ash: limestone powder: chemical additives=200:75:125:100:100:3.5; the fineness of the Portland cement clinker and gypsum is 350m 2 / kg; the fineness of the granulated blast furnace slag is 500m 2 / kg; the fineness of the fly ash is 300m 2 / kg; the fineness of the limestone powder is 800m 2 / kg.

[0029] The preparation method of above-mentioned mechanical construction plastering mortar comprise...

Embodiment 3

[0039] A kind of plastering mortar for mechanical construction, which is made by mixing powder, aggregate and water, wherein the mass ratio of various components is: powder: aggregate: water = 300:700:250; the aggregate is The mixed sand has a fineness modulus of 2.0, and the moisture content of the aggregate is 5%; the water is urban tap water. The powder is made of Portland cement clinker, gypsum, granulated blast furnace slag, fly ash, limestone powder, and chemical additives. The mass ratio of the various components is: Portland cement clinker: Gypsum: granulated blast furnace slag: fly ash: limestone powder: chemical additives=300:100:50:250:400:5; the fineness of the Portland cement clinker and gypsum is 400m 2 / kg; the fineness of the granulated blast furnace slag is 600m 2 / kg; the fineness of the fly ash is 350m 2 / kg; the fineness of the limestone powder is 1200m 2 / kg.

[0040] The preparation method of above-mentioned mechanical construction plastering mortar c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com