Production method of high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar

A production method and high-strength technology, applied in the field of building materials, can solve the problems of poor stubble and self-cleaning ability, not widely used, easy to appear color difference, etc., to achieve good cement adaptability, low chloride ion content and alkali content, Excellent slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

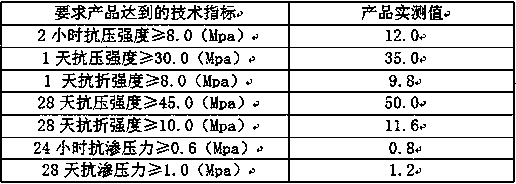

Examples

Embodiment 1

[0075] The production method of high-strength anti-vibration environment-friendly smooth facing prefabricated mortar includes the following raw materials in parts by weight: 25 parts of limestone machine-made sand, 25 parts of limestone powder, 35 parts of rapid hardening sulphoaluminate cement, ordinary Portland cement 4 parts, 2 parts of composite coupling agent, 0.1 part of polycarboxylate superplasticizer, 1 part of ethyl acetate and ethylene copolymer rubber powder, 0.05 part of methyl cellulose ether, 0.02 part of potato starch ether, 0.1 part of sodium tetraborate, Lithium carbonate 0.2 part, defoamer 0.5 part, polypropylene fiber 0.02 part.

[0076] The production method of the high-strength anti-vibration environment-friendly smooth facing prefabricated mortar comprises the following steps:

[0077] First, the limestone machine-made sand, 0.3 mm limestone powder tail powder, high-strength ultra-fine quick-hardening sulphoaluminate cement, and 52.5-strength grade ordin...

Embodiment 2

[0080] The production method of high-strength anti-vibration environment-friendly smooth facing prefabricated mortar comprises the following raw materials in parts by weight: 30 parts of limestone machine-made sand, 26 parts of limestone powder, 40 parts of rapid hardening sulphoaluminate cement, ordinary portland cement 4.5 parts, 3 parts of composite coupling agent, 0.2 parts of polycarboxylate superplasticizer, 2 parts of vinyl acetate and higher fatty acid vinyl ester copolymer rubber powder, 0.07 parts of hydroxyethyl cellulose ether, 0.03 parts of corn starch ether, tetraboric acid 0.2 parts of sodium, 0.25 parts of lithium carbonate, 0.6 parts of defoamer, and 0.03 parts of polyacrylonitrile fiber.

[0081] The production method of the high-strength anti-vibration environment-friendly smooth facing prefabricated mortar comprises the following steps:

[0082] First, the limestone machine-made sand, 0.3 mm limestone powder tail powder, high-strength ultra-fine quick-harde...

Embodiment 3

[0085]The production method of the high-strength anti-vibration environment-friendly smooth facing prefabricated mortar comprises the following raw materials in parts by weight: 35 parts of limestone machine-made sand, 28 parts of limestone powder, 45 parts of rapid hardening sulphoaluminate cement, ordinary portland cement 5 parts, 3.5 parts of composite coupling agent, 0.3 parts of polycarboxylate superplasticizer, 3 parts of vinyl acetate homopolymer rubber powder, 0.09 parts of hydroxypropyl methylcellulose ether, 0.04 parts of tapioca starch ether, 0.3 parts of sodium tetraborate parts, 0.3 parts of lithium carbonate, 0.7 parts of defoamer; 0.04 parts of polypropylene fiber.

[0086] The production method of the high-strength anti-vibration environment-friendly smooth facing prefabricated mortar comprises the following steps:

[0087] First, the limestone machine-made sand, 0.3 mm limestone powder tail powder, high-strength ultra-fine quick-hardening sulphoaluminate cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com