A type of steel area confined concrete rectangular column and its manufacturing method

A regional restraint and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of reducing the restraining effect of the concrete rectangular column of the regional restraint, the restraining effect is not ideal, and the construction cost increases, so as to increase the restraining effect and strengthen the restraint The effect, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

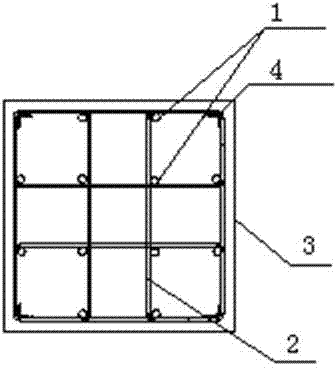

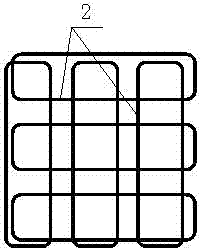

[0015] Embodiments of the present invention: when making area-confined concrete rectangular columns, a method for manufacturing steel-shaped area-confined concrete rectangular columns of the present invention is used for manufacturing, and the manufacturing method of the present invention includes using traditional longitudinal steel bars and stirrups to make rectangular columnar structures When making the skeleton of a rectangular columnar structure, replace the traditional longitudinal reinforcement with section steel at the four corners of the rectangle, and make the section steel at the four corners parallel to each other, and then arrange the longitudinal reinforcement parallel to the section steel In between, the diameter and amount of longitudinal reinforcement can be determined according to the traditional method, but the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com