Filter press and filter pressing method

A filter press and filter belt technology, applied in chemical instruments and methods, dewatering/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc. degree, reduce the occupation, and solve the effect of oversized equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

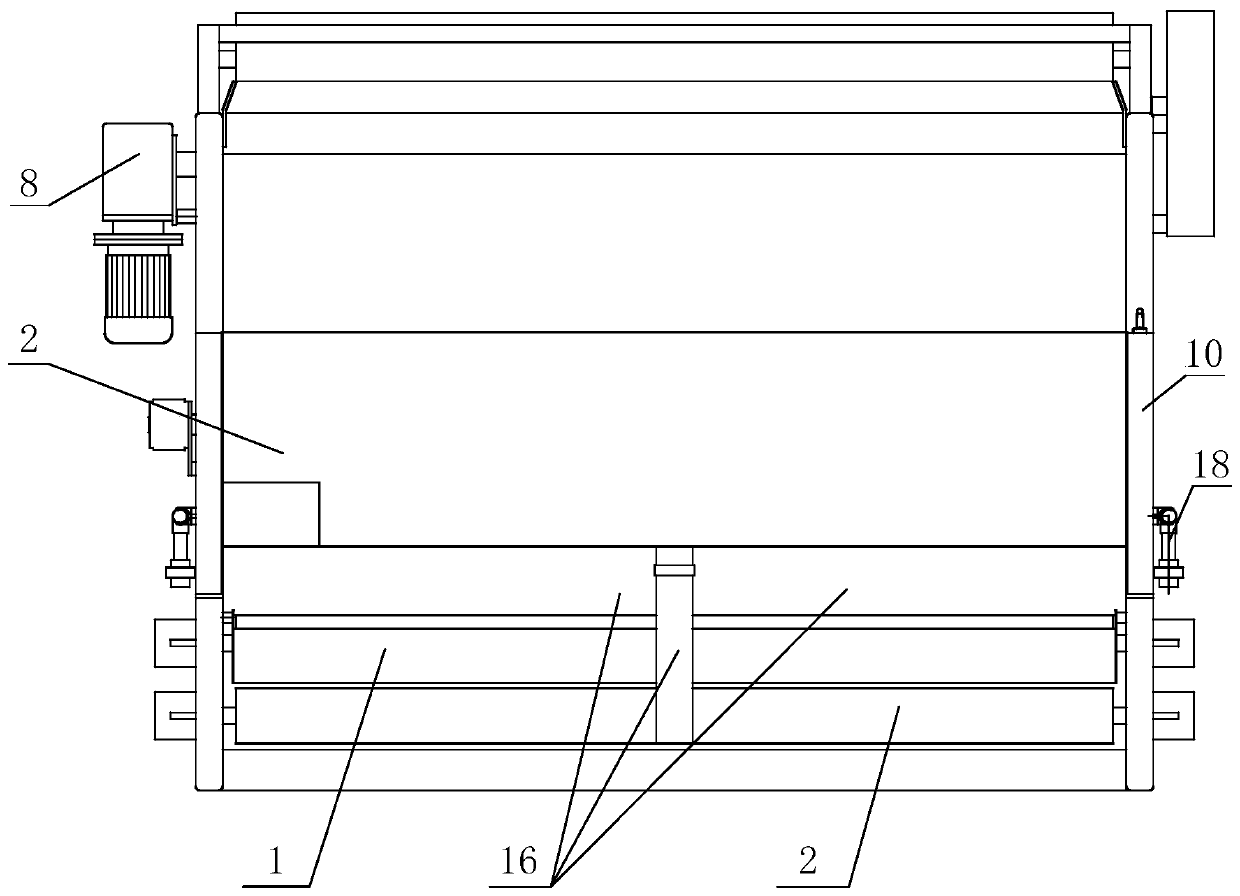

[0044] Such as Figure 1 to Figure 4 As shown, a filter press includes a structural frame 10 and a first filter press system installed in the structural frame 10, a second filter press system and a press roller 4, and the two ends of the roller shaft of the press roller 4 are supported by the structural frame 10 .

[0045] A first filter belt 1 is included in the first filter press system, a second filter belt 2 is included in the second filter press system, and a section of mutual attachment is arranged between the first filter belt 1 and the second filter belt 2. The overlapping portion 3 formed together, the overlapping portion 3 inside is clamped with the material to be pressed, and one side of the overlapping portion 3 is provided with a pressing roller 4, and the pressing roller 4 squeezes the overlapping portion 3, and will be located in the overlapping portion 3. The liquid to be filtered is squeezed out.

[0046] In order to facilitate the description of the overlap...

Embodiment 2

[0058] In the case that other basic technical solutions of Embodiment 1 remain unchanged, the difference of this embodiment is that there are two pressure rollers 4 located at the front filter press position, which together form a large pressure roller group 401; There are three pressure rollers 4 in the position, which jointly form a small pressure roller group 403, and three transitional pressure roller groups 402 are arranged between the large pressure roller group and the small pressure roller group. The large pressure roller group 401 performs combined preliminary pressure filtration on the material to be filtered in the overlapping part, which improves the defect that the single pressure roller pressure filter is prone to excessive extrusion resistance, realizes uniform extrusion on the overlapping part, and then passes through the transitional pressure The roller set 402 corrects and supplements the press filter, and finally uses the small press roll set 403 to carry out...

Embodiment 3

[0060] In the case that other basic technical solutions of Embodiment 2 remain unchanged, the third filter belt 16 of this embodiment is provided with a scraper 151 for scraping and dropping the material to be filtered onto the first filter belt 1 . The inclination angle of the third filter belt 16 relative to the horizontal plane is not less than 3°, so that the third filter belt 16 is in a climbing conveying state. Specifically, the feed port of the third filter belt 16 is located at the lower end, and a baffle plate is also provided at this end 9. Prevent the material to be filtered placed on the third filter belt 16 from slipping out of the third filter belt 16, correspondingly, the third filter belt 16 has a higher outlet. With the above-mentioned structural arrangement, more materials can be accumulated on the third filter belt 16, the time interval for cleaning can be extended, and the material to be filtered has more time to precipitate free water. The inclination angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com