Wax inhibitor added during fracturing construction and preparation method and application thereof

A kind of anti-wax agent, flat technology, applied in the field of anti-wax agent added during fracturing construction and its preparation, can solve the problems of high construction cost and long cycle, and achieve the advantages of convenient construction, long effective time and enlarged range of action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

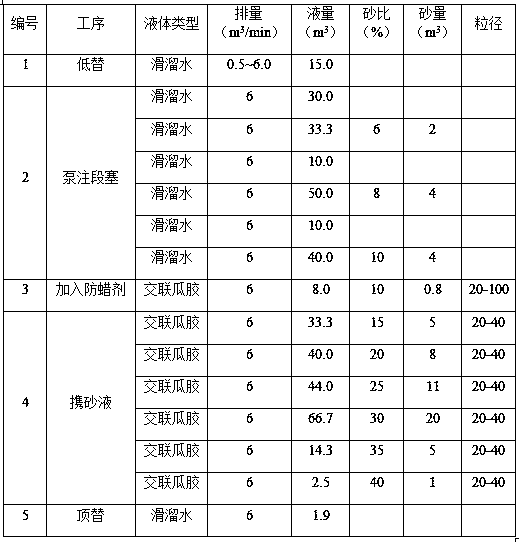

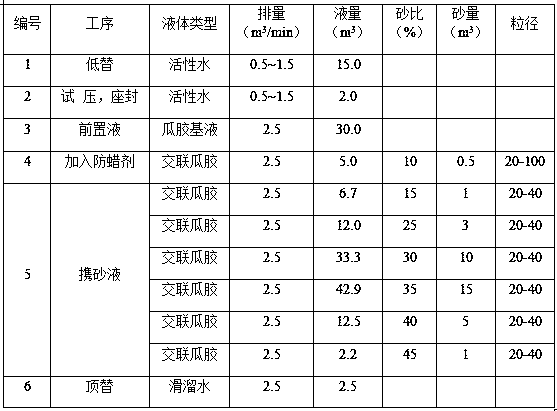

Image

Examples

Embodiment 1

[0031] A wax inhibitor added during fracturing, based on 100%, is composed of the following raw materials by weight percentage: sodium stearate 18%, flat addition of 0-25 15%, fatty alcohol polyoxyethylene ether sodium sulfate AES 12 %, 10% sodium dodecylbenzene sulfonate ABS, 1% sodium ethylenediaminetetraacetate, 2% rosin powder, 42% quartz sand through 70-100 mesh sieve;

[0032] The preparation method of the above wax inhibitor includes the following steps:

[0033] (1) Add sodium stearate, flat addition O-25, fatty alcohol polyoxyethylene ether sodium sulfate AES, sodium dodecylbenzene sulfonate ABS, sodium ethylenediaminetetraacetate, and rosin powder into the reaction kettle according to the proportions. In the medium, heat and stir at a temperature of 80°C until all is dissolved before use;

[0034] (2) Heat the quartz sand to 50°C while stirring in the dry powder mixer, stop heating, continue stirring, and slowly add the product of step (1) under stirring, subject to the pr...

Embodiment 2

[0038] A wax inhibitor added during fracturing, based on 100%, is composed of the following raw materials by weight percentage: sodium stearate 10%, flat addition of 0-25 10%, fatty alcohol polyoxyethylene ether sodium sulfate AES 15 %, 10% sodium dodecylbenzene sulfonate ABS, 1% sodium ethylenediaminetetraacetate, 1% rosin powder, 53% of quartz sand passing a 70-100 mesh sieve;

[0039] The preparation method of the above wax inhibitor is the same as in Example 1.

Embodiment 3

[0041] A wax inhibitor added during fracturing, based on 100%, is composed of the following raw materials in weight percentage: sodium stearate 20%, flat addition of 0-25 15%, fatty alcohol polyoxyethylene ether sodium sulfate AES 15 %, sodium dodecylbenzene sulfonate ABS 5%, sodium ethylenediaminetetraacetate 1%, rosin powder 2%, 42% quartz sand passing through a 70-100 mesh sieve;

[0042] The preparation method of the above wax inhibitor is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com