Repairing material of cement concrete structure and preparation method for same

A technology of cement concrete and repair materials, applied in the field of construction, can solve the problems of affecting load-bearing strength and durability, affecting road traffic conditions, and expensive repair materials, etc., to achieve the effect of reducing raw material costs, shortening curing time, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Such as figure 1 Shown, a kind of preparation method of the restoration material of cement concrete building, specifically can comprise:

[0056] Step A, using alkali slag to prepare alkali slag composite calcined product.

[0057] Specifically, the corresponding step of using alkali slag to prepare the alkali slag composite calcined product may include:

[0058] In step a1, the alkali slag is mixed with an aluminum chromium phosphate binder accounting for 1.2% of the total mass of the alkali slag, so as to prepare an alkali slag mixture.

[0059] In step a2, stir the alkali slag mixture evenly so that the water content is not greater than 30%.

[0060] In step a3, the uniformly stirred alkali slag mixture is placed in a calciner, and calcined at 650° C. to 750° C. for 8 to 12 hours.

[0061] In step a4, the calcined alkali slag mixture is continuously stuffed in the calciner for at least 48 hours, and after natural cooling, the alkali slag calcined product is obtain...

Embodiment 1

[0101] A repairing material for cement concrete structures, its components may include: alkali slag composite calcined product, lithium hydroxide, sodium fluorosilicate, polycarboxylate water reducing agent, lithium carbonate, calcium aluminate, borax, metaaluminic acid Sodium, calcium sulfate, rosin powder, magnesium oxide and silicon dioxide; wherein the mass ratio of each component to the overall can adopt the value of Example 1 in Table 5.

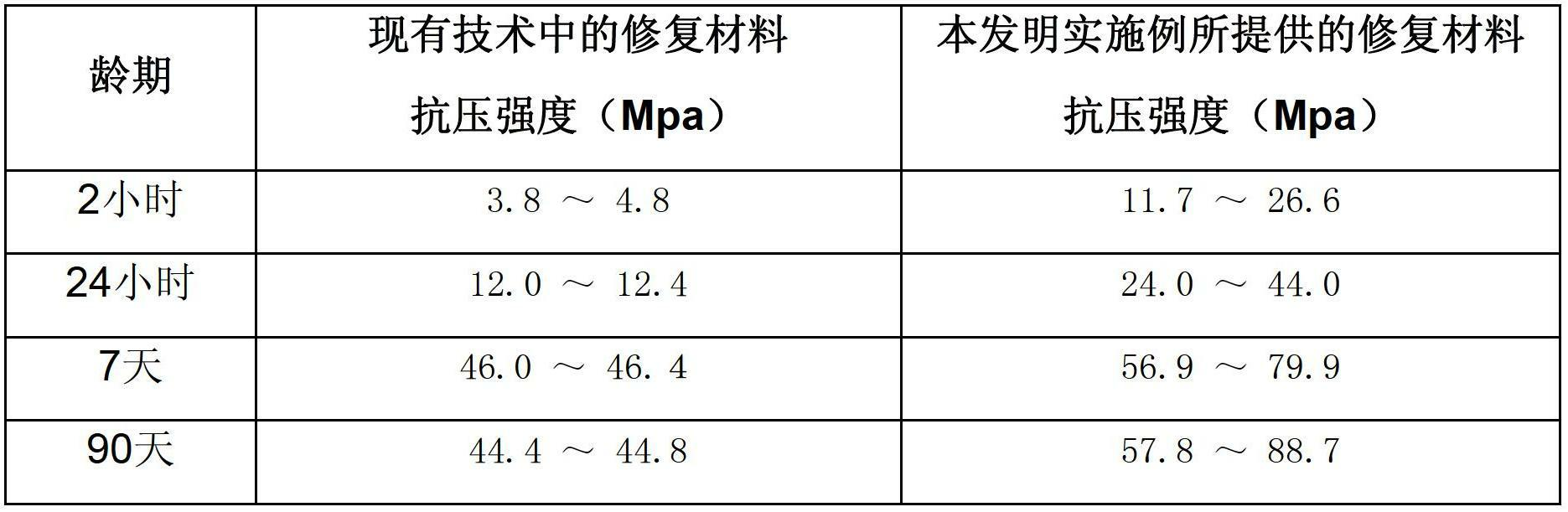

[0102] The performance parameters of the repair material of the cement concrete structure can refer to the data in the following Table 6 (unconfined compressive strength data table), Table 7 (bond strength data table) and Table 8 (water stability data table):

[0103] Table 6:

[0104] age

[0105] Table 7:

[0106]

[0107] Table 8:

[0108] age

[0109] As can be seen from Table 6, Table 7 and Table 8: the cement concrete building repair material provided by the embodiment of the present invention not only ha...

Embodiment 2

[0111] A repairing material for cement concrete structures, its components may include: alkali slag composite calcined product, lithium hydroxide, sodium fluorosilicate, polycarboxylate water reducing agent, lithium carbonate, calcium aluminate, borax, metaaluminic acid Sodium, calcium sulfate, rosin powder, magnesium oxide and silicon dioxide; Wherein the mass ratio of each component can adopt the numerical value of embodiment two in table 5.

[0112] The performance parameters of the repair material of the cement concrete structure can refer to the data in the following Table 9 (unconfined compressive strength data table), table 10 (bond strength data table) and table 11 (water stability data table):

[0113] Table 9:

[0114] age

[0115] Table 10:

[0116]

[0117] Table 11:

[0118] age

[0119] As can be seen from Table 9, Table 10 and Table 11: the cement concrete building repair material provided by the embodiment of the present invention not o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com