Castable for steel ladle integral casting working lining

A technology of integral pouring and castables, which is applied in the field of refractory materials, can solve the problems of weakened slag resistance of castables, affecting service life, poor resistance to slag erosion and permeability of corundum or bauxite, and achieves slag resistance and permeability Excellent, reduced raw material cost, excellent effect of slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

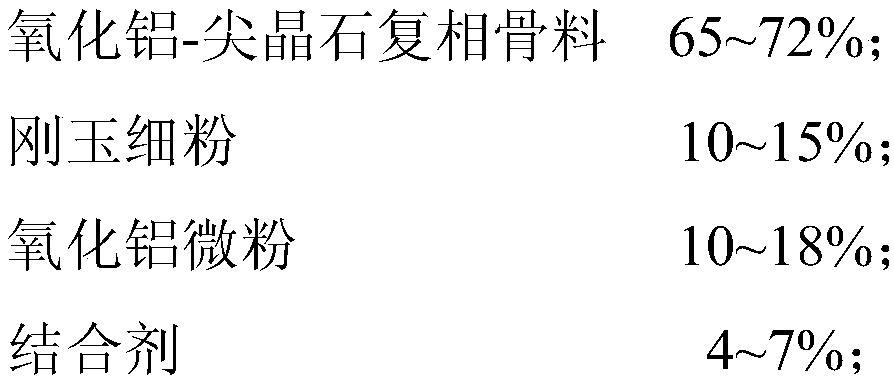

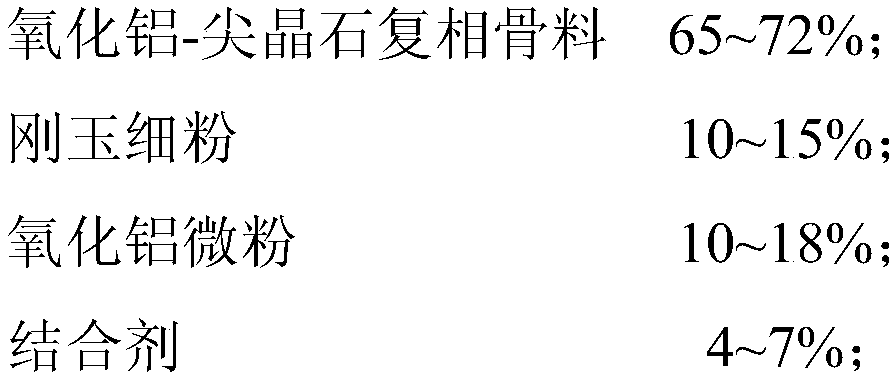

[0025] The castable for ladle integral pouring working lining with alumina-spinel composite material as aggregate is made by mixing the following raw materials by weight percentage: 72% alumina-spinel composite phase aggregate, 10% Corundum fine powder, 14% alumina fine powder, 4% binder; plus 1% dispersant, 0.01% explosion-proof agent, 0.1% anti-bleeding agent.

[0026] In this example, the alumina-spinel composite phase aggregate is divided into four grades according to the particle size: 5mm<particle size≤8mm, 3mm<particle size≤5mm, 1mm<particle size≤3mm, and particle size≤1mm. The weight percentage 8%, 32%, 30% and 30% respectively; the particle size of corundum fine powder is divided into two gradations of 20μm<particle size≤45μm and <particle size≤20μm, and the weight ratio is 2:1; Alumina micropowder, the particle size is ≤5μm; the binder is pure calcium aluminate cement; the dispersant is polycarboxylate dispersant ADS1 / ADW1 (product of Qingdao Anmai Aluminum Co.); the...

Embodiment 2

[0028] The castable for ladle integral pouring working lining with alumina-spinel composite material as aggregate is made by mixing the following raw materials by weight percentage: 65% alumina-spinel composite material, 15% corundum Fine powder, 15% alumina fine powder, 5% binder; plus 0.1% dispersant, 0.05% explosion-proof agent, 0.05% anti-bleeding agent.

[0029] In this example, the alumina-spinel composite phase aggregate is divided into four grades according to the particle size: 5mm<particle size≤8mm, 3mm<particle size≤5mm, 1mm<particle size≤3mm, and particle size≤1mm. The weight percentage 15%, 35%, 30% and 20% respectively; the particle size of corundum fine powder is divided into two gradations: 20μm<particle size≤45μm and <particle size≤20μm, the weight ratio is 3:1; Alumina micropowder, its particle size is ≤ 5 μ m; Described binding agent is hydrated alumina; Dispersant is polycarboxylate dispersant FS60 (product of German BASF company); The combination of anaer...

Embodiment 3

[0031] The castable for ladle integral pouring working lining with alumina-spinel composite material as aggregate is made by mixing the following raw materials by weight percentage: 68% alumina-spinel composite phase aggregate, 15% Corundum fine powder, 10% alumina fine powder, 7% binder; plus 0.15% dispersant, 0.05% explosion-proof agent, 0.2% anti-bleeding agent.

[0032]In this example, the alumina-spinel composite phase aggregate is divided into four grades according to the particle size: 5mm<particle size≤8mm, 3mm<particle size≤5mm, 1mm<particle size≤3mm, and particle size≤1mm. The weight percentage 15%, 30%, 30% and 25% respectively; the particle size of corundum fine powder is divided into two gradations of 20μm<particle size≤45μm and <particle size≤20μm, and its weight ratio is 2.5:1; Any one of alumina micropowder or activated alumina micropowder or a mixture of the two, the particle size is ≤5μm; the binder is aluminosilica gel powder; the dispersant is a phosphate d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com