Preparation method of air entraining agent

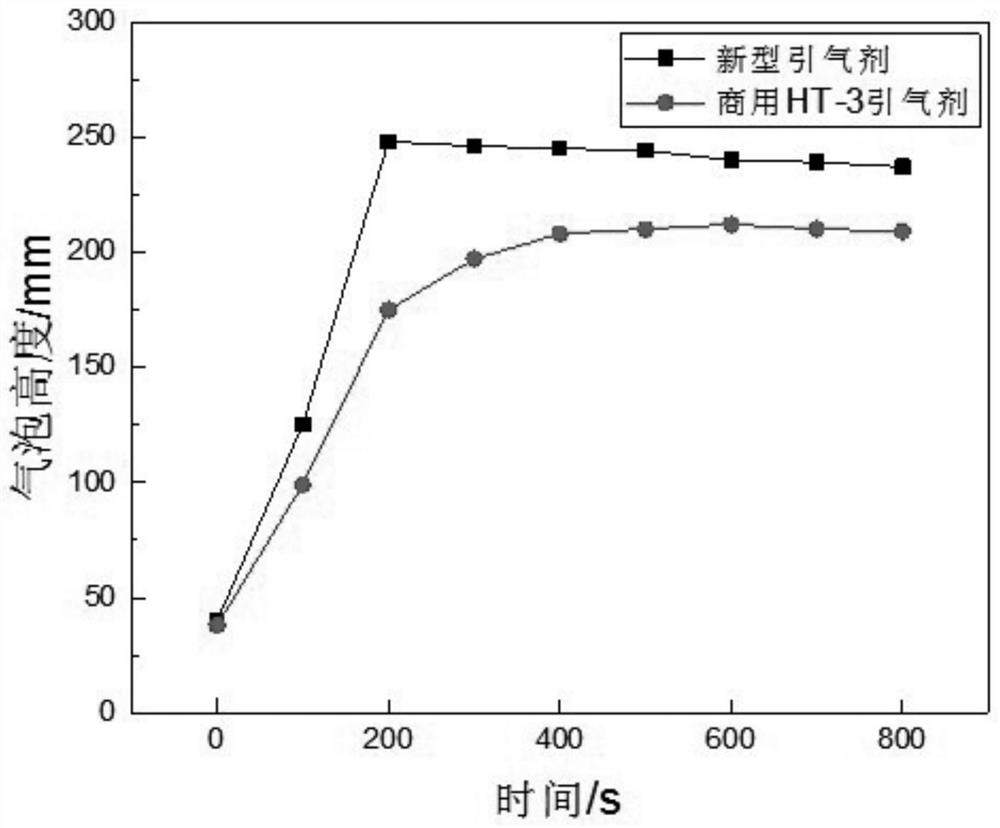

A technology of air-entraining agent and initiator, which is applied in the field of air-entraining agent preparation and can solve the problems of poor foam stabilization effect of air-entraining agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

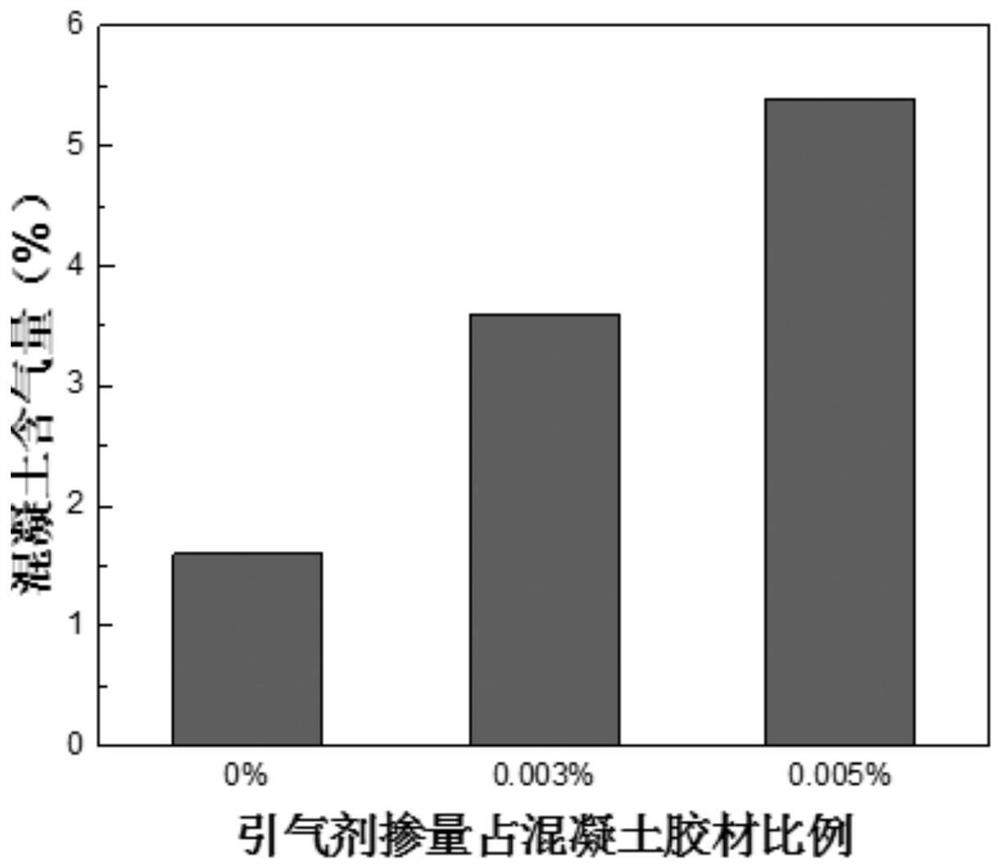

Examples

Embodiment 1

[0027] Embodiment 1: the preparation method of this air-entraining agent is carried out according to the following steps:

[0028] Step 1: Under stirring, add 18 parts of 4-n-nonylphenol and 0.04 parts of sodium hydroxide to the reaction kettle A equipped with a self-made multi-blade stirring paddle, heat up to 70°C, and then vacuumize and stir for 30-90 minutes. The distance between the self-made multi-blade stirring paddle and the bottom of the reactor is 20mm, and the inner diameter of the reactor is 200mm;

[0029] Step 2: Put 90.6 parts of ethylene oxide into reactor B, and drop 1 part of ethylene oxide from reactor B into reactor A;

[0030] Step 3: Raise the temperature of reactor A to 120°C, and maintain the system pressure at 0.2MPa;

[0031] Step 4: Slowly add the remaining ethylene oxide in the reactor B to the reactor A dropwise, the total dropping time is controlled at 4h, and the intermediate A is obtained;

[0032] Step 5: Add 10 parts of Intermediate A, 1 par...

Embodiment 2

[0034] Example 2: The difference between this embodiment and Example 1 is that in step 1, 4-n-nonylphenol is 22 parts.

Embodiment 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the total dropwise addition time of ethylene oxide in step 4 is 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com