Oil paint slurry for colorful balloons as well as preparation method and use method thereof

A kind of colorful, balloon technology, applied in the direction of pigment slurry, toys, entertainment, etc., can solve the problems of natural latex balloon coloring can not meet the market application requirements, the production process is complicated, the production cost is increased, and the environmental protection performance is superior, The effect of increasing phase adhesion and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

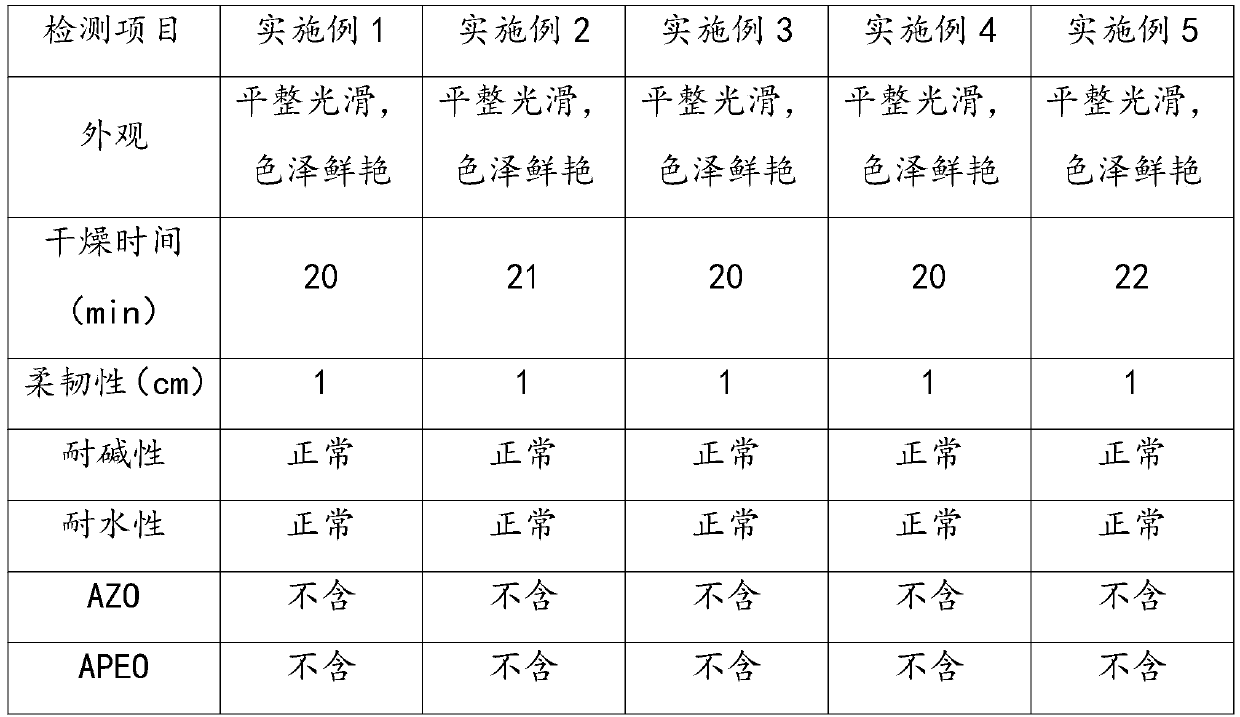

Examples

Embodiment 1

[0040] Oil color paste for colorful balloons, made of the following raw materials: 40kg of natural rubber, 80kg of 200# gasoline, 5kg of n-butanol, 10kg of phthalocyanine pigments, 2kg of liquid paraffin, 0.5kg of acrylic modified polymer and butyl stearate Ester 1kg.

[0041] The preparation method specifically comprises the following steps:

[0042] (1) take each raw material by the weight of the above-mentioned colorful balloon oil paste;

[0043] (2) Carry out the first stage of mastication of natural rubber, and then completely dissolve in 200# gasoline, n-butanol and light aromatics mixed solution to obtain solvent A for subsequent use;

[0044] (3) butyl stearate is added in the phthalocyanine pigment and mixed, and the natural rubber of the first stage of mastication adopts the second stage of mastication to carry out mixing, and then completely dissolves in 200# solvent naphtha, obtains solvent B, spare;

[0045] (4) Mix solvent A, solvent B, liquid paraffin and ac...

Embodiment 2

[0051] Oil color paste for colorful balloons, made of the following raw materials: 45kg of natural rubber, 100kg of 200# gasoline, 5kg of n-butanol, 12kg of phthalocyanine pigments, 2kg of liquid paraffin, 0.2kg of methyl polysiloxane and stearic acid Butyl ester 1kg.

[0052] The preparation method specifically comprises the following steps:

[0053] (1) take each raw material by the weight of the oil color paste for colorful balloons described in any one of claims 1 to 6;

[0054] (2) Carry out the first section of mastication of natural rubber, then completely dissolve in 200# solvent oil, n-butanol, mixed liquor, obtain solvent A, for subsequent use;

[0055] (3) Add butyl stearate to phthalocyanines for mixing, and at the same time mix with the natural rubber in the first stage of mastication by second stage of mastication, and then completely dissolve in 200# solvent oil to obtain solvent B, which is set aside ;

[0056] (4) Mix solvent A, solvent B, liquid paraffin a...

Embodiment 3

[0062] Oil color paste for colorful balloons, made of the following raw materials: 50kg of natural rubber, 100kg of light aromatic hydrocarbons, 5kg of n-butanol, 15kg of benzimidazolone pigments, 1.5kg of liquid paraffin, 0.3kg of methyl polysiloxane and multi-component Alcohol 0.5kg.

[0063] The preparation method specifically comprises the following steps:

[0064] (1) take each raw material by the weight of the above-mentioned colorful balloon oil paste;

[0065] (2) Carrying out the first stage of mastication of natural rubber, and then completely dissolving in light aromatic hydrocarbon and n-butanol mixed solution to obtain solvent A for subsequent use;

[0066] (3) polyhydric alcohol is added in the benzimidazolone pigment and mixed, and the natural rubber of the first stage of mastication is mixed with the second stage of mastication, and then completely dissolved in light aromatic hydrocarbons to obtain solvent B for subsequent use;

[0067] (4) Mix solvent A, sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com