Bi-component water-borne wood paint and preparation method thereof

A water-based wood paint, two-component technology, applied in the field of coatings, can solve the problems of uneven paint film surface, limited defoaming effect of defoamers, etc., and achieve the goal of promoting dispersion rate, good defoaming ability and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

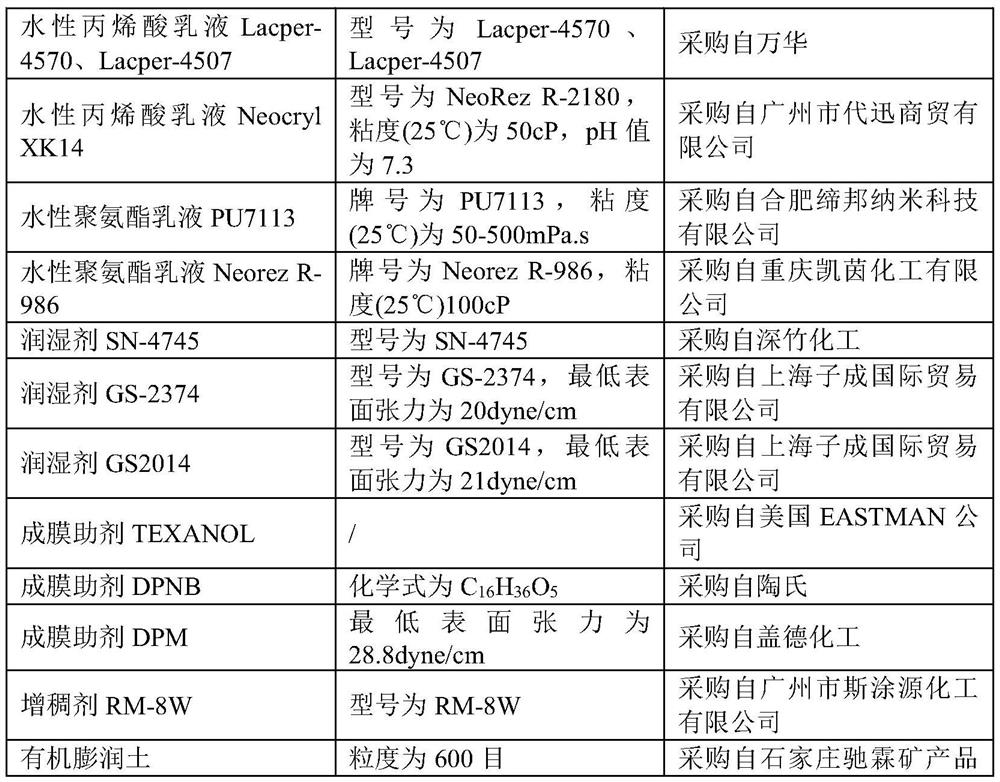

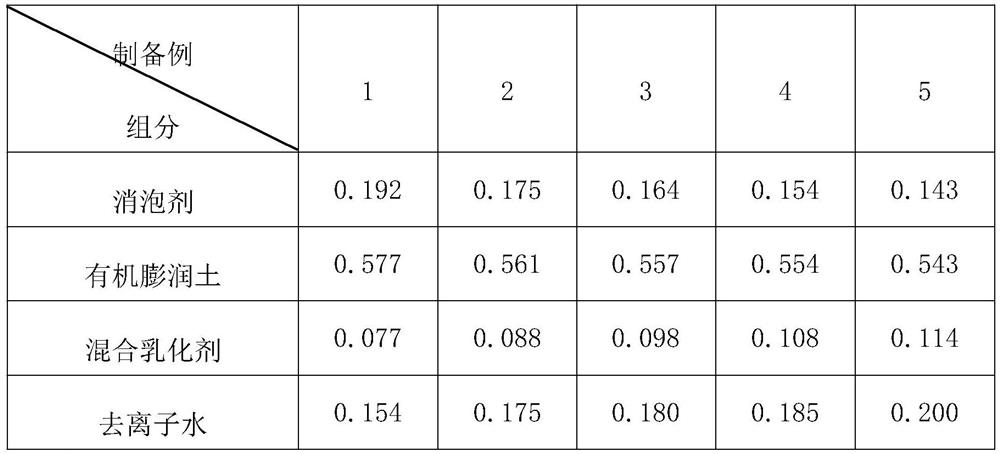

[0052] A modified defoamer, calculated according to the total weight of the modified defoamer as 1kg, the components and their corresponding weights are shown in Table 1, and are prepared through the following steps:

[0053] A1: Add 0.077kg of sodium dodecyl diphenyl ether sulfonate into the emulsification pot, raise the temperature to 50°C, and stir and mix for 20 minutes at a stirring speed of 600r / min to obtain an emulsifier mixture.

[0054] A2: Heat the emulsification pot to 60°C, add 0.192kg of defoamer BNK-G408 and 0.577kg of organic bentonite to the emulsification pot, stir and mix for 10min at a stirring speed of 600r / min; continue to add 0.0154kg of deionized water (accounting for 10% of the total weight of the total deionized water), after stirring and mixing for 2 minutes, add 0.077kg emulsifier mixed solution, and stir and mix for 20 minutes.

[0055] A3: Cool the emulsification pot to 40°C and reduce the stirring speed to 350r / min. Within 20 minutes, add the rem...

preparation example 2-5

[0060] A modified defoamer, the difference from Preparation Example 1 is that each component and its corresponding weight are shown in Table 1.

[0061] Each component and its weight (kg) in table 1 preparation example 1-5

[0062]

preparation example 6

[0064] A modified defoamer, the difference from Preparation Example 3 is that except that the defoamer is composed of Surfynol AD01, BNK-G408, TEG0810 and BYK022 in a weight ratio of 1:0.5:0.5:1.0, the others are mixed with Preparation example 3 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com