Modified polyether

A polyether and modification technology, applied in the field of modified polyether, can solve the problems affecting production and construction quality, and achieve the effects of small adverse effects, good compatibility and outstanding defoaming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

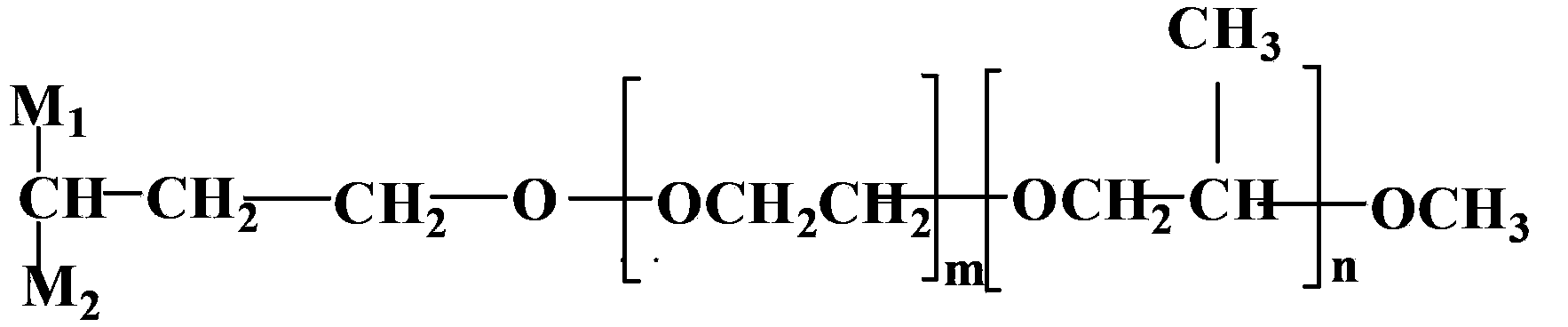

[0016] A modified polyether, the molecular chain of the modified polyether is added by acetylene glycol polyethoxy polypropoxy ether and low molecular weight hydrogen-containing siloxane, and its structural formula is as follows:

[0017]

[0018] M1 and M2 are low molecular siloxane groups, molecular weight M=50, m=1, n=1. A kind of antifoaming agent, is made up of each component of following parts by weight: modified polyether 30 parts, hydrophobically modified meteorological silica 1 part, emulsifier S-80 1 part, emulsifier T-80 1 part, 5 parts of light paraffin.

Embodiment 2

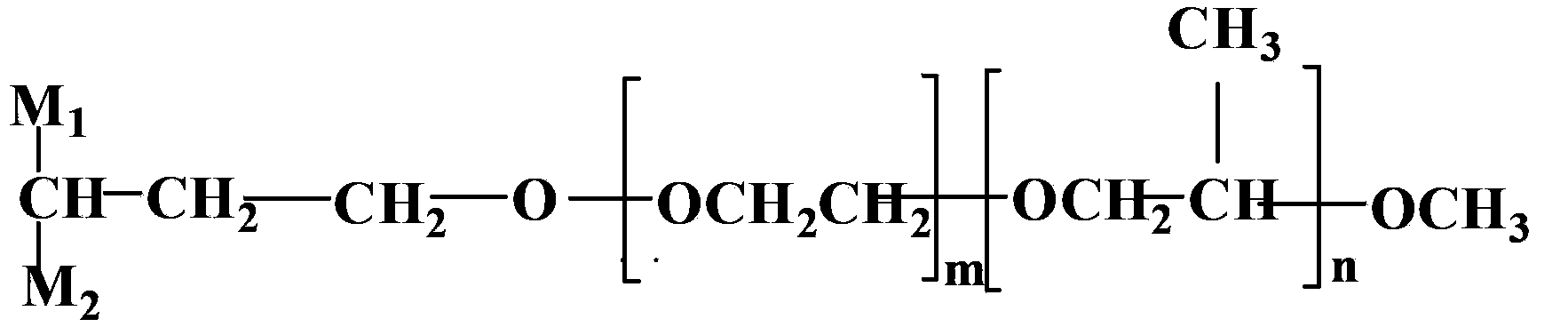

[0020] A modified polyether, the molecular chain of the modified polyether is added by acetylene glycol polyethoxy polypropoxy ether and low molecular weight hydrogen-containing siloxane, and its structural formula is as follows:

[0021]

[0022] M1 and M2 are low molecular siloxane groups, molecular weight M=100, m=5, n=3. A kind of defoamer, is made up of each component of following parts by weight: modified polyether 80 parts, hydrophobically modified meteorological silica 10 parts, emulsifier S-80 5 parts, emulsifier T-80 5 parts, 20 parts of light paraffin.

Embodiment 3

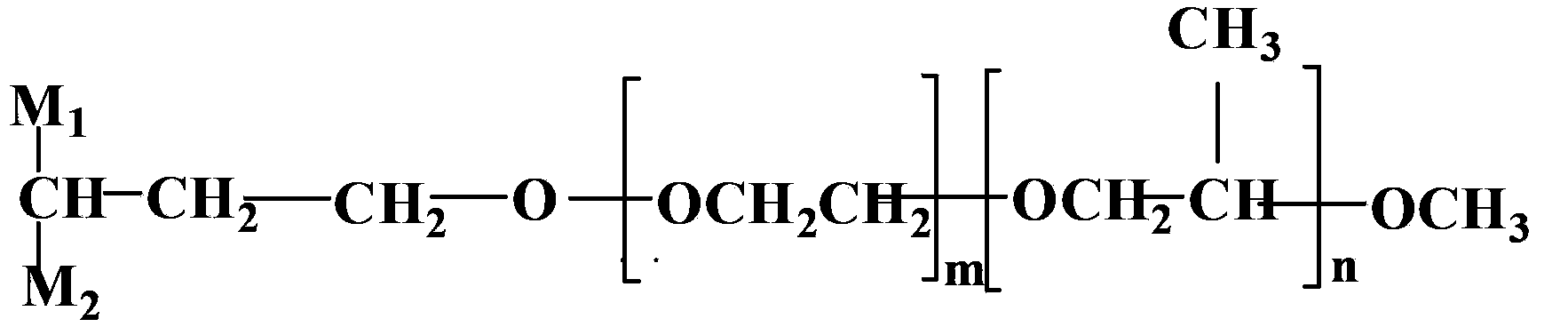

[0024] A modified polyether, the molecular chain of the modified polyether is added by acetylene glycol polyethoxy polypropoxy ether and low molecular weight hydrogen-containing siloxane, and its structural formula is as follows:

[0025]

[0026] M1 and M2 are low molecular siloxane groups, molecular weight M=120, m=10, n=5. A kind of defoamer, is made up of each component of following parts by weight: modified polyether 50 parts, hydrophobically modified meteorological silica 5 parts, emulsifier S-80 3 parts, emulsifier T-80 3 parts, 15 parts of light paraffin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com