Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Solve poisoning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc phosphating solution of aluminium and aluminium alloy

InactiveCN101812682ALower working temperatureEnergy savingMetallic material coating processesBuilding materialChromium

The invention belongs to the field of metal surface treatment, relating to a zinc phosphating solution of aluminium and aluminium alloy. The invention is mainly used for zinc phosphating treatment of the aluminium and aluminium alloy in the industries of home appliances, automobiles, hardware, building materials and railway locomotives. The zinc phosphating solution is composed of 8-25g / l of PO4<-3>, 6-16g / l of NO3<-1>, 1.6-8.0g / l of Zn<+2>, 0.12-0.38g / l of F<-1>, 0.6-8.0g / l of Fe<+2>, 0.01-1.5g / l of Ni<+2>, 0.0002-0.0006g / l of accelerating agent, 0.001-1.2g / l of organic complexing agent and the balance of water. When the phosphating solution of the invention is used for processing the aluminium and aluminium alloy, the obtained phosphating film has favourable matching capability with the coating, and the griding test of the paint film can reach 0 grade. The phosphating solution of the invention does not use toxic chromium, and the phosphating film does not contain chromium so as to solve the problems of environment pollution and toxic hazard on the human body when the chromium is used for processing the aluminium and aluminium alloy, and lower treatment cost.

Owner:中化化工科学技术研究总院有限公司

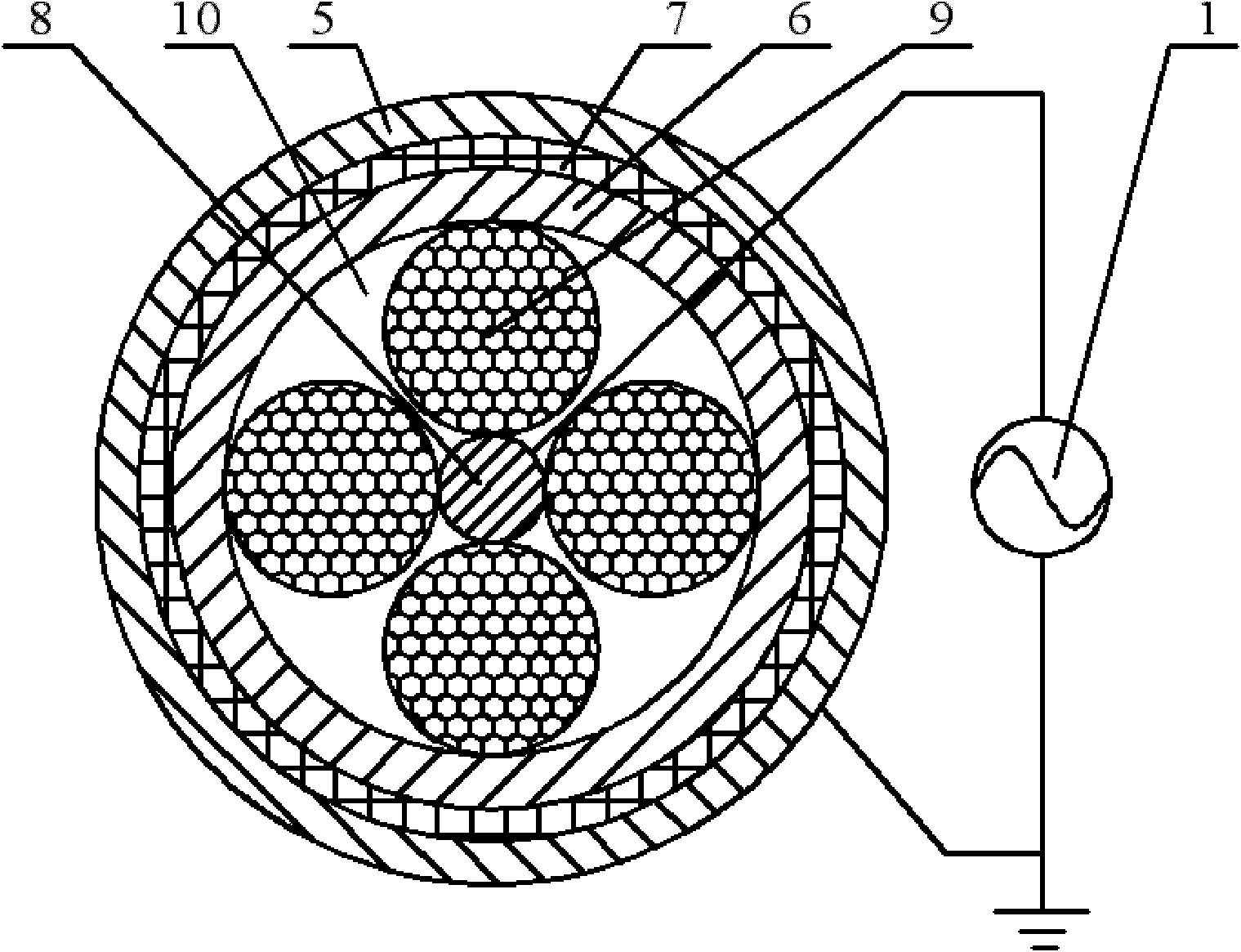

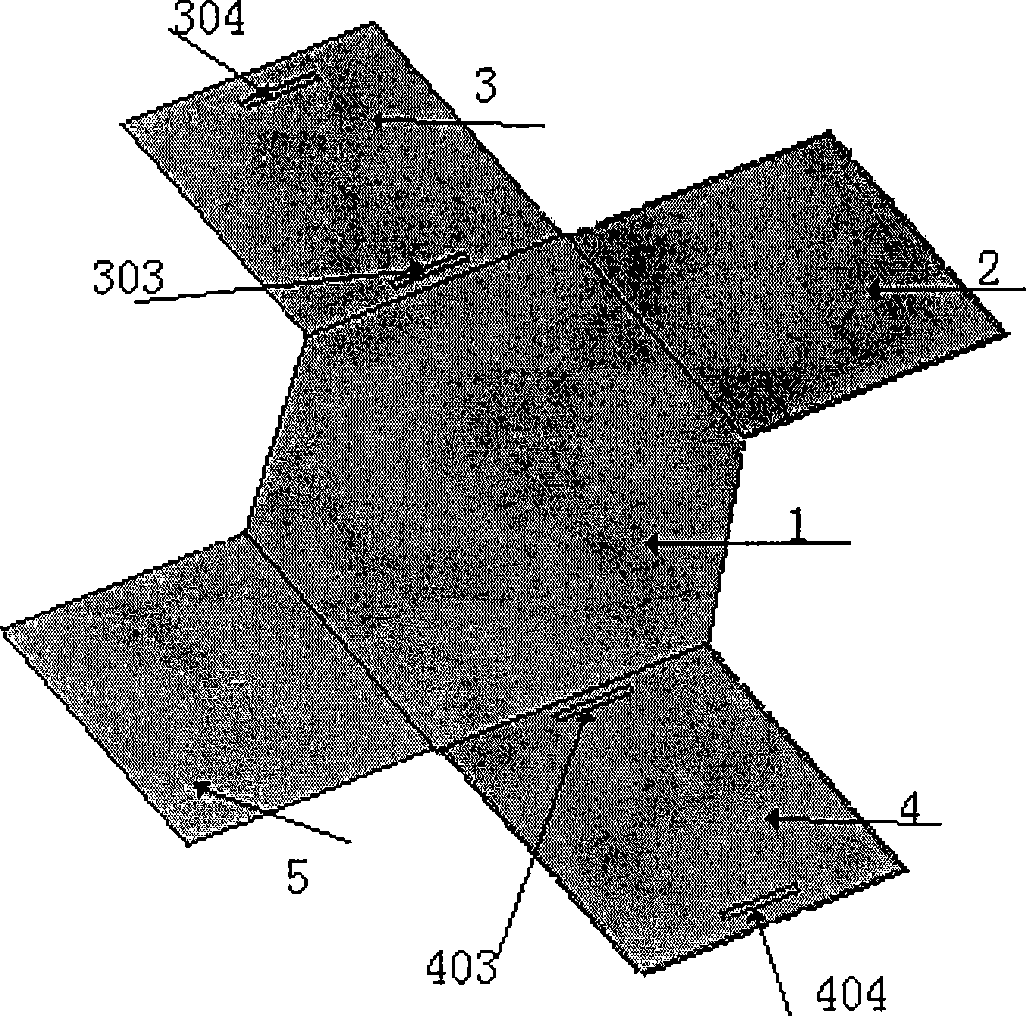

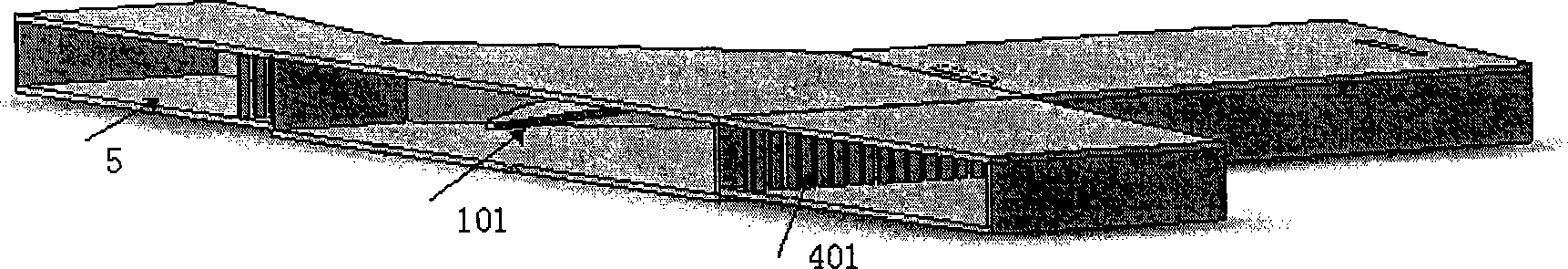

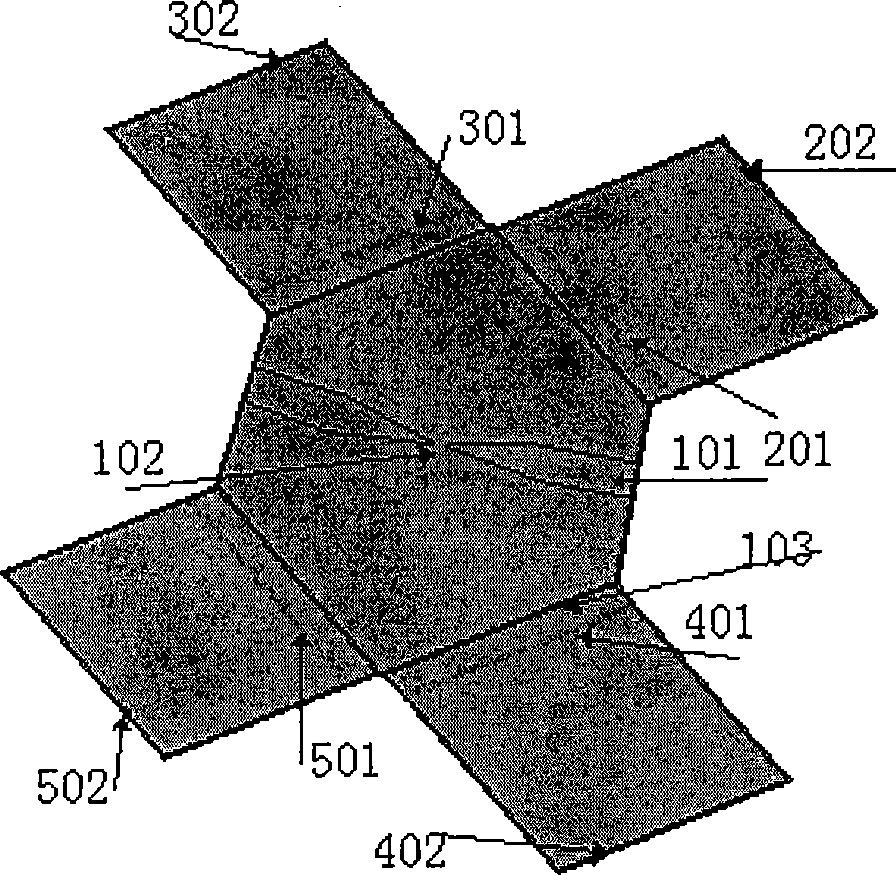

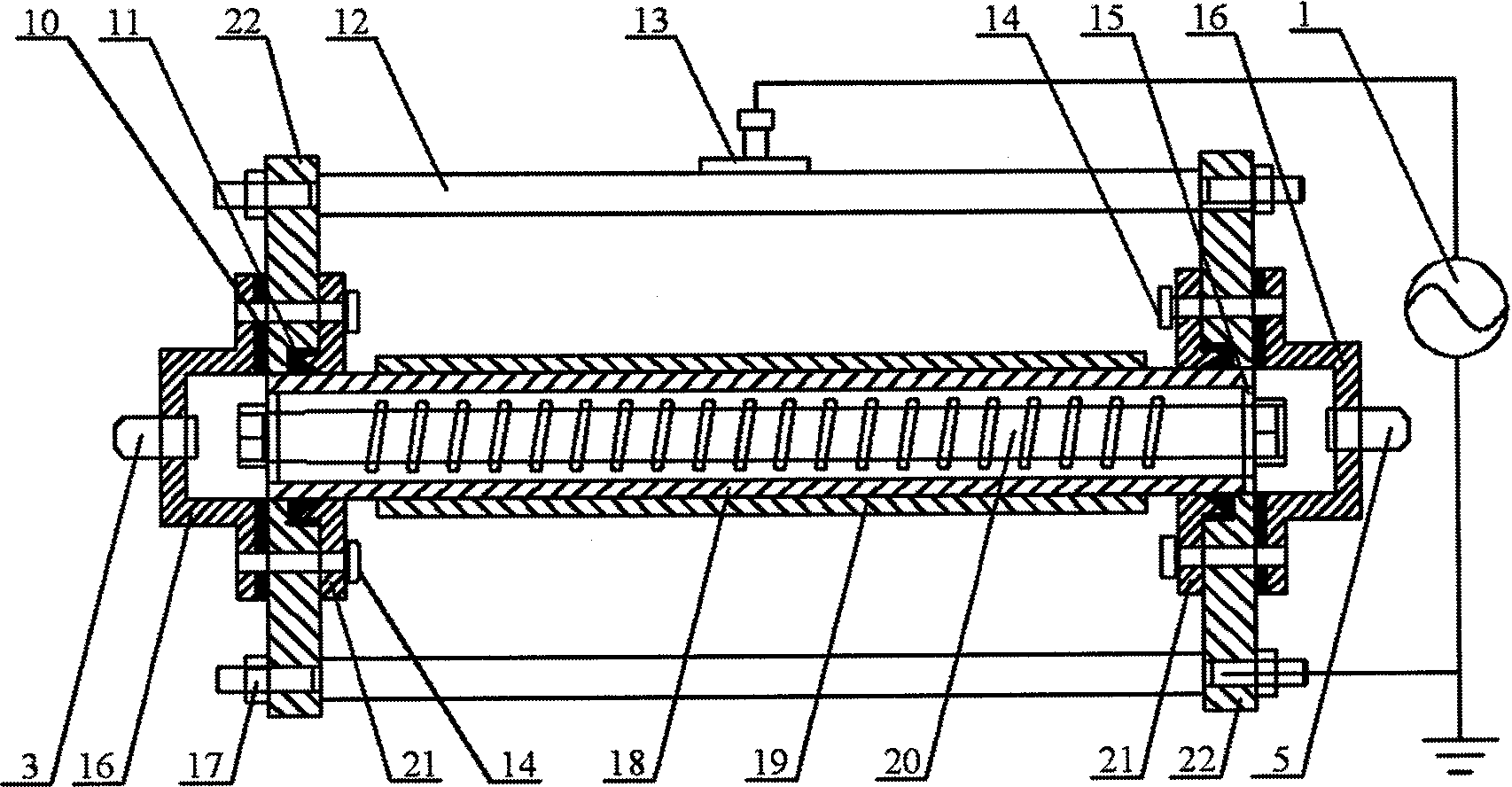

Integral reactor of dielectric barrier discharge coupling catalyst for removing NOx in diesel engine

InactiveCN101832168AReduce usageSolve poisoningInternal combustion piston enginesExhaust apparatusExhaust gasProcess engineering

The invention discloses an integral reactor of a dielectric barrier discharge coupling catalyst for removing NOx in a diesel engine, belonging to the technical field of the control of gaseous pollutants of tail gas from a diesel engine. In the invention, the integral reactor filled with an SCR (Selective Catalyst Reduction) catalyst is adopted, i.e. the integral reactor is subjected to dielectric barrier discharge in the presence of the SCR catalyst. By utilizing a synergism purification effect of low-temperature plasma purification generated by the dielectric barrier discharge and the purification of the SCR catalyst, the integral reactor modifies the tail gas of the diesel engine, which contains NO, O2, H2O, SO2 and hydrocarbon (HCs), and modifies the SCR catalyst placed in a discharging area, thereby greatly improving the low-temperature reactivity of the SCR catalyst, broadening the temperature window of the SCR catalyst and reducing the NOx effectively within the wide temperature reaction window at 100-550 DEG C; and meanwhile, the integral reactor also effectively solves the problem of sulfur poisoning of the catalyst, is suitable for the high-sulfur containing diesel in China and can greatly improve the NOx conversion efficiency of NH3-SCR when the diesel engine is in cold start at low temperature or is idling.

Owner:SHANGHAI JIAO TONG UNIV

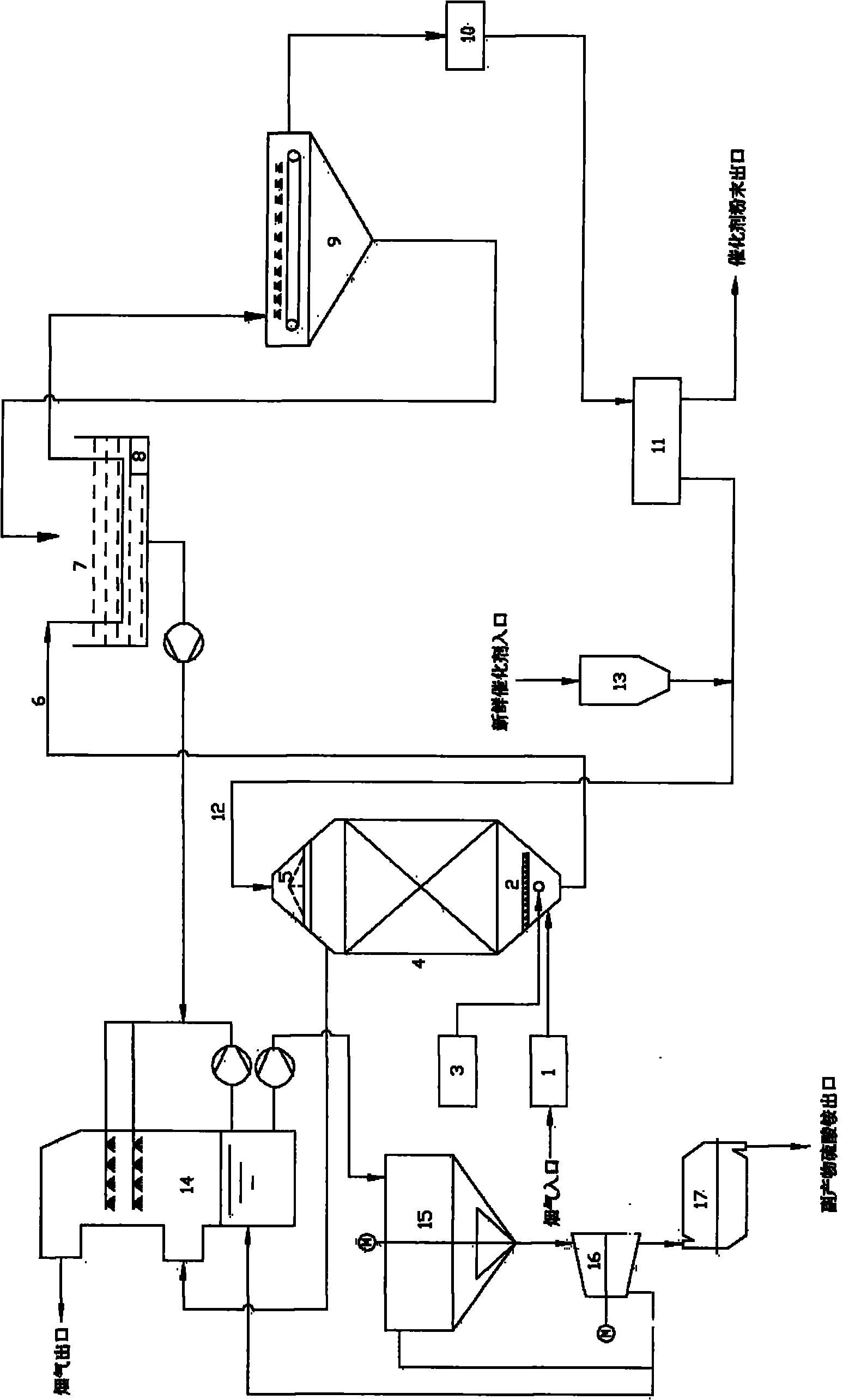

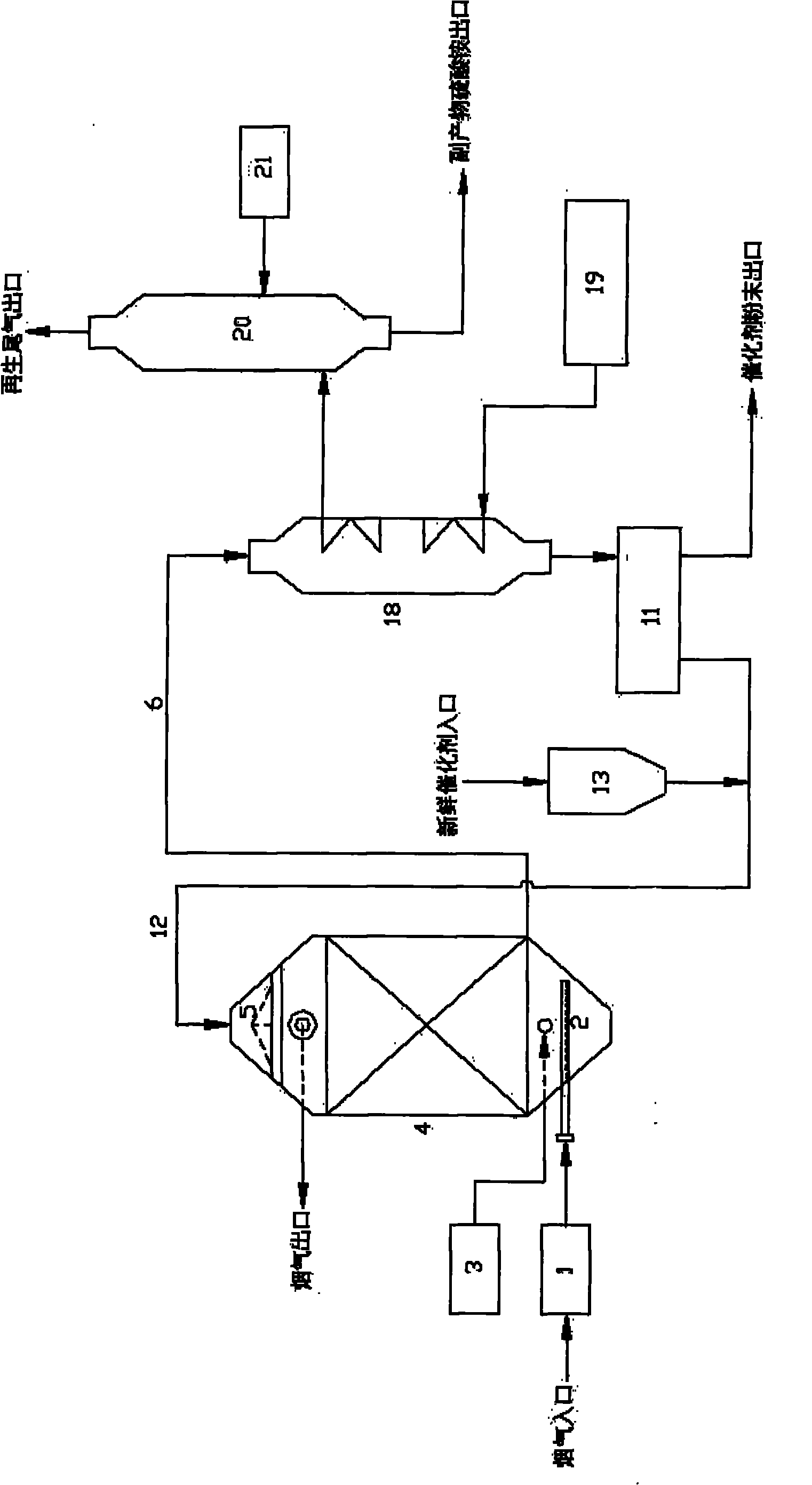

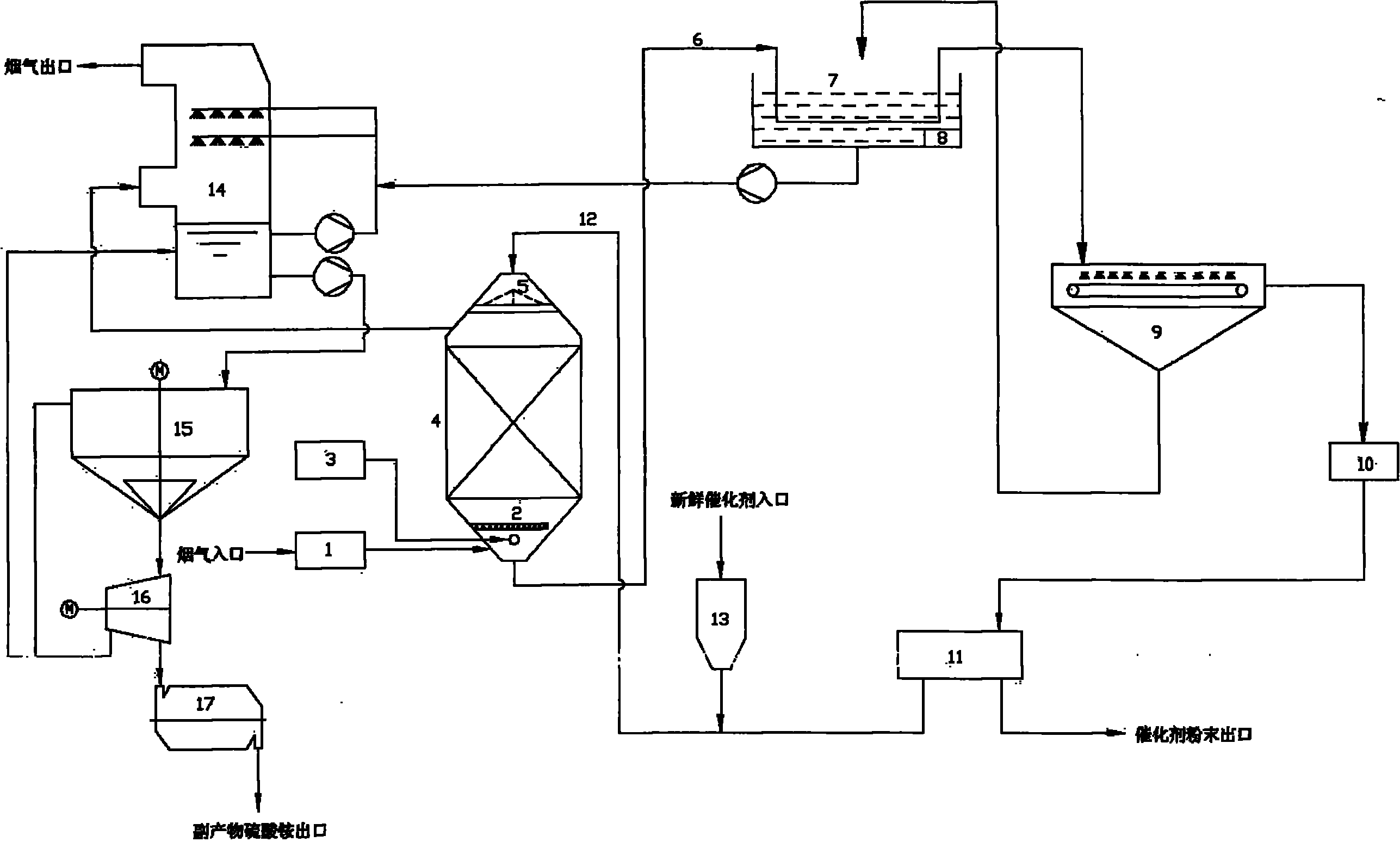

Low temperature SCR moving bed flue gas denitration method for coal-fired boiler

InactiveCN102008893AImprove denitrification performanceImprove denitrification efficiencyDispersed particle separationProcess engineeringFlue gas

The invention relates to a low temperature selective catalytic reduction (SCR) moving bed flue gas denitration method for a coal-fired boiler. Boiler flue gas subjected to dust removal and a denitration reducer NH3 are introduced into a denitration reactor respectively; a low temperature SCR catalyst is continuously input from one end of the denitration reactor and continuously output from the other end of the denitration reactor to form a moving bed; the flue gas and the NH3 are in gas-solid contact with the catalyst which moves directionally in a countercurrent or crosscurrent mode in the reactor; NOx and NH3 in the flue gas are reacted with each other and the generated N2 and water vapor are discharged out of the denitration reactor along with the denitrified flue gas; in the process, parts of SO2 and NH3 in the flue gas are reacted with each other and the generated sulfate is deposited on the catalyst; and an inactivated catalyst which is continuously output from the denitration reactor enters a regenerative process, the regenerated catalyst returns to the reactor and the steps are continuously and repeatedly circulated by the method. By continuously regenerating the catalyst, the method solves the problem of catalyst poisoning and improves the denitration efficiency and running stability of a system.

Owner:GUODIAN SCI & TECH RES INST +1

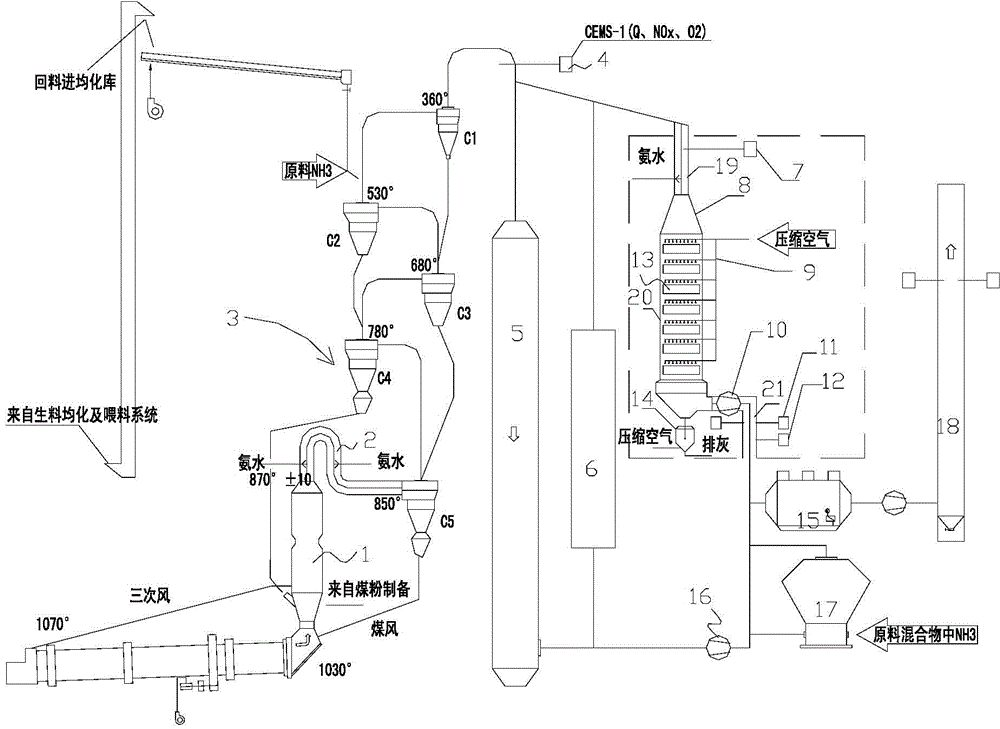

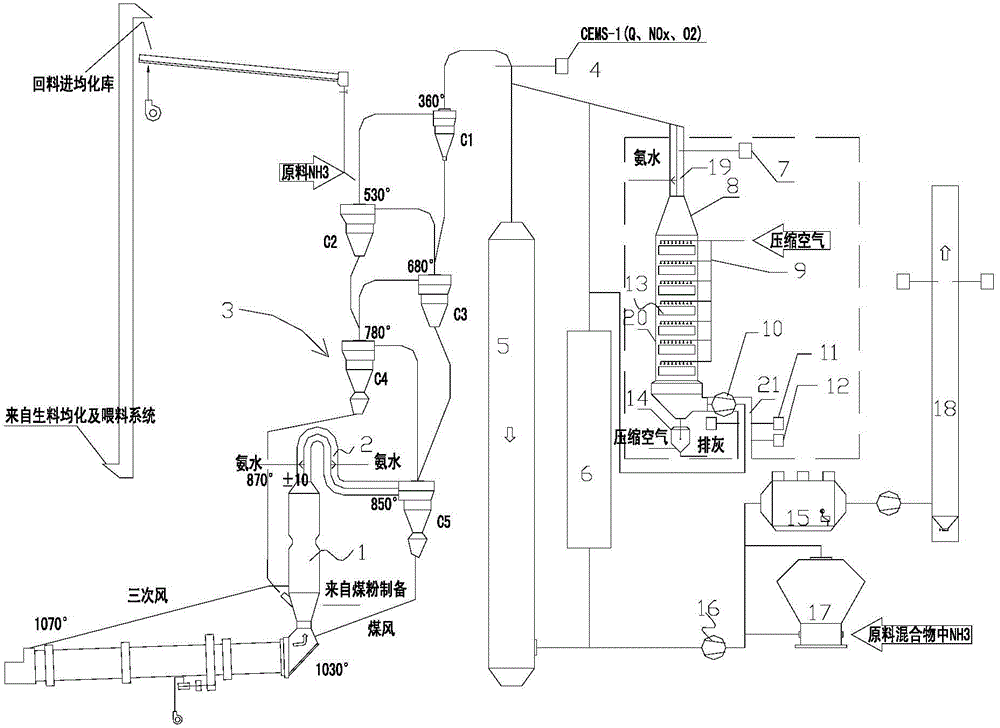

SCR denitration device and method applied to high-dust-content smoke from kiln tail of cement clinker production line

ActiveCN104645828AFlow field stabilityDoes not affect thermal efficiencyNitrous oxide captureDispersed particle separationProduction lineSprayer

The invention discloses an SCR (selective catalytic reduction) denitration device and an SCR denitration method applied to high-dust-content smoke from a kiln tail of a cement clinker production line. The device comprises a cement kiln decomposing furnace, a preheater, an afterheat boiler, a raw mill, an electric dust remover and a kiln tail chimney which are connected in sequence along the smoke direction, and further comprises an SCR reactor, wherein the SCR reactor comprises a reactor shell; an inlet divergent section is arranged at the top of the reactor shell, and an ash bucket is arranged at the bottom of the reactor shell; an inlet flue of the SCR reactor is connected with the preheater and the inlet divergent section and is provided with a reducer sprayer; a plurality of catalyst layers are arranged in the reactor shell in sequence from top to bottom; a plurality of steam ash blowers correspond to the catalyst layers one to one and are arranged above the corresponding catalyst layers; an outlet flue of the SCR reactor is connected with the bottom of the reactor shell and an upstream flue or a downstream flue of the afterheat boiler and is additionally provided with a high-temperature fan. On the basis that a high-temperature dust remover is not arranged, the SCR denitration device can handle with the smoke characteristics of high NOx load fluctuation, temperature fluctuation and high dust content.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE +1

Manufacture method of tilted fiber grating hydrogen sensor based on optical catalytic oxidation

InactiveCN101871885AHigh sensitivityShort response timePhase-affecting property measurementsIonSolvent

The invention relates to a manufacture method of a tilted fiber grating hydrogen sensor based on optical catalytic oxidation. A traditional sensor is influenced obviously by temperature. In the manufacture method, a platinum-doped tungsten oxide thin film is plated on the circumference of the surface of a tilted fiber grating by a sel-gel method, and the method comprises the following steps of: preparing sel-gel like tungstic acid by using protonation cation exchange resin with sodium tungstate, and washing the prepared tungstic acid with deionized water and centrifuging N times; heating to 50-60 DEG C and standing for 5-7 hours to dry into powder; then adding chloroplatinic acid, stirring and heating to 400-500 DEG C and standing for 1-2 hours to obtain the platinum-doped tungsten oxide powder with platinum-adsorbed surfaces, wherein the molar ratio of the platinum to tungsten is 1:14; and finally adding the platinum-doped tungsten oxide powder into an ethanolamine solvent, and uniformly depositing the platinum-doped tungsten oxide powder on the surface of the tilted fiber grating by using a dipping and coating method. The sensor produced by the method can improve sensitivity of hydrogen measurement and shorten response time.

Owner:CHINA JILIANG UNIV

MEMS spectrum gas-sensitive sensor

InactiveCN101470074AImprove performanceSolve poisoningColor/spectral properties measurementsInterference resistanceGas detector

The invention discloses a MEMS optical spectrum gas sensor, which utilizes optical spectrum to realize qualitative and quantitative analysis of object gas. The sensor obtains the concentration of object gas via the adsorbed amount of infrared light emitted by the discharge of the target gas in the object, while the adsorbed amount is determined by the light intensity difference between the infrared light of a reference chamber and a measurement chamber. The sensor is mainly composed of a radio frequency luminous tube, a target gas characteristic adsorption reference chamber (a main reference chamber), a target gas characteristic adsorption measurement chamber (a main measurement chamber), a non-characteristic adsorption measurement (an auxiliary measurement chamber) and a non-characteristic adsorption reference chamber (an auxiliary reference chamber). The main reference chamber and the main measurement chamber are used for detecting the concentration of target gas. The auxiliary reference chamber and the auxiliary measurement chamber are used for determining if the infrared adsorption in the main measurement chamber is caused by interference gas. The invention can resolve the defects of prior sensors such as low selectivity, low interference resistance and short service life, having low cost and wide application.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Reactivation method of biotin-intermediate hydrogenation palladium-carbon catalyst

ActiveCN106732656AEfficient activationSolve poisoningCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsAlkaline waterHigh activation

The invention discloses a reactivation method of a biotin-intermediate hydrogenation palladium-carbon catalyst. The current biotin-intermediate hydrogenation palladium-carbon catalysts have the defects of deep poisoning and difficult treatment of poisoning impurities. The reactivation method comprises the following steps: firstly, washing an inactivated palladium-carbon catalyst with an alcohol, ketone or ester solvent, filtering, washing with pure water, performing oxidation treatment on the palladium-carbon catalyst with hydrogen peroxide, washing the palladium-carbon catalyst with alkaline water after oxidation treatment, then washing with pure water to neutral, filtering, adding a reducer for performing reduction after filtering, washing the palladium-carbon catalyst with pure water to neutral, filtering and drying to obtain the reactivated palladium-carbon catalyst. The reactivation method effectively activates deeply poisoned palladium-carbon catalysts, has high activation efficiency, restores the activity of the poisoned catalysts like a raw catalyst, can effectively solve the problem of catalyst poisoning when applied in production, realizes continuous application and reduces the production cost.

Owner:ZHEJIANG NHU CO LTD +1

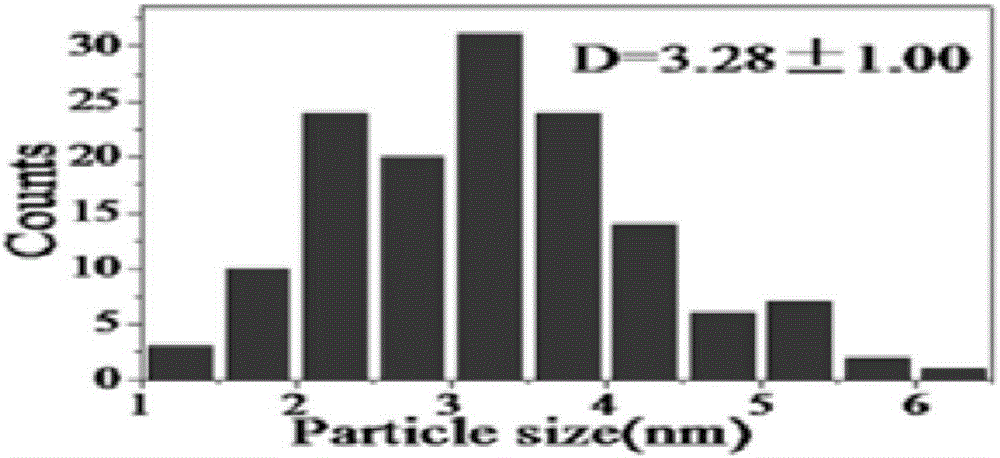

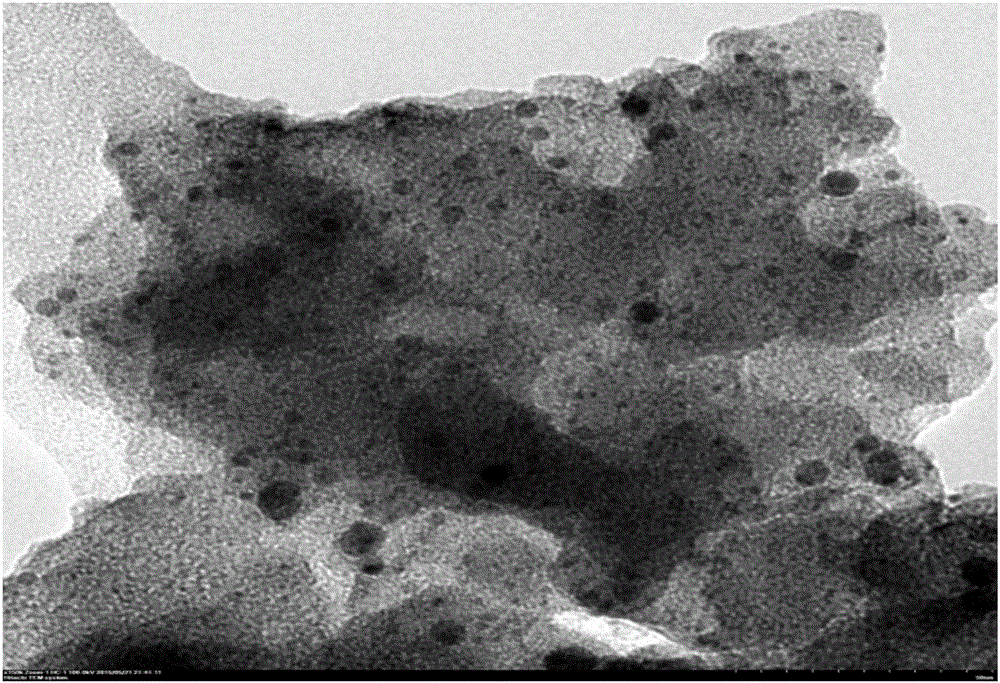

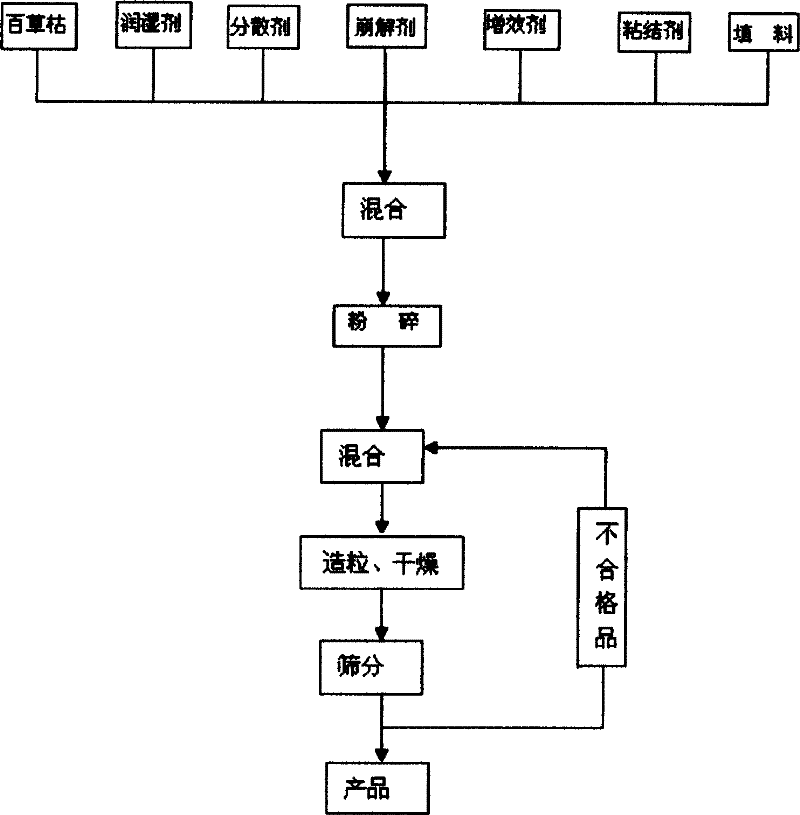

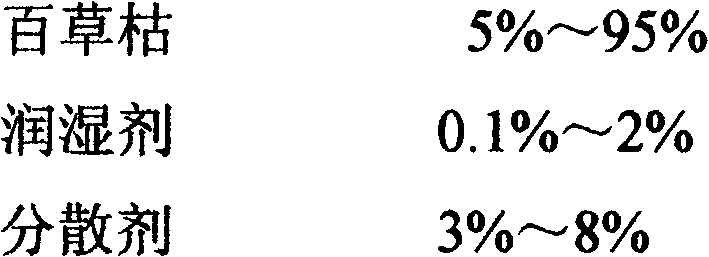

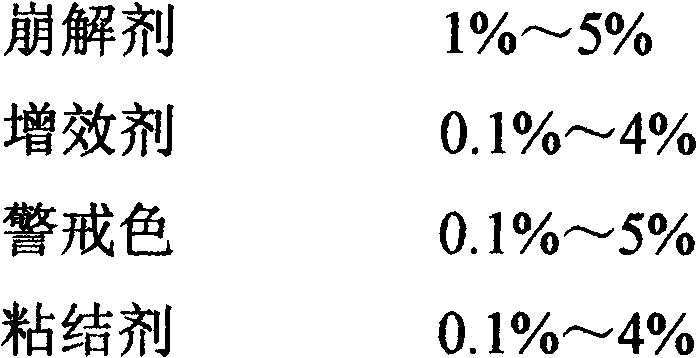

Paraquat-containing water dispersible granules and preparation method thereof

The invention relates to paraquat-containing water dispersible granules for pesticides and herbicides, and a preparation method for the paraquat-containing water dispersible granules. The invention aims to solve the problem of animal poisoning in the processes of producing, storing and using the conventional paraquat water dispersible granules. The paraquat water dispersible granules comprise the following components in percentage by weight: 5 to 95 percent of paraquat, 0.1 to 2 percent of wetting agent, 3 to 8 percent of dispersing agent, 1 to 35 percent of disintegrating agent, 0.1 to 4 percent of stabilizing agent, 0.1 to 4 percent of adhesive and the balance of filler. The paraquat water dispersible granules with the formula have the characteristics of good weeding effect, quick disintegration, high dispersibility, light pollution to environment, safety for users, simple packaging, convenience for storage and transportation and the like in the using process.

Owner:吴希法

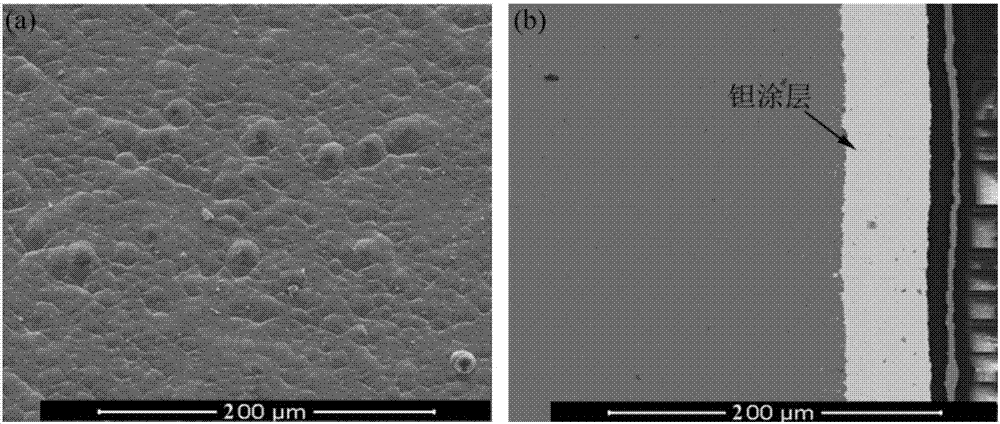

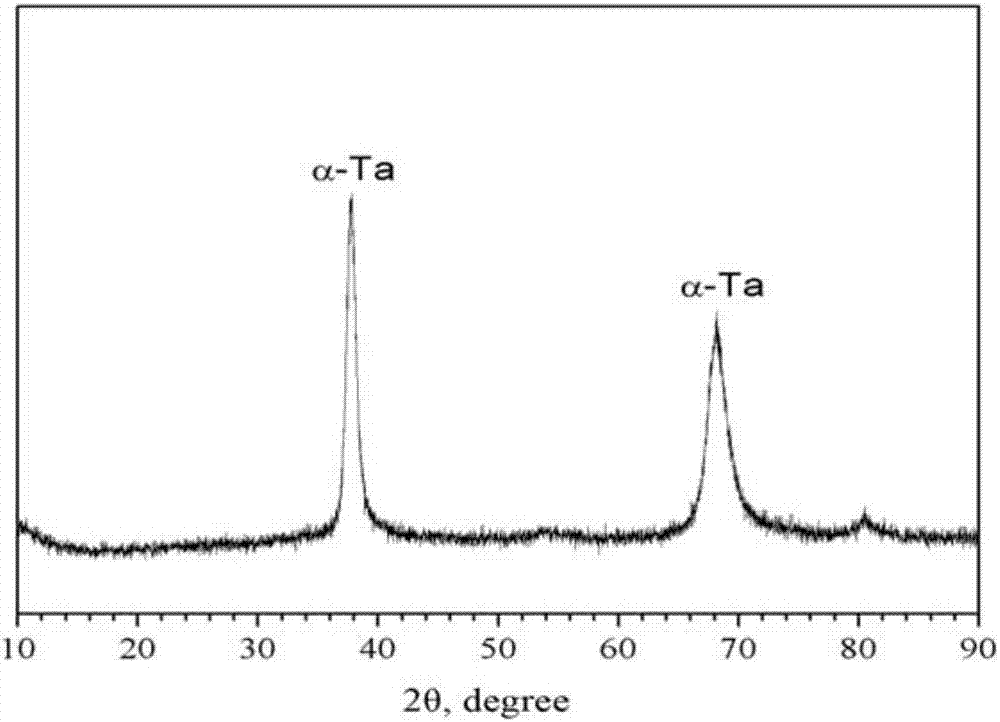

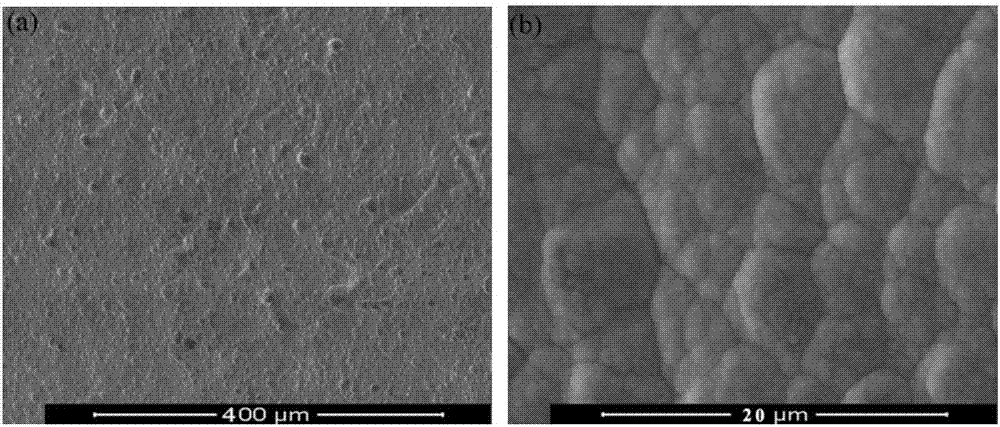

High-hardness wear-resistant thermal-shock-resistant thick tantalum coating and preparation method thereof

ActiveCN107130212AImprove toughnessHigh hardnessVacuum evaporation coatingSputtering coatingWear resistantNitrogen gas

The invention relates to the field of wear-resistant coatings, in particular to a high-hardness wear-resistant thermal-shock-resistant thick tantalum coating and a preparation method thereof. The tantalum coating comprises 100% of alpha-phase tantalum and has relatively high toughness. Meanwhile, trace nitrogen atoms are fixedly dissolved in the alpha-phase tantalum of a body-centered cubic lattice, and the hardness and elasticity modulus of the tantalum coating are improved, so that the wear resistance and thermal shock resistance of the coating are improved. The final thickness of the tantalum coating can reach 60 microns or above. The preparation method of the high-hardness wear-resistant thermal-shock-resistant thick tantalum coating is magnetron sputtering under the environment of argon and nitrogen. Pure tantalum serves as a target material, under a certain vacuum degree, argon (Ar) and nitrogen (N2) are used as sputtering gas, and a layer of nanocrystalline thick tantalum coating is directly deposited on the surface of a base material. The coating has excellent comprehensive properties such as high hardness, high toughness, wear resistance and thermal shock resistance.

Owner:NORTHEASTERN UNIV

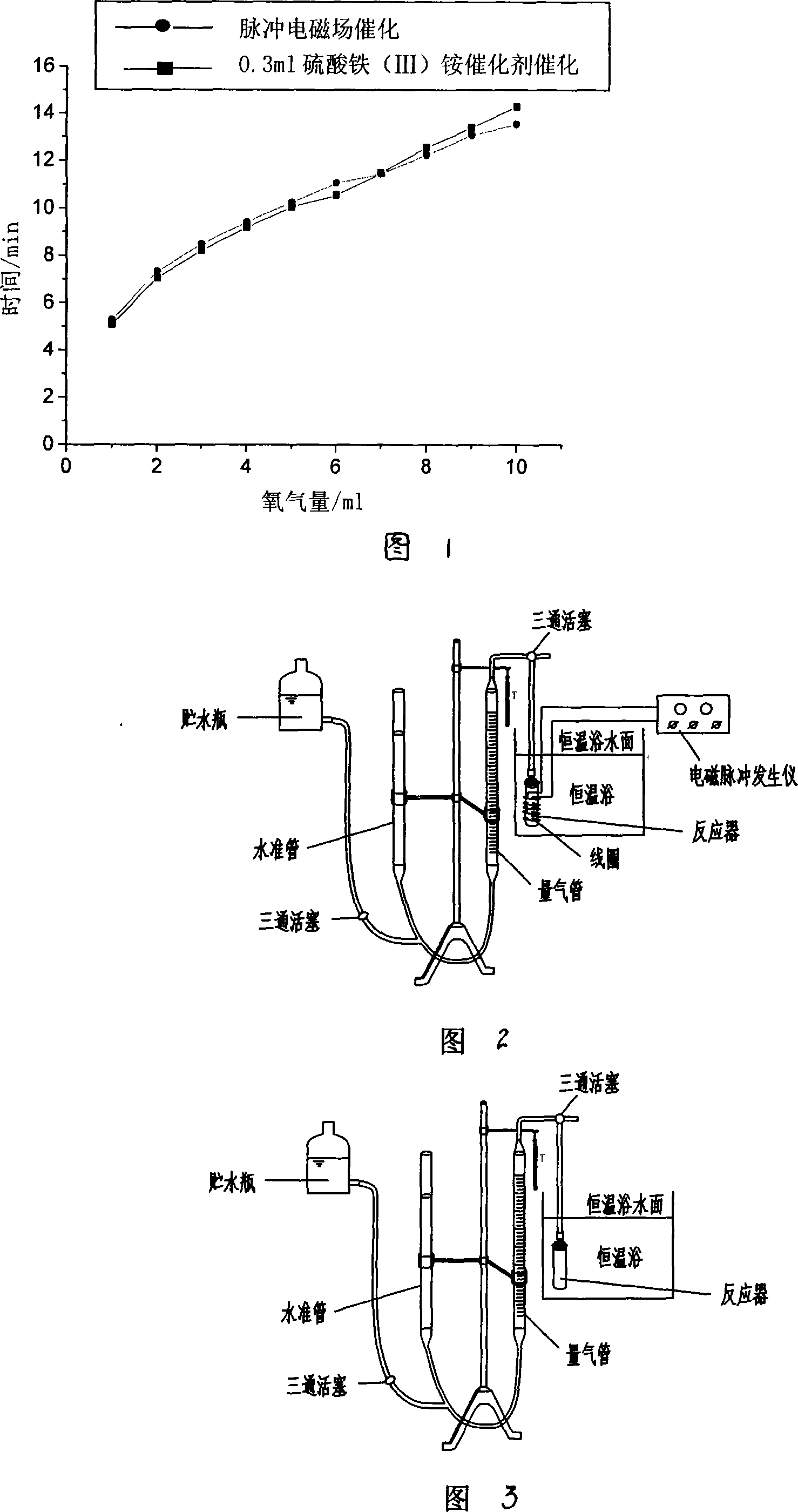

Method for catalyzing chemical reaction through pulse electromagnetic field

InactiveCN101091899ASolve poisoningPlay a catalytic roleEnergy based chemical/physical/physico-chemical processesChemical reactionCatalytic effect

The invention is a pulse electromagnetic field catalytically chemical reaction method, injecting reactants into reactor, then applying pulse magnetic field outside the reactor, where the electrodes do not contact with the reactants, pulse voltage is 1-1000V, pulse frequency is 0.1-500Hz, and the catalytic treatment time of the pulse magnetic field is determined by the reactants. And its advantage: it can play a role in catalysis or catalysis acceleration and solve the problems that catalyst is deactivated and poisoned and pollutes environment.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Method for preparing N-butylphthalimide

InactiveCN102344405ASimple processProcess environmental protectionOrganic chemistryPhthalic anhydrideN-Butylamine

The invention discloses a method for preparing N-butylphthalimide, which comprises the following steps of: (1) a charging reaction step: adopting phthalic anhydride and n-butylamine as raw materials, taking water as solvent, and carrying out reflux reaction for 0.5-20 hours at the temperature of 100-160 DEG C under the action of phase transfer catalyst to obtain slight yellow turbidliquid; and (2) a cooling separation step: cooling to 55-65 DEG C after reaction is finished, static placing and layering, and separating to obtain slight yellow oilyliquid, i.e. the N-butylphthalimide when the temperature goes down to 35-45 DEG C. The method disclosed by the invention has simple process, is environmentally-friendly and non-toxic, and has high production efficiency.

Owner:山东昌邑灶户盐化有限公司

Lubricant formulations and methods of lubricating a combustion system to achieve improved emissions catalyst durability

ActiveCN101659896ASolve poisoningIntoxication helps control and minimizeAdditivesMaterial testing goodsDecompositionChemistry

The invention relates to lubricant formulations and methods of lubricating a combustion system to achieve improved emissions catalyst durability. Different zinc dialkyldithiophosphate (ZDDPs) exhibit different volatilities and have different effects on automotive emissions control catalysts. The ZDDPs and their respective decomposition fragments that have low volatility will have a correspondingly lower detrimental effect on combustion emissions control systems, because there are simply fewer phosphorous atoms that will pass through the combustion system to reach the emissions control system.Specifically, it has been discovered that ZDDPs that contain a significant fraction of MIBC ZDDP exhibit significantly lower volatility than other ZDDPs.

Owner:AFTON CHEMICAL

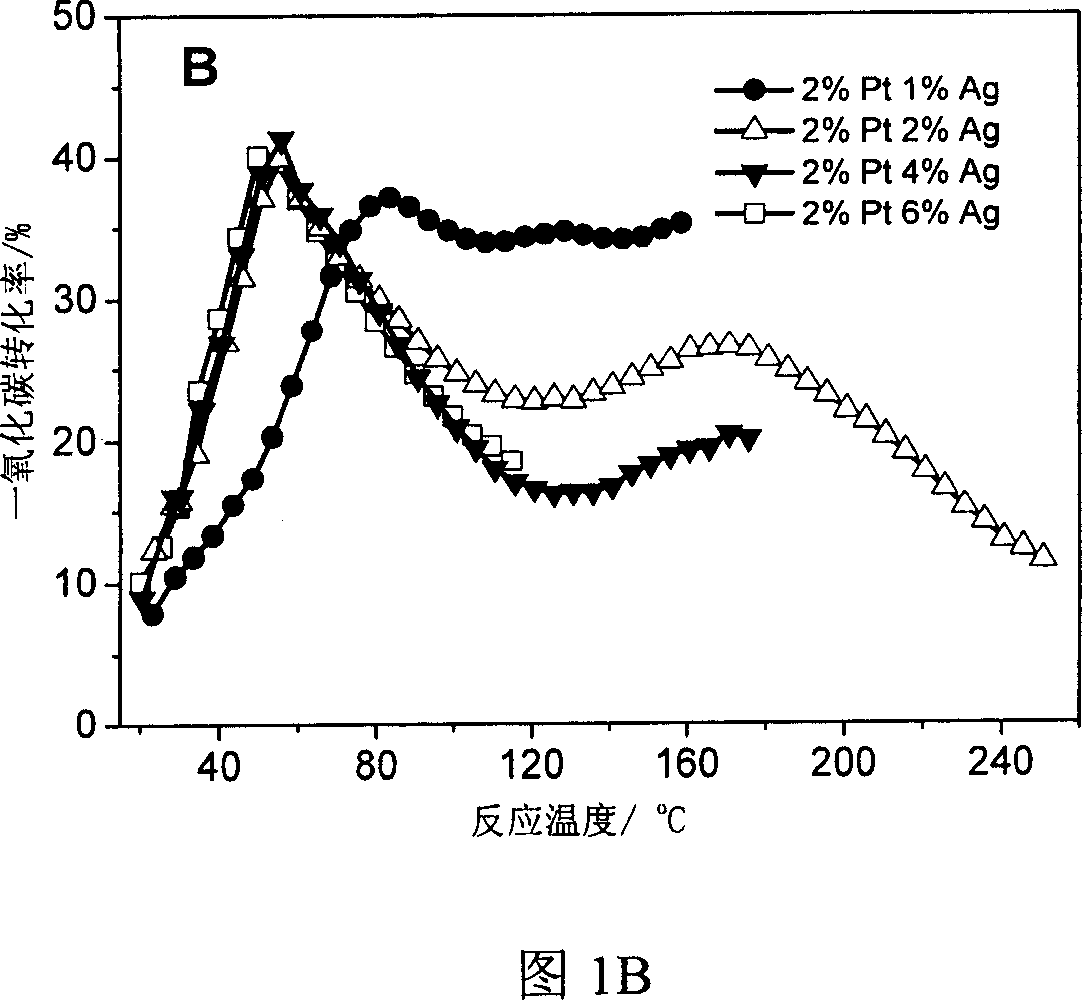

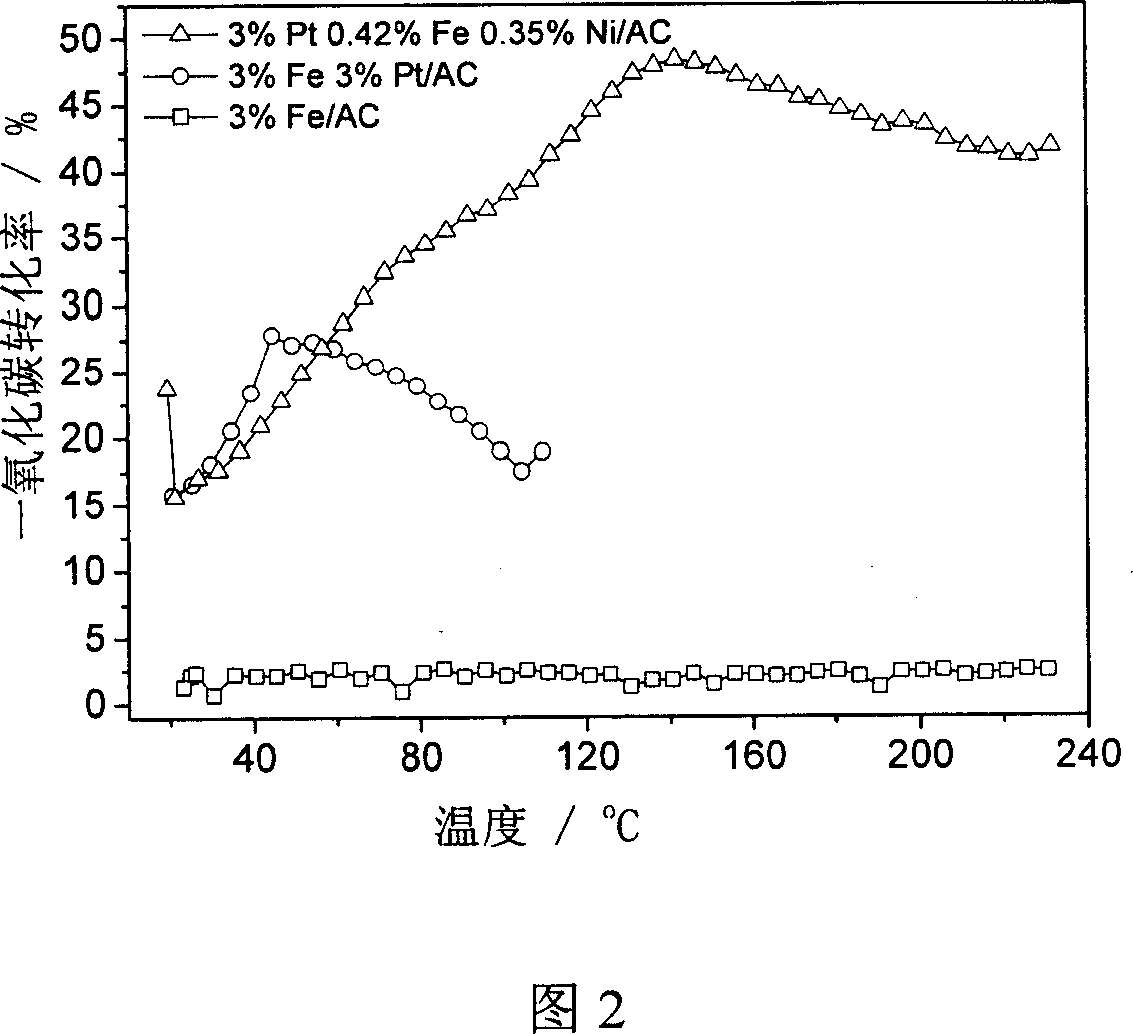

Catalyst for carbon monoxide oxidation in hydrogen and preparation method thereof

InactiveCN101062478AHigh activityGood choiceCatalyst carriersHydrogen separationActivated carbonPtru catalyst

The invention relates to a CO catalyst made of the carrier and the active carbon. The active carbon, carbon black, middle hole carbon, carbon nanometer tube as the carrier, metal platinum, silver and iron in single or compound form to be the active element, with metal weighing 0. 5-25%, silver or iron percentage to platinum being 16:1-16, and platinum: iron: Nickel being 10:1-5:1-5 in weight. It has excellent activity and selectivity, easy for manufacturing, low in cost, unnecessary for extra oxygen, safe in CO and O2 reaction, improved in catalyst energy utilization.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-barrier HDPE (high-density polyethylene) membrane production process

ActiveCN104004212APrevent membrane yellowingGood barrierCoatingsBulk chemical productionTemperature resistanceChemistry

The invention discloses a high-barrier HDPE (high-density polyethylene) membrane production process which comprises the steps: blending of a bottom coating solution, unreeling, corona treatment, bottom coating, drying, surface coating, surface coating drying, and reeling. By adopting the manner, the high-barrier HDPE membrane production process disclosed by the invention has the advantages of good barrier property, simple production process, high chemical stability, long service life, good temperature resistance, and high membrane strength; a release member is effectively prevented from yellowing, and the problem of catalyst poisoning during production is solved.

Owner:UPASS MATERIAL TECH JIANGSU

Formaldehyde-free plywood and preparation thereof

InactiveUS20140272403A1Improve physical performanceImprove water resistanceLayered product treatmentPlastic recyclingWood veneerAlloy

The present invention discloses a method for preparation of formaldehyde-free plywood from scrap plastic alloys. Different scrap plastics are used to prepare plastic alloy film, which is then used as an adhesive material for the preparation of new plywood without formaldehyde emission. The formaldehyde-free plywood according to the present invention is prepared by the following steps: different scrap plastics are crushed, cleaned separately, and then corresponding fillers and additives are added to the above crushed material or their mixtures which mixed according to a certain blending ratio; plastic alloy film of certain size and thickness is prepared after the film blowing and rolling processes; after being assembled with wood veneers to form a lay-up mat, the mat is hot pressed and then cold pressed. The present invention provides a method of preparing non-toxic and environmentally friendly formaldehyde-free plywood, solving the problem that the environment and human beings being poisoned by the free formaldehyde released from ordinary plywood and at the same time providing a way of recycling and reusing scrap plastics.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Novel industrialized synthesis technique for preparing cinnamic acid from cinnamic aldehyde by catalytic oxidation

InactiveCN102826992AExtended service lifeSolve poisoningOrganic compound preparationCarboxylic compound preparationPtru catalystCatalytic oxidation

The invention belongs to the technical field of intermediate synthesis in fine chemical engineering, and particularly relates to a novel industrialized synthesis technique for preparing cinnamic acid from cinnamic aldehyde by catalytic oxidation. The technique comprises the following steps: (A) adding sodium hydroxide, pure water and catalyst mixed solution in a mass ratio of (8-40):180:(1.1-2.2) into a reaction kettle, stirring, introducing pure oxygen, dropwisely adding cinnamic aldehyde into the mixed solution at proper rate to generate sodium cinnamate, and standing for 10-40 minutes to deposit the catalyst; and (B) leading out the sodium cinnamate solution obtained in the step (A), carrying out acid precipitation at 70-80 DEG C, keeping the reaction for 15-40 minutes, and naturally cooling to room temperature, thereby obtaining the cinnamic acid. The catalyst is nano silver particles. By adopting the supporter-free nano silver particles as the catalyst for the first time, the invention solves the problems of catalyst poisoning, high shedding tendency, high loss and the like, simplifies the production technique, greatly lowers the production cost, has the advantage of high yield, and implements industrialized mass production.

Owner:湖北远成赛创科技有限公司

Proton exchange film and its preparation method

This invention discloses a proton exchange film and its preparation method. The film is made of a ceramic thin film with thickness of h is less than or equal to 1mm and distributed with several microholes on it with the diameter n is less than or equal to 2mm, distributed on the whole thin film and fully filled with high conductivity electrolyte. Diameter of hole n is better is nanometer degree. The preparation method is as follow: first to prepare ordered microholes on the metal film with thickness in h is less than or equal to 1mm to be oxidated to ceramic film by electrochemical or other ways, then to fill with high conductivity electrolyte. The above mentioned metal film is better A1 film with the advantage of easy filming, low cost solving the problem of catalyst poisoning by increasing operation temperature of the proton exchange film.

Owner:HUAZHONG UNIV OF SCI & TECH

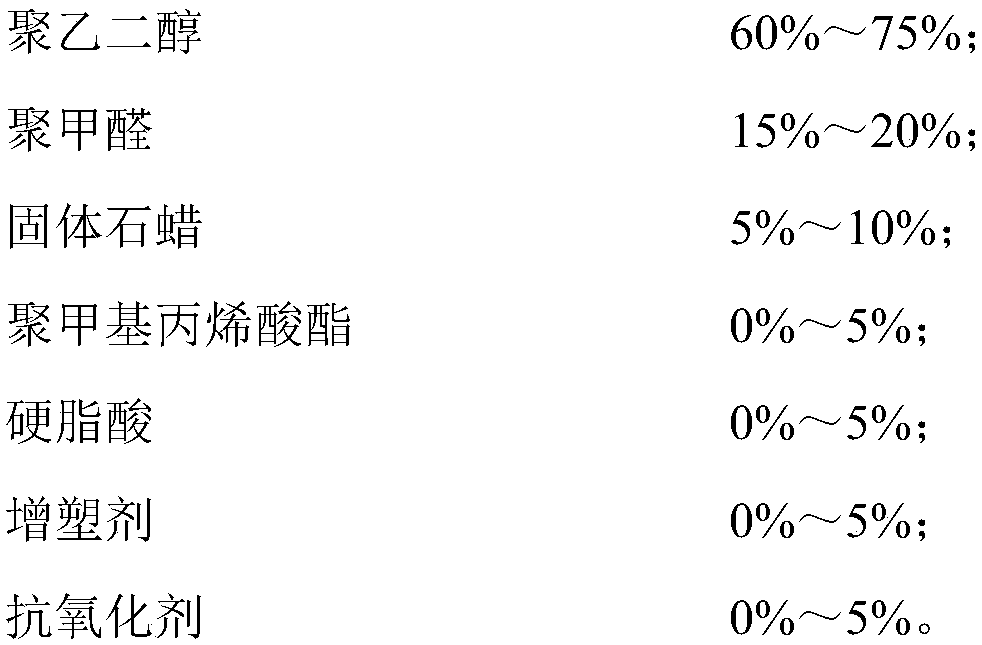

Water-based debinding binder used for ceramic injection moulding

InactiveCN108947545AAddressing Toxic and Pollution IssuesSafe recyclingSolventEnvironmental resistance

The invention relates to the technical field of ceramic injection moulding and specifically discloses a water-based debinding binder used for ceramic injection moulding. The water-based debinding binder comprises the following ingredients (by weight): 60-75% of polyethylene glycol, 15-20% of polyformaldehyde, 5-10% of solid paraffin, 0-5% of polymethacrylate, 0-5% of stearic acid, 0-5% of a plasticizer, and 0-5% of an antioxidant. The water-based debinding binder can be greatly wetted and wrapped with the ceramic powder, has good fluidity, and is beneficial to mold filling during injection moulding. Meanwhile, as the binder system contains a water-soluble component, water can be used as a debinding solvent to remove the binder, thus avoiding the use of toxic chemical solvents for debindingand greatly reducing the harm to operation staff and environmental pollution. The product is economic and environmentally-friendly.

Owner:SHENZHEN ELEMENT TECH CO LTD

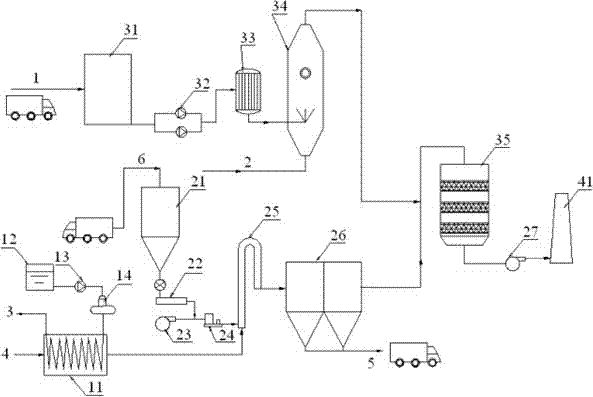

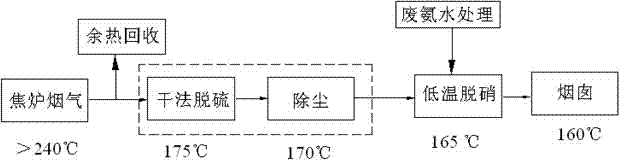

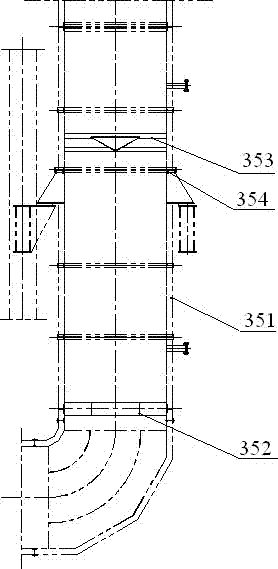

Coke oven flue gas waste heat and desulfurization and denitration dedusting system

InactiveCN106925108AReduce pollutionSolve temperature problemsDispersed particle filtrationIncreasing energy efficiencyFlue gasEmission standard

The invention discloses a coke oven flue gas waste heat and desulfurization and denitration dedusting system. The system comprises a waste heat recovery subsystem, a dry desulfurization subsystem, a dedusting subsystem, an ammonia water treatment subsystem, an SCR denitration subsystem and a chimney. A flue gas inlet end of the waste heat recovery subsystem is communicated with a coke oven main flue, a flue gas outlet end of the waste heat recovery subsystem is connected to a flue gas inlet end of the dry desulfurization subsystem, a flue gas outlet end of the dry desulfurization subsystem is communicated with a flue gas outlet end of the dedusting subsystem, an input end of the SCR denitration subsystem is communicated with an output end of the ammonia water treatment subsystem, and a flue gas outlet end of the SCR denitration subsystem is communicated with the chimney. The system provided by the invention performs waste heat recovery, desulfurization, dedusting and denitration treatment on coke oven flue gas, enables coke oven flue gas to reach the emission standard requirements, and has the characteristics of excellent economic performance and good environmental protection effect.

Owner:无锡市东方环境工程设计研究所有限公司

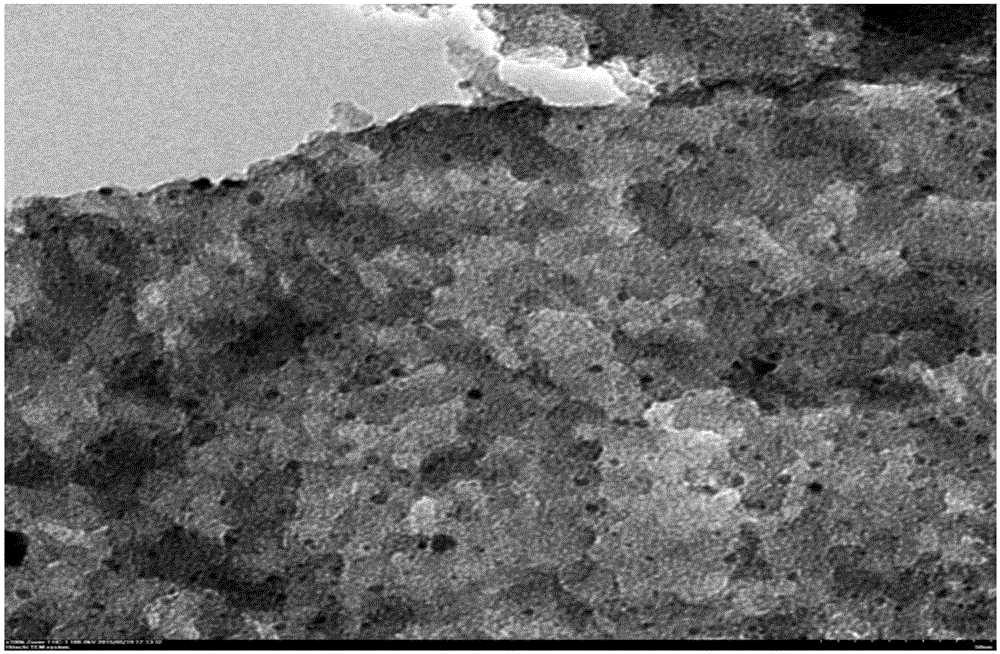

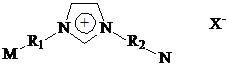

Catalyst for preparing carbon monoxide by electrochemically reducing carbon dioxide and preparation method and application thereof

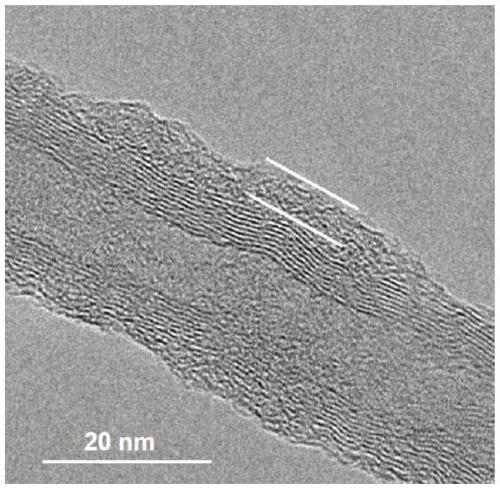

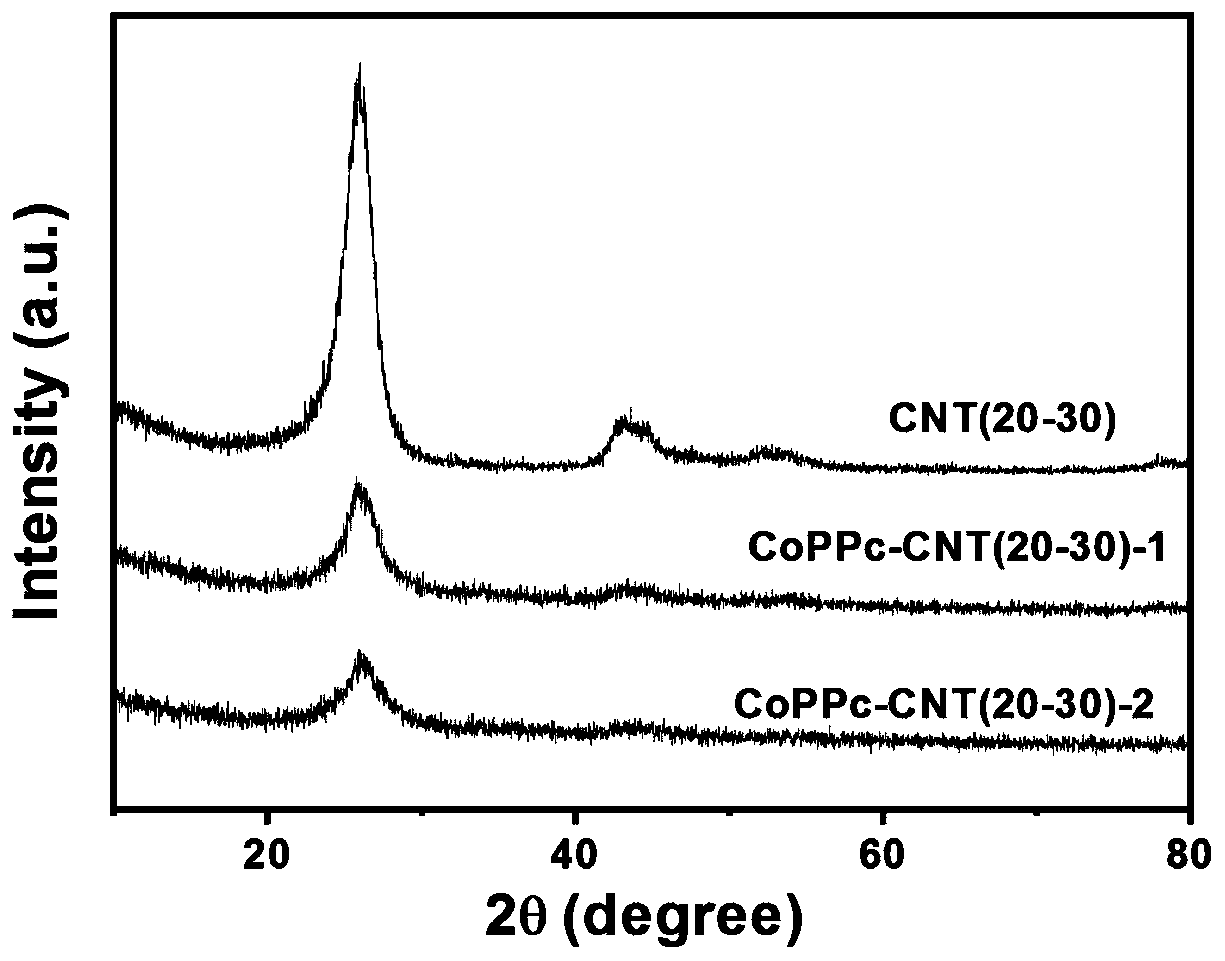

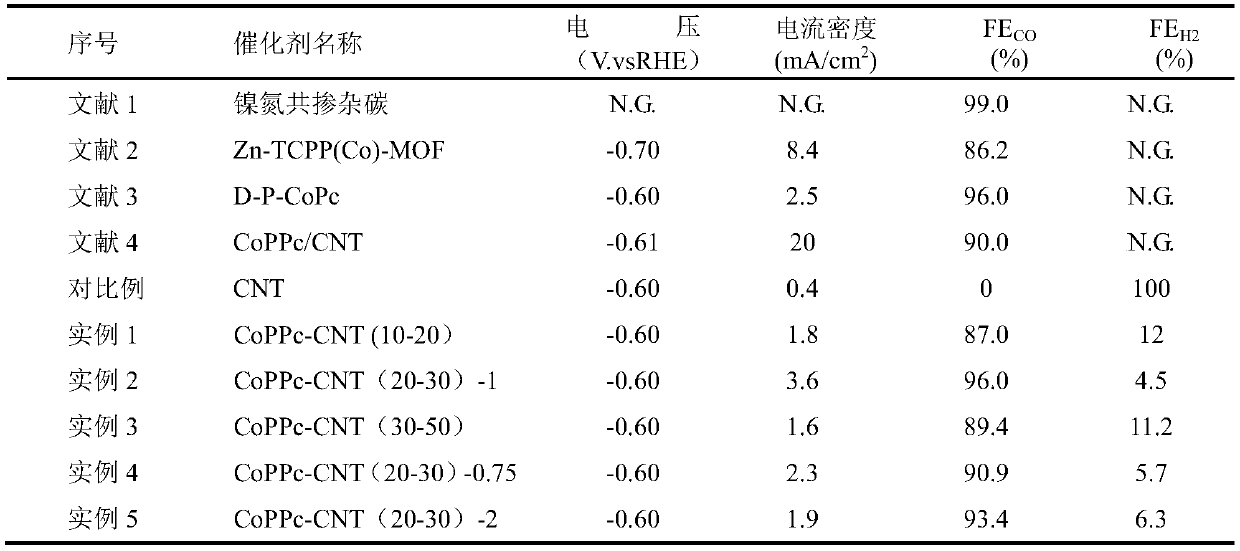

InactiveCN110090668AAchieving controllable equipmentThe synthesis steps are simpleOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesMass ratioElectrochemistry

The invention relates to a catalyst for preparing carbon monoxide by electrochemically reducing carbon dioxide, and the catalyst comprises a carbon material and a surface organic polymerization layer.The outer surface of the carbon material is coated with the surface organic polymer layer. A non-noble metal is distributed in the surface organic polymer layer. The mass ratio of the surface organicpolymer layer to the carbon nano material is 1: 0.5-1: 4, and the mass fraction of the non-noble metal in the catalyst is 1-10%. Compared with the prior art, a solvent (ethanol / water) used by the invention is more green and environment-friendly, and the preparation process is simpler; the synthesized catalyst has higher catalytic activity, selectivity and stability, provides a new idea for the electrocatalytic efficient conversion of the carbon dioxide, and has a better industrial prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

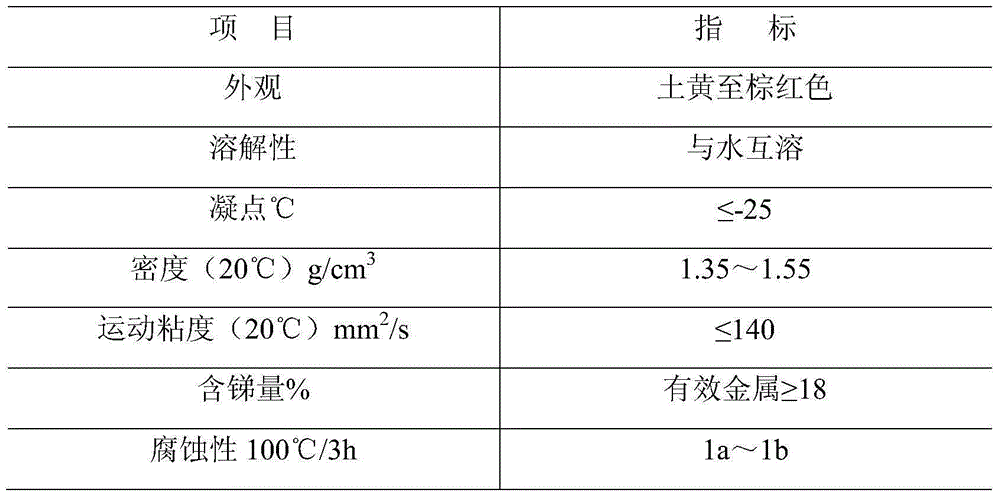

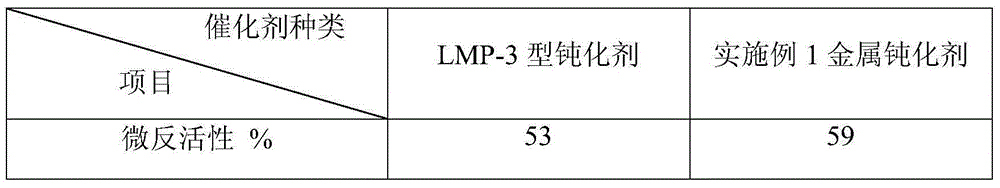

Deactivator and preparation method thereof

The invention discloses a deactivator. The deactivator comprises the following raw materials by mass percentage: 10-20% of a metal oxide, 20-40% of an oxidizing agent, 5-20% of an organic amine, and 25-40% of a solvent. The deactivator comprises the following steps: mixing the organic amine and the solvent, adding the metal oxide, heating the materials to the temperature of 90 DEG C, dropping the oxidizing agent so that the oxidizing agent and metal oxide are subjected to a reaction, controlling the reaction temperature at 90-120 DEG C; after the reaction is complete, and filtering a reaction solution to remove impurity to obtain the deactivator. The deactivator enables reasonable complex formulation of the components, antimony oxide is converted to pentavalent antimony under effect of hydrogen peroxide, and is simultaneously mixed with the organic amine and water, catalyst poisoning problem can be solved, hydrogen yield is reduced, light oil yield is increased, and the deactivator is suitable for a catalytic cracking apparatus with high residual oil-blending percentage.

Owner:JIANGSU KECHUANG PETROCHEM

Arthrobacter HW08 for degrading swainsonine and application thereof

InactiveCN101724590AEfficient degradationAvoid poisoningBacteriaBacteria material medical ingredientsInorganic saltsArthrobacter

The invention discloses Arthrobacter sp. HW08 for degrading swainsonine, which is preserved in a common microbe center of the China Microbial Culture Preservation Commission in September 28th, 2009 and has the preservation number of CGMCC No. 3313. The bacterial colony of a bacterial strain is in a circular shape and gradually changed into faint yellow from oyster white with the prolongation of culture time, has a smooth, moist and raised surface and neat edges and is non-transparent; and the bacterial strain is cultured within 48 hours in an inorganic salt culture medium, basically belongs to a stab cell, has the size of 0.3-0.5 micrometer*0.5-1.0 micrometer, is gradually changed into a ball shape after cultured for 48 hours and has the diameter about 0.60-0.8 micrometer. The bacterial strain is obtained by separating and screening from soil embedding yellowflower crazyweed herbs (loco weeds) and has the capacity of efficiently degrading the swainsonine, i.e. toxins of the loco weeds.

Owner:NORTHWEST A & F UNIV

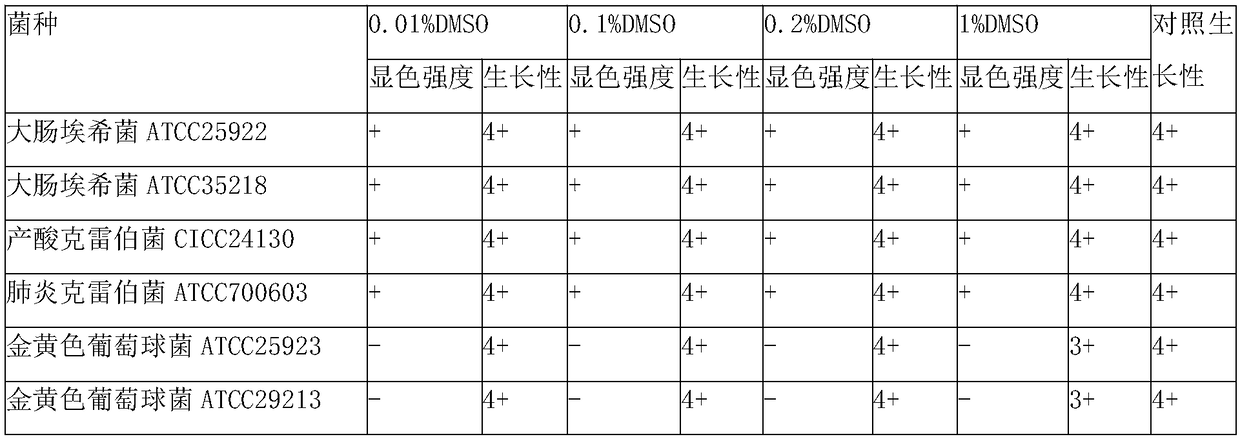

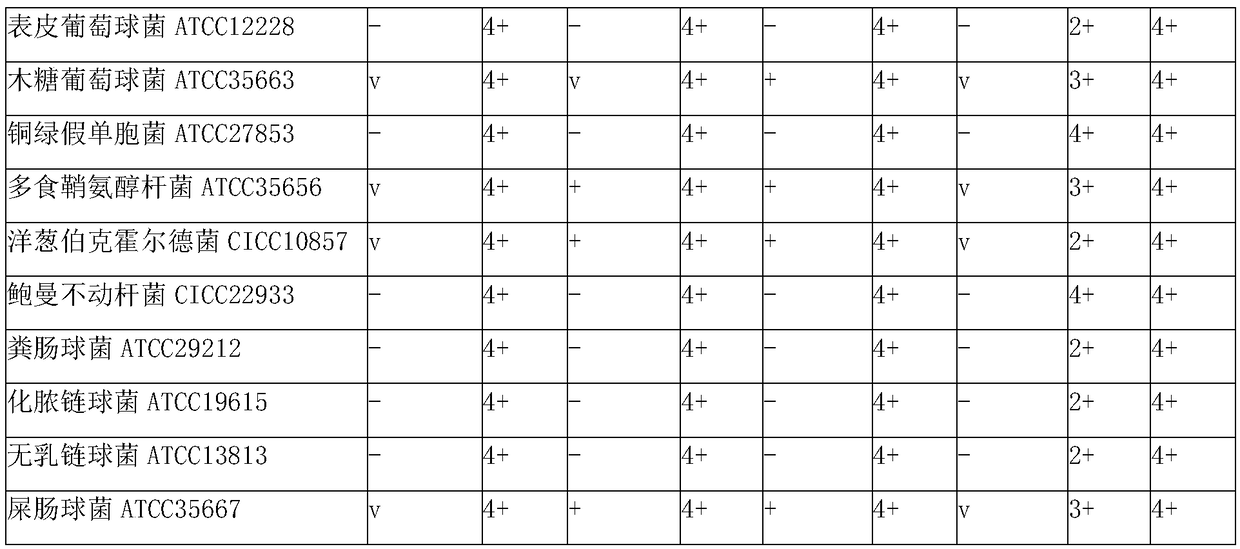

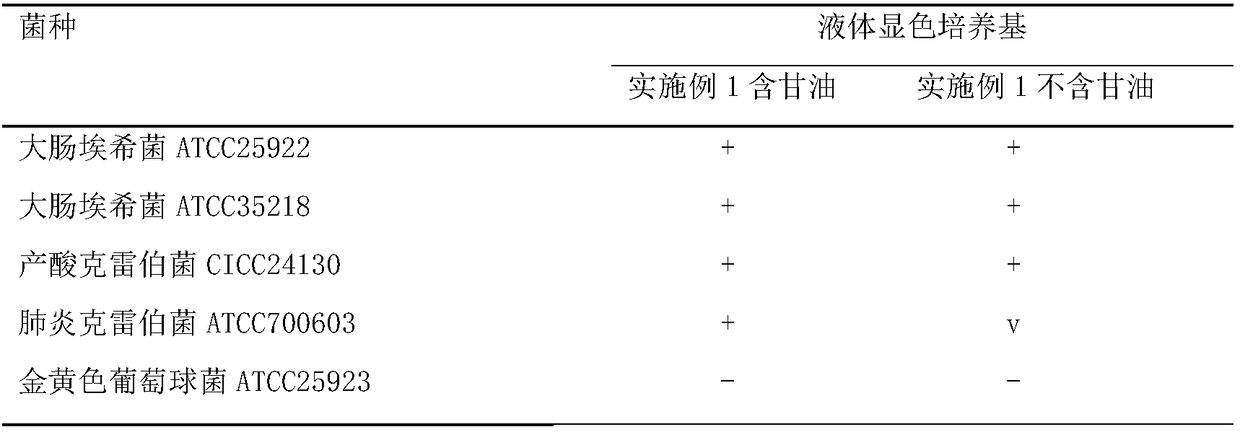

Liquid culture medium for detecting beta-galactosidase and application of liquid culture medium in bacterium identification

InactiveCN109355352ASolve solubilitySolve poisoningMicrobiological testing/measurementBiological material analysisSolventGalactoside

The invention discloses a liquid culture medium for detecting beta-galactosidase and application of the liquid culture medium in bacterium identification. Every 1,000 ml of the liquid culture medium for detecting beta-galactosidase is prepared from 5-50 g of nutrient substances, 2-10 g of sodium chloride, 50-250 ml of 0.2 mol / L PBS, 0.5-4 g of a specificity chromogenic substrate, 0.5-4 g of an enzyme induction agent, 0.1-10 ml of a cosolvent and 0.1-10 ml of a protection agent. According to the culture medium, 5-bromine-4-chlorine-3-indol-beta-D-galactoside is used as a substrate, the low-toxic cosolvent and the protection agent are adopted, and beta-galactosidase of living bacteria can be accurately and effectively detected through a liquid method; the culture medium can be applied to a commercial identification testing card, a drying substrate in a micro hole can be effectively redissolved, beta-galactosidase of the living bacteria is detected, the negative and positive results are clearer, and the identification accuracy for clinical common gram negative and positive bacteria is improved.

Owner:湖南迈瑞医疗科技有限公司

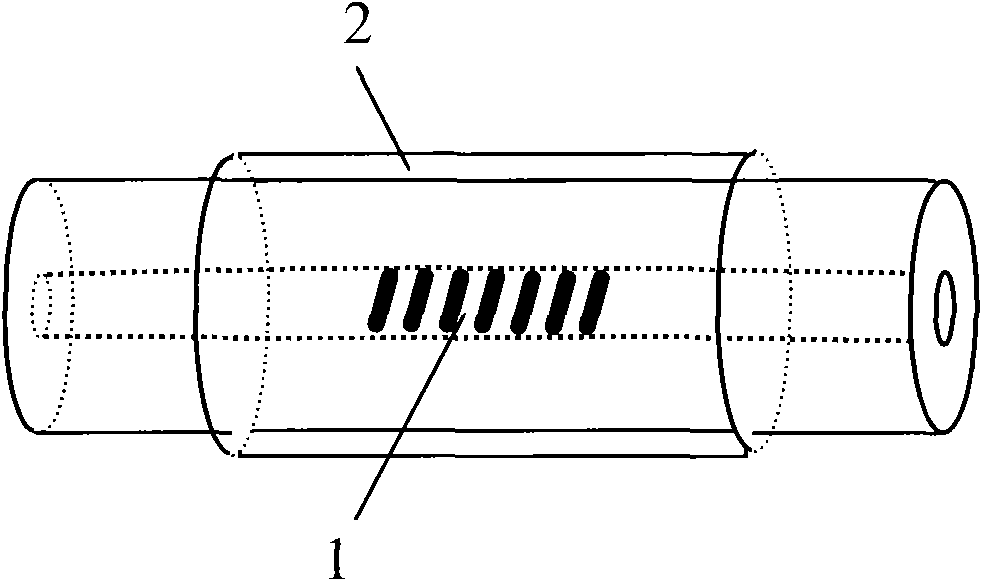

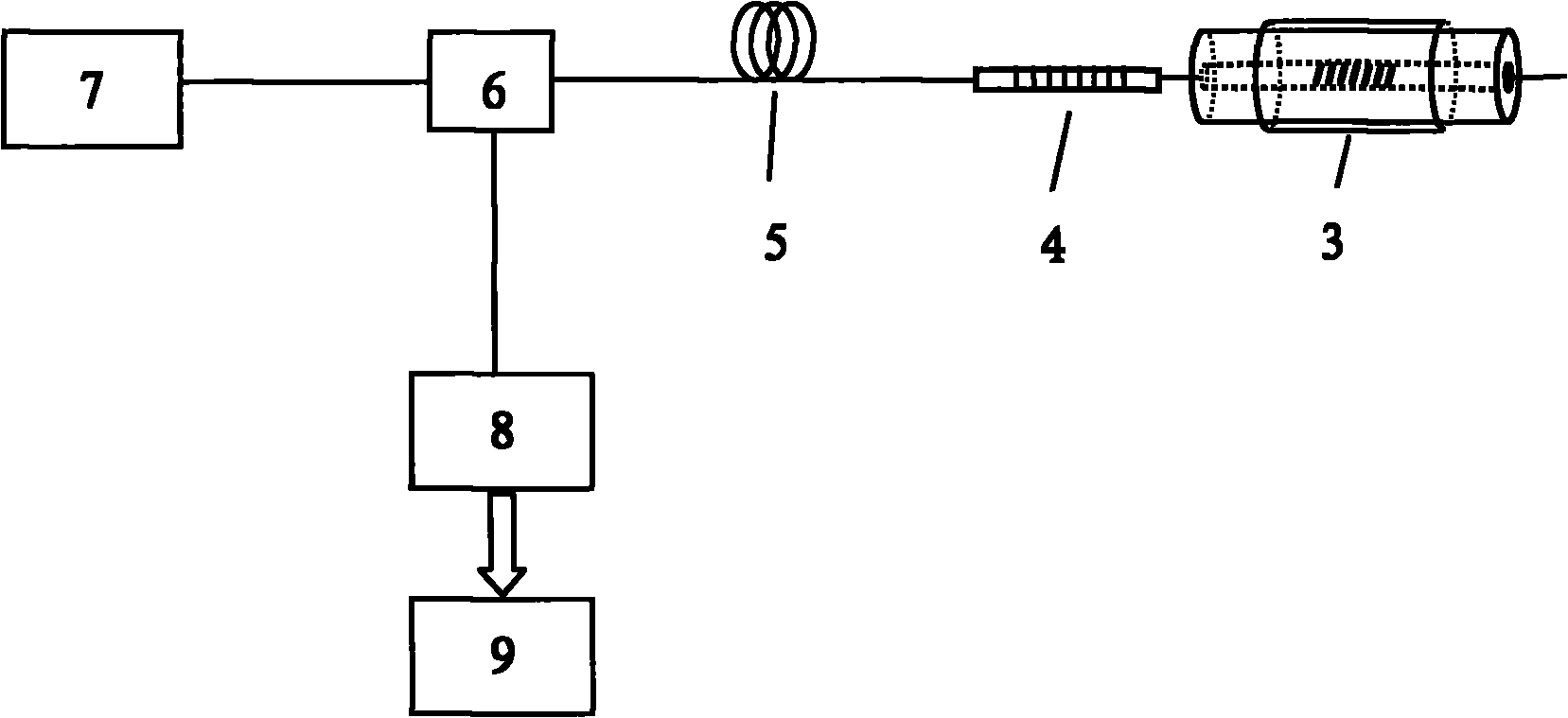

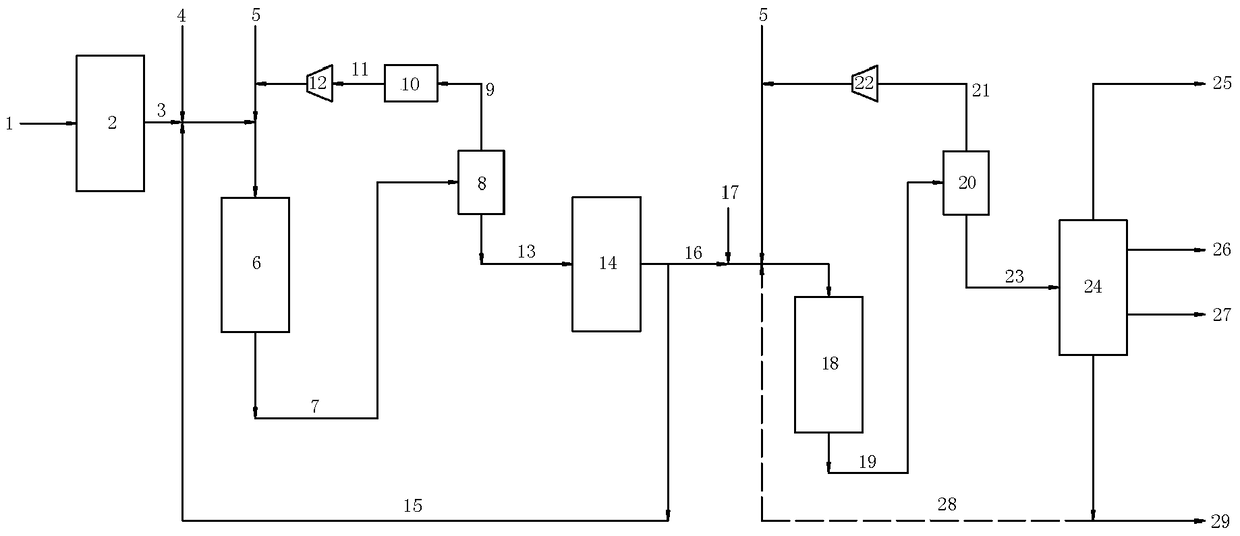

System for low temperature plasma pre-oxidizing NOx of auxiliary NH3-SCR fine purification diesel engine

InactiveCN101344026BImprove Catalytic Reduction EfficiencyLow quality (sulfur content) requirementsInternal combustion piston enginesExhaust apparatusSulfurCombined use

The invention relates to a system for using NH3-SCR to purify NOx in a diesel engine by the assistance of pre-oxidization of a low-temperature plasma, and belongs to the control technical field of the exhaust pollutants of the tail gas of the diesel engine; the invention adopts the combining use of a DBD reactor and an SCR reactor in the working condition of low temperature, wherein, the DBD reactor adopts coaxial medium to block a discharging reactor, which has good safety performance, simple structure and stable, uniform and dispersing discharging and can effectively reduce the energy consumption which is needed by the medium for blocking the discharging; the process of the low-temperature plasma replaces the process of noble metal catalytic oxidization to carry out the pre-oxidization to NO, thus realizing that NOx is reduced in the wide temperature window at the temperature of 100 DEG C to 550 DEG C, avoiding the use of the noble metal catalyst and solving the problem of sulfur poisoning of the catalyst simultaneously and effectively. The system of the invention is applicable to the diesel with high sulfur in China and can improve the NOx conversion efficiency of NH3-SCR when the diesel engine carries out cold starting or is in idle speed in the low temperature.

Owner:SHANGHAI JIAOTONG UNIV

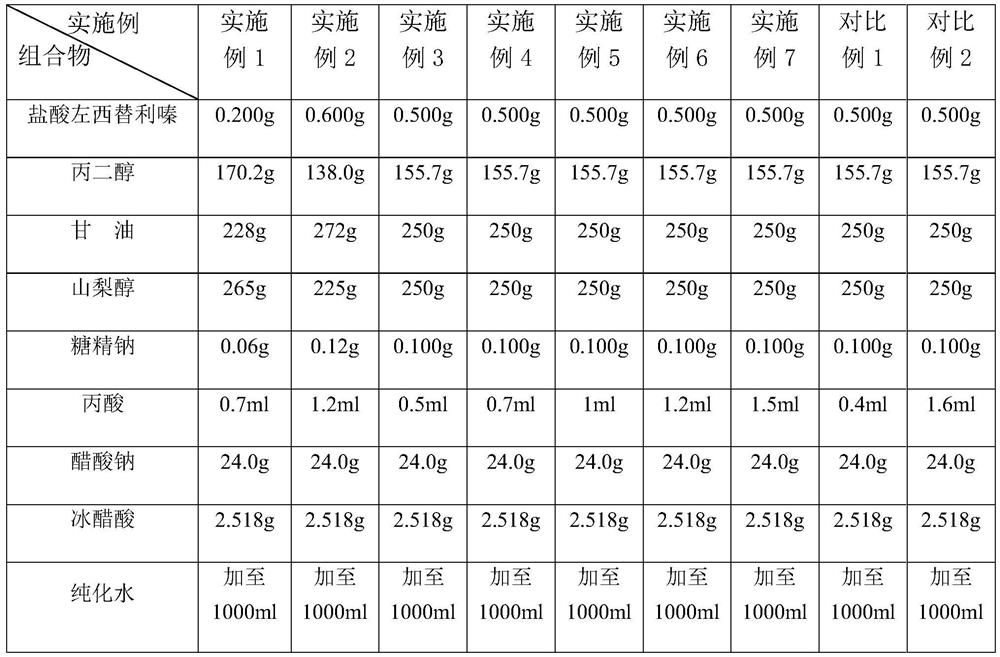

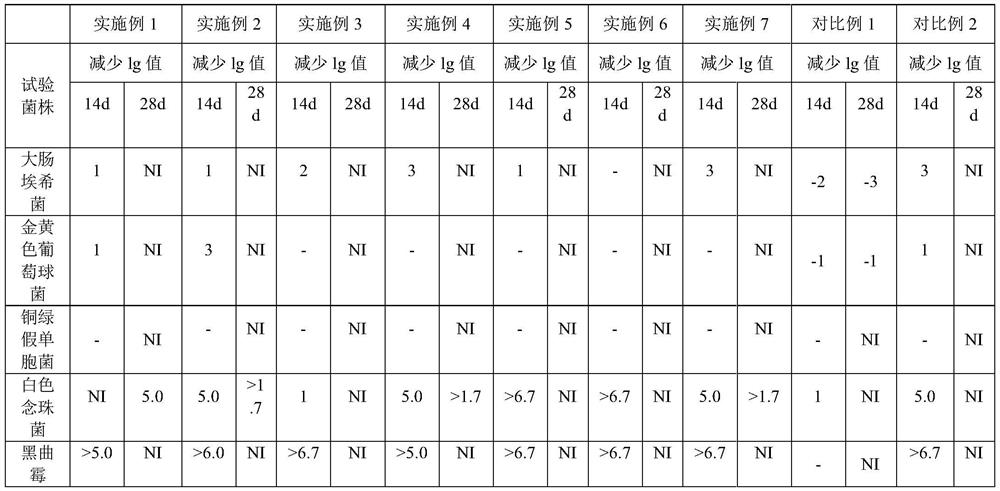

Stable levocetirizine hydrochloride oral solution and preparation method thereof

InactiveCN112006982ASolve poisoningSame antiseptic effectOrganic active ingredientsDispersion deliveryPropanoic acidPreservative

The invention belongs to the field of pharmaceutical preparations, and particularly relates to a stable levocetirizine hydrochloride oral solution and a preparation method thereof. According to the levocetirizine hydrochloride oral solution, propionic acid is used as a preservative, and a volume percentage of propionic acid in the levocetirizine hydrochloride oral solution is 0.05%-0.15%. Propionic acid is added into the levocetirizine hydrochloride oral solution, and compared with a traditional preservative, propionic acid has the same preservative effect, and is smaller in toxicity and higher in safety. The levocetirizine hydrochloride oral solution prepared by the invention has the advantages of high stability, simple prescription, smaller preservative toxicity and higher safety, and the method for preparing the levocetirizine hydrochloride oral solution is simple to operate and easy for industrial production.

Owner:CHONGQING HUAPONT PHARMA

A method of using waste animal and vegetable oil to produce aviation biofuel

ActiveCN106281401BAvoid toxic effectsSave hydrogen and energyFatty-oils/fats refiningLiquid hydrocarbon mixture productionKeroseneCarbon deposition

The invention discloses a method for producing aviation biofuel by using waste animal and plant oil. Raw oil is treated by a pretreatment unit, a hydrotreating unit, a degassing dehydration unit, a hydrogenation conversion unit and a rectification unit to obtain a high-quality aviation kerosene product. Under the condition of completely taking the waste animal and plant oil as the raw material, the biological aviation kerosene product conforming to ASTM D7566-11 standards is successfully produced, at the same time, the problem of catalyst poisoning caused by animal and plant oil hydrogenation for producing water, metal deposition and carbon deposition and the like is effectively solved, and large-scale and long-term operation of the device is realized.

Owner:SINOPEC ENG +2

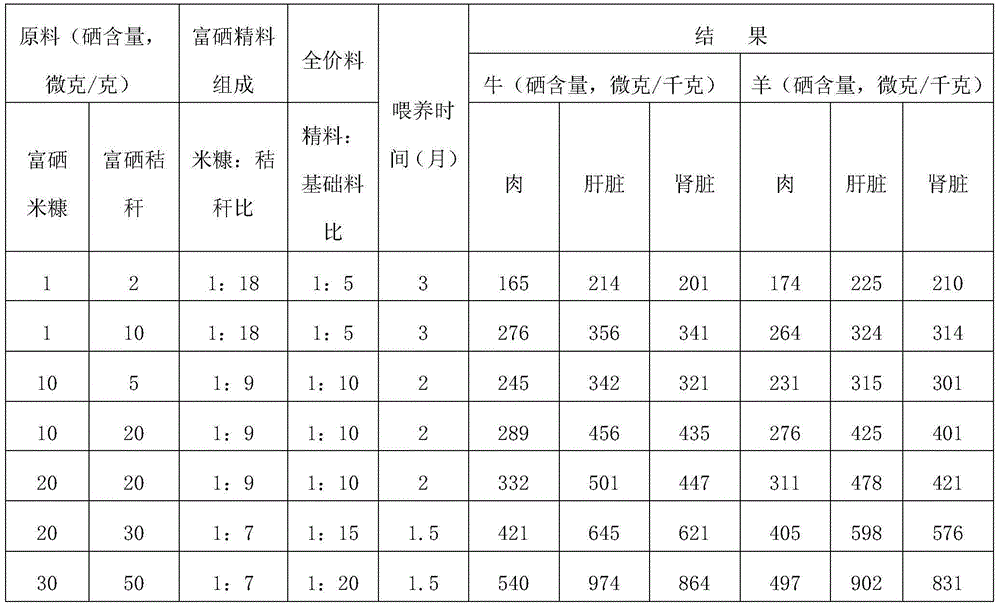

Selenium-rich fine fodder for feeding cattle and sheep and using method thereof

InactiveCN103976144ASolve poisoningSolve AbsorbencyFood processingAnimal feeding stuffBiotechnologyAnimal poisoning

The invention discloses selenium-rich fine fodder for feeding cattle and sheep and a using method thereof. The selenium-rich fine fodder comprises rice bran having a selenium content of 1-30 [mu]g / g and rice straw powder having a selenium content of 2-50 [mu]g / g. The weight ratio of the rice straw to the rice bran is 0.5-1:7-9. The selenium-containing rice bran and the selenium-containing rice straw are obtained by fertilizing a selenium fertilizer during the culturing process of rice. The selenium relates to organic selenium which is mainly selenium-substituted amino acids. According to the fine fodder and the using method thereof, animal absorption is achieved in a manner of the organic selenium, thus solving the problems of animal poisoning and low absorption.

Owner:HUNAN UNIV

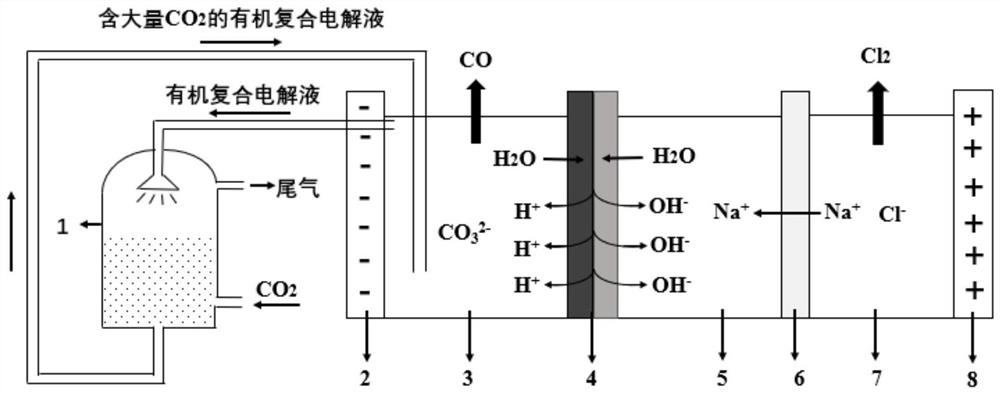

Bipolar membrane electrolysis method for preparing carbon monoxide by electrolyzing carbon dioxide in organic electrolyte and simultaneously producing chlorine and metal hydroxide as byproducts

The invention relates to a bipolar membrane electrolysis method for preparing carbon monoxide by electrolyzing carbon dioxide in an organic electrolyte and simultaneously producing chlorine and metal hydroxide as byproducts, and belongs to the technical field of phosgene chemical industry. The electrolytic tank is divided into a cathode chamber, a middle chamber and an anode chamber by a bipolar membrane and a cation exchange membrane to form a three-compartment electrolytic tank; wherein the electrolyte in the cathode chamber is an organic composite electrolyte in which a large amount of carbon dioxide is dissolved, the electrolyte in the middle chamber is a metal hydroxide aqueous solution, and the electrolyte in the anode chamber is a metal chloride aqueous solution. In the electrolytic reaction process, carbon monoxide is generated on the cathode, chlorine is generated on the anode, and the content of metal hydroxide in the middle chamber is increased. The method can synchronously produce carbon monoxide, chlorine and metal hydroxide under the conditions of normal temperature and normal pressure. The method has the advantages of short process flow, simple operation method, low production cost, small occupied area of equipment, easiness in starting and stopping, greenness, no pollution and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for removing heavy metal in algae

InactiveCN106190852ASolve the problem of heavy metal poisoningSolve poisoningUnicellular algaeMicroorganism based processesAcetic acidDisodium Edetate

The invention provides a method for removing heavy metal in algae. The method comprises the following step: when the density of microalgae is up to 0.1-1 million cells / ml, adding disodium edetate, wherein the concentration of the disodium edetate is 2-10mg / L. The method provided by the invention solves the problem of removing heavy metal in algae and solves the problem of heavy metal poisoning of seedlings in aquiculture; the method can simultaneously guarantee stability of heavy metal ions in an aquatic environment and normal growth demands of algae; and the method is suitable for removing heavy metal ions in large-scale aquiculture.

Owner:TIANJIN OCEAN PAL CAROL BIOTECH +1

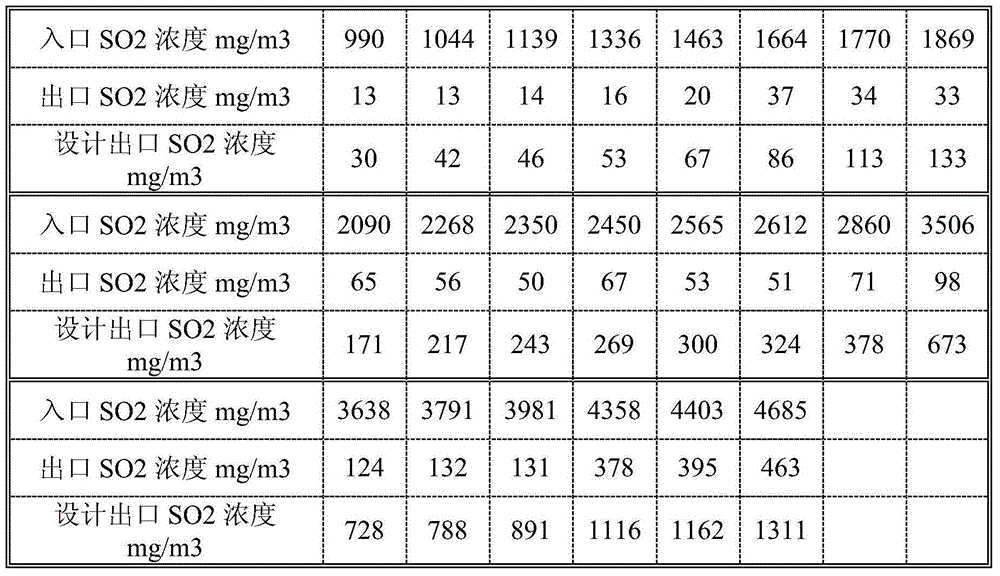

A composite additive for limestone flue gas desulfurization

ActiveCN103071381BSolve poisoningGuaranteed uptimeDispersed particle separationGlutaric acidSalicylic acid

A composite additive for flue gas desulfurization according to a limestone method is composed of the following materials by mass: 85 to 90 percent of nylon acid extracted residue, 1 to 3 percent of salicylic acid, 1 to 3 percent of humic acid, 1 to 5 percent of manganese chloride, and 1 to 5 percent of dimethyl silicone antifoaming agent which are mixed with each other, wherein nylon acid extracted residue is the residue of nylon acid extracted with a large part of glutaric acid. The composite additive has the beneficial effects that the defects of deeper color and unqualified desulfuration drainage chromaticity caused when a nylon acid-type additive is used for flue gas desulfurization are overcome; the pH value buffer zone is wider; sulfur dioxide gas can be dissolved in limestone paste faster; the dissolution of limestone calcium carbonate can be accelerated; the desulfuration efficiency is improved; the cost is greatly reduced; the oxidation efficiency of calcium sulfite is improved; the poisoning problem of limestone paste liquid is solved; foam of a desulfurization tower is eliminated; and the efficient steady operation of the desulfurization tower can be guaranteed.

Owner:天津海得润滋食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com